Services de Fraisage CNC de Haute Qualité

Basé en France,

nous proposons des prix compétitifs et des délais de livraison rapides pour donner vie à vos projets.

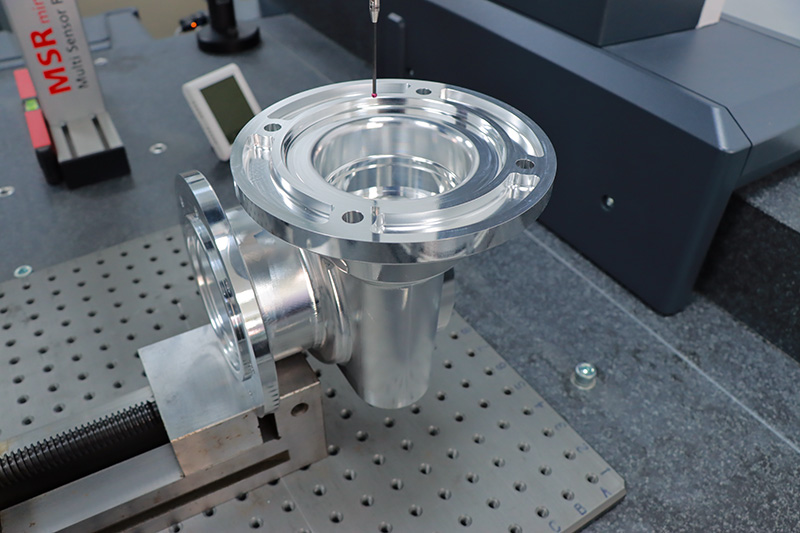

- Tolérances strictes de ±0,005 mm avec inspection CMM Zeiss

- Finitions personnalisées pour répondre à vos spécifications

- Délais de livraison à partir de 5 jours pour une livraison rapide

- Gestion sécurisée des données pour votre tranquillité d'esprit

Services de Fraisage CNC Experts pour tous les secteurs

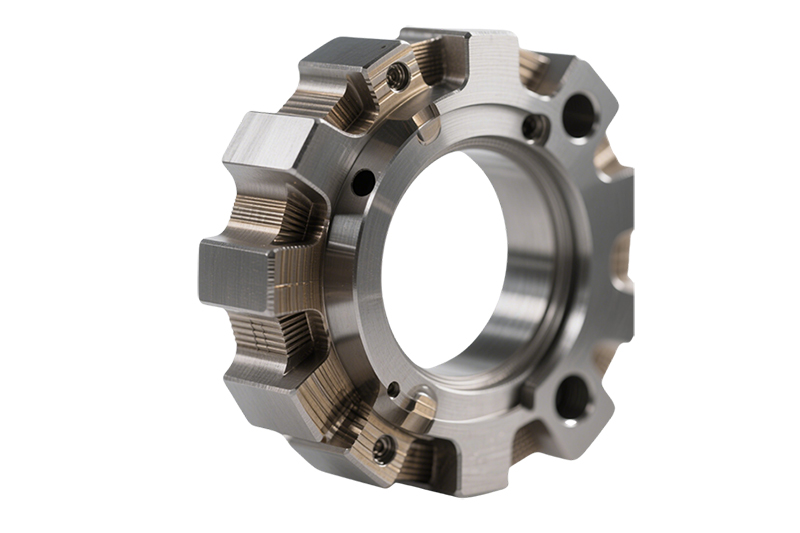

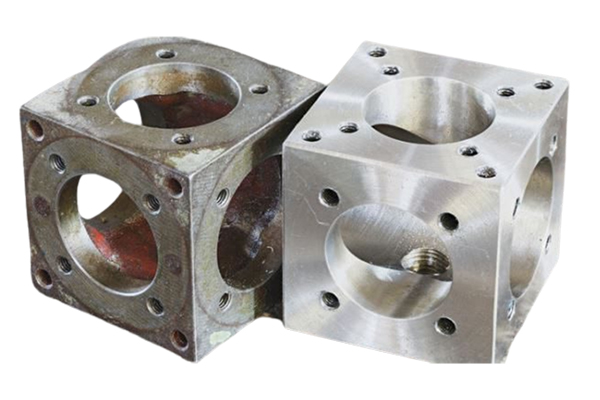

Chez XTJ Machining, nous sommes spécialisés dans la livraison de pièces usinées avec précision et qualité exceptionnelle. Nos plus de 100 machines CNC de pointe nous permettent de gérer des projets de toute envergure, des prototypes à la production en grande série, garantissant une précision CNC pour tous vos besoins.

Pourquoi choisir XTJ pour le Fraisage CNC ?

Tarification abordable

Services de fraisage CNC à faible coût, leader dans l'industrie, vous permettant d'économiser davantage sans compromettre la qualité.

Capacité de volume élevé

Plus de 100 machines CNC de pointe assurent une production rapide et une évolutivité.

Délai de réalisation rapide

Des flux de travail efficaces livrent la plupart des projets en 5 à 10 jours ouvrables.

Précision inégalée

Tolérances aussi strictes que ±0,005 mm, vérifiées par équipement d'inspection CMM Zeiss.

Expertise des matériaux

Nous usinons l'aluminium, l'acier, le titane, le laiton, les plastiques et plus encore pour répondre à vos besoins.

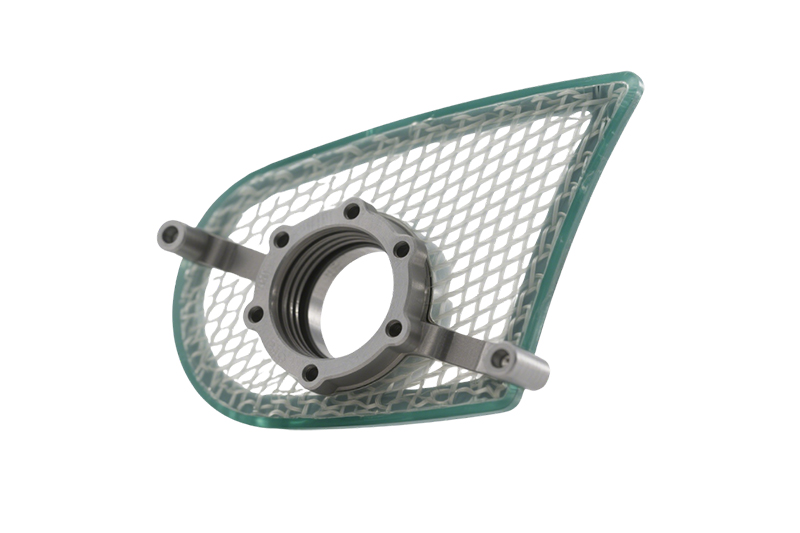

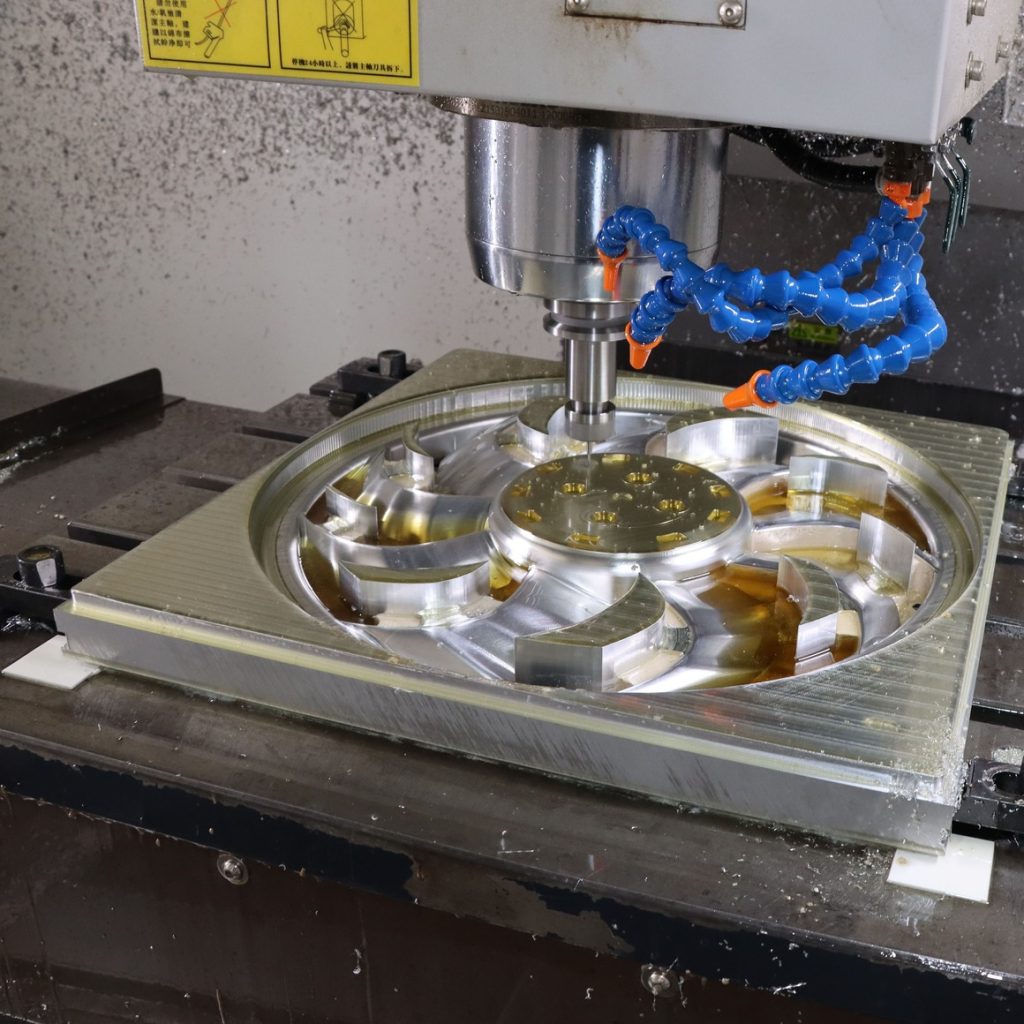

Qu'est-ce que le fraisage CNC ?

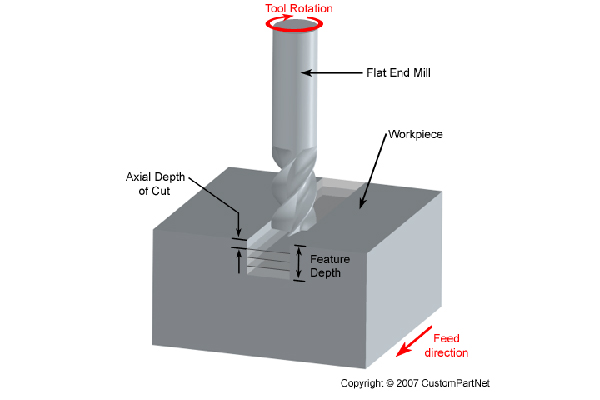

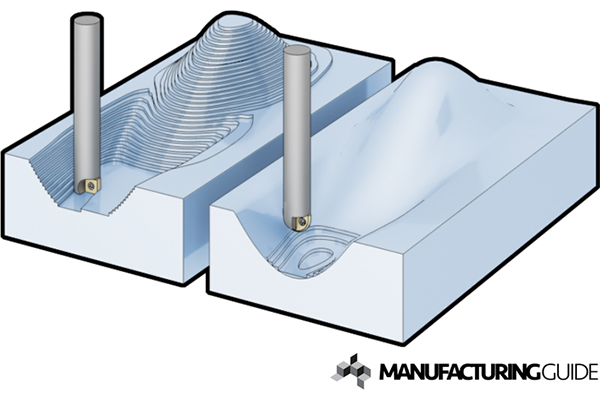

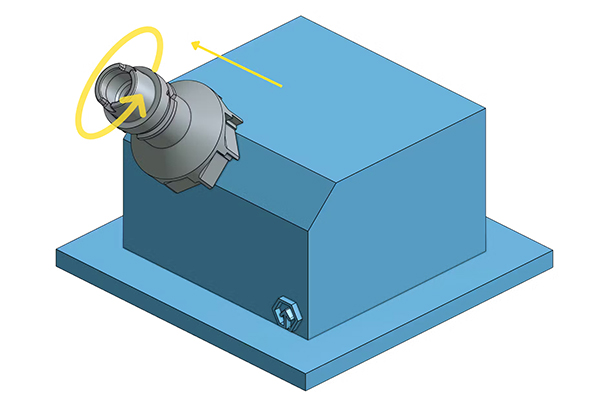

L'usinage par fraiseuse CNC est un procédé de fabrication soustractive qui utilise des machines contrôlées par ordinateur pour enlever de la matière d'une pièce. Des outils de coupe rotatifs créent des caractéristiques précises telles que des rainures, des trous, des filetages et des contours complexes. Chez XTJ, nous proposons des fraiseuses CNC 3 axes, 4 axes et 5 axes pour produire des pièces allant de surfaces planes simples à des géométries 3D complexes, garantissant une grande polyvalence pour vos conceptions.

Types d'opérations de fraisage CNC chez XTJ

Nous offrons une gamme de techniques de fraisage CNC pour répondre aux différents besoins de projet :

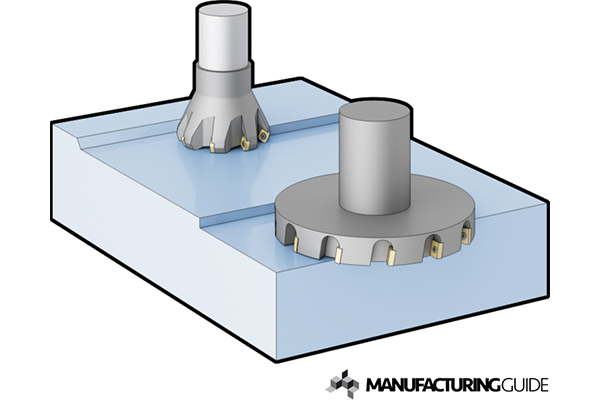

Fraisage de face

Crée des surfaces planes et des finitions lisses, idéales pour de grandes zones uniformes.

Fraisage en bout

Produisent des rainures, des poches et des contours en utilisant le côté et la face de l'outil.

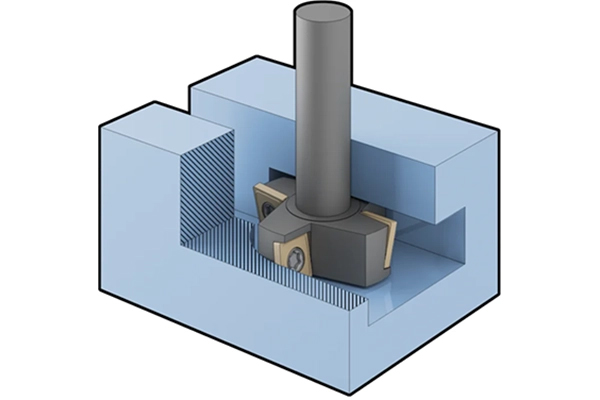

Fraisage de rainure

Fait des canaux ou des rainures étroits dans la pièce pour des raisons fonctionnelles ou esthétiques.

Fraisage de profil

Façonne les contours extérieurs d'une pièce, souvent utilisé pour des géométries complexes.

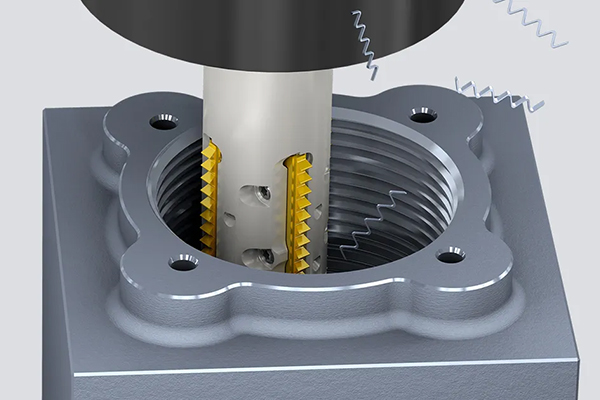

Fraisage de filet

Usine des filetages internes et externes avec précision pour les fixations et raccords.

Fraisage angulaire

Crée des caractéristiques angulaires comme des chanfreins ou des queues d'aronde pour des composants spécialisés.

Matériaux et finitions de surface supportés par l'usinage XTJ

Varie selon le type de matériau, généralement à haute dureté. La sélection des outils et les paramètres de coupe doivent être basés sur la composition spécifique, en prêtant attention à la résistance à l'usure et à la stabilité thermique.

Aluminium (par ex., 6061, 7075)

Caractéristiques : Léger, bonne conductivité thermique, facile à usiner, les copeaux se cassent facilement. Peut provoquer un collage de l'outil ; nécessite un refroidissement et une lubrification appropriés. Convient pour le fraisage à haute vitesse.

Acier (par ex., inoxydable, carbone)

Caractéristiques : Haute dureté, résistante à l'usure, mais génère des forces de coupe et de la chaleur élevées lors de l'usinage. Nécessite un fraisage à basse vitesse avec des outils durs (par exemple, carbure). L'acier inoxydable peut présenter un durcissement en travail.

Titane

Caractéristiques : Haute résistance, faible conductivité thermique, la chaleur se concentre lors de l'usinage, provoquant l'usure de l'outil. Nécessite une coupe à basse vitesse, des outils haute performance et un refroidissement adéquat.

Laiton

Caractéristiques : Doux et facile à usiner, bonne machinabilité, les copeaux se cassent facilement, finition de surface élevée. Convient pour le fraisage à haute vitesse, génère moins de chaleur.

Cuivre

Caractéristiques : Haute conductivité thermique, ductile, sujet à l'adhérence de l'outil lors de l'usinage. Nécessite des outils tranchants et une lubrification appropriée. Les copeaux peuvent être longs, donc l'élimination des copeaux est importante.

ABS

Caractéristiques : Bonne ténacité, facile à usiner, mais susceptible de ramollissement par la chaleur. Nécessite une vitesse de coupe contrôlée et un refroidissement pour éviter la fusion ou les bavures.

POM (Polyoxyméthylène)

Caractéristiques : Hardness modérée, résistant à l'usure, auto-lubrifiant, stable lors de l'usinage, bonne finition de surface. Faire attention à la déformation thermique.

PEEK

Caractéristiques : Résistance à haute température, résistance chimique, dureté élevée. Nécessite des outils durs, génère des forces de coupe importantes et nécessite un contrôle de la température pour éviter la déformation.

Polycarbonate

Caractéristiques : Transparent, haute ténacité, mais sujet à la fissuration sous contrainte. Nécessite une coupe à faible vitesse pour éviter la surchauffe, et des outils tranchants sont indispensables.

Nylon

Caractéristiques : Haute ténacité, résistant à l'usure, mais hygroscopique et susceptible de déformation lors de l'usinage. Nécessite une vitesse de coupe contrôlée, adapté au fraisage à basse vitesse.

Fibre de carbone

Caractéristiques : haute résistance, léger, mais très dur. Sujet à la délamination ou aux bavures lors de l'usinage. Nécessite des outils en diamant ou en carbure, et une protection contre la poussière est nécessaire.

Fibre de verre

Caractéristiques : haute dureté, résistant à la corrosion, mais abrasif pour les outils et génère de la poussière lors de l'usinage. Nécessite une extraction efficace de la poussière et des outils durs.

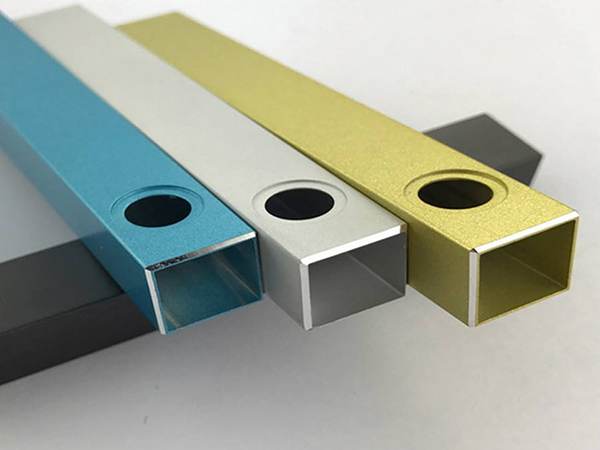

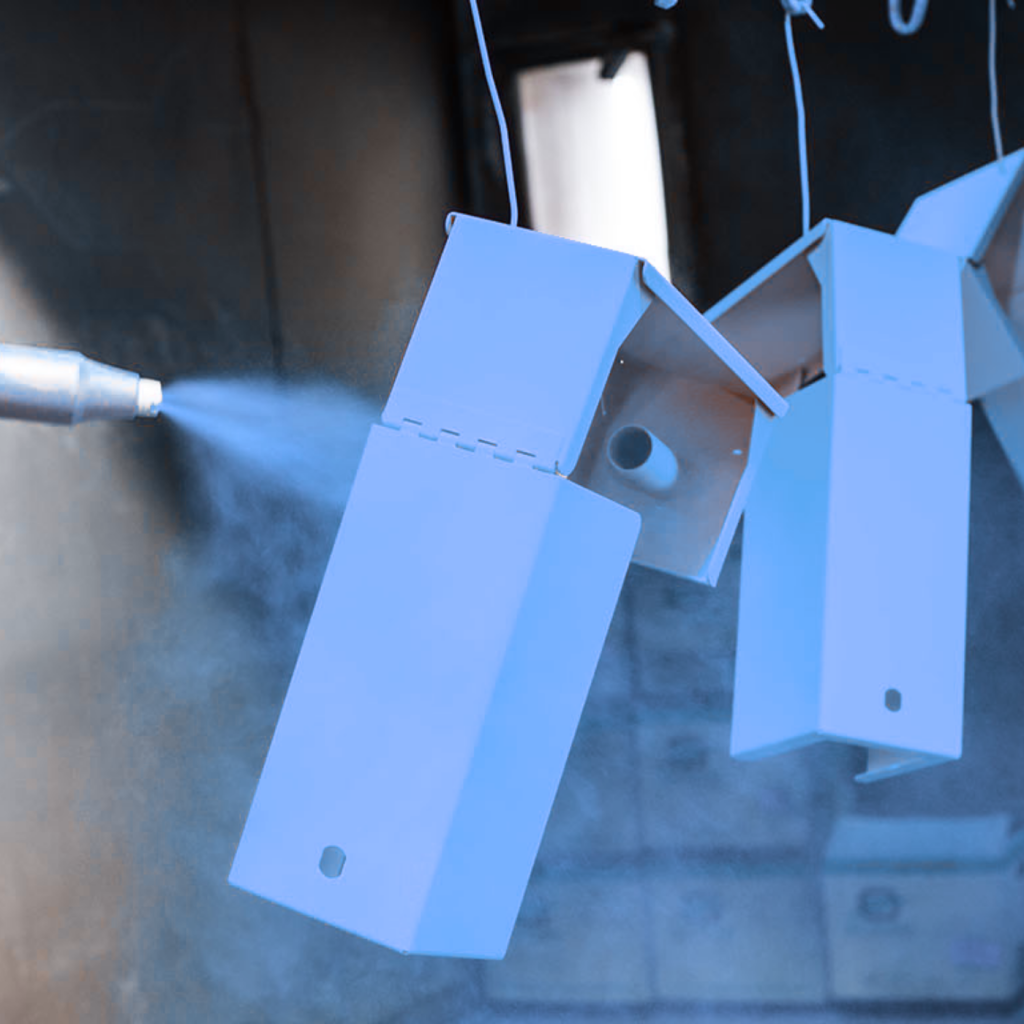

Sublimez vos pièces avec des finitions de surface avancées

Améliorez la durabilité, la fonctionnalité et l'esthétique de vos composants avec la gamme d'options de finition de surface d'XTJ. Chaque processus est adapté pour répondre à des exigences spécifiques de performance et de conception, garantissant que vos pièces non seulement fonctionnent de manière exceptionnelle mais aussi ont fière allure.

Revêtement durable et polyvalent pour une protection longue durée

Le revêtement en poudre applique une poudre sèche—généralement un mélange de résine et de pigment—électrostatiquement sur la pièce, qui est ensuite durcie sous chaleur pour former une couche protectrice résistante. Cette finition est reconnue pour sa durabilité et sa résistance à l’écaillage, aux rayures et à la corrosion.

Revêtement durable et polyvalent pour une protection longue durée

Le revêtement en poudre applique une poudre sèche—généralement un mélange de résine et de pigment—électrostatiquement sur la pièce, qui est ensuite durcie sous chaleur pour former une couche protectrice résistante. Cette finition est reconnue pour sa durabilité et sa résistance à l’écaillage, aux rayures et à la corrosion.

Finition mate uniforme pour une esthétique améliorée

Le sablage à l’aide de petites billes de verre propulsées à haute pression crée une finition mate cohérente et non réfléchissante sur la surface des pièces. Ce processus élimine les imperfections de surface et offre une texture propre et uniforme.

Finition miroir pour applications haut de gamme

Le polissage consiste à lisser mécaniquement la surface d’une pièce pour obtenir une finition brillante, semblable à un miroir. Ce processus améliore à la fois l’attrait visuel et la qualité tactile du composant.

Résistance accrue à la corrosion pour l’acier inoxydable

La passivation est un traitement chimique qui élimine le fer libre de la surface des pièces en acier inoxydable, formant une couche d’oxyde passive qui améliore considérablement la résistance à la corrosion.

Capacités de fraisage CNC d’XTJ

Options multi-axes : Fraisage 3 axes, 4 axes et 5 axes pour des géométries simples à complexes.

Tolérances : Précision jusqu’à ±0,005 mm pour des applications de haute précision.

Taille des pièces : De petits composants à des pièces jusqu’à 1000 mm x 800 mm x 600 mm.

Flexibilité de production : De prototypes uniques à des milliers de pièces, nous gérons tout.

Équipements avancés : Broches à haute vitesse, outillage moderne et plus de 100 machines pour une efficacité supérieure.

Notre processus d'usinage CNC

Collaborez avec nous facilement : soumettez votre conception, recevez un retour d'expert, approuvez votre devis et lancez la production. Restez informé à chaque étape pour des résultats fiables et de haute qualité.

L'engagement de XTJ envers la qualité

Chez XTJ Machining, la qualité est notre priorité. Nous utilisons des outils d'inspection de classe mondiale comme le CMM Zeiss pour garantir que chaque pièce respecte les normes les plus élevées. Notre contrôle strict des tolérances et nos processus d'assurance qualité rigoureux font de nous un choix fiable pour les services d'usinage CNC dans le monde entier.

Foire aux questions (FAQ)

Nous usinons une large gamme de matériaux, y compris l'aluminium, l'acier, le titane, le laiton et les plastiques. Contactez-nous pour discuter du meilleur matériau pour votre projet.

Nous atteignons des tolérances aussi strictes que ±0,005 mm, garantissant la précision même pour les applications les plus exigeantes.

Avec plus de 100 machines, nous proposons des délais de livraison rapides — la plupart des projets sont terminés en 5 à 10 jours ouvrables, selon la complexité.

Oui, nous proposons des finitions telles que l'anodisation, la peinture en poudre et le sablage pour améliorer la durabilité et l'apparence de vos pièces.

Absolument ! Notre capacité de production à grande échelle garantit que nous pouvons gérer efficacement des commandes volumineuses tout en maintenant la qualité.

Vous avez d'autres questions ? Contactez XTJ pour des conseils d'experts

Vous recherchez des services d'usinage CNC fiables et abordables ? Partenairez avec XTJ Machining pour la précision, l'efficacité et une valeur imbattable. Contactez-nous dès maintenant pour discuter de votre projet et obtenir un devis gratuit.