Current CNC Machining Cost Landscape in China

China’s CNC machining market offers some of the most competitive pricing worldwide, making it a top choice for many businesses. On average, hourly rates for CNC services in China range from $20 to $50, depending on the complexity and scale of the project. Small prototype runs or simple parts generally lean toward the lower end, while large-scale or highly detailed production can increase costs accordingly.

Regional variations play a significant role in pricing. For example, CNC shops in manufacturing hubs like Shenzhen and Guangzhou tend to offer prices slightly higher than inland provinces, reflecting higher labor and overhead costs. However, these cities also provide faster lead times and stronger infrastructure, balancing out the investment.

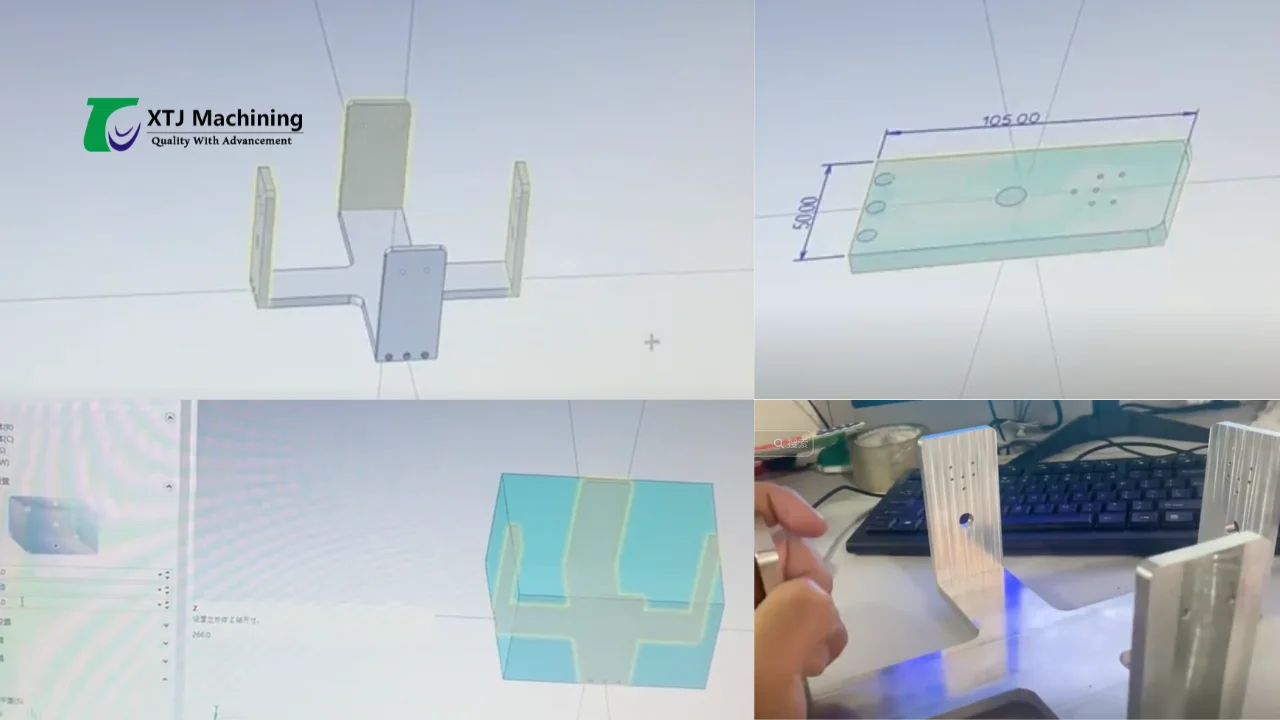

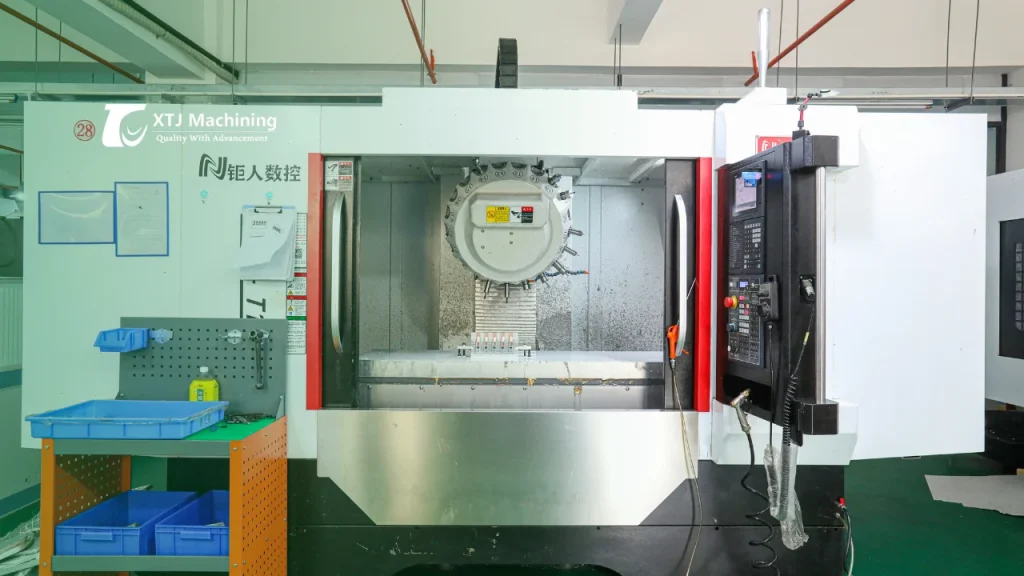

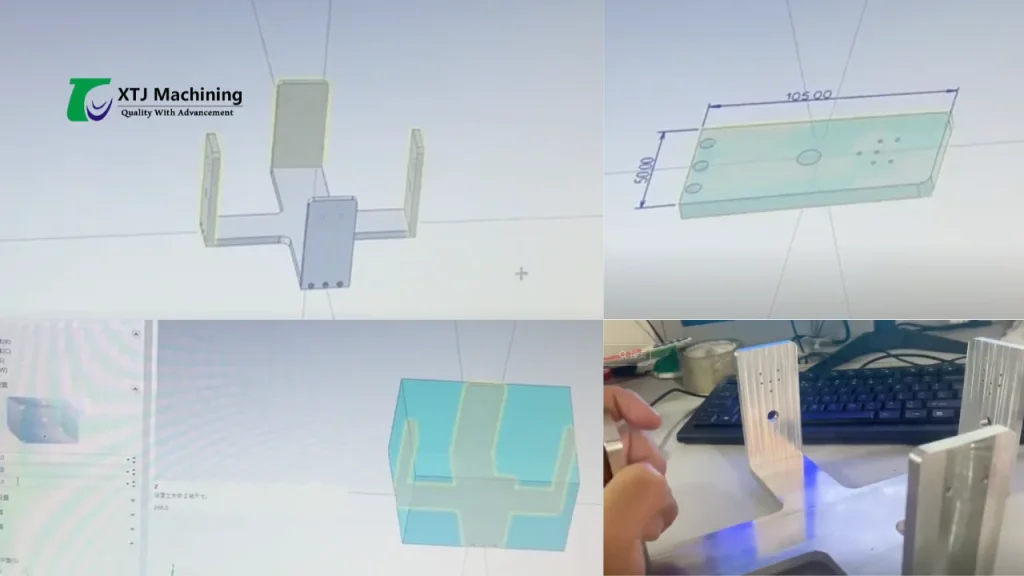

XTJ Precision Mfg stands out by combining cost efficiency with quality. Leveraging advanced automation and optimized workflows, XTJ minimizes waste and reduces setup times. This approach allows us to maintain competitive prices, especially for bulk CNC production, while delivering precise, reliable parts. Our transparent pricing models and local expertise further enhance the value clients receive when choosing XTJ for their projects.

For more on China’s machining development and cost trends, explore the growth history of CNC machining in China.

CNC Machining Pricing Factors in China

Several factors influence the cost of CNC machining in China. First up, material selection plays a big role—some metals or plastics are more expensive, directly affecting your part’s price. Next, design complexity and tolerance matter a lot. The tighter the tolerances or the more detailed the design, the higher the cost since it requires more precision and time.

Production volume is another key driver. Larger orders usually lower the cost per piece because setup fees and machine time get spread out. Speaking of setup, small batches may have higher setup fees, so that impacts pricing too.

Don’t forget labor, overhead, and post-processing costs. While Chinese labor is generally more affordable than in the US, some finishing steps like polishing or heat treating add to the total. Finally, external factors such as currency fluctuations and tariffs can affect the final price. Changes in exchange rates or new trade policies may push costs up or down unexpectedly.

Understanding these key factors helps you get more accurate CNC machining cost estimates and make the best decisions for your project.

China vs Global CNC Pricing

When comparing CNC machining costs in China to global options, there are a few key points to consider—hourly rates, material access, lead times, and quality risks.

Hourly Rate and Material Access

| Location | Average Hourly Rate | Material Options | Notes |

|---|---|---|---|

| China | $25 – $45 | Wide variety, often cheaper | Many factories source local and imported materials |

| USA | $75 – $120 | High-quality materials | Easier access to specialty alloys but pricier |

| Europe | $70 – $110 | Large range | Strict quality and environment standards |

China’s lower hourly rates make it attractive, especially for larger runs or cost-sensitive projects. Material variety in China is broad, but specialty or aerospace-grade materials may cost more or require extra sourcing time.

Lead Times and Quality Risks

Lead Times: China CNC jobs usually have longer shipping times but competitive production speeds. Many Chinese suppliers manage bulk orders well but have slower turnaround on complex parts. Quality Risks: Some may worry about consistency and quality. However, factories like XTJ Precision Mfg, with ISO certification, reduce risk by following strict quality controls.

Pros and Cons of Choosing China for CNC Machining

| Avantages | Inconvénients |

|---|---|

| Lower hourly rates | Longer shipping times |

| Competitive prices on materials | Possible communication challenges |

| Strong capacity for large orders | Risk of variable quality without certified vendors |

| XTJ’s ISO certification assures quality compliance | Potential tariffs or customs delays |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. Real Case Study: How XTJ Cut a U.S. Client’s CNC Quote from ¥3,800 → ¥380 (90% Savings in 30 Minutes)

1. The Original Request

Part Specs (Initial Drawing):

| Item | Value |

|---|---|

| Matériau | 6061-T6 Aluminum |

| Taille | 120 × 80 × 45 mm |

| Caractéristiques | 8 deep pockets (12 mm depth), 16 M3 threaded holes, sharp internal corners |

| Tolérance | ±0.01 mm on all surfaces |

| Finition de surface | Ra 1.6 (mirror-level on non-functional faces) |

| Quantité | 1 pc (prototype) |

| Supplier Quote | ¥3,800 (China local CNC shop) |

2. XTJ’s 5-Minute DFM Audit (What Was Wrong)

| Issue | Cost Driver | XTJ Fix |

|---|---|---|

| Sharp 90° corners | Requires Ø0.5 mm ball-end mill + extra finishing pass | ➜ Change to R0.5 fillet |

| ±0.01 mm everywhere | Forces 5-axis or multiple setups + CMM inspection | ➜ Keep only ±0,05 mm on mating faces |

| Deep pockets (12 mm) | High L/D ratio → tool vibration → slow feed | ➜ Reduce depth to 8 mm (function unchanged) |

| Mirror finish on top face | Extra polishing step (2–3 hrs) | ➜ Keep Ra 3.2 (as-milled) |

| 16 blind M3 holes | Separate tapping after milling | ➜ Use cURL Too many subrequests. cURL Too many subrequests. |

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | Veuillez fournir le texte à traduire. | Cost Impact |

|---|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | R0.5 fillet | cURL Too many subrequests. |

| Tolérance | cURL Too many subrequests. | ±0,05 mm cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | 8 mm | cURL Too many subrequests. |

| Finition de surface | cURL Too many subrequests. | Ra 3.2 | cURL Too many subrequests. |

| Filetage | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

Total Savings: ¥3,800 → ¥380 Time to Revise CAD: 18 mins New Quote (Same Shop, 2 Hours Later): ¥380

4. Before vs After Quote Breakdown

| Item | Original (¥) | Optimized (¥) |

|---|---|---|

| Matériau | 80 | 80 |

| Finition grossière | 600 | 400 |

| Finition | 1,200 | 100 |

| Filetage | 800 | 80 |

| Inspection | 600 | 120 |

| Polissage | 520 | 0 |

| Total | 3,800 | 380 |

5. Key Takeaways (XTJ’s DFM Golden Rules)

- Never over-spec tolerance — 90% of features need only ±0.1 mm.

- Add radii — avoids tiny tools & finishing passes.

- Combine operations — flow-drill > drill + tap.

- Question non-functional finish — Ra 3.2 is free from the mill.

- Talk to your machinist — they quote based on pain, not geometry.

6. Want XTJ to Do This for Your Part?

Send us:

- Photo/PDF of your drawing

- Material + quantity

- Current quote

We’ll return:

- Annotated redline CAD

- Cost breakdown

- 70–90% savings estimate

Contact XTJ Precision Mfg — we’ll optimize it live just like this real case!

Get Your Tailored Quote If you’re looking for affordable CNC prototyping or bulk production savings, XTJ’s precision manufacturing can deliver. Reach out for a custom quote based on your project needs, and see how our experience can trim your CNC machining cost in China without compromise.

Future Trends to Watch in China’s CNC Pricing

China’s CNC machining costs are set to evolve quickly, thanks to new tech and bigger industry shifts. Automation and AI are already making waves, cutting down labor costs and speeding up production. This means prices could stay competitive or even drop as factories get smarter.

At the same time, sustainability is becoming a big focus. More regulations and green incentives are pushing manufacturers to use eco-friendly materials and energy-saving processes. This might cause slight price increases but also offers long-term savings and a smaller environmental footprint.