Small Batch CNC Machining Services Fast 3 Day Prototypes

- Flexible Production

- Flexible Lösungen für verschiedene Branchen

- Cost-Effective

- Maßgeschneiderte Dienstleistungen, um einzigartige Anforderungen zu erfüllen

What Is Small Batch CNC Machining?

Small batch CNC machining is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce a limited quantity of parts or components, often ranging from 1 to 1,000 units, balancing precision, flexibility, and cost-efficiency for low-volume needs. Unlike mass production, which requires extensive tooling and setup for high volumes, this approach is ideal for prototypes, custom orders, or short production runs where quick turnaround and customization are key.

It typically involves subtractive manufacturing techniques where material is removed from a solid block (workpiece) using automated tools controlled by pre-programmed software. Common methods include:

The process starts with designing a 3D model in CAD software, converting it to CAM instructions (G-code), and then loading it into the CNC machine for execution. Materials can vary widely, from metals like aluminum and steel to plastics and composites.

Key Benefits

Kosteneffizienz

No need for custom molds or dies, reducing upfront costs for small runs.

High Precision and Quality

CNC ensures consistent accuracy, often to tolerances of ±0.001 inches or better.

Flexibilität

Easy to iterate designs or switch between part types without major retooling.

Geschwindigkeit

Faster production compared to manual machining, with lead times as short as a few days for small batches.

If you’re considering implementing it, factors like material selection, machine capabilities, and vendor expertise play a crucial role in optimizing outcomes.

Why Choose XTJ for Small Batch CNC Machining?

At XTJ Precision Mfg, we specialize in custom small batch CNC machining with versatile 3- to 5-axis milling for metals and plastics. Here’s why we’re a top choice for your low volume CNC orders:

- Quick Turnaround: Fast production cycles help you meet tight deadlines without compromising quality.

- Cost-Effective: Competitive pricing designed for small runs and prototype machining, saving you money on low MOQ CNC machining.

- Wide Material Range: From aluminum and steel to advanced plastics, we handle diverse materials for custom machined components.

- Precision You Can Trust: Tight tolerance machining ensures your parts meet demanding specs every time.

- Flexible Production: Whether you need batch CNC machining service or rapid CNC prototyping, we scale to your needs.

| Merkmal | XTJ Small Batch CNC Machining |

|---|---|

| Machine Types | 3-, 4-, and 5-axis CNC milling |

| Materials Supported | Metals, plastics, advanced composites |

| Turnaround Time | Standard 10-day delivery, same-day services available |

| Mindestbestellmenge | Low MOQ, ideal for prototypes and small runs |

| Preise | Transparent and competitive for on-demand CNC parts manufacturing |

Based in Shenzhen, China, XTJ Precision Mfg benefits from the comprehensive CNC machining ecosystem surrounding the Pearl River Delta, enabling us to fulfill even the most demanding requirements. With two decades of expertise in the field, we secure premium materials at competitive costs and extend those benefits directly to our clients.

Materials Stocked for Small Batch CNC Machining

cURL Too many subrequests.

cURL Too many subrequests.

Aluminium

cURL Too many subrequests.

Stahl

cURL Too many subrequests.

Kunststoffe

cURL Too many subrequests.

Verbundstoffe

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

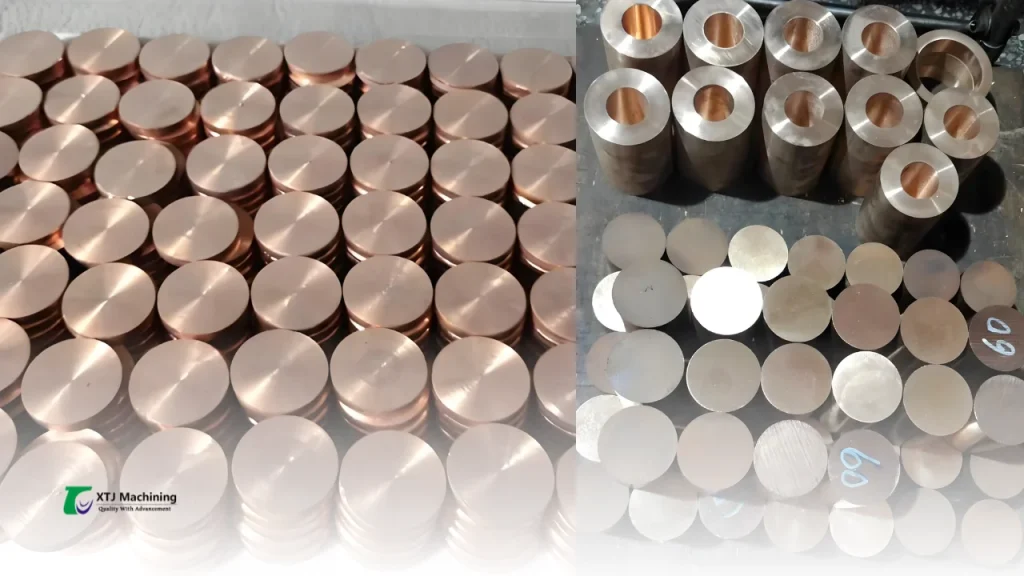

Kupfer und Messing

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Speed to Market

Accelerate product launch times by quickly moving from prototype to production with on-demand CNC parts manufacturing.

Choosing small batch proof production supports smarter, more efficient manufacturing — exactly what you need for fast-paced U.S. markets and evolving designs.

Toleranzen und Präzisionsstandards

Präzision ist unser Versprechen. Standardtoleranzen folgen ISO 2768-m (±0,005–0,010 mm), mit kundenspezifischen Spezifikationen bis zu ±0,001 mm, die durch unsere Messtechnologien (CMM, optische Messgeräte) erreichbar sind. Faktoren wie Legierungstyp und Teilegröße beeinflussen die endgültige Genauigkeit—geführte Legierungen wie C932 halten engere Maße mit weniger thermischer Ausdehnung.

We design for manufacturability to avoid costly iterations, ensuring your parts meet or exceed specs every time.

small batch CNC machining FAQS

Here are answers to some of the most common questions about small batch CNC machining, based on our expertise at XTJ Precision Manufacturing.

The key advantages include cost-effectiveness for low volumes (no need for expensive molds or tooling), high precision and repeatability (tolerances as tight as ±0.001 inches), flexibility for design changes, and faster turnaround times compared to traditional methods. It’s also scalable, allowing easy transitions to larger production if needed, and reduces material waste through efficient programming.

Unlike large-scale production, which focuses on high-volume runs (thousands or millions of units) with dedicated assembly lines and custom tooling, small batch machining emphasizes customization and quick iterations. It uses versatile CNC machines that can handle multiple part designs without major retooling, making it more suitable for R&D, niche markets, or on-demand manufacturing. However, unit costs are higher in small batches due to setup time.

A wide range of materials can be machined, including metals like aluminum, stainless steel, titanium, and brass; plastics such as ABS, nylon, and polycarbonate; and even composites or woods. Material choice depends on the part’s requirements for strength, weight, corrosion resistance, or aesthetics. Consult with a machinist to ensure compatibility with CNC processes.

It’s widely used in aerospace (for custom prototypes), automotive (testing components), medical devices (precision implants and tools), electronics (housings and connectors), and consumer products (custom gadgets). Startups and R&D teams particularly value it for rapid prototyping and market testing without large inventories.

Turnaround times vary based on complexity, material availability, and order size, but simple projects can be completed in 3-7 days, while more intricate ones may take 1-4 weeks. Factors like design revisions or post-processing (e.g., anodizing or assembly) can extend this. Many service providers offer expedited options for urgent needs.

Costs depend on factors like material type, part complexity, tolerances, quantity, and finishing requirements. Expect to pay $50-$500 per part for small runs, with setup fees ranging from $100-$1,000. Economies of scale apply even in small batches—higher quantities within the batch reduce per-unit costs. Get quotes from multiple vendors for accurate pricing.

Get Your Instant Quote Today

Ready to jumpstart your small batch CNC machining project? Get an instant quote in seconds using our drag-and-drop STEP file uploader. Need help? Our free Design for Manufacturability (DFM) analysis ensures your parts are optimized before production, saving you time and cost.