Factory-Direct CNC Machining Services – Fast Quote & Precision Parts

- No Middlemen. ISO Certified. Fast Prototyping to Mass Production.

- Engineers Worldwide Trust Us for Fast, Reliable, and Factory-Direct CNC Services

What We Offer

✅ CNC Milling (3/4/5-Axis)

✅ Tight Tolerances: ±0.01mm

✅ Fast Prototyping & Small Batch to Mass Production

✅ CNC Turning, Swiss Lathe, EDM

✅ Surface Finishing: Anodizing, Powder Coating, Sandblasting, etc.

✅ Wide Materials: Aluminum, SS, Titanium, Plastics

XTJ Strict Quality Control Process

Jetzt kostenloses Angebot erhalten!

- Tips*

- NDA Available

- Engineers Review Every File

- Quote in 24h or Less

Industries We Serve

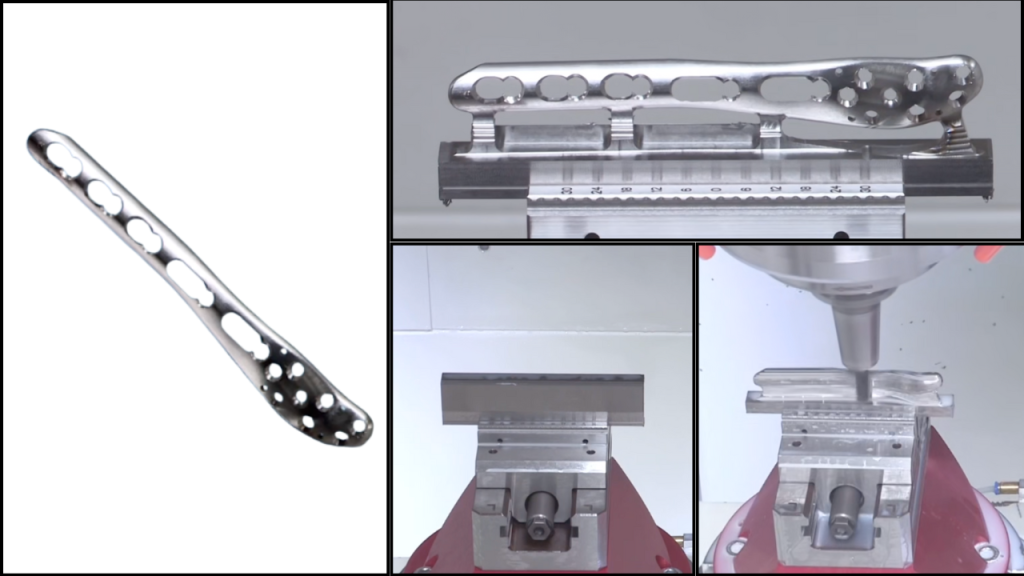

Product Name: Distal Fibular Lateral Locking Plate

Branche: Medical Orthopedics

Brief Requirement: Precision machining of a titanium or stainless steel locking plate with 75% material removal, extensive curved surfaces, and 23 holes (4 types) for bone fixation. Challenges include large roughing volume, long machining time (71 minutes), and a surface finish of Ra ≤ 0.6μm.

Lösung: Employ 5-axis CNC machining with optimized tool paths to handle high material removal and complex curves efficiently. Use multi-stage finishing processes to achieve Ra ≤ 0.6μm, with specialized drilling for 23 varied holes. Rigorous quality control ensures biocompatibility, delivered by XTJ Precision Mfg for medical-grade precision.

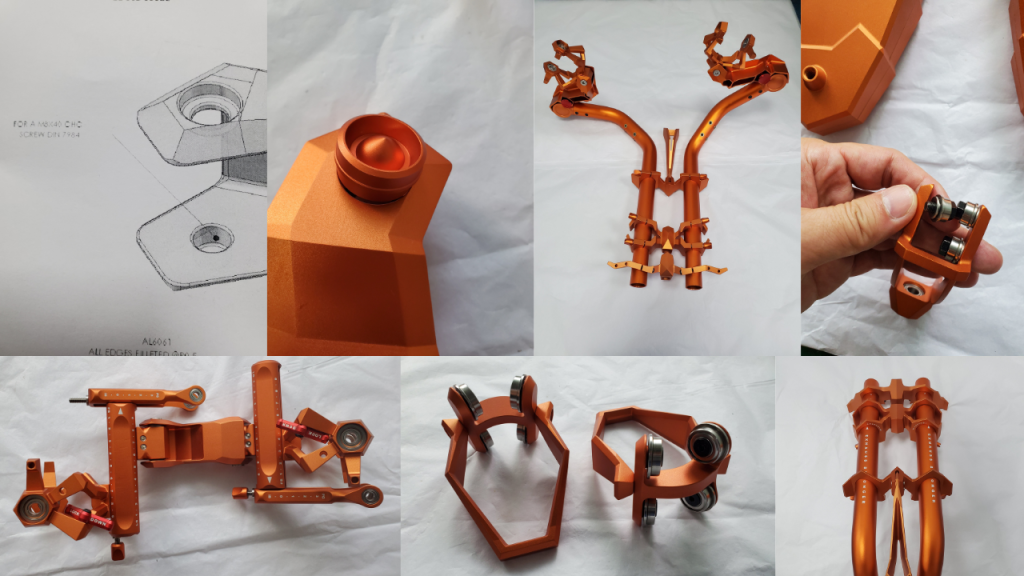

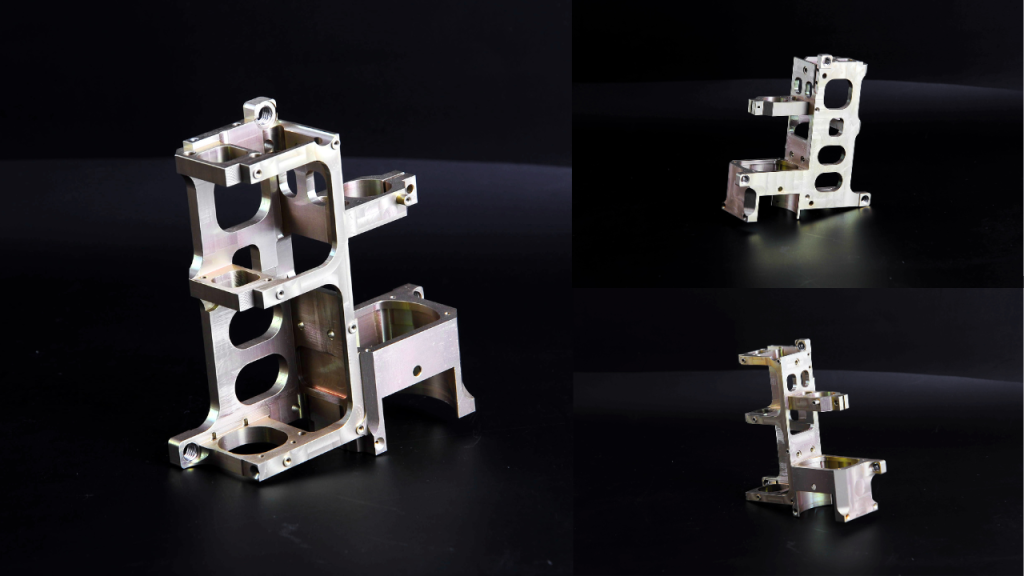

Product Name: Robotic Assist Arm Joint

Branche: Robotics and Automation

Brief Requirement: Precision-machined aluminum alloy joint with integrated bearings, requiring tight tolerances (±0.02mm), high strength, and smooth rotational movement to support dynamic load-bearing in robotic assist arms.

Lösung: Utilize 5-axis CNC machining for complex geometries and bearing housings, ensuring seamless rotation and durability. Surface anodizing enhances wear resistance, delivered with rigorous quality checks by XTJ Precision Mfg for cutting-edge robotics projects.

Product NamecURL Too many subrequests.

BranchecURL Too many subrequests.

Brief RequirementcURL Too many subrequests.

LösungcURL Too many subrequests.

Product NamecURL Too many subrequests.

BranchecURL Too many subrequests.

Brief RequirementcURL Too many subrequests.

LösungcURL Too many subrequests.

Product NamecURL Too many subrequests.

BranchecURL Too many subrequests.

Brief RequirementcURL Too many subrequests.

LösungcURL Too many subrequests.

Product NamecURL Too many subrequests.

BranchecURL Too many subrequests.

Brief RequirementcURL Too many subrequests.

LösungcURL Too many subrequests.

Bereit, Ihr CNC-Bearbeitungsprojekt zu starten?

Laden Sie Ihr Design für ein kostenloses Angebot hoch oder kontaktieren Sie unser Team, um Ihre Anforderungen zu besprechen.