Servicios de Torneado CNC de Precisión

Soluciones de Torneado CNC ConfiablesCon sede en China, ofrecemos precios competitivos y plazos de entrega rápidos para satisfacer sus necesidades de fabricación demandas.

- Seguridad de Datos para Proteger Sus Diseños

- Más de 100 Máquinas CNC para Alta Eficiencia

- Plazos de Entrega desde 5 Días para una Rápida Entrega

Servicios Expertos de Torneado CNC para Sus Proyectos

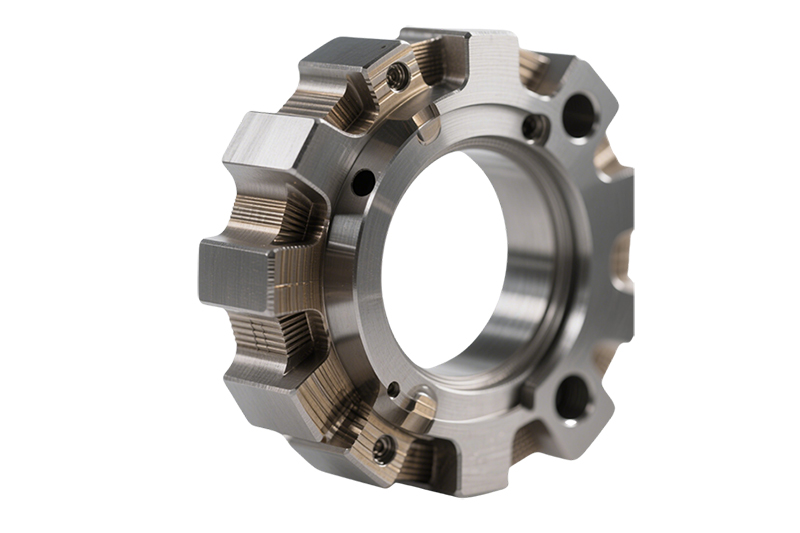

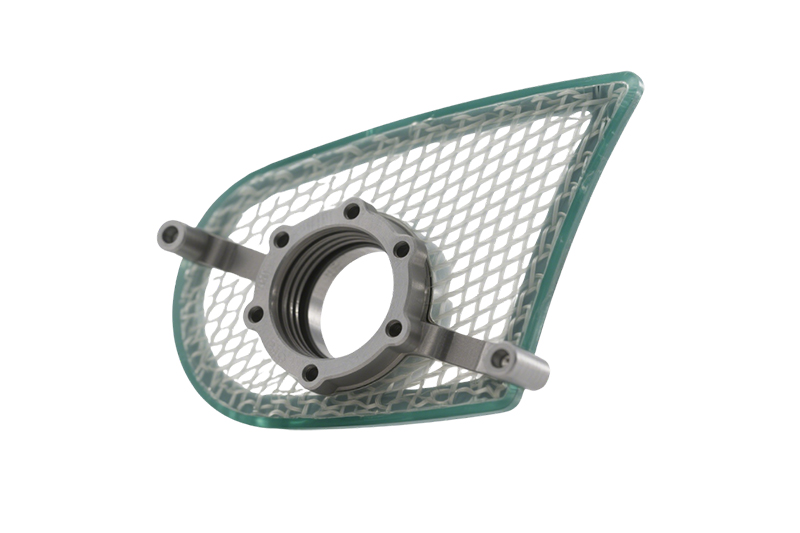

En XTJ Machining, destacamos en el torneado CNC de precisión para producir componentes cilíndricos de alta calidad. Con más de 100 máquinas de torneado CNC avanzadas, ofrecemos soluciones rentables, plazos de entrega rápidos y una precisión excepcional para prototipos y producción a gran escala.

manejamos proyectos desde componentes simples hasta diseños complejos. Sirviendo a industrias como la aeroespacial, automotriz y médica, XTJ ofrece piezas rápidas, confiables y de alta calidad, haciendo que la fabricación de precisión sea accesible y eficiente para sus necesidades.

¿Por Qué Elegir XTJ para Torneado CNC?

Precios Competitivos

Nuestros servicios de torneado CNC ofrecen un valor excepcional a través de soluciones rentables sin comprometer la calidad. Al aprovechar la tecnología avanzada, los procesos optimizados y el abastecimiento estratégico, entregamos componentes de ingeniería de precisión a precios que lideran la industria. Ya sea que sea una pequeña empresa o un fabricante a gran escala, nuestro compromiso con la asequibilidad garantiza que reciba un servicio de primer nivel adaptado a su presupuesto, lo que nos convierte en la opción preferida para soluciones de torneado CNC de alta calidad y bajo costo.

Alta Capacidad de Producción

En XTJ, nuestras instalaciones de vanguardia cuentan con más de 100 máquinas CNC avanzadas y más de 40 tornos de precisión, lo que garantiza una escalabilidad inigualable y una entrega rápida para proyectos de cualquier tamaño. Esta extensa línea de equipos nos permite gestionar de manera eficiente la producción de alto volumen, los diseños intrincados y los plazos ajustados con una calidad constante. Ya sea que necesite prototipos de lotes pequeños o fabricación a gran escala, la sólida capacidad y las operaciones optimizadas de XTJ ofrecen soluciones de torneado CNC confiables y de alto rendimiento adaptadas a sus necesidades, lo que nos convierte en su socio de confianza para obtener resultados superiores.

Precisión Superior

ofrecemos una precisión excepcional con tolerancias de hasta ±0.005 mm, lo que garantiza que los componentes cumplan con las especificaciones más estrictas. Nuestra precisión se valida a través de rigurosas inspecciones utilizando máquinas de medición de coordenadas (MMC) Zeiss de última generación, lo que garantiza una calidad y consistencia incomparables. Ya sea para las industrias aeroespacial, médica o de alta tecnología, nuestras capacidades avanzadas de torneado CNC y los meticulosos procesos de control de calidad brindan soluciones confiables y de alta precisión que superan las expectativas, lo que convierte a XTJ en la opción preferida para aplicaciones de misión crítica.

Versatilidad de Materiales

nuestra experiencia abarca una amplia gama de materiales, incluidos aluminio, acero inoxidable, latón, titanio y varios plásticos, lo que garantiza soluciones personalizadas para diversas aplicaciones. Nuestro equipo capacitado y las capacidades avanzadas de torneado CNC nos permiten manejar las propiedades únicas de cada material con precisión y eficiencia, entregando componentes de alta calidad para industrias como la aeroespacial, automotriz, médica y más. Ya sea que requiera aleaciones ligeras, metales resistentes a la corrosión o plásticos duraderos, el dominio versátil de materiales de XTJ garantiza un rendimiento y una confiabilidad óptimos para las necesidades de su proyecto.

Referencia de Diseño para Torneado CNC

Esta guía, desarrollada por nuestros expertos en torneado, proporciona especificaciones ideales para fabricar componentes torneados precisos. Incluye medidas recomendadas y límites factibles para guiar tu proceso de producción.

| Componente | Medida Ideal | Límite Aceptable |

|---|---|---|

| Característica más pequeña | Ø 2.0 mm | Ø 0.4 mm |

| Radio Interno | R 7 mm | R 0.3 mm |

| Sección más delgada | 0.7 mm (metales) / 1.4 mm (plásticos) | 0.4 mm (metales) / 0.9 mm (plásticos) |

| Diámetro: Ø 0.6 mm / Profundidad: 12x diámetro | Diámetro: herramientas estándar / Profundidad: 5x diámetro | Diámetro: Ø 0.6 mm / Profundidad: 12x diámetro |

| Normas de rosca | Tamaño: M5 o mayor / Longitud: 4x diámetro | Tamaño: M2 / Longitud: 2x diámetro |

Guía de tolerancias en torneado CNC

Desarrollado por nuestro equipo de ingeniería de precisión, esta referencia describe las tolerancias estándar para proyectos de torneado CNC, cumpliendo con las normas ISO 9001. Nuestras tornadoras avanzadas aseguran precisión desde dispositivos médicos hasta componentes industriales, con tolerancias tan ajustadas como ±0.005 pulgadas.

| Componente | Rango de tolerancia |

|---|---|

| Medición de longitud | ± 0.03 mm / ± 0.0012 pulgadas |

| Tamaños de orificios (sin reamer) | ± 0.03 mm / ± 0.0012 pulgadas |

| Tamaños de eje | ± 0.03 mm / ± 0.0012 pulgadas |

| Dimensiones del componente | 900 * 550 * 480 mm |

| Dimensiones del componente | 35.4 * 21.7 * 18.9 pulgadas |

¿Necesita una operación de torneado específica?

Tipos de operaciones de torneado CNC en XTJ

Ofrecemos una variedad de técnicas de torneado para satisfacer sus necesidades:

Torneado recto

Da forma al diámetro externo de una pieza para cilindros uniformes.

Torneado cónico

Crea formas cónicas para componentes especializados.

Roscar

Muele roscas internas y externas para tornillos y accesorios.

Ajuste de cara

Suaviza la cara final de una pieza para un acabado limpio.

Perforación y fresado interior

Agrega agujeros o amplía los existentes con precisión.

Ranurado y separación

Corta ranuras o separa piezas terminadas del material de origen.

Materiales y acabados superficiales soportados por el mecanizado XTJ

Varía según el tipo de material, generalmente de alta dureza. La selección de herramientas y parámetros de corte debe basarse en la composición específica, con atención a la resistencia al desgaste y la estabilidad térmica.

Aluminio (por ejemplo, 6061, 7075)

Características: Ligero, buena conductividad térmica, fácil de mecanizar, las virutas se rompen fácilmente. Puede causar adherencia a la herramienta; requiere enfriamiento y lubricación adecuados. Adecuado para fresado de alta velocidad.

Acero (por ejemplo, inoxidable, carbono)

Características: Alta dureza, resistente al desgaste, pero genera altas fuerzas de corte y calor durante el mecanizado. Requiere fresado a baja velocidad con herramientas duras (por ejemplo, carburo). El acero inoxidable puede presentar endurecimiento por trabajo.

Titanio

Características: Alta resistencia, baja conductividad térmica, el calor se concentra durante el mecanizado, causando desgaste de la herramienta. Requiere corte a baja velocidad, herramientas de alto rendimiento y refrigeración suficiente.

Latón

Características: Blando y fácil de mecanizar, buena maquinabilidad, las virutas se rompen fácilmente, alto acabado superficial. Adecuado para fresado a alta velocidad, genera menos calor.

Cobre

Características: Alta conductividad térmica, dúctil, propenso a que la herramienta se pegue durante el mecanizado. Requiere herramientas afiladas y lubricación adecuada. Las virutas pueden ser largas, por lo que la evacuación de virutas es importante.

ABS

Características: Buena resistencia, fácil de mecanizar, pero propenso a ablandarse por el calor. Requiere velocidad de corte controlada y enfriamiento para evitar derretimiento o rebabas.

POM (Polioximetileno)

Características: Resistencia moderada, resistente al desgaste, autolubricante, estable durante el mecanizado, buen acabado superficial. Tener cuidado con la deformación térmica.

PEEK

Características: Alta resistencia a temperaturas, resistencia química, alta dureza. Requiere herramientas duras, genera fuerzas de corte elevadas y necesita control de temperatura para prevenir deformaciones.

Policarbonato

Características: Transparente, alta resistencia, pero propenso a agrietamiento por estrés. Requiere corte a baja velocidad para evitar sobrecalentamiento, y herramientas afiladas son necesarias.

Nylon

Características: Alta resistencia, resistente al desgaste, pero higroscópico y propenso a deformaciones durante el mecanizado. Requiere velocidad de corte controlada, adecuado para fresado a baja velocidad.

Fibra de carbono

Características: Alta resistencia, ligero, pero muy duro. Propenso a delaminación o rebabas durante el mecanizado. Requiere herramientas de diamante o carburo, y es necesario protección contra el polvo.

Fibra de vidrio

Características: Alta dureza, resistente a la corrosión, pero abrasivo para las herramientas y genera polvo durante el mecanizado. Requiere extracción eficiente de polvo y herramientas duras.

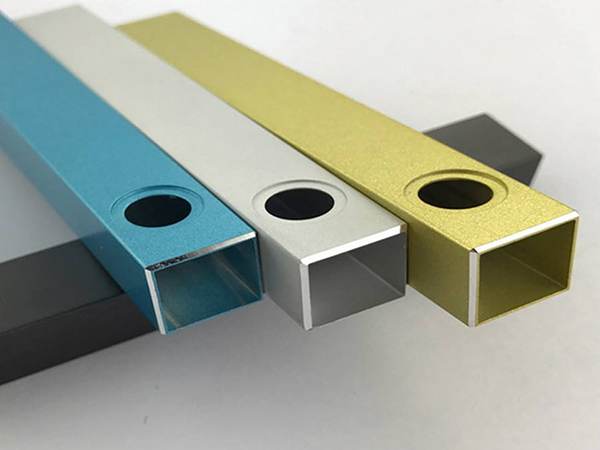

Eleva tus piezas con acabados superficiales avanzados

Mejora la durabilidad, funcionalidad y estética de tus componentes con la gama de opciones de acabado superficial de XTJ. Cada proceso está diseñado para cumplir con requisitos específicos de rendimiento y diseño, asegurando que tus piezas no solo funcionen excepcionalmente sino que también luzcan su mejor aspecto.

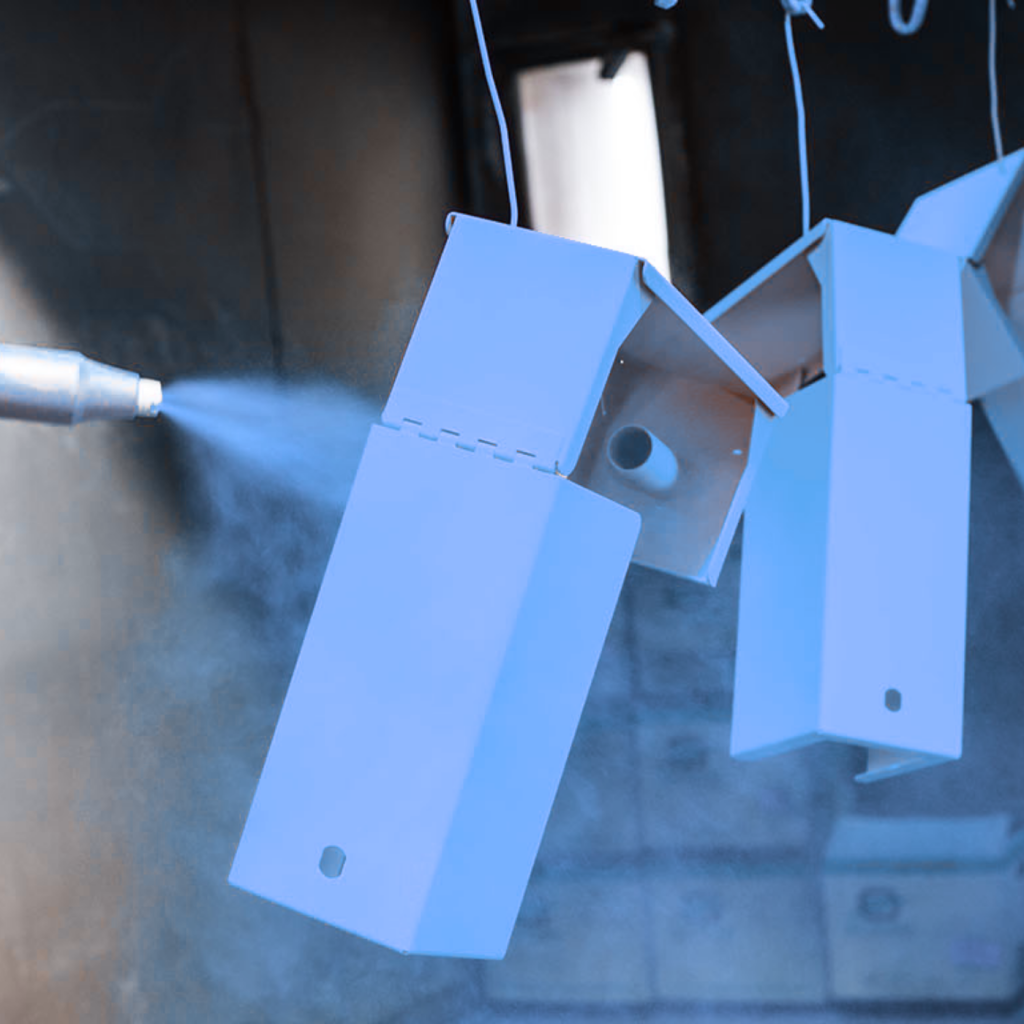

Revestimiento duradero y versátil para una protección de larga duración

El recubrimiento en polvo aplica un polvo seco—generalmente una mezcla de resina y pigmento—electrostáticamente sobre la pieza, que luego se cura bajo calor para formar una capa resistente y protectora. Este acabado es conocido por su durabilidad y resistencia a astilladuras, arañazos y corrosión.

Revestimiento duradero y versátil para una protección de larga duración

El recubrimiento en polvo aplica un polvo seco—generalmente una mezcla de resina y pigmento—electrostáticamente sobre la pieza, que luego se cura bajo calor para formar una capa resistente y protectora. Este acabado es conocido por su durabilidad y resistencia a astilladuras, arañazos y corrosión.

Acabado mate uniforme para una estética mejorada

El chorro de perlas utiliza pequeñas perlas de vidrio impulsadas a alta presión para crear un acabado mate uniforme y no reflectante en la superficie de las piezas. Este proceso elimina imperfecciones superficiales y proporciona una textura limpia y uniforme.

Acabado similar a un espejo para aplicaciones premium

El pulido implica suavizar mecánicamente la superficie de una pieza para lograr un acabado brillante, similar a un espejo. Este proceso mejora tanto el atractivo visual como la calidad táctil del componente.

Mayor resistencia a la corrosión para acero inoxidable

La pasivación es un tratamiento químico que elimina el hierro libre de la superficie de piezas de acero inoxidable, formando una capa pasiva de óxido que mejora significativamente la resistencia a la corrosión.

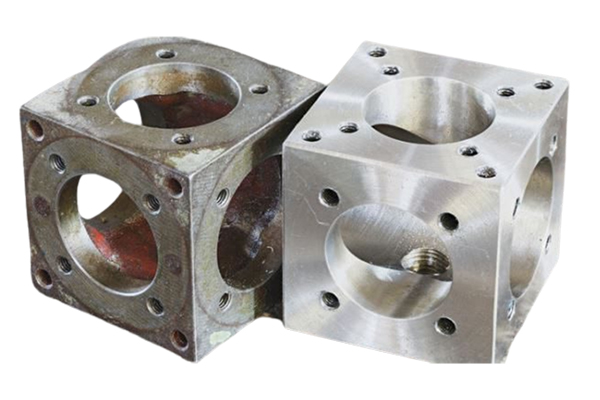

¿Qué es el torneado CNC?

El torneado CNC es un proceso sustitutivo en el que una herramienta de corte se desplaza a lo largo de una pieza de trabajo giratoria para crear piezas cilíndricas. En XTJ, utilizamos torneado CNC de 2, 3 y múltiples ejes para producir componentes con características como roscas, ranuras y conos, ofreciendo flexibilidad para diseños simples a complejos.

Sirviendo a diversas industrias con piezas de torneado CNC

Aeroespacial

Fabricar piezas ligeras y de alta resistencia como palas de turbina y componentes estructurales que cumplen con estrictos estándares aeroespaciales.

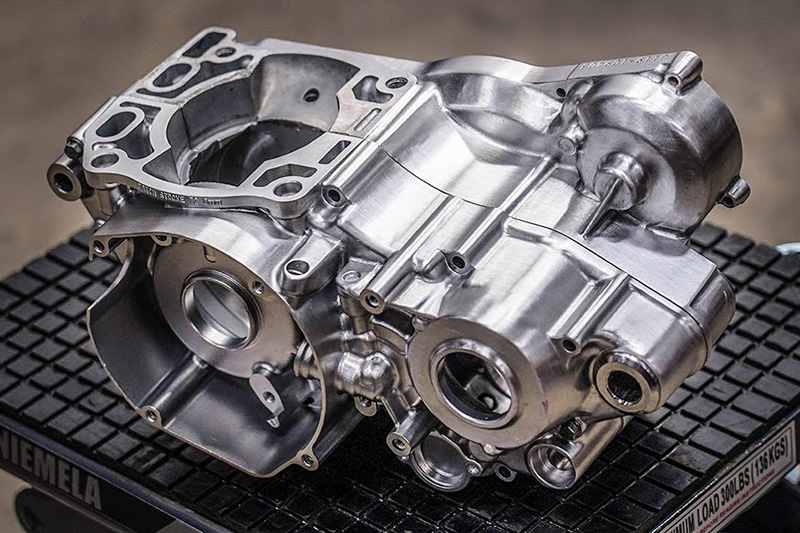

Automoción

Producir componentes de motor, piezas de transmisión y accesorios personalizados con tolerancias precisas para vehículos de alto rendimiento.

Medicina

Crear instrumentos de precisión e implantes con materiales biocompatibles como titanio y PEEK para aplicaciones médicas.

Electrónica

Fabricar piezas pequeñas e intrincadas como carcasas y disipadores de calor para electrónica de consumo y telecomunicaciones.

Desde el diseño hasta la entrega en 5 pasos simples

Colabora con nosotros sin esfuerzo: Envía tu diseño, recibe retroalimentación experta, aprueba tu presupuesto y lanza la producción. Mantente informado en cada etapa para resultados confiables y de alta calidad.

¿Buscas servicios de torneado CNC asequibles y confiables?

Asóciate con XTJ Precision Mfg para precisión, eficiencia y gran valor.