Nylon 66 (PA66), known for its excellent toughness, strength, and wear resistance, is widely used in mechanical manufacturing. However, burrs often pose a challenge during CNC machining of small grooves, frustrating engineers. Burrs not only affect the product’s appearance and assembly precision but can also reduce its service life. This article provides professional and practical deburring solutions, covering process optimization, tool selection, post-processing techniques, and design prevention, ensuring smooth, high-quality surfaces for CNC-machined Nylon 66 grooves.

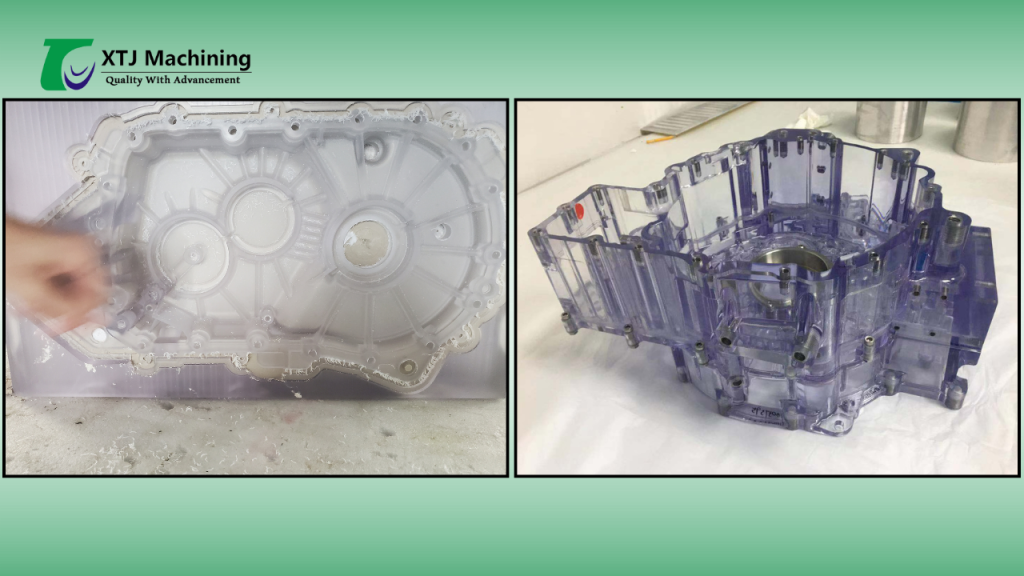

At XTJ Precision Mfg, we have extensive experience in CNC plastic machining, specializing in high-quality plastic components tailored to specific application needs using techniques like CNC turning and milling to produce custom nylon parts.

1. Burr Formation Analysis: Why Do Small Grooves in CNC Nylon Machining Generate Burrs?

The material properties of Nylon 66 make it prone to burr formation when machining narrow or deep grooves. Key reasons include:

- High Toughness: The material resists complete cutting, leading to stretching, tearing, or curling during machining, resulting in burrs, especially at groove entrances, exits, and corners.

- Thermal Softening and Tool Sticking: Heat from cutting friction softens or even melts the material locally, causing it to adhere to the tool’s cutting edge, forming irregular burrs or built-up edges.

- Tool Extrusion: Dull tools or improper cutting parameters cause the material to be extruded rather than cut, leading to flanging burrs.

- Core Principle: Prevention first, treatment second. Optimizing machining processes and design minimizes burr formation from the outset.

2. Process Optimization: Controlling Burrs at the Source

Effective deburring starts with precise control during machining. Below are key considerations for tools, parameters, cooling, and toolpaths:

2.1 Tool Selection: Sharpness is Key

- Preferred Choice: Diamond-coated tools, with their ultra-low friction coefficient and high wear resistance, maintain sharp edges for extended periods, reducing material sticking and burr formation. Alternatively, high-performance uncoated carbide tools are viable.

- Tool Geometry: Use a large positive rake angle and sharp cutting edge to avoid edge dulling (negative land), ensuring smooth cutting.

- Size Matching: The milling cutter diameter should match the groove width to avoid excessive radial cutting depth, which causes extrusion. Multi-flute end mills (3-4 flutes) enhance cutting stability.

- Tool Management: Nylon 66 is sensitive to tool wear. Implement strict tool life management and regular replacement to maintain edge sharpness.

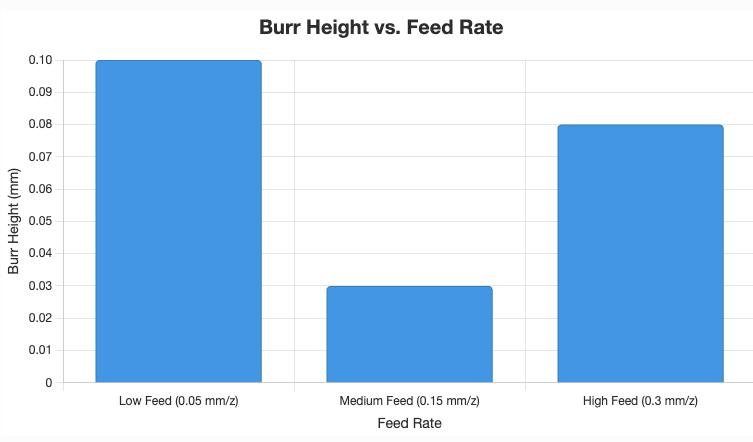

2.2 Cutting Parameters: Finding the Optimal Balance

- Avoid Low Feed Rates: Excessively low feed per tooth increases friction heat, softening the material and causing sticking and burrs.

- Avoid High Feed Rates: Overly high feed rates generate excessive cutting forces, tearing the material instead of cutting it, leading to burrs.

- High Spindle Speed: Moderately increase spindle speed to improve chip formation, reduce heat buildup, and minimize material adhesion.

- Finishing Strategy: Use small cutting depths with multiple passes or a dedicated finishing toolpath instead of single-pass machining. Control radial cutting depth (stepover) to reduce burr risk.

2.3 Cooling and Lubrication: Balancing Temperature and Friction

-

- Purpose: Remove cutting heat to prevent material softening, clear chips to avoid secondary scratches, and reduce cutting forces to minimize burrs.

- Recommended Solutions:

- Water-Soluble Coolant: cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.“

cURL Too many subrequests.

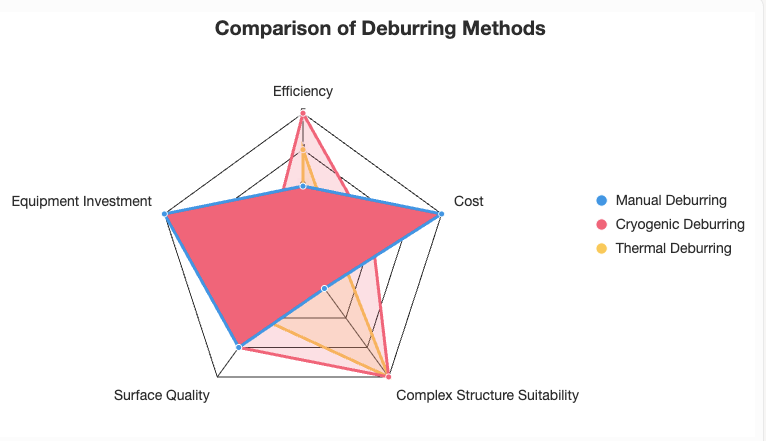

- cURL Too many subrequests.

- cURL Too many subrequests.

- High-Precision Requirements: Thermal deburring, but validate processes rigorously to avoid material damage.

- Chemical Polishing: Too risky, best avoided.

Design Support: Chamfers/fillets at groove edges are a “game-changer” for burr prevention—strongly recommended.

Diagnose First: Analyze burr shape and location to identify root causes (e.g., tool wear, insufficient cooling, or improper feed), then optimize processes accordingly.

Small-Batch Testing: Validate tools and parameters through trial machining, refining the approach iteratively.

6. cnc nylon machining factory suggestion

Burr issues in CNC machining of small Nylon grooves can be addressed through process optimization (sharp tools, reasonable parameters, effective cooling, climb milling), efficient post-processing (cryogenic deburring prioritized), and proactive design (chamfers/fillets). Focus on preventing burrs at the source, combined with appropriate post-processing for the specific scenario, to achieve both machining efficiency and product quality.

XTJ Precision Mfg specializes in machining nylon and other plastics, delivering high dimensional accuracy and surface finish. Our custom CNC machining services meet diverse application needs, providing tailored solutions for industries requiring high-quality plastic components. Contact us today to explore how our expertise can meet your specific requirements.