CNC Steel Machining Services

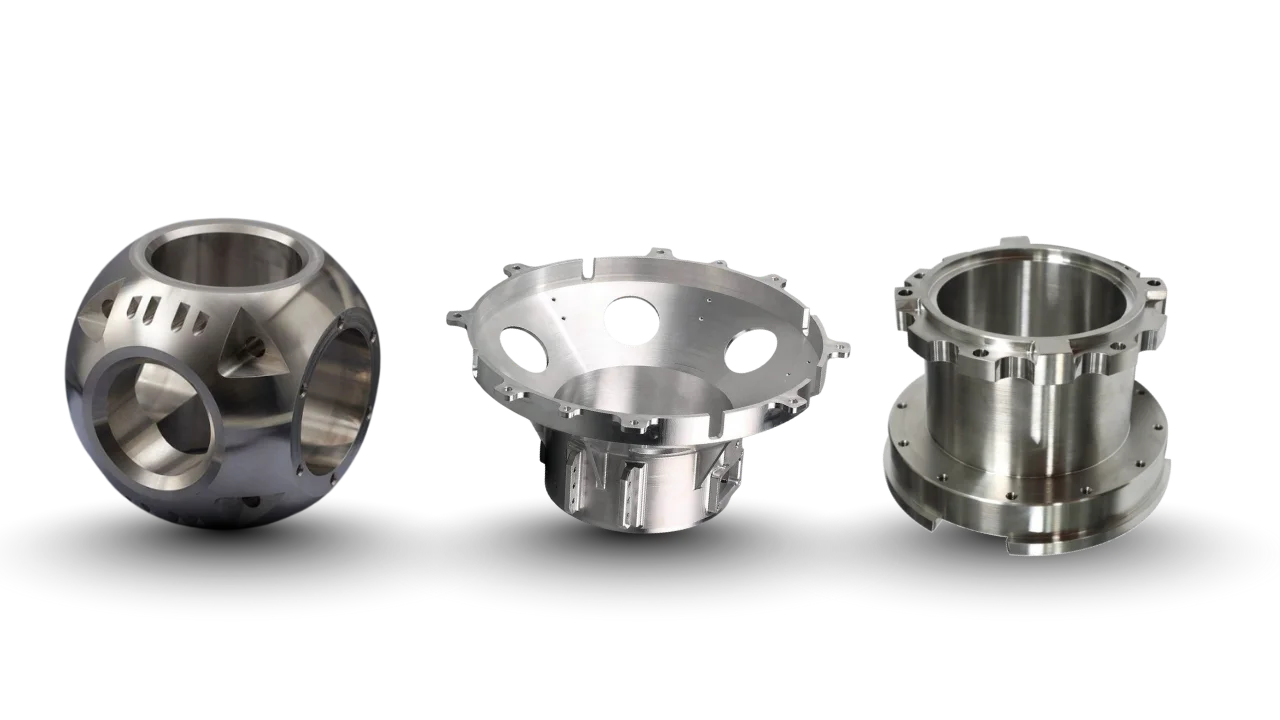

CNC Machining of Steel Alloys for Custom Parts and Prototypes

- Präzisionsbearbeitung für komplexe Designs

- Flexible Lösungen für verschiedene Branchen

- Lieferzeiten ab 5 Tagen für schnelle Lieferung

- Maßgeschneiderte Dienstleistungen, um einzigartige Anforderungen zu erfüllen

we specialize in high-precision CNC steel machining, delivering custom parts that offer unmatched strength, durability, and versatility.

Why Choose Steel for CNC Machining?

Steel, primarily an iron-carbon alloy with up to 2% carbon and optional alloying elements like chromium or nickel, is the backbone of modern engineering due to its remarkable strength-to-weight ratio and adaptability. It outperforms many metals in load-bearing scenarios, providing a cost-effective alternative to exotic materials while maintaining reliability in extreme conditions. Compared to softer alloys like aluminum, steel’s higher hardness enables longer-lasting parts but demands optimized machining to manage tool wear and heat.

High Strength and Hardness

Withstands heavy loads and impacts, ideal for structural and mechanical components.

Verschleißfestigkeit

Excels in abrasive environments, reducing downtime and replacement needs.

Vielseitigkeit

Easily heat-treated for tailored properties, from ductile to ultra-hard.

Kosteneffizienz

Abundant and recyclable, offering excellent value for high-volume production.

Corrosion Options

Alloyed variants like stainless steel provide protection in harsh settings.

Our CNC expertise harnesses these traits to create parts with precise geometries and minimal defects, surpassing casting or forging in speed and accuracy for complex designs.

Steel Material Properties

Steel alloys are engineered by varying carbon content (0.05–2%) and additives, customizing traits for specific demands. Typical properties include:

- Density: 7.8–8.0 g/cm³, delivering robust yet manageable weight.

- Hardness: Rockwell B 70–100 (up to C 60 in tool steels), balancing toughness and edge retention.

- Tensile Strength: 400–2,000 MPa, scalable via grade and treatment.

- Elongation: 5–50%, supporting formability in low-carbon types.

- Maximum Service Temperature: Up to 1,000°F in heat-resistant alloys.

These qualities position steel as a staple for parts needing superior mechanical performance and environmental adaptability.

Available Steel Grades for Machining

We maintain a comprehensive inventory of steel alloys for your CNC projects. Below is a curated list of popular grades, highlighting essential specifications:

| Legierung | Bearbeitbarkeitsbewertung (AISI) | Zugfestigkeit | Härte | Wichtige Merkmale | Typische Anwendungen |

|---|---|---|---|---|---|

| 1018 (Low Carbon Steel) | 70–80 | 440 | B 71 | Excellent ductility, weldable, easy to form | Shafts, pins, structural brackets |

| 1045 (Medium Carbon Steel) | 60–70 | 515 | B 86 | Balanced strength, heat-treatable for hardness | Gears, crankshafts, machinery parts |

| 4140 (Alloy Steel) | 50–60 | 655–1,000 | C 22–30 | High toughness, fatigue-resistant, good corrosion resistance | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | 505 | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | 550 | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

Hinweis:cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests. 17-4PH cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

Toleranzen und Präzisionsstandards

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Yes, CNC excels at steel with robust tooling and cooling, handling everything from milling to turning for precise, repeatable results on complex parts.

Carbon steel prioritizes raw strength and affordability but rusts easily, while stainless adds chromium (10%+) for corrosion resistance at a higher cost and machinability challenge.

Essential, especially for stainless or alloy steels, to dissipate heat, prevent galling, and extend tool life—high-pressure systems are standard in our operations.

Higher density increases weight and machining time versus aluminum, plus potential warping from heat treatment; however, its strength justifies use in demanding roles.

Get Your Custom Steel Parts Today

Harness the reliability of CNC steel machining with XTJ—upload your designs for an instant quote or discuss alloy selection with our experts. We deliver precision, speed, and value every step of the way.