Services d'usinage CNC en aluminium

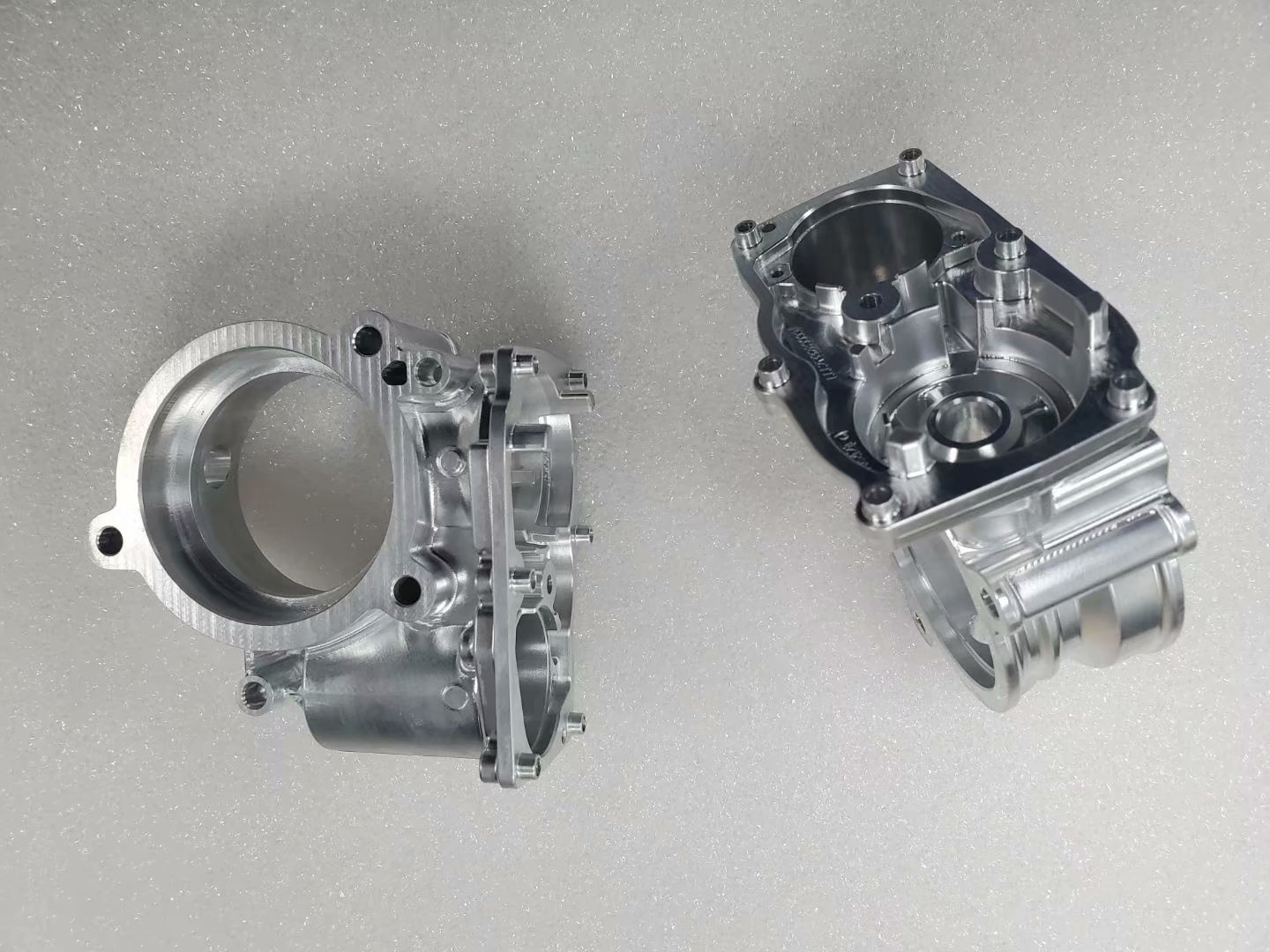

we specialize in high-precision aluminum CNC machining, delivering custom parts that meet your exact specifications.

- Commande flexible : pas de quantités minimales—idéal pour prototypes ou séries de production.

- Enceintes sans quantité minimum de commande

- Livraison mondiale, Usine réelle, bienvenue à visiter

Why Choose Aluminum for CNC Machining

Aluminum is a versatile material prized for its excellent strength-to-weight ratio, which is superior to many steels, making it ideal for lightweight applications. It offers exceptional corrosion resistance, good machinability, and high thermal conductivity, allowing for efficient heat dissipation in demanding environments. Key benefits include:

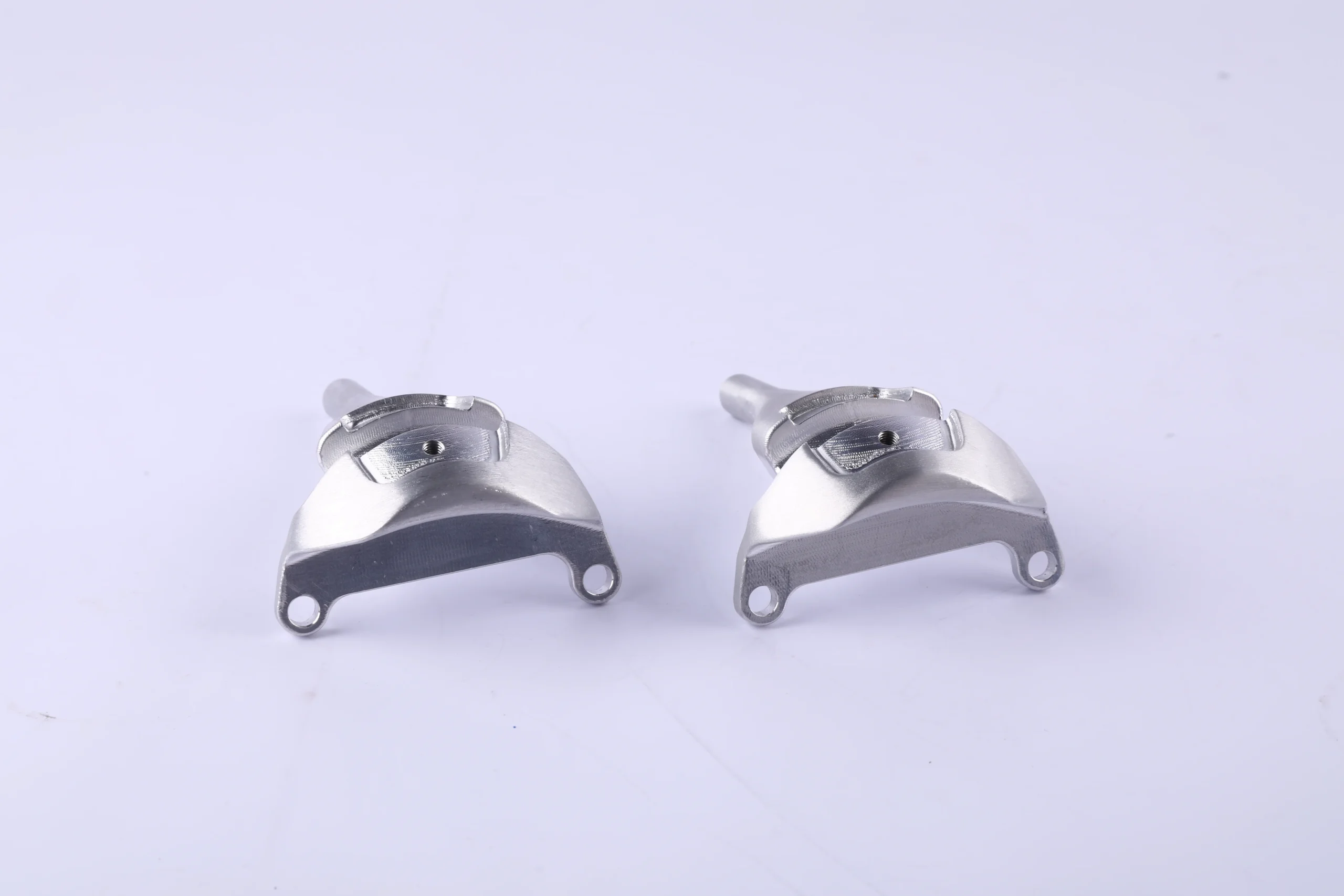

Lightweight Design

Reduces overall weight in products like aircraft components and automotive parts, improving fuel efficiency and performance.

Résistance à la corrosion

Forms a natural oxide layer that protects against rust, perfect for marine and outdoor uses.

Versatile Machinability

Easily shaped via CNC processes without cracking, supporting complex geometries.

Cost-Effective

Affordable material with easy recyclability, lowering long-term production expenses.

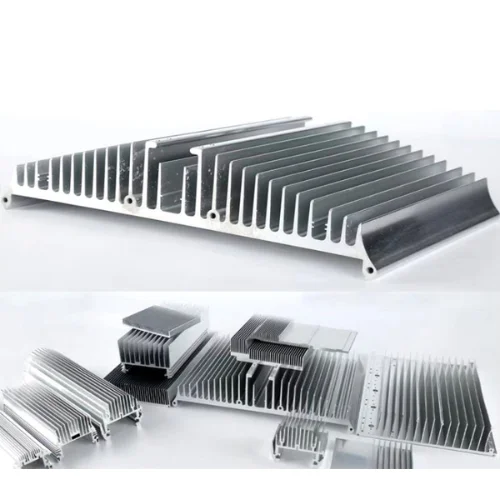

Thermal and Electrical Conductivity

Excellent for heat sinks and electronic housings.

Aluminum alloys can be heat-treated or cold-worked to enhance strength, with yield strengths ranging from 30 MPa in pure forms to over 500 MPa in high-strength series.

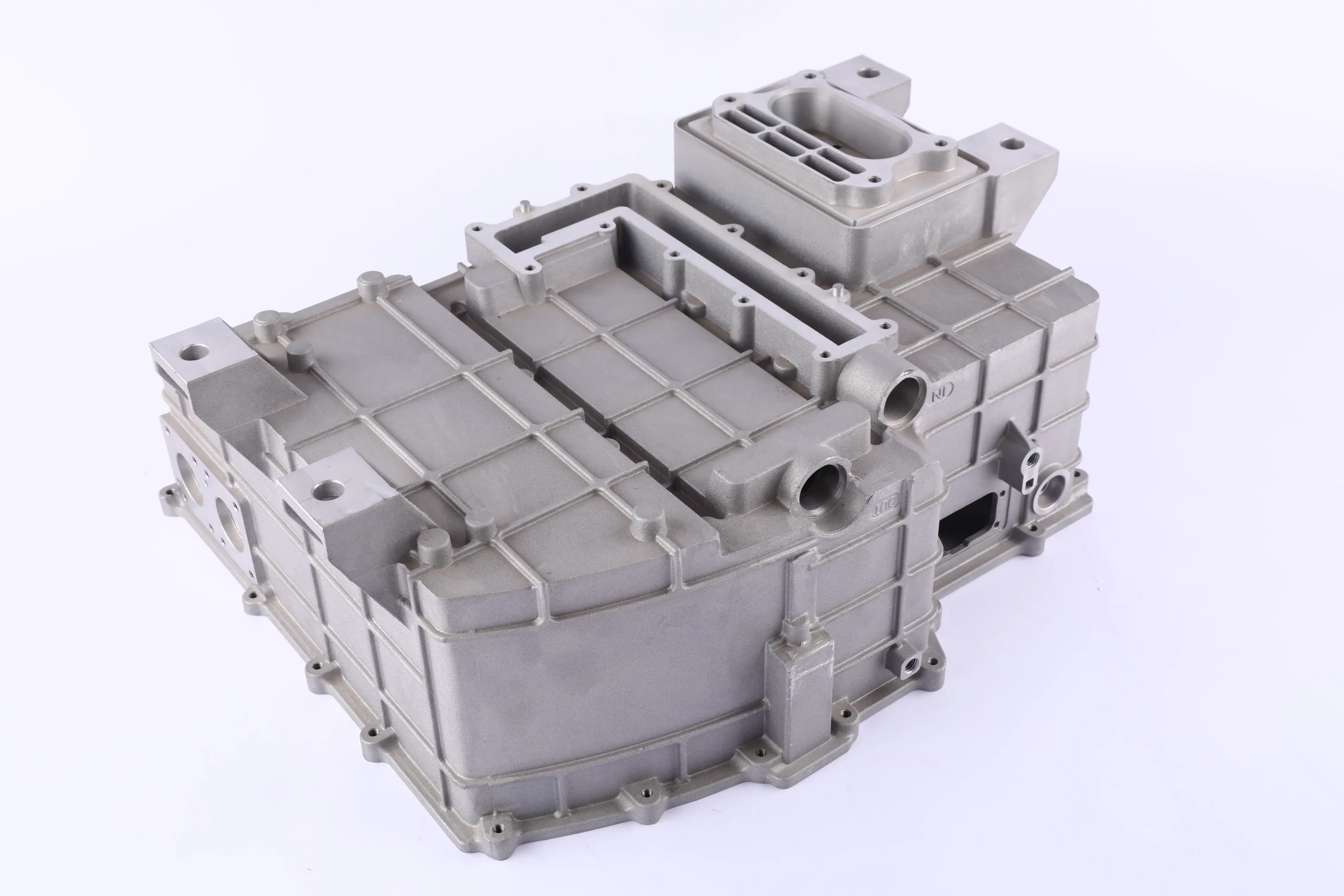

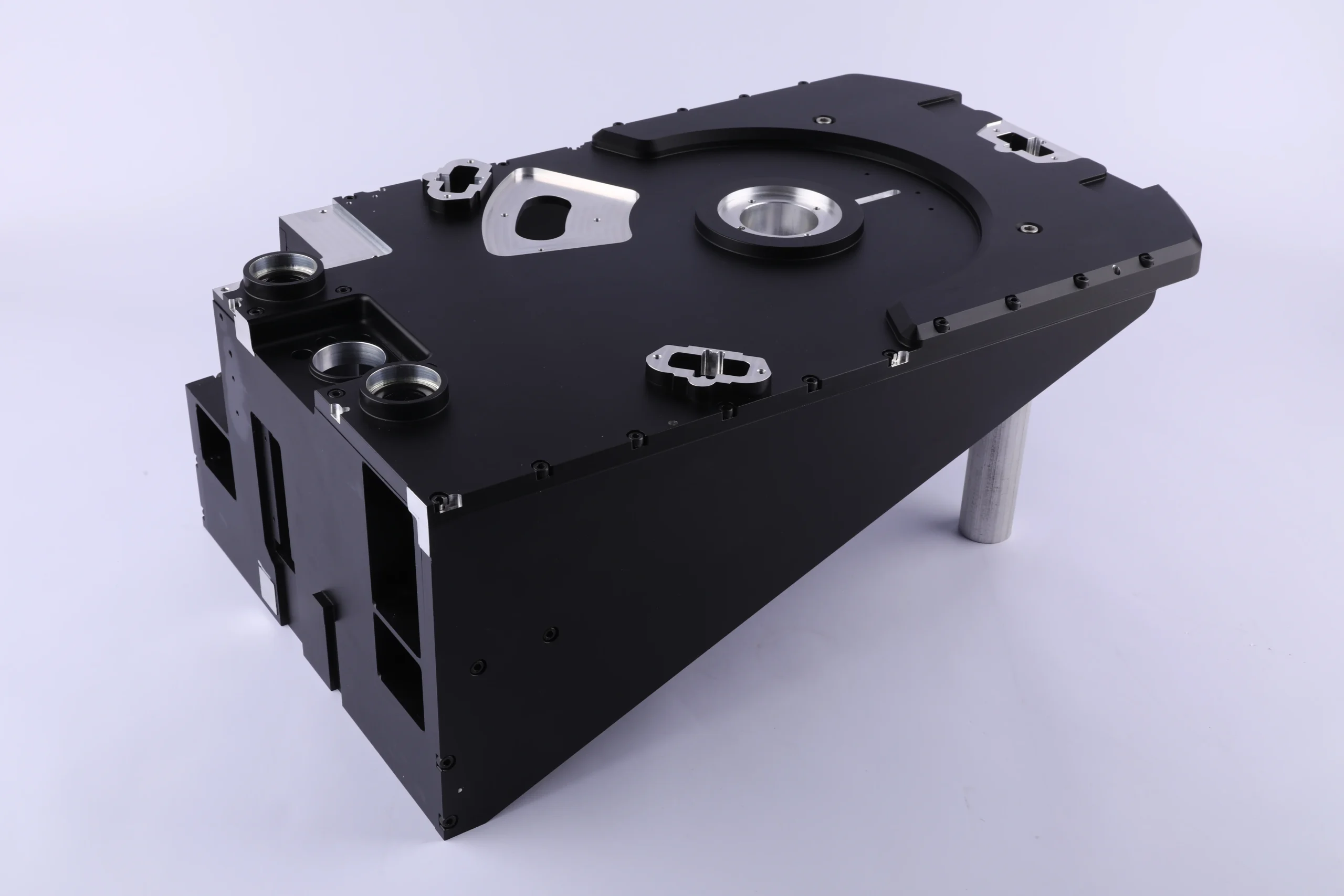

With years of experience in precision manufacturing, XTJ Precision Mfg leverages aluminum’s unique properties to deliver high-quality, reliable components for various industries including aerospace, automotive, and electronics.

“Our advanced CNC machining capabilities combined with aluminum’s exceptional properties ensure superior performance and durability for your most demanding applications.”

Common Aluminum Alloys We Machine

We work with a range of aluminum alloys tailored to your application’s needs. Below is a comparison of popular options, based on key properties for CNC machining. Contact us for custom alloy recommendations.

| Alloy Grade | Coût | Résistance à la traction (MPa) | Résistance à l'élasticité (MPa) | Densité (g/cm³) | Résistance à la corrosion | Applications courantes |

|---|---|---|---|---|---|---|

| 6061-T6 | $ | 290-310 | 240-275 | 2.70 | Excellent | Automotive frames, marine hardware, structural components |

| 7075-T6 | $$$ | 500-570 | 400-500 | 2.81 | Bon | Aerospace structures, high-stress aircraft parts |

| 5083-H116 | $$ | 300-350 | 125-250 | 2.66 | Superior (marine) | Shipbuilding, pressure vessels, marine equipment |

| 6082-T6 | $ | 260-310 | 200-260 | 2.70 | Bon | Bridges, transportation, structural frames |

6061: Versatile heat-treatable alloy with magnesium and silicon; offers balanced strength, weldability, and corrosion resistance.

7075: Zinc-based for ultra-high strength; ideal for aerospace but requires coatings for corrosion protection.

5083: Magnesium alloyed for marine excellence; non-heat-treatable with high weldability.

6082: Structural alloy with good formability; heat-treatable for medium-strength needs.

Other alloys like 2024 (fatigue-resistant for aerospace) and 7050 (tough for thick sections) are available upon request.

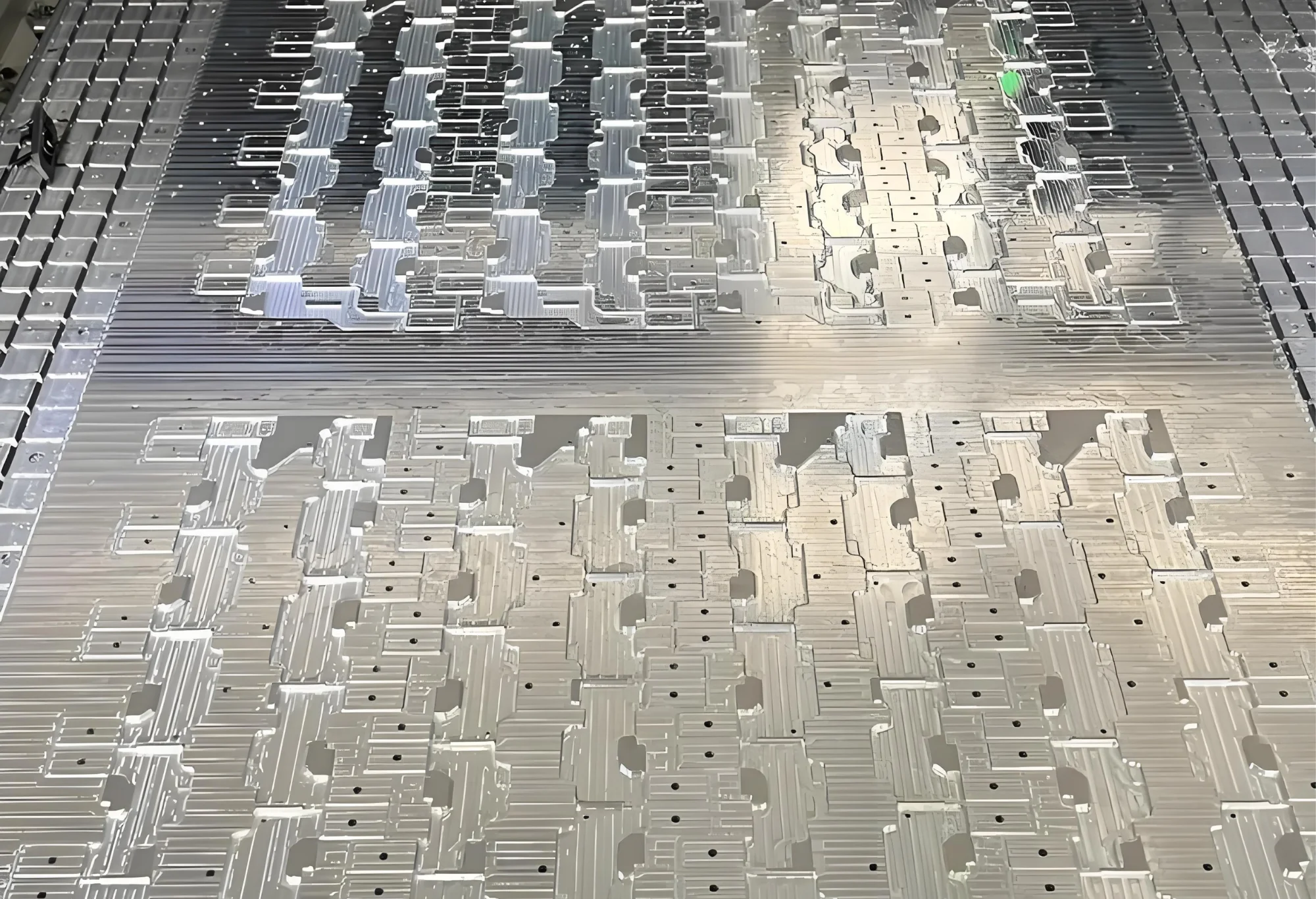

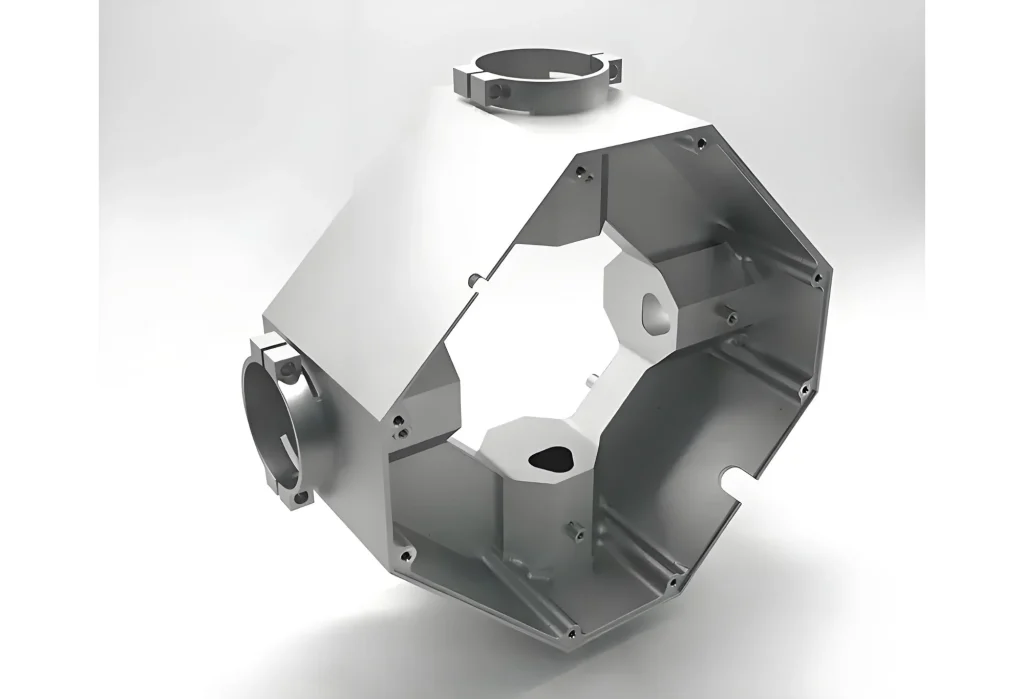

Our Aluminum CNC Machining Capabilities

XTJ Precision Mfg delivers precision manufacturing solutions with state-of-the-art CNC technology and expert craftsmanship.

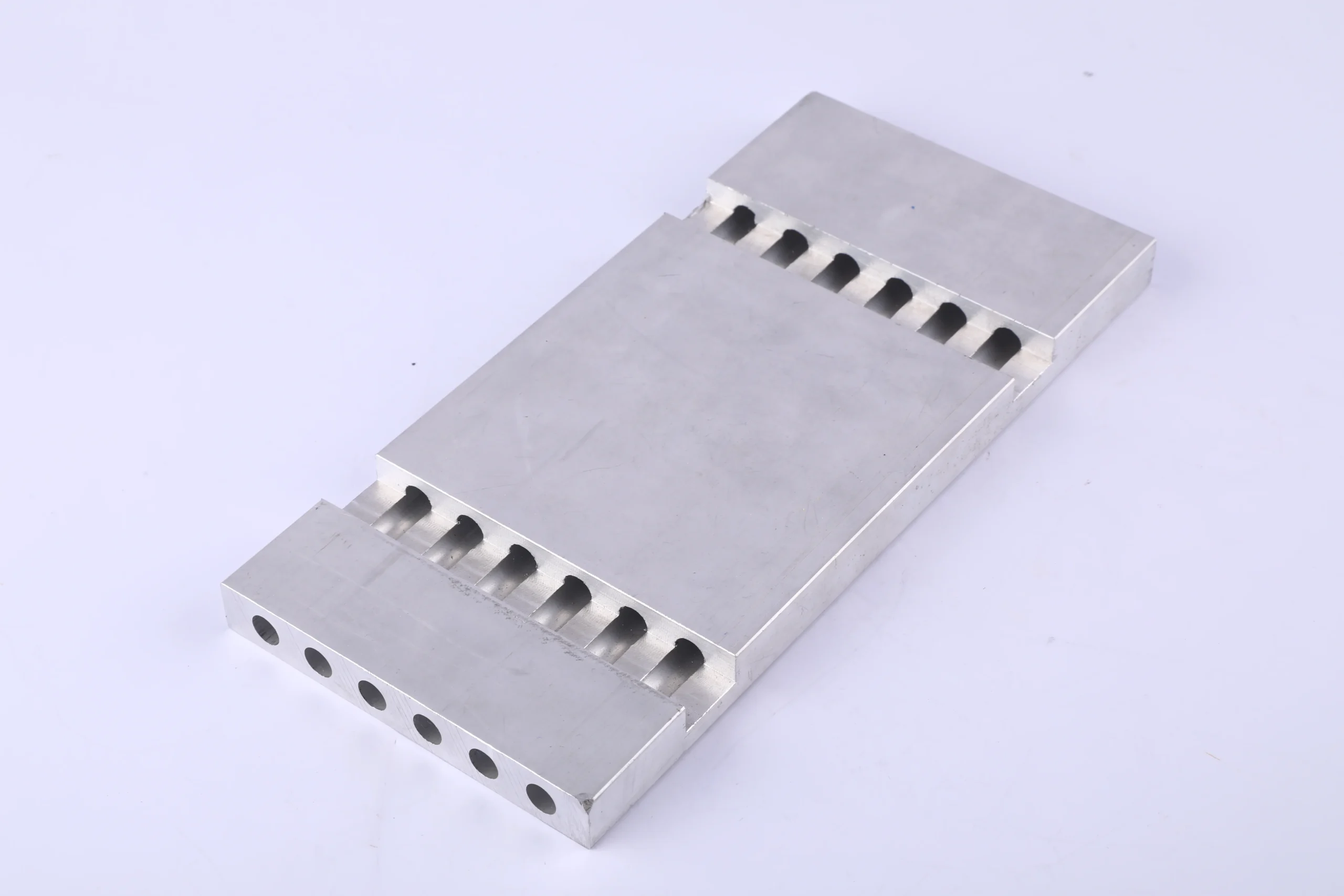

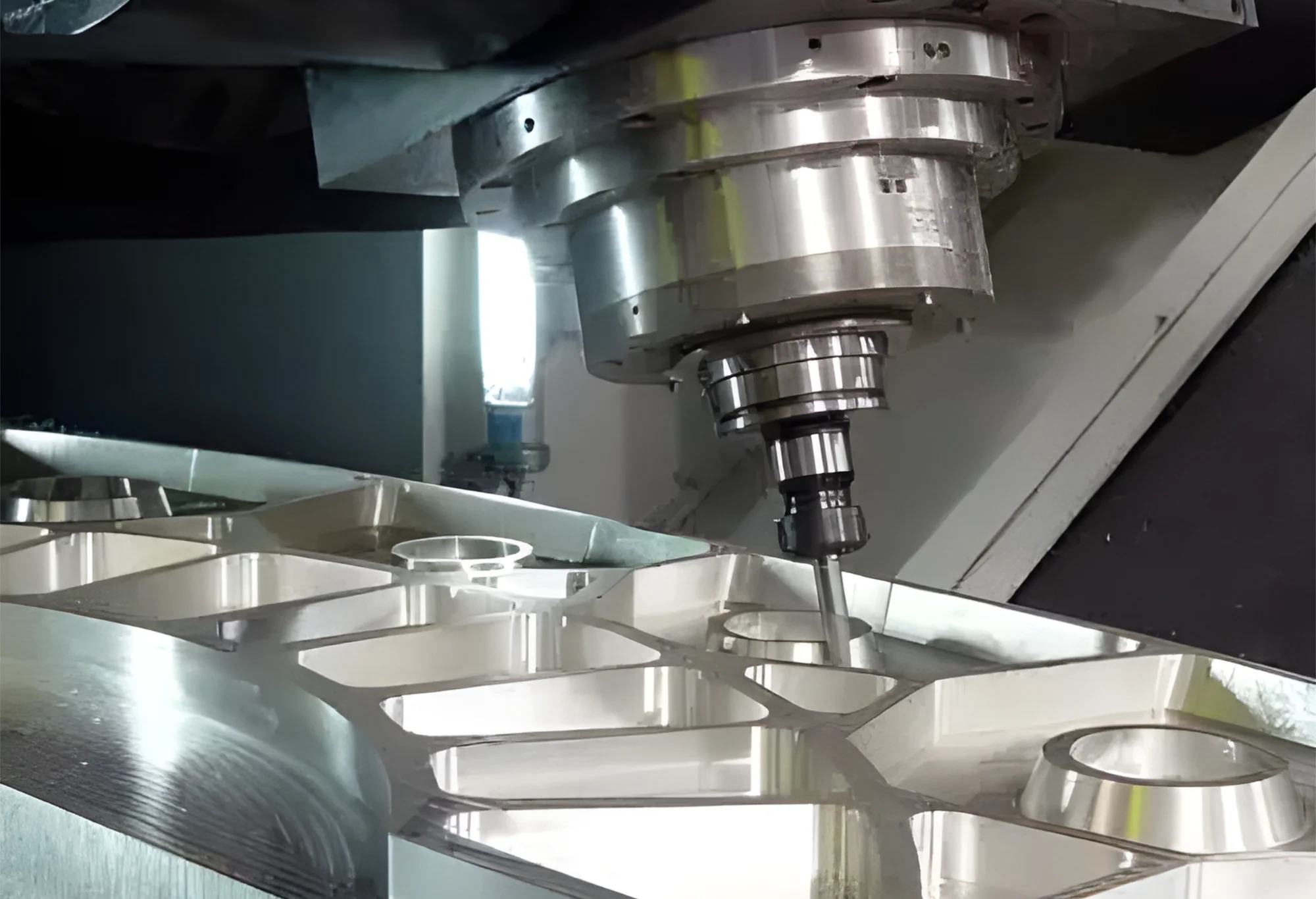

Fraisage CNC

Precision multi-axis milling services for complex geometries and tight tolerances in various materials.

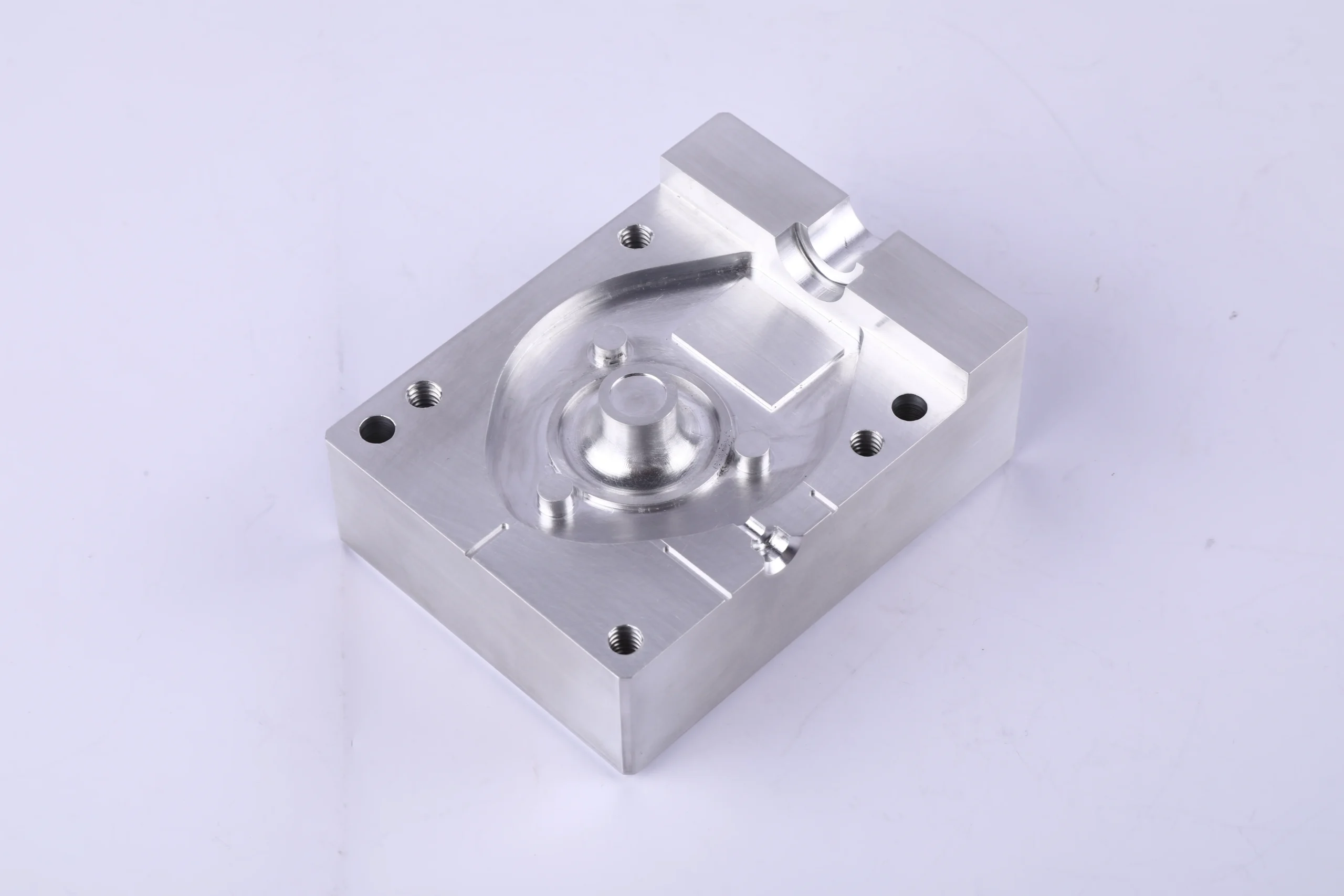

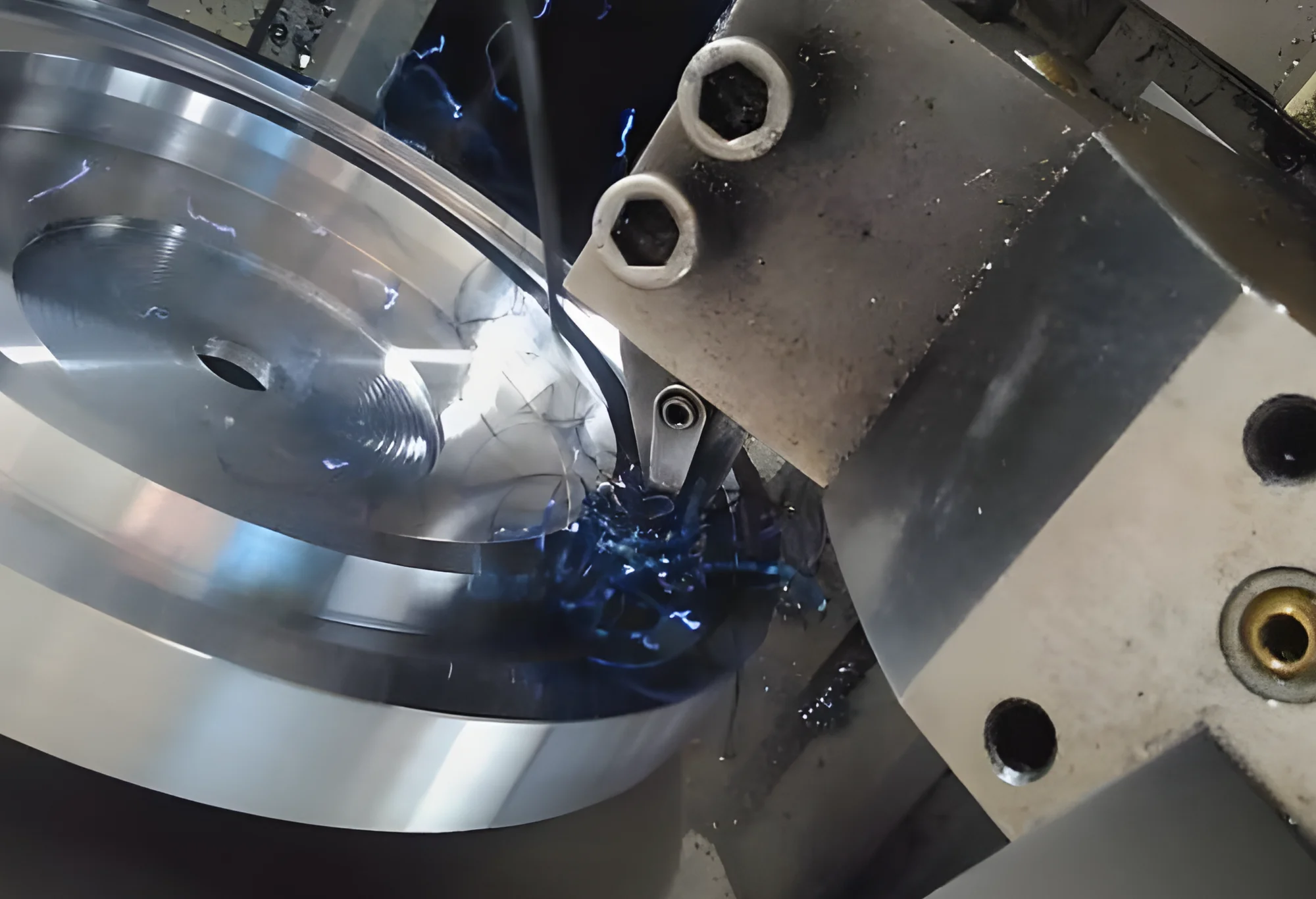

Tournage CNC

High-precision lathe operations for cylindrical parts with excellent surface finishes and dimensional accuracy.

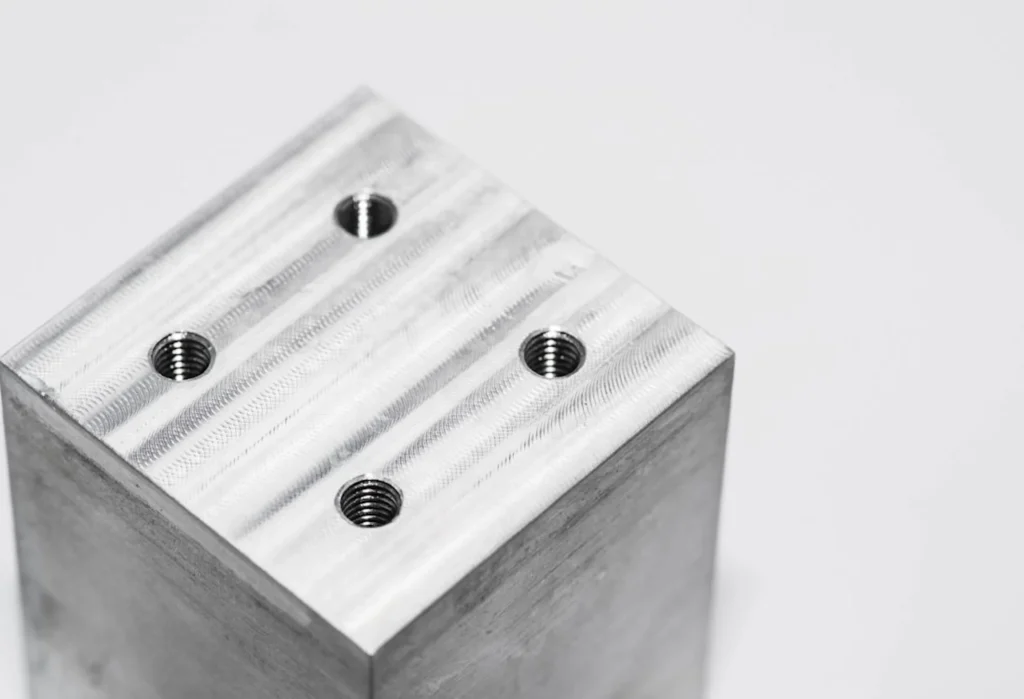

Secondary Operations

Complete post-processing services including drilling, tapping, threading, and surface treatment for finished parts.

Why Choose XTJ Precision Mfg?

With decades of experience and advanced CNC technology, we deliver precision components that meet the highest quality standards for industries worldwide.

- ISO 9001:2015 Certified

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Custom Finishes

XTJ Precision Mfg offers custom surface treatment solutions tailored to your specific requirements and industry standards.

Our experts will help you choose the perfect finish for your aluminum parts

As Machined

The natural finish straight from CNC machining with visible tool marks, ideal for functional parts where appearance isn’t critical.

cURL Too many subrequests.

A uniform matte surface achieved by bombarding with glass beads, eliminating tool marks and creating a smooth, non-reflective finish.

Anodisation

Electrochemical process that creates a durable, corrosion-resistant oxide layer, available in various colors and hardness levels.

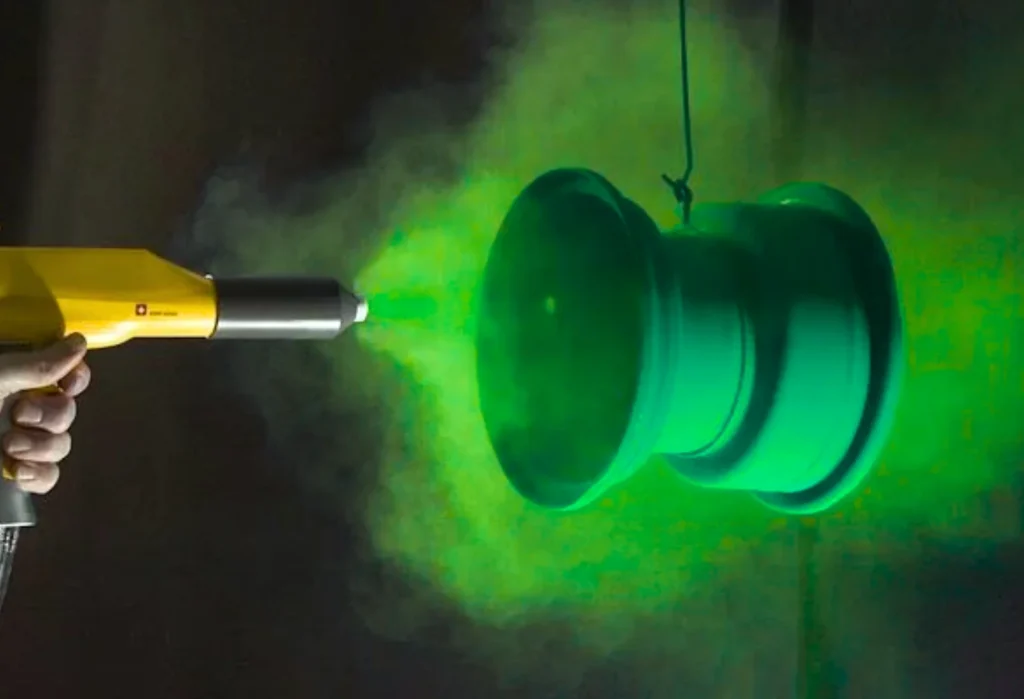

Thermolaquage

Dry finishing process that applies decorative and protective layers in various colors and textures with excellent durability.

Chromate Conversion

Chemical conversion coating that provides corrosion resistance and improves paint adhesion, commonly used in aerospace applications.

Ready for Precision Manufacturing?

Partner with XTJ Precision Mfg for components that meet your exact specifications with unwavering accuracy and reliability.

Questions fréquemment posées

None—we support prototypes to high-volume runs.

STEP, IGES, STL for 3D; PDF/DWG for 2D with dimensions.

We achieve standard tolerances of ±0.005″ (±0.127mm) per ISO 2768-m, with precision options down to ±0.001″ (±0.025mm) for critical features. Our equipment minimizes distortion in heat-treatable alloys like 6061-T6.

Popular options include as-machined for prototypes, anodizing (Type II/III) for corrosion resistance and aesthetics, and powder coating for wear protection. We recommend anodizing for aerospace and marine applications.

Aluminum offers better machinability, lighter weight, and lower cost, making it ideal for prototypes and lightweight designs. Steel provides higher strength for heavy-duty parts but is more expensive and harder to machine.