Precision CNC Turning Services

Trusted CNC Turning Solutions,Based in China, we offer competitive pricing and fast lead times to meet your manufacturing demands.

- Data Security to Safeguard Your Designs

- Over 100 CNC Machines for High Efficiency

- Lead Times from 5 Days for Quick Turnaround

Expert CNc Turning Services for Your Projects

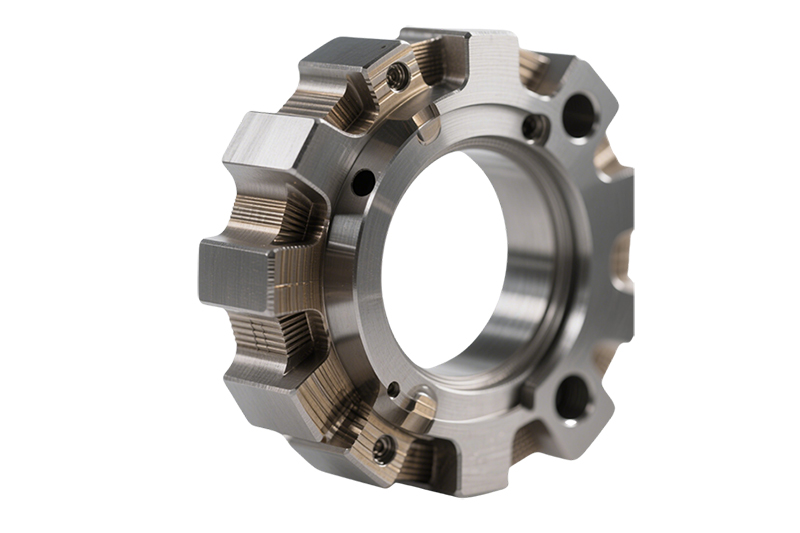

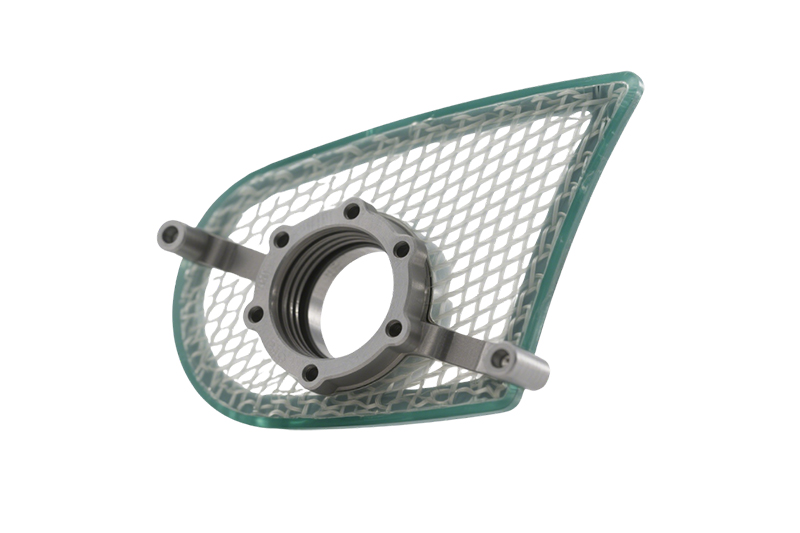

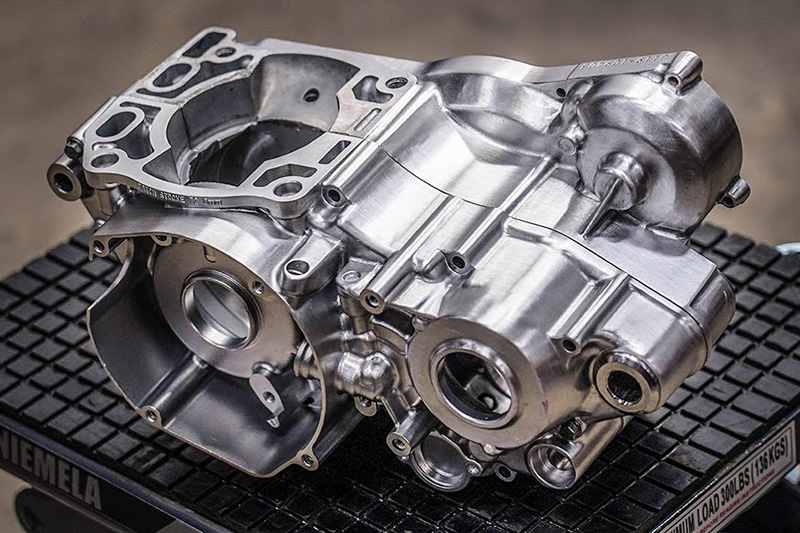

At XTJ Machining, we excel in precision CNc turning to produce high-guality cylindricalcomponents. With over 100 advanced CNC turning machines, we deliver cost-effectivesolutions, fast turnarounds, and exceptional accuracy for prototypes and large-scaleproduction.

we handle projects from simple components to complex designs. Serving industries like aerospace, automotive, and medical, XTJ delivers fast, reliable, and top-quality parts, making precision manufacturing accessible and efficient for your needs.

Why Choose XTJ for CNC Turning?

Competitive Pricing

Our CNC turning services offer exceptional value through cost-effective solutions without compromising quality. By leveraging advanced technology, optimized processes, and strategic sourcing, we deliver precision-engineered components at prices that lead the industry. Whether you’re a small business or a large-scale manufacturer, our commitment to affordability ensures you receive top-tier service tailored to your budget, making us the preferred choice for high-quality, low-cost CNC turning solutions.

High Production Capacity

At XTJ, our cutting-edge facility boasts over 100 advanced CNC machines and more than 40 precision lathes, ensuring unmatched scalability and rapid delivery for projects of any size. This extensive equipment lineup empowers us to efficiently manage high-volume production, intricate designs, and tight deadlines with consistent quality. Whether you need small-batch prototypes or large-scale manufacturing, XTJ’s robust capacity and streamlined operations deliver reliable, high-performance CNC turning solutions tailored to your needs, making us your trusted partner for superior results.

Superior Precision

we deliver exceptional accuracy with tolerances as tight as ±0.005 mm, ensuring components meet the most stringent specifications. Our precision is validated through rigorous inspections using state-of-the-art Zeiss Coordinate Measuring Machines (CMM), guaranteeing unparalleled quality and consistency. Whether for aerospace, medical, or high-tech industries, our advanced CNC turning capabilities and meticulous quality control processes provide reliable, high-precision solutions that exceed expectations, making XTJ the preferred choice for mission-critical applications.

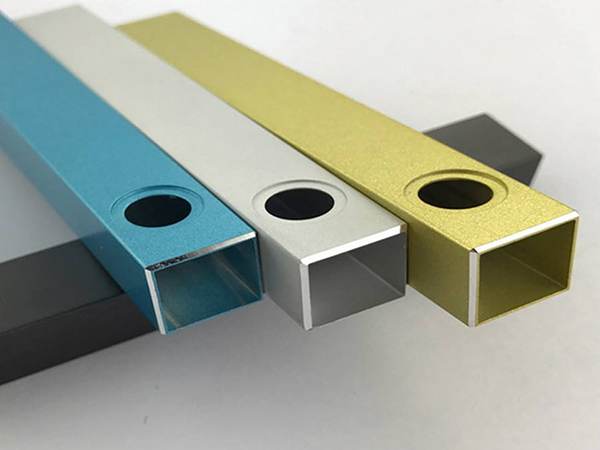

Polyvalence des matériaux

our expertise spans a wide range of materials, including aluminum, stainless steel, brass, titanium, and various plastics, ensuring tailored solutions for diverse applications. Our skilled team and advanced CNC turning capabilities allow us to handle each material’s unique properties with precision and efficiency, delivering high-quality components for industries like aerospace, automotive, medical, and more. Whether you require lightweight alloys, corrosion-resistant metals, or durable plastics, XTJ’s versatile material proficiency guarantees optimal performance and reliability for your project needs.

CNC Turning Design Reference

This guide, developed by our turning experts, provides ideal specifications for crafting precise turned components. It includes recommended measurements and feasible limits to guide your production process.

| Composant | Ideal Measurement | Acceptable Limit |

|---|---|---|

| Smallest Feature | Ø 2.0 mm | Ø 0.4 mm |

| Internal Radii | R 7 mm | R 0.3 mm |

| Thinnest Section | 0.7 mm (metals) / 1.4 mm (plastics) | 0.4 mm (metals) / 0.9 mm (plastics) |

| Diameter: Ø 0.6 mm / Depth: 12x diameter | Diameter: standard tools / Depth: 5x diameter | Diameter: Ø 0.6 mm / Depth: 12x diameter |

| Thread Standards | Size: M5 or larger / Length: 4x diameter | Size: M2 / Length: 2x diameter |

CNC Turning Tolerance Guide

Developed by our precision engineering team, this reference outlines standard tolerances for CNC turning projects, adhering to ISO 9001 standards. Our advanced lathes ensure accuracy from medical devices to industrial components, with tolerances as tight as ±0.005 inches.

| Composant | Tolerance Range |

|---|---|

| Length Measurement | ± 0.03 mm / ± 0.0012 inch |

| cURL Too many subrequests. | ± 0.03 mm / ± 0.0012 inch |

| cURL Too many subrequests. | ± 0.03 mm / ± 0.0012 inch |

| cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Tournage conique

cURL Too many subrequests.

Filetage

cURL Too many subrequests.

Faceage

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Matériaux et finitions de surface supportés par l'usinage XTJ

Varie selon le type de matériau, généralement à haute dureté. La sélection des outils et les paramètres de coupe doivent être basés sur la composition spécifique, en prêtant attention à la résistance à l'usure et à la stabilité thermique.

Aluminium (par ex., 6061, 7075)

Caractéristiques : Léger, bonne conductivité thermique, facile à usiner, les copeaux se cassent facilement. Peut provoquer un collage de l'outil ; nécessite un refroidissement et une lubrification appropriés. Convient pour le fraisage à haute vitesse.

Acier (par ex., inoxydable, carbone)

Caractéristiques : Haute dureté, résistante à l'usure, mais génère des forces de coupe et de la chaleur élevées lors de l'usinage. Nécessite un fraisage à basse vitesse avec des outils durs (par exemple, carbure). L'acier inoxydable peut présenter un durcissement en travail.

Titane

Caractéristiques : Haute résistance, faible conductivité thermique, la chaleur se concentre lors de l'usinage, provoquant l'usure de l'outil. Nécessite une coupe à basse vitesse, des outils haute performance et un refroidissement adéquat.

Laiton

Caractéristiques : Doux et facile à usiner, bonne machinabilité, les copeaux se cassent facilement, finition de surface élevée. Convient pour le fraisage à haute vitesse, génère moins de chaleur.

Cuivre

Caractéristiques : Haute conductivité thermique, ductile, sujet à l'adhérence de l'outil lors de l'usinage. Nécessite des outils tranchants et une lubrification appropriée. Les copeaux peuvent être longs, donc l'élimination des copeaux est importante.

ABS

Caractéristiques : Bonne ténacité, facile à usiner, mais susceptible de ramollissement par la chaleur. Nécessite une vitesse de coupe contrôlée et un refroidissement pour éviter la fusion ou les bavures.

POM (Polyoxyméthylène)

Caractéristiques : Hardness modérée, résistant à l'usure, auto-lubrifiant, stable lors de l'usinage, bonne finition de surface. Faire attention à la déformation thermique.

PEEK

Caractéristiques : Résistance à haute température, résistance chimique, dureté élevée. Nécessite des outils durs, génère des forces de coupe importantes et nécessite un contrôle de la température pour éviter la déformation.

Polycarbonate

Caractéristiques : Transparent, haute ténacité, mais sujet à la fissuration sous contrainte. Nécessite une coupe à faible vitesse pour éviter la surchauffe, et des outils tranchants sont indispensables.

Nylon

Caractéristiques : Haute ténacité, résistant à l'usure, mais hygroscopique et susceptible de déformation lors de l'usinage. Nécessite une vitesse de coupe contrôlée, adapté au fraisage à basse vitesse.

Fibre de carbone

Caractéristiques : haute résistance, léger, mais très dur. Sujet à la délamination ou aux bavures lors de l'usinage. Nécessite des outils en diamant ou en carbure, et une protection contre la poussière est nécessaire.

Fibre de verre

Caractéristiques : haute dureté, résistant à la corrosion, mais abrasif pour les outils et génère de la poussière lors de l'usinage. Nécessite une extraction efficace de la poussière et des outils durs.

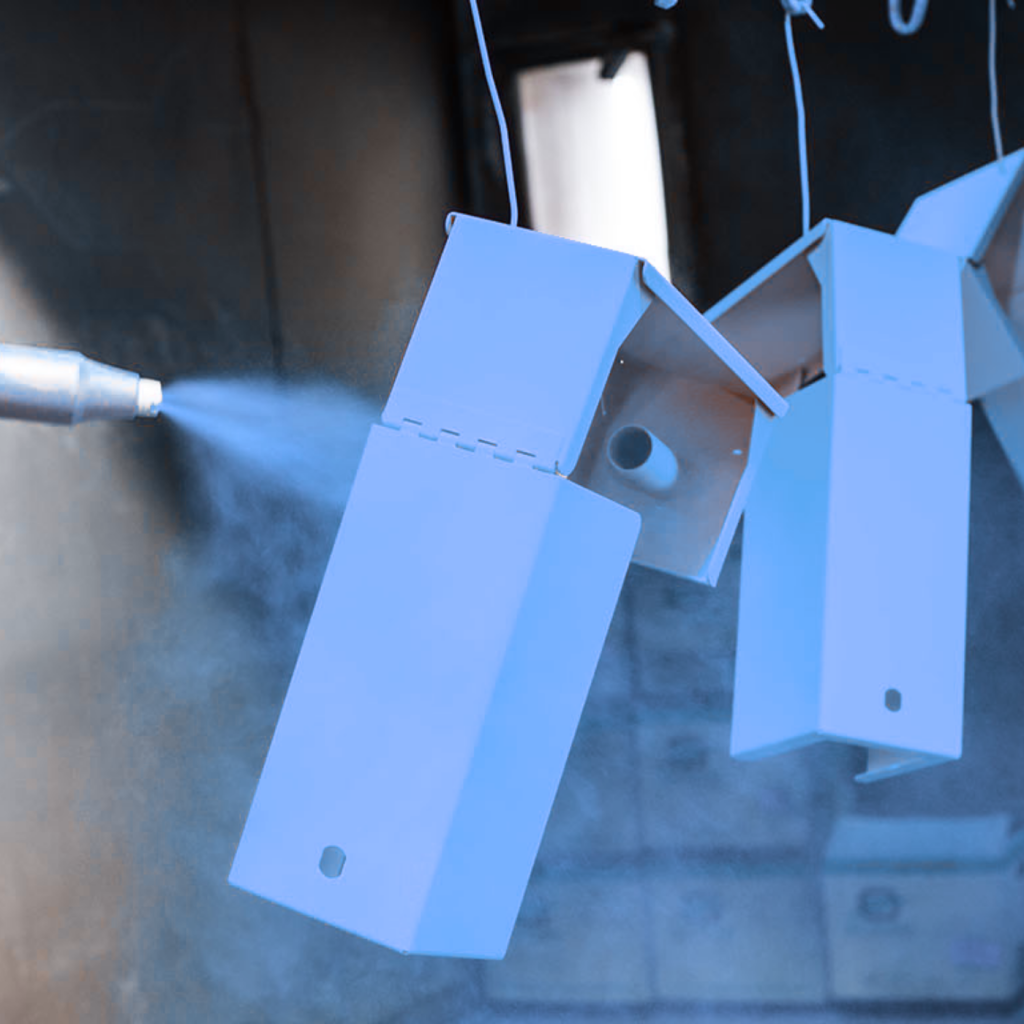

Sublimez vos pièces avec des finitions de surface avancées

Améliorez la durabilité, la fonctionnalité et l'esthétique de vos composants avec la gamme d'options de finition de surface d'XTJ. Chaque processus est adapté pour répondre à des exigences spécifiques de performance et de conception, garantissant que vos pièces non seulement fonctionnent de manière exceptionnelle mais aussi ont fière allure.

Revêtement durable et polyvalent pour une protection longue durée

Le revêtement en poudre applique une poudre sèche—généralement un mélange de résine et de pigment—électrostatiquement sur la pièce, qui est ensuite durcie sous chaleur pour former une couche protectrice résistante. Cette finition est reconnue pour sa durabilité et sa résistance à l’écaillage, aux rayures et à la corrosion.

Revêtement durable et polyvalent pour une protection longue durée

Le revêtement en poudre applique une poudre sèche—généralement un mélange de résine et de pigment—électrostatiquement sur la pièce, qui est ensuite durcie sous chaleur pour former une couche protectrice résistante. Cette finition est reconnue pour sa durabilité et sa résistance à l’écaillage, aux rayures et à la corrosion.

Finition mate uniforme pour une esthétique améliorée

Le sablage à l’aide de petites billes de verre propulsées à haute pression crée une finition mate cohérente et non réfléchissante sur la surface des pièces. Ce processus élimine les imperfections de surface et offre une texture propre et uniforme.

Finition miroir pour applications haut de gamme

Le polissage consiste à lisser mécaniquement la surface d’une pièce pour obtenir une finition brillante, semblable à un miroir. Ce processus améliore à la fois l’attrait visuel et la qualité tactile du composant.

Résistance accrue à la corrosion pour l’acier inoxydable

La passivation est un traitement chimique qui élimine le fer libre de la surface des pièces en acier inoxydable, formant une couche d’oxyde passive qui améliore considérablement la résistance à la corrosion.

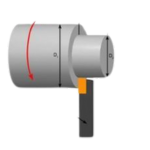

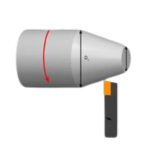

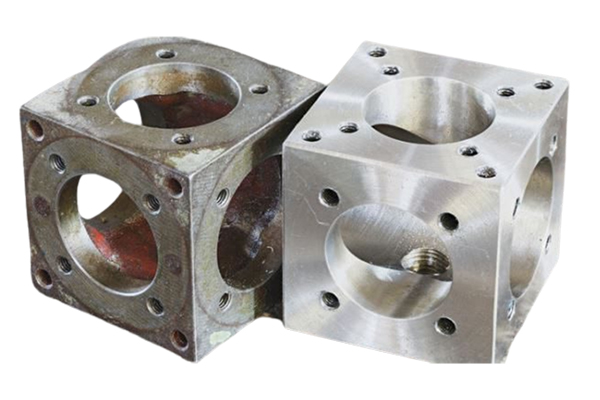

What is CNC Turning?

CNC turning is a subtractive process where a cutting tool moves along a rotating workpiece to create cylindrical parts. At XTJ, we utilize 2-axis, 3-axis, and multi-axis CNC turning to produce components with features like threads, grooves, and tapers, offering flexibility for simple to complex designs.

Serving Diverse Industries with CNC Turning Parts

Aérospatiale

Manufacture lightweight, high-strength parts like turbine blades and structural components that meet stringent aerospace standards.

Automobile

Produce engine components, transmission parts, and custom fittings with tight tolerances for high-performance vehicles.

Médical

cURL Too many subrequests.

Électronique

cURL Too many subrequests.

De la conception à la livraison en 5 étapes simples

Collaborez avec nous facilement : soumettez votre conception, recevez un retour d'expert, approuvez votre devis et lancez la production. Restez informé à chaque étape pour des résultats fiables et de haute qualité.

Looking for affordable, reliable CNC turning services?

Partenariat avec XTJ Precision Mfg pour la précision, l'efficacité et un excellent rapport qualité-prix.