Automotive Prototyping Services

At XTJ Precision MFG, we provide advanced automotive prototyping services, including custom parts manufacturing, design optimization, and production-ready solutions. Our expertise in CNC machining ensures high-quality prototypes for concept validation, testing, and pilot production.

The Critical Role of Automotive Prototyping

Rapid prototyping drives automotive innovation by turning ideas into tangible parts. It reduces development time, visualizes designs, mitigates risks, and ensures parts are functional and safe before production.

Process Highlights:

- CAD modeling for precise design

- Performance and structural validation

- Manufacturing process refinement

- Seamless transition to production

These parts, which open and close sections of an assembly line to allow material to be transported, can easily be cut out of metal by CNC tools. They are often found on conveyor belts.

Spiegel

While the mirror assembly was once made using manual methods, this process has been largely replaced by CNC machining. This is possible because CNC machinery, with its ability to precisely cut the glass and assemble the components, can be used to create the best quality parts.

Engine Blocks

Engine blocks are machined to increase the efficiency of an engine. This process, which involves creating perfect surfaces by cutting and forming the material, can be easily be carried out by CNC machines.

Cylinder heads

CNC machining is a technology that is used to create precise and intricate parts from a variety of materials. When it comes to machining cylinder heads, this technology offers several advantages over traditional methods.

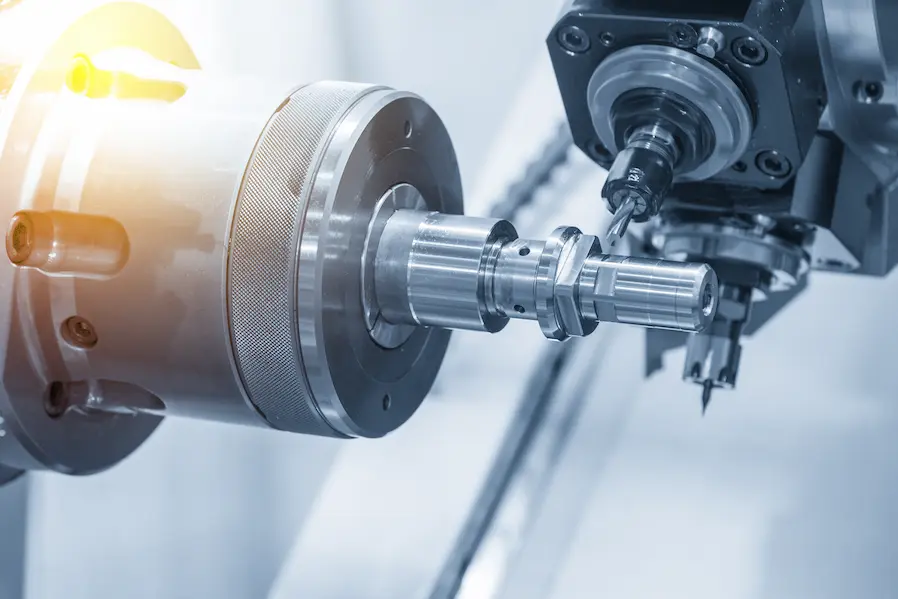

Camshafts

Camshafts are used in order to accurately tune the speed of an engine. Camshafts are CNC machined to ensure that they are precisely accurate.

Connecting rods

CNC machines are utilized in order to create precision machined connecting rods. These cylinders are used to ensure that the engine components are held together firmly.

Manufacturing Prototyping Method

XTJ supports your automotive development phases with expert prototyping. From initial design to final production, we ensure precision, quality, and efficiency to meet your project needs.

Choosing the right prototyping method maximizes your project’s quality and efficiency. Our tailored approaches ensure the best results for your automotive parts.

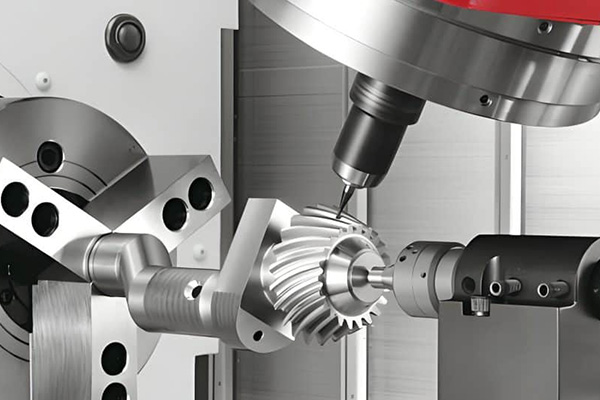

CNC-Zerspanung

Shapes precise automotive prototypes with high accuracy and repeatability.

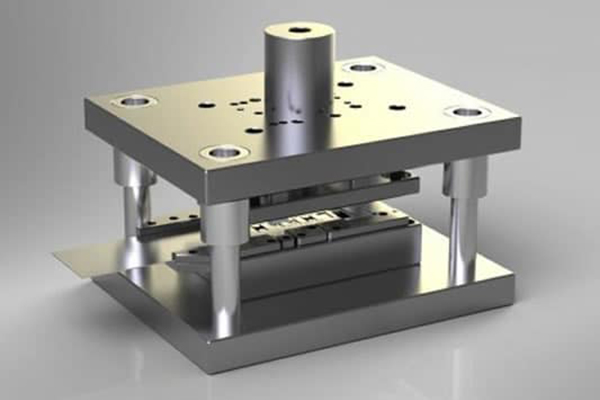

Vakuumguss

Creates high-quality, cost-effective prototypes using silicone molds.

3D-Druck

Produces detailed, functional parts with rapid precision.

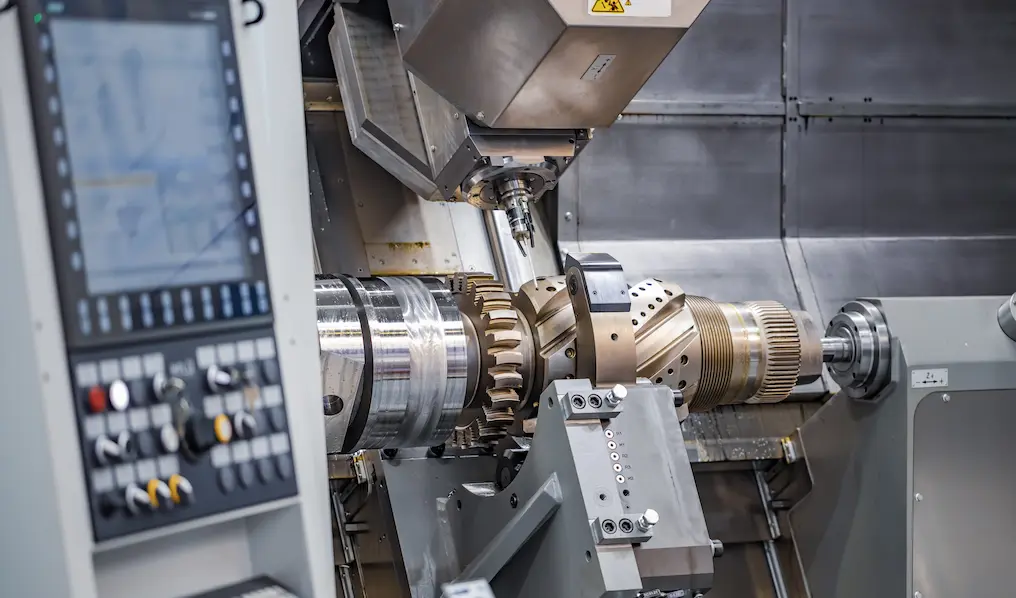

The Different CNC Machines Used in the Automotive Industry

There are a variety of CNC machines used in the automotive industry, including lathes, milling machines, and routers. These machines are used to create parts for cars and trucks.

The different CNC machines used in the automotive industry are:

CNC lathes are used extensively in the automotive industry for a variety of machining operations. They are especially well-suited for manufacturing high-precision parts with complex geometries. Depending on the model, a CNC lathe can handle long lengths of up to 10m.

Mills

Many parts for cars and trucks are produced using CNC mills. These machines are capable of creating various metal products, such as parts for a car engine or transmission. These parts include engine blocks, cylinder heads, gears, and suspension components. CNC mills are also used to cut and shape metal parts for air conditioners, cars, cranes, and dump trucks.

Routers

CNC routers are used in the automotive industry for a variety of applications, including trimming and routing car body panels, cutting and shaping engine parts, and milling and drilling wheels. CNC routers can be used in vertical and horizontal positions, and they are versatile enough to cut complex shapes.

Benefits of Using CNC Machining in the Automotive Industry

CNC machining is a cost-effective and time-saving method of manufacturing in the automotive industry. CNC machining can offer many benefits in the car industry including improved accuracy, repeatability, and consistency of parts, as well as increased efficiency and productivity. CNC machining can also help to reduce waste and improve the overall quality of parts.

CNC machining offers repeatability and accuracy that is unmatched by manual machining. When a part is produced using CNC machining, the same process is used each time the part is made. This ensures that each part is identical to the last.

Reduced setup time and lead time.

CNC machining automotive parts is an efficient way to reduce setup time and lead time. The process of CNC machining can be completed in a single setup, which reduces the need for multiple setups and lead times associated with traditional machining methods.

Increased productivity.

CNC machining is a process that can be completely automated. This means that once the machine is set up, it can run without any human intervention. This increases productivity because the machine can run for longer periods without needing to be monitored.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Starten Sie Ihr Projekt mit einem kostenlosen Angebot

Wenn Sie nach einem zuverlässigen Partner suchen, der Ihnen beim Start Ihres Luft- und Raumfahrt-Bearbeitungsprojekts hilft, sind Sie bei uns genau richtig. Wir verfügen über eine lange Geschichte in der Bereitstellung präziser Bearbeitungsdienstleistungen für Kunden aus verschiedenen Branchen. Lassen Sie uns unsere Erfahrung für Sie einsetzen und Ihr Projekt erfolgreich starten.