Precision Medical Device CNC Machining Services

XTJ delivers ISO 13485-certified CNC machining with over 20 years of expertise in medical component manufacturing. We combine high precision tolerances, full regulatory compliance, and rapid turnaround times—with no minimum order requirements. Save up to 30% on manufacturing costs while ensuring exceptional quality and patient safety through our advanced machining capabilities.

-

Precision Tolerances

Exceptional accuracy for critical medical components -

On-Time Delivery

Reliable production schedules you can trust -

Minimum Order

Full flexibility from prototype to production -

Days for Prototypes

Rapid turnaround for development cycles

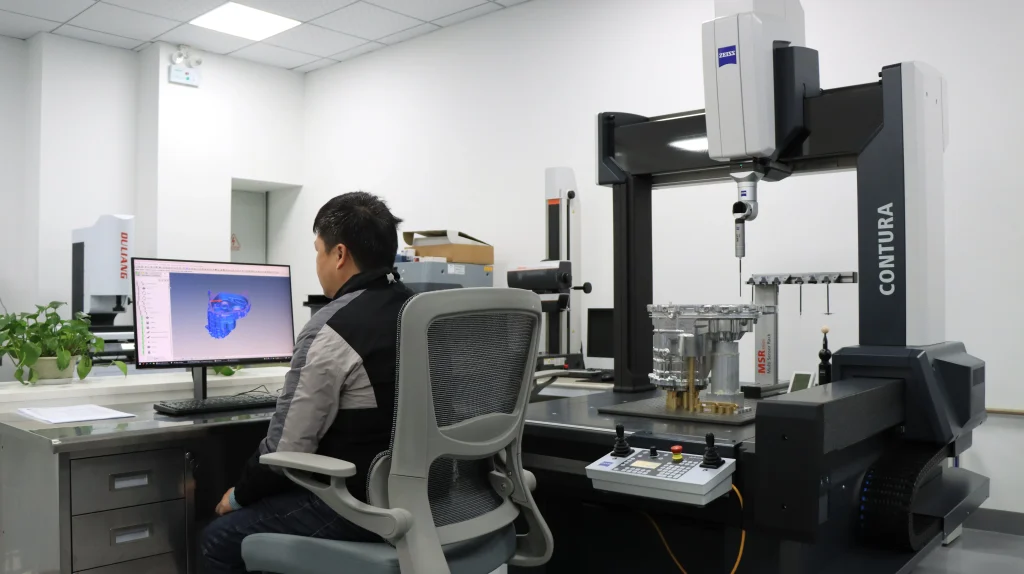

Uncompromising Precision and Quality Standards

The life-critical nature of medical devices demands exceptional precision and uncompromised quality. Any deviation in manufacturing tolerances could lead to device failure and jeopardize patient safety. At XTJ, we recognize this responsibility and implement rigorous quality protocols at every production stage.

We double-check engineering drawings and machining specifications throughout the entire process—from initial prototype development through low-volume validation runs to high-volume production. During prototyping, our engineering team collaborates closely on design iterations to ensure flawless execution before committing to production tooling.

Our management considers overlooking quality details completely unacceptable. This commitment guarantees you receive standardized, reliable parts that meet your exact specifications every time, maintaining consistency across production batches.

Deep Technical Expertise

20+ years specializing in medical device precision machining with proven capabilities in complex geometries

Räätälöidyt ratkaisut

Custom manufacturing approaches aligned perfectly with your unique device requirements

Your Success Defines Ours

We measure our performance by your product success and market acceptance

Material Compliance and Regulatory Certainty

Ensuring materials meet rigorous regulatory standards is non-negotiable for medical device manufacturing. Biocompatibility, sterilization compatibility, and full material traceability are essential requirements. Our material selections strictly comply with FDA regulations, ISO 13485 standards, and CE Marking requirements to safeguard device performance and patient well-being.

XTJ sources materials exclusively from trusted domestic suppliers who meet stringent global safety benchmarks. For specialized applications requiring premium grades, we import raw materials directly from certified European and US suppliers, complete with comprehensive certification documentation including MSDS and RoHS/REACH compliance reports.

cURL Too many subrequests.

Ti-6Al-4V Grade 5 & 23 ELI: Biocompatible, lightweight, and high-strength—ideal for implants, prosthetics, and

load-bearing medical components requiring excellent corrosion resistance.

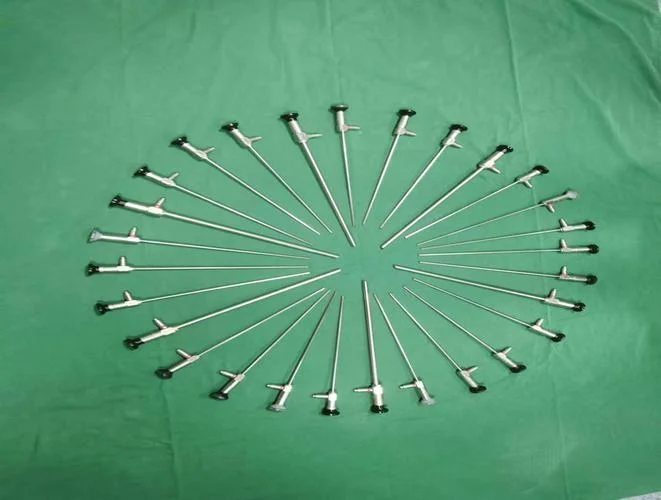

Ruostumaton teräs

316L, 17-4PH: Superior corrosion resistance and sterilization compatibility make these grades perfect for surgical

instruments and reusable medical tools.

Cobalt Chrome

CoCrMo: Exceptional wear resistance and biocompatibility for demanding applications like joint replacements

and dental framework structures.

Engineering Polymers

PEEK & UHMWPE: Radiolucent materials with bone-like modulus for spinal cages, orthopedic applications,

and applications requiring MRI compatibility.

Aluminum Alloys

6061, 7075: Cost-effective solutions for non-implant device housings, enclosures, and structural components

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests.

Material Compliance and Regulatory Certainty

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- Reduced Setup Time cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Suuri sarjatuotanto

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Suunnittelu valmistettavuuden mukaan

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Uncompromising Precision and Quality Standards

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Deep Technical Expertise

20+ years specializing in medical device precision machining with proven capabilities in complex geometries

Räätälöidyt ratkaisut

Custom manufacturing approaches aligned perfectly with your unique device requirements

Your Success Defines Ours

We measure our performance by your product success and market acceptance

cURL Too many subrequests.

We’re proud to support pioneering medical device companies and healthcare innovators worldwide. Our partnerships with industry leaders demonstrate our capability to meet the most demanding technical specifications and regulatory requirements while delivering exceptional quality and reliability.

Through our advanced technology center, we collaborate with global medical technology leaders including LEPU Medical, Yuwell Medical, Haier Biomedical, and United Imaging Medical. These strategic partnerships drive peak manufacturing performance, consistently exceed expectations, and deliver precise solutions through unmatched craftsmanship and engineering expertise.

Elevate Your Medical Devices with XTJ Precision

Partner with XTJ for compliant, high-quality CNC machining solutions that accelerate your development timeline and reduce manufacturing costs. Our ISO 13485-certified facility combines decades of medical device expertise with cutting-edge technology to deliver the precision, quality, and reliability your innovations demand.

Full Regulatory Compliance

ISO 13485, FDA, and CE certified manufacturing with complete documentation

Nopea toimitus

Prototypes in 3-7 days with scalable production capabilities

Cost Optimization

Save 20-40% through DFM expertise and efficient processes

IP Protection

Comprehensive NDAs and secure systems safeguard your innovations

No Minimum Orders

Complete flexibility from single prototypes to high-volume production

Asiantuntijatuki

Dedicated engineering assistance throughout your project lifecycle

From concept validation through full-scale manufacturing, XTJ provides the precision machining partnership you need to bring life-changing medical devices to market faster and more cost-effectively. Experience the difference that true medical manufacturing expertise makes.

Usein kysytyt kysymykset

Here are answers to some of the most common questions about medical device machining, based on our expertise at XTJ Precision Manufacturing.

Common choices include titanium alloys (Ti-6Al-4V), medical-grade stainless steel (316L, 17-4PH), cobalt chrome, aluminum alloys, and high-performance engineering polymers like PEEK. Materials are selected based on biocompatibility, sterilization compatibility, corrosion resistance, and mechanical properties required to meet essential FDA and ISO medical standards.

Five-axis machining enables complex three-dimensional shapes and intricate features with superior precision and consistency. It dramatically reduces setup time by accessing multiple angles in a single operation, improves surface finish quality, and enhances overall production efficiency—making it perfect for complex implants, surgical instruments, and components with challenging geometries.

All XTJ-manufactured medical components meet ISO 13485 quality management standards, FDA regulations for medical device manufacturing, and CE Marking requirements for European markets. We provide complete documentation packages including material certificates, inspection reports, and traceability records to support your regulatory submissions and quality assurance processes.

CNC machining delivers exceptional precision, excellent repeatability, and minimal material waste compared to traditional manufacturing methods. The process accelerates development timelines, reduces tooling costs for low to medium volumes, and eliminates expensive secondary operations. At XTJ, optimized processes and DFM expertise often save clients up to 30% compared to alternative suppliers.

Swiss-type CNC machines excel at producing ultra-precise micro components as small as 0.5mm diameter with exceptional concentricity and surface finish. The guide bushing support and sliding headstock design deliver tight tolerances and superior accuracy—making this technology ideal for catheter components, micro-implants, dental instruments, and other miniature medical parts requiring extreme precision.