ABS plastic is a popular part manufacturing and prototyping material with wide industrial applications due to its unique mechanical properties.

The thermoplastic is applicable in manufacturing products regardless of the designs using processes such as CNC machining, 3D printing, and injection molding. This article talks about ABS material and its compatible manufacturing processes.

What Is ABS Plastic Material?

ABS (Acrylonitrile Butadiene Styrene) is an opaque thermoplastic known for its rigidity and strength. The polymer is amorphous and consists of three monomers: acrylonitrile, butadiene, and styrene:

Acrylonitrile is responsible for the material’s chemical stability and heat resistance.

Butadiene gives the polymer its toughness and impact strength.

Styrene is responsible for its rigidity and processability in creating various forms.

Properties Of ABS Plastic

ABS plastic material has wide applications in several industries and compatibility with several manufacturing processes due to its properties. Below are some ABS material properties and why ABS rapid prototyping and manufacturing are common.

properties of ABS plastic

Impact Resistance

Impact resistance is the ability of a material to resist intense and sudden force. ABS plastic material has a high impact resistance at low temperatures. As a result, it is an important part of the automotive industry in making parts such as bumpers.

Excellent Insulator

Like any plastic, ABS is an excellent insulator and low conductor of heat. As a result, it is popular in prototyping and manufacturing products that require insulation protection.

Abrasion Resistance

The polymer has high abrasion resistance. As a result, it is applicable in making products that should have a smooth surface irrespective of their choice of use. As a result, ABS is common in the automotive industry in making parts such as dashboards.

Surface Brightness

The plastic polymer has a quality, well-polished, and shiny surface. As a result, its aesthetic appeal ranks it as a top plastic polymer in the automotive industry.

Resistencia Química

ABS is highly chemical resistant as it is usable in environments containing alcohols, hydrocarbons, and other chemicals.

Different Types Of ABS Grades

There are different grades of ABS materials used in part prototyping and manufacturing. Each grade has its properties well explained below:

ABS Extrusion Grade

The extrusion grade is named because they come from the plastic extrusion process and are common in industries requiring their ABS prototype with heightened strength and elasticity. A common example is an ABS569 plastic and ABS-PA749SK.

ABS Flame-retardant Grade

The flame-retardant grade of ABS is a heat-resistant ABS plastic material applicable in making products and parts that need strong heat resistance. An example is the Prime ABS 860 FR, which is moldable/extrudable and joinable with other materials such as polycarbonate and polyvinyl chloride.

ABS Injection Molding Grade

This ABS material grade is suitable for making products using injection molding. They have high impact resistance and are applicable in plastic prototyping.

Other Grades of ABS Plastic

These include ABS grades combined with different materials to boost their mechanical properties. Examples include ABS plastics combined with materials such as glass fiber, graphite fiber, and stainless-steel fiber.

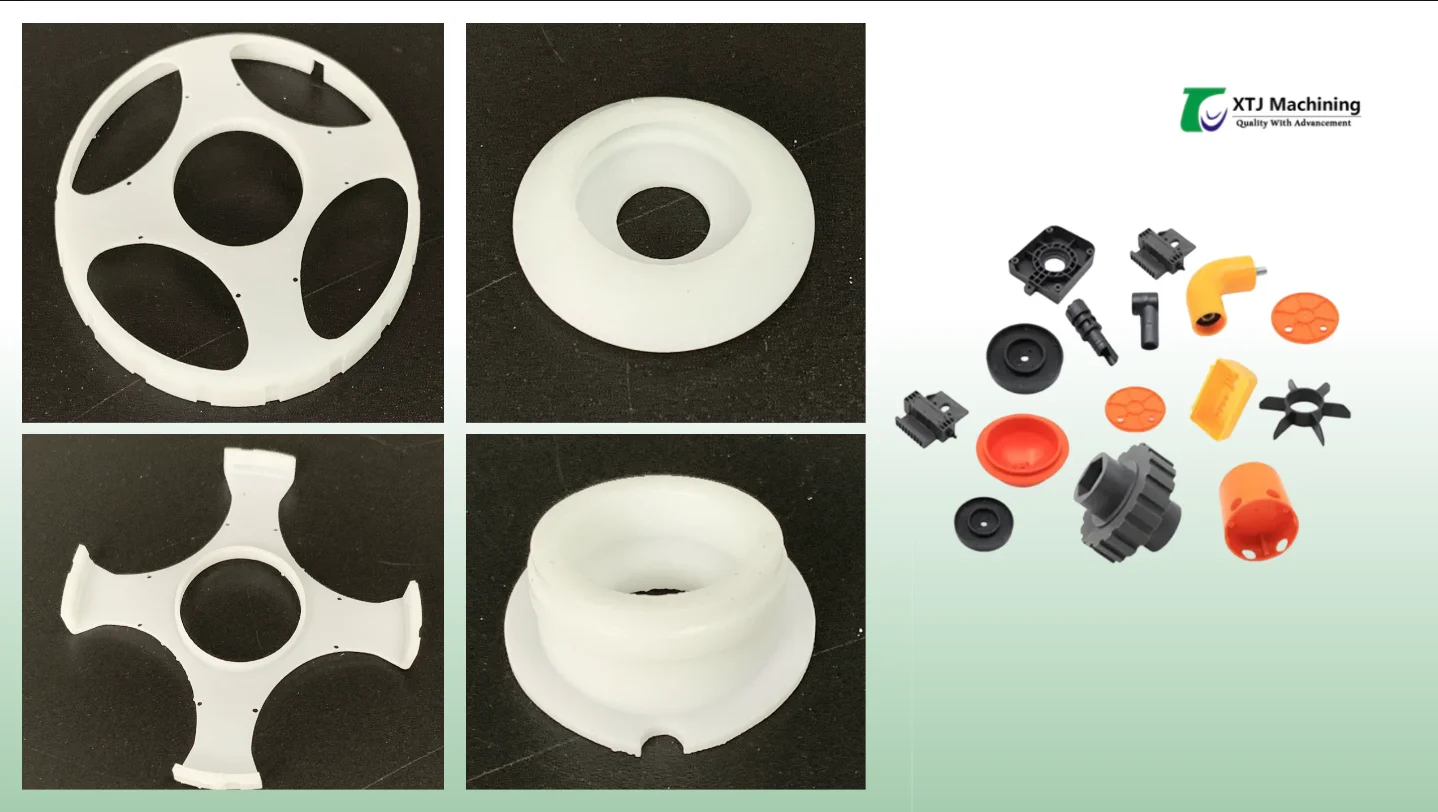

Types Of Processes For Manufacturing ABS Plastics

There are different types of manufacturing processes suitable for working with ABS. Below are the common manufacturing processes used in plastic prototyping and manufacturing.

1. 3D Printing for ABS

3D printing is an additive manufacturing process that uses a 3D printer to manufacture a 3D part aided by Computer-Aided Design (CAD) models. The printer constructs the part layer by layer till it creates a full physical part.

There are several 3D printing techniques. However, Fused Deposition Modeling (FDM) technology is the most popular for ABS plastics. After printing, you can also subject the part to post-processing options to improve its function and aesthetics.

Using 3D printing with ABS plastic comes with several defects. Below are a few to consider:

- Warping: This is the most common 3D printing defect in which the lower part of the printed ABS parts curls up. It occurs due to irregular temperature that causes uneven shrinkage. Several solutions include reducing the printing speed, using adhesives, and printing with a heated bed.

- Cracking (delamination): It occurs when the printed ABS layers separate because they don’t bond due to temperature differences. You can prevent cracking by printing with an enclosure to control the operating temperature.

- Z-wobble: This occurs due to a skewed printer movement which causes the incoherent movement to move incorrectly. You can avoid Z-wobble by tuning all z-axis components.

- Stringing: This is when tiny ABS thermoplastic remains on a 3D-printed model due to the extruder moving to a random spot and leaking plastic. A common preventive measure is reducing print speed and unclogging the nozzle.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.;

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Pros of Using ABS in Rapid Prototyping

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Industria Automotriz

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Conclusión

cURL Too many subrequests.

cURL Too many subrequests.

Preguntas Frecuentes

cURL Too many subrequests.

ABS, or Acrylonitrile Butadiene Styrene, is an amorphous and thermoplastic polymer. As a thermoplastic, it is moldable by applying and removing heat. Furthermore, being amorphous means that it is not crystalline.

Is ABS plastic toxic?

ABS is fairly harmless to humans due to the absence of carcinogens. Also, there’s been no record of adverse health problems relating to exposure to ABS. However, they are unsuitable or recommended for medical implants.

For prototype manufacturing, which is better, ABS plastics or normal plastics?

Choosing the right plastic depends on the desired mechanical properties. For example, ABS is stronger and more durable than polyvinyl chloride. However. It would be best if you talked to experts on the right material for your project.

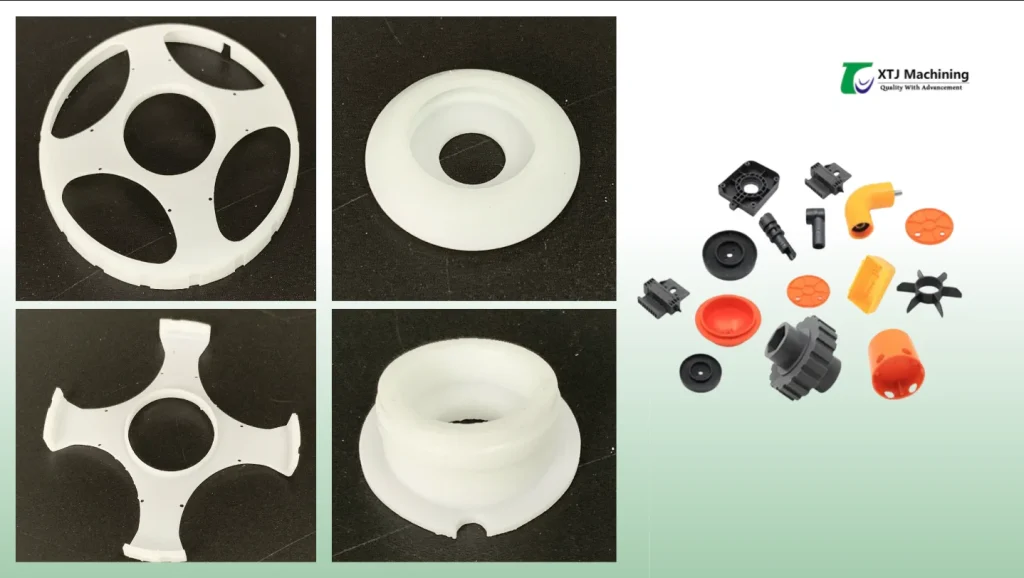

XTJ es un fabricante OEM líder que se dedica a proporcionar soluciones de fabricación integral de ABS Plastic Parts desde prototipo hasta producción. Nos enorgullece ser una empresa certificada con sistema de gestión de calidad ISO 9001 y estamos decididos a crear valor en cada relación con el cliente. Lo logramos a través de la colaboración, la innovación, las mejoras en los procesos y una mano de obra excepcional.