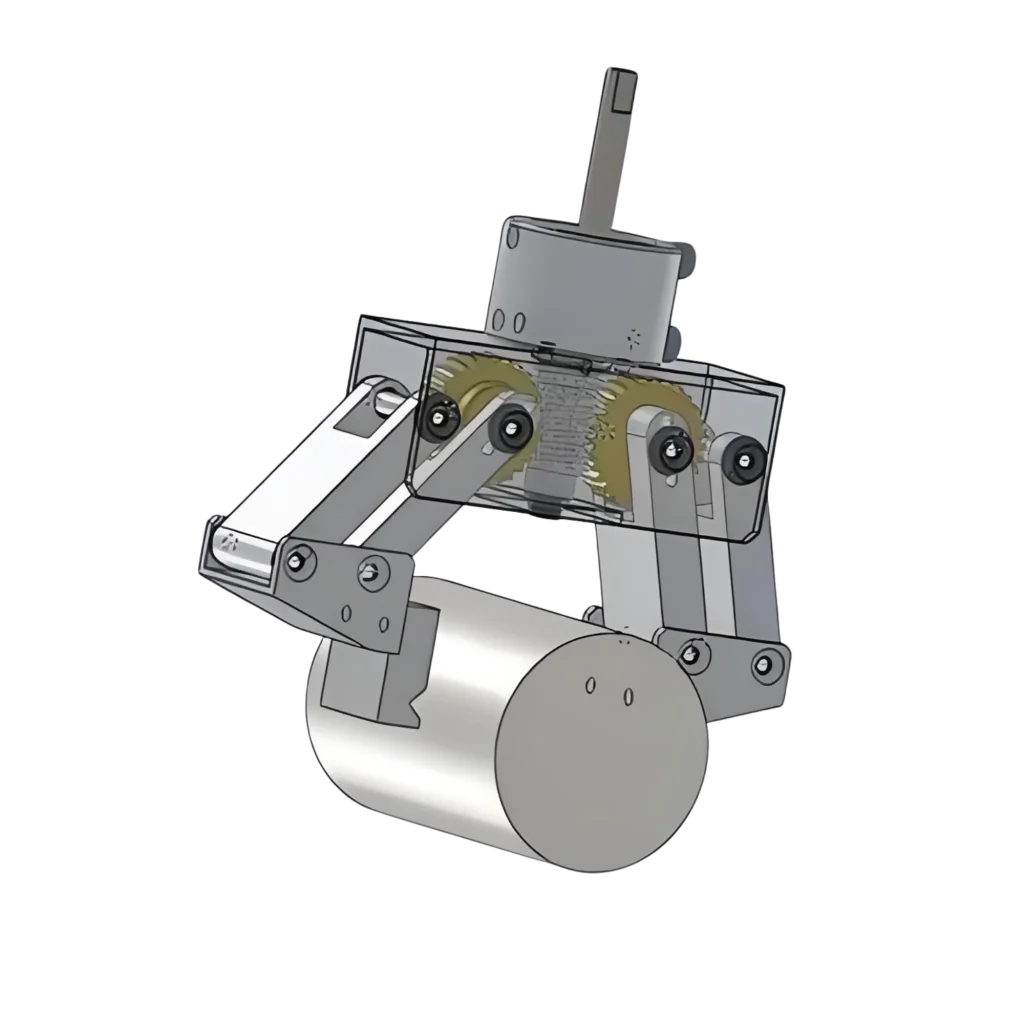

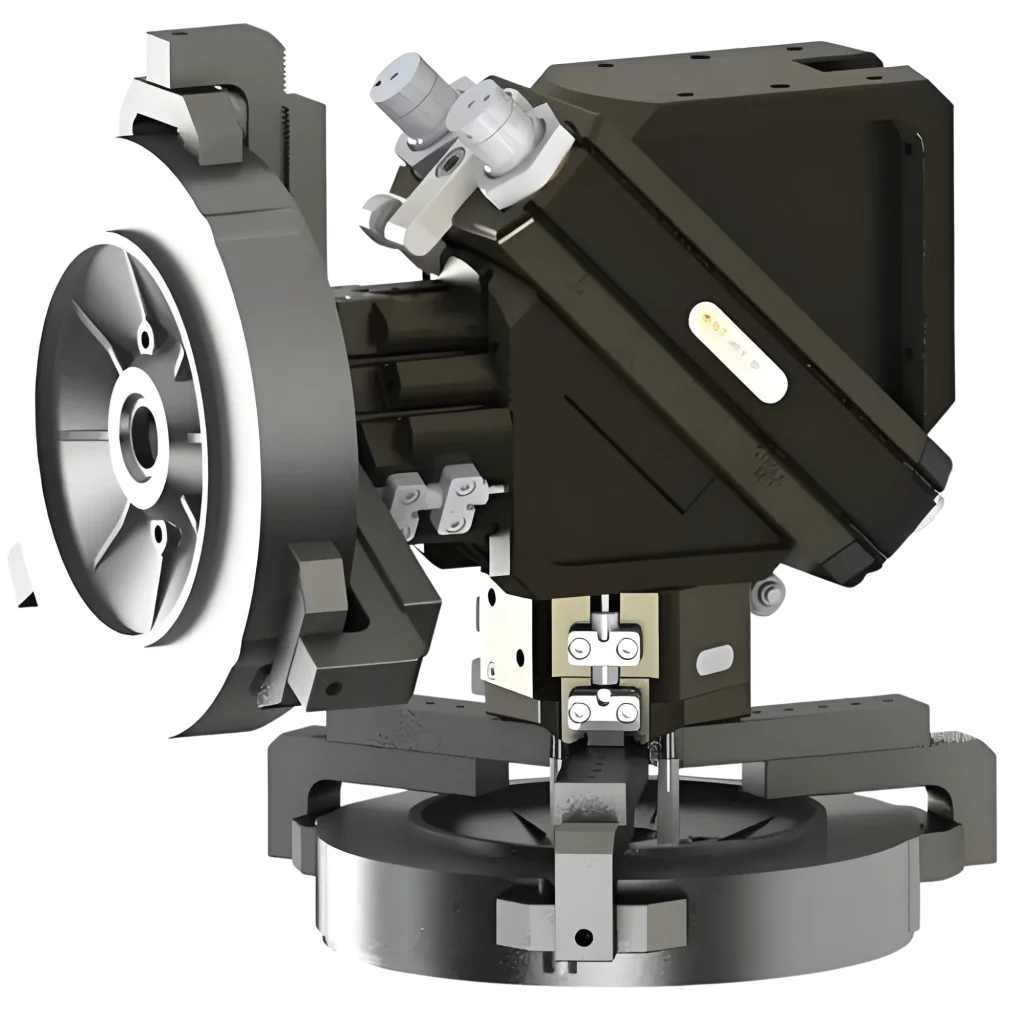

Precision Automation Equipment Parts Machining Services

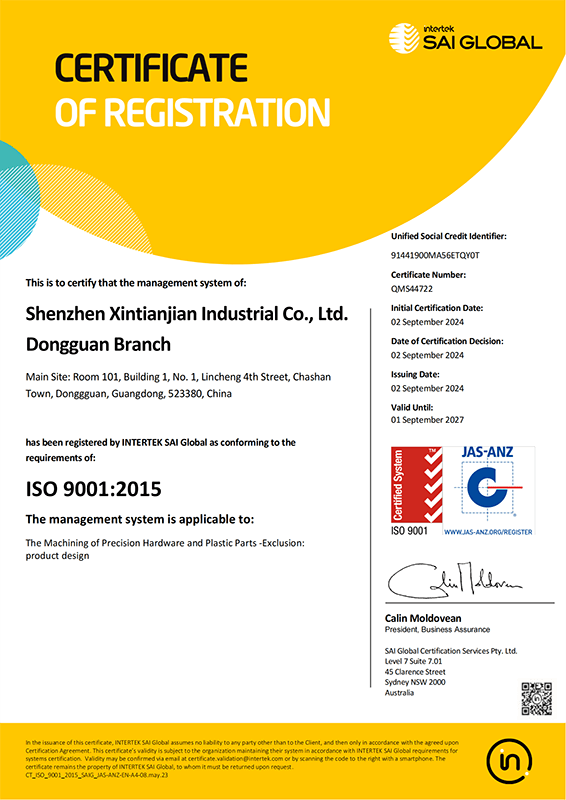

At XTJ Precision Mfg, we specialize in delivering high-precision machined parts for automation equipment, leveraging over 20 years of expertise in CNC machining. Our ISO 9001:2015 and IATF 16949 certified facilities in Shenzhen and Dongguan, China, ensure components meet the highest standards for reliability in demanding industrial environments. With no minimum order quantity and lead times as fast as 3-5 days, we transform your designs into functional parts using advanced materials and technologies.

-

Automation SystemPrecision Parts

custom solutions with 99% customer satisfaction -

On-Time Delivery

Reliable production schedules you can trust -

Minimum Order

Full flexibility from prototype to production -

Days for Prototypes

Rapid turnaround for development cycles

The Critical Role of Precision Machining in Automation

Automation systems demand components that endure continuous cycles, extreme conditions, and precise operations. At XTJ Precision Mfg, we understand these challenges and deliver parts with micro-precision tolerances (±0.002mm), complex geometries, and optimized materials to minimize downtime and enhance system efficiency.

Our expertise includes:

- Micro-precision tolerances down to ±0.002mm

- Multi-axis CNC machining for intricate designs

- Material optimization for durability and performance

- Advanced surface finishes like anodizing and powder coating

- Rigorous quality assurance with CMM inspections and full traceability

Deep Technical Expertise

Over 20 years of experience in CNC machining of automation equipment components

Maßgeschneiderte Lösungen

Custom manufacturing approaches aligned perfectly with your unique device requirements

Super Team

Our team of 300+ professionals delivers

Key Capabilities for Automation Equipment Parts

With 120+ advanced machines and partnerships with 200+ suppliers, XTJ Precision Mfg offers comprehensive capabilities tailored to automation needs, from prototypes to high-volume production.

Materials Expertise for Automation Applications

We offer over 50 materials, including RoHS & REACH compliant options, selected for optimal performance in automation environments.

| Material Category | Common Types | Wichtige Eigenschaften | Typische Anwendungen |

|---|---|---|---|

| Aluminiumlegierungen | 6061, 7075, 5052 | Lightweight, good machinability, thermal conductivity | Frames, brackets, heat sinks |

| Edelstahl | 303, 304, 316 | Corrosion resistance, strength, wear resistance | Load-bearing parts, washdown environments |

| Titan | Ti-6Al-4V | High strength-to-weight, corrosion resistance | High-performance robotic components |

| Engineering Plastics | ABS, POM, PEEK, Nylon | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Verbundstoffe | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests."

- cURL Too many subrequests.

- Hardness and roughness testing

- 3D scanning for CAD comparison

- DFM Analysis & Design Review

- Material Certification

- First Article Inspection

- In-Process Verification

- Final Inspection & Testing

- Documentation & Traceability

ISO 9001:2015

IATF 16949

RoHS- & REACH-Konformität

Industries We Serve

From high-volume production for automotive assembly lines to custom components for aerospace robotics, we tailor our services to meet industry-specific standards, including ISO 9001:2015 and IATF 16949 compliance. With over 20 years of experience, we’ve supported innovations in automation, helping clients reduce downtime, improve efficiency, and scale operations globally.

Automobil

We machine components for EV battery assembly lines, robotic welding systems, and automated quality inspection equipment. Our parts ensure high durability and precision in high-volume production environments, helping manufacturers like those in electric vehicle sectors meet stringent safety and efficiency standards while reducing assembly time and costs.

cURL Too many subrequests.

Lightweight, high-strength parts for drone assembly, satellite robotics, and defense automation systems. We adhere to AS9100 standards, providing traceable materials and components that withstand extreme conditions, such as vibration and temperature fluctuations, for mission-critical applications.

Medical & Life Sciences

Biocompatible components for robotic surgical systems, pharmaceutical packaging automation, and laboratory robotics. Our cleanroom capabilities ensure contamination-free production, meeting ISO 13485 requirements for precision parts that enable accurate drug delivery and minimally invasive procedures.

Electronics & Semiconductors

ESD-safe precision parts for pick-and-place machines, automated testing equipment, and semiconductor fabrication robots. We support miniaturization trends with micro-machining capabilities, ensuring components that handle delicate wafers and circuit boards with zero defects.

Logistics & Warehousing

Durable components for AS/RS systems, conveyor sortation, and AGV robotics. Our parts optimize material handling in e-commerce warehouses, providing wear-resistant solutions that support 24/7 operations and integrate seamlessly with Industry 4.0 technologies.

Energy & Oil/Gas

High-pressure resistant parts for drilling automation, renewable energy robotics, and pipeline inspection systems. We use specialty alloys to withstand harsh environments, ensuring safety and reliability in offshore and onshore operations.

FAQs about Precision Automation Equipment Parts Machining Services

Here are some common questions we receive at XTJ Precision Mfg. If you have additional inquiries, feel free to contact us at [email protected].

We specialize in micro-precision machining with tolerances as tight as ±0.002mm (±0.00008 inches). This level of accuracy is ideal for critical components like robotic joints, sensor mounts, and actuator housings, ensuring reliable performance in high-cycle automation systems. Our advanced CNC and EDM capabilities allow us to meet even stricter custom requirements upon request.

XTJ offers over 50 materials, including aluminum alloys (e.g., 6061, 7075), stainless steel (e.g., 304, 316), titanium (Ti-6Al-4V), engineering plastics (e.g., PEEK, Nylon), and composites like carbon fiber. All materials are RoHS and REACH compliant. Our engineers provide free material selection guidance based on your application’s needs, such as corrosion resistance, lightweight design, or high-temperature tolerance.

For prototypes, we offer rapid turnaround times of 3-5 days. Production runs vary based on volume and complexity but typically range from 7-15 days for small to medium batches (up to 10,000 units). We maintain a 99% on-time delivery rate and can expedite orders for urgent automation projects. No minimum order quantity (MOQ) applies, making us flexible for both testing and scaling.

Yes, we offer free DFM feedback with every quote. Our engineering team reviews your CAD files to optimize designs for cost, efficiency, and quality—suggesting improvements like geometry adjustments or material alternatives. This helps reduce manufacturing issues and ensures your automation components perform optimally in real-world applications.

We are ISO 9001:2015 and IATF 16949 certified, with full traceability and compliance for industries like automotive and medical. Quality processes include CMM inspections, 3D scanning, surface roughness testing, and first article inspections (FAI). Every part undergoes rigorous verification to meet automation demands, such as millions of cycles without failure.

Absolutely. Beyond machining, we provide full assembly of subsystems, including mechanical integration and functional testing. Finishing options include anodizing, powder coating, passivation, and heat treatment to enhance durability, corrosion resistance, and aesthetics. This one-stop service streamlines your supply chain for complete automation solutions.