What is Micromachining?

Micromachining refers to the process of cutting the surface of a workpiece at the micron or nanometer level using mechanical micro-tools with geometrically defined cutting edges. This technology is often employed in fields that require extremely high precision, such as manufacturing optical components, microdevices, and medical devices, and more.

Different Types of Micromachining

- Surface Micromachining

Surface micro-processing refers to the micro-scale processing and treatment of the workpiece surface to improve its quality and performance. It typically involves several common methods:

| Micro-Milling | Uses small tools to achieve micro or nano-level cutting on the workpiece surface to obtain fine surface quality and high-precision processing. |

| Micro-Brushing | Utilizes micro-probes or brushes for microscopic grinding or polishing of the workpiece surface to remove surface defects and improve smoothness |

| Micro-Spraying | Leverages small nozzles to spray liquid or gas onto the workpiece exterior to achieve micron-level spray coatings for surface protection or modification. |

| Micro-Grinding | Apply micron-sized abrasive particles to achieve microscopic grinding on the workpiece facade to eliminate surface roughness and improve flatness. |

| Micro-Drilling | Processing micro-holes or grooves on the workpiece surface employing micro-drills or micro-hole machining tools for micro-scale applications such as fluid transfer and sensors. |

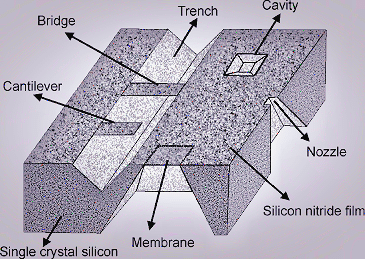

- Bulk Micromachining

Bulk micro-processing technology has wide application prospects in the medical industry. Through precision processing means, it provides unprecedented precision and flexibility for the manufacture of medical instruments, especially demonstrating enormous potential in minimally invasive surgery and biomedical research.

Definition and Principles:

Bulk micro-processing is a technology used to manufacture micro-scale three-dimensional structures. It also involves processing the material’s overall parts to create specific shapes and functions. Fundamentally, its core is selectively removing certain material portions to create complex three-dimensional structures.

Key Technologies:

It includes two key technologies: wet etching and dry etching.

| Wet Etching | A chemical reaction process encompasses etchants, chemical reactions, reaction products, and other steps. |

| Dry Etching | Provides reaction energy to the material to be etched through high-energy ion acceleration, with the most common form being reactive ion etching (RIE). |

- Laser Micromachining

In the field of medical device manufacturing, laser micro-processing is used for the production of micro-medical devices such as endoscopes, cardiac stents, and artificial cochlears.

Laser micro-processing typically includes several common techniques:

| Corte Láser | Uses high-energy laser beams to cut materials, achieving high-precision cutting and processing of microstructures. |

| Perforación Láser | Utilizes laser beams for hole processing in materials, realizing processing of small apertures and high-precision hole positions. |

| Laser Ablation | Applies laser energy to evaporate or dissolve the material surface for micro-patterns and surface treatment. |

| Laser Welding | Leverages laser beams for precise welding of materials, attaining high-strength welding connections. |

The Benefits and Constraints of Micromachining cURL Too many subrequests.

Beneficios

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

Utilizado en cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Non-metals have lower hardness and strength compared to metals but may possess unique chemical or physical properties. Proper tool selection and parameters based on material characteristics are crucial to avoid cracks or fractures.

Ceramics:

Ceramics have high hardness but are brittle, and gentle cutting is necessary to reduce damage, requiring the use of special ceramic tools.

Plastics:

With low hardness and good plasticity, controlling temperature and humidity during processing is essential to prevent deformation.

In conclusion, parameter optimization tailored to the different material characteristics is essential to ensure machining quality.

XTJ – Your Trusted Micromachining Partner

With over 10 years of CNC manufacturing experience, XTJ has become a reliable manufacturer for producing micro-mechanical components for surgical instruments, tools, and medical device prototypes. Our skilled machinists excel in custom machining part designs to meet the highest standards of the medical industry. Are you ready to start your next CNC machining project with us?

XTJ es un fabricante OEM líder dedicado a ofrecer soluciones integrales de fabricación de mecanizado de aluminio 6061, desde prototipos hasta producción. Nos enorgullece ser una empresa certificada con sistema de gestión de calidad ISO 9001 y estamos decididos a crear valor en cada relación con el cliente. Lo logramos a través de la colaboración, innovación, mejoras en los procesos y una mano de obra excepcional.