CNC automation parts are specialized components designed specifically for automated machinery, ensuring seamless operation, minimal errors, and maximized output.Automation equipment relies heavily on precision-machined parts because even the slightest deviation in dimensions can lead to system failures, increased downtime, or compromised product quality. These parts must withstand repetitive motions, high speeds, and harsh environments while maintaining accuracy down to microns. For instance, in a factory setting, a misaligned shaft or bracket could halt an entire production line, costing thousands in lost productivity.

The growing demand for custom CNC automation components is driven by the rise of Industry 4.0, where smart factories emphasize connectivity, efficiency, and customization. According to recent market reports, the global CNC machining market is projected to reach over $140 billion by 2030, with automation parts accounting for a significant share due to expansions in sectors like robotics and electric vehicles. As industries push for faster innovation cycles, companies are increasingly turning to custom solutions to meet unique specifications, reducing reliance on off-the-shelf items that may not fit perfectly.

In this complete guide, we’ll explore everything beginners and professionals need to know about CNC automation parts—from definitions and types to materials, processes, and selection tips. Whether you’re an engineer designing a new automation system or a business owner optimizing your production line, understanding these components is key to staying competitive.

What Are CNC Automation Parts?

Definition

CNC automation parts are the precision-engineered components used in automated machinery and industrial equipment to facilitate controlled, repeatable operations. These parts are manufactured using CNC technology, where computers direct cutting tools to remove material from workpieces like metal blocks or plastic sheets, creating shapes defined by CAD (Computer-Aided Design) software.

In essence, they form the mechanical and structural backbone of automation systems. For example, in a robotic arm used for welding in an automotive plant, CNC automation parts might include the arm’s joints, mounts, and grippers—all machined to exact tolerances to ensure fluid movement and safety. Unlike manual machining, CNC processes automate the fabrication, allowing for complex geometries that would be impossible or time-consuming by hand.

These parts are integral to systems like conveyor belts, pick-and-place robots, and CNC routers themselves, bridging the gap between digital instructions and physical actions.

Key Characteristics

What sets CNC automation parts apart is their ability to perform reliably in demanding environments. Here are the primary traits:

- Haute précision: Tolerances as tight as ±0.001 mm ensure parts fit perfectly, reducing assembly issues and enhancing system accuracy. This is crucial in automation where sub-millimeter errors can accumulate over thousands of cycles.

- Consistent Repeatability: CNC machines produce identical parts batch after batch, minimizing variations that could affect performance. This repeatability is vital for scalable production, such as in semiconductor manufacturing where uniformity is non-negotiable.

- Polyvalence des matériaux: From metals to plastics, CNC automation parts can be made from a wide range of materials, allowing customization based on application needs like weight reduction or corrosion resistance.

- Durability Under Continuous Operation: Designed for 24/7 use, these parts incorporate features like hardened surfaces or reinforced structures to withstand wear, vibration, and thermal stresses.

These characteristics make CNC automation parts indispensable for modern automation, where efficiency and reliability directly impact profitability.

Common Types of CNC Automation Parts

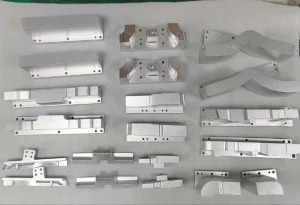

Automation systems are diverse, so CNC parts come in various forms to suit specific functions. Below, we categorize them for clarity.

Mechanical Components

These are the moving parts that enable motion and power transfer.

- Shafts, Rollers, Guides: Shafts transmit rotational force, rollers facilitate smooth material handling (e.g., in conveyor systems), and guides ensure linear movement without deviation. Precision machining prevents wobbling, which could lead to breakdowns.

- Couplings, Spacers, Brackets: Couplings connect rotating elements, spacers maintain gaps for alignment, and brackets provide secure mounting. In a packaging machine, for example, brackets hold sensors in place for accurate detection.

Structural Components

These provide the framework and stability for automation equipment.

- Aluminum Frames, Housings, Blocks: Lightweight frames support robotic structures, housings protect internal components from dust or moisture, and blocks serve as foundational elements for mounting.

- Mounting Plates, Machine Bases: Plates distribute loads evenly, while bases anchor the entire system to the floor, absorbing vibrations in high-speed operations like CNC milling centers.

Functional Components

These perform specific tasks within the automation process.

- End Effectors, Grippers, Moving Parts: End effectors are the “hands” of robots, grippers handle objects with precision, and moving parts like slides enable dynamic positioning.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Aluminium (6061, 7075)

- cURL Too many subrequests.: Aluminium cURL Too many subrequests.

Acier inoxydable (304, 316, 17-4)

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

Engineering Plastics cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Fraisage CNC

cURL Too many subrequests.

- cURL Too many subrequests.

- Easily produces deep pockets, narrow slots, countersinks, threaded holes, chamfers, thin walls, and free-form surfaces.

- 3-axis for prismatic parts; 4-axis for parts with features on multiple sides. Covers ≈90% of structural components in automation equipment.

Tournage CNC

The workpiece rotates at high speed while a single-point cutting tool feeds linearly. Specialized for parts of revolution.

- Best for all kinds of shafts, bushings, sleeves, rollers, rotary joints, pistons, spindles, and connectors.

- Achieves excellent roundness, cylindricity, concentricity, and surface finish in a single setup.

- With modern turn-mill centers (C-axis + live tools), drilling, milling, tapping, keyways, and off-center features can all be completed without re-clamping.

5-Axis Simultaneous Machining

The tool or table can move along X, Y, Z plus two rotary axes (usually A/B or B/C) at the same time, enabling true “one-setup, five-side/full-contour” machining.

- Essential for complex, sculptured, or multi-angle parts: robot grippers, fingers, impellers, spiral bevel gears, intricate manifolds, camera gimbals, turbine blades, and contoured flow-channel blocks.

- Eliminates cumulative errors from multiple setups, dramatically improving accuracy and part-to-part consistency.

- Parts that once required 6–8 setups can now be finished in a single operation, significantly reducing lead time.

Common Surface Finishing Processes

- Hard Anodizing Forms a thick, dense oxide layer that greatly improves wear resistance and corrosion protection. Widely used on moving or exposed components.

- Thermolaquage Electrostatic application of thermoset powder followed by oven curing. Produces a tough, uniform, colored finish with excellent impact and weather resistance. Typical on enclosures and visible panels.

- Mirror Polishing / Electropolishing Achieves surface roughness below Ra 0.05 μm for an extremely smooth, low-friction, easy-to-clean finish. Used on high-speed sliding parts and sanitary applications.

- Sandblasting / Glass-Bead Blasting Creates a uniform matte or lightly textured surface that hides tool marks and improves grip. Common on gripper jaws, handles, pedals, and anti-slip areas.

- Other frequent treatments Black oxide, chromate conversion coating, electroless nickel plating, DLC or diamond-like carbon coating, ceramic coating, laser engraving/marking, etc.

By properly combining milling, turning, 5-axis machining, and the right surface finishes, virtually any high-precision functional part required in automation systems can be manufactured efficiently, accurately, and repeatably.

Contrôle qualité

Ensures compliance:

- CMM (Coordinate Measuring Machine): Scans for dimensional accuracy.

- Digital Calipers: Quick checks for tolerances.

- Hardness Testing: Verifies material strength.

These processes guarantee parts meet automation demands.

Industries That Use CNC Automation Parts

CNC parts power innovation across sectors.

Robotique

From joint shafts to end effectors, they enable precise movements in collaborative robots (cobots).

Factory Automation (FA)

Conveyors and pick-and-place systems rely on brackets and guides for efficient workflows.

Fabrication de dispositifs médicaux

Sterile, precise fixtures ensure accuracy in assembling implants or diagnostic tools.

Semiconductor Production

High-precision housings protect sensitive chips in cleanroom environments.

Automotive Assembly Lines

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests. Pièces CNC personnalisées

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Capacités d'usinagecURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Materials SupportedcURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- Délai de LivraisoncURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

3. Final & Incoming Quality Inspection

Zeiss Coordinate Measuring Machines (CMM) XTJ Precision Mfg operates multiple Zeiss CMMs (including Contura, Accura, and Prismo series) in a dedicated 20 ± 0.5 °C temperature-controlled metrology lab.

- Touch-trigger and scanning probes deliver measurement uncertainty down to 1.5 μm.

- Zeiss CALYPSO and PiWeb software generate color deviation maps and full GD&T reports that are attached to every shipment.

Advanced Optical & Vision Systems Structured-light 3D scanners (GOM ATOS) and high-resolution vision systems are used for complex free-form surfaces and soft/jaw grippers where contact measurement is impractical.

Surface Roughness and Contour Measurement Zeiss Surfcom and Contourecord instruments verify Ra, Rz, and profile tolerances on all sealing and sliding surfaces.

Hardness & Microstructure Verification Rockwell, Vickers, and microhardness testers confirm that every heat-treatment or coating process meets specification.

Functional and Thread Gauging Comprehensive Go/No-Go gauges, custom fixtures, and spline checks guarantee 100 % assemblability.

Non-Destructive Testing (when specified) Fluorescent dye penetrant, ultrasonic, and industrial CT for internal integrity of safety-critical rotating components.

4. Statistical Process Control & Documentation

- CPk > 1.67 is the internal target for all key characteristics.

- Every batch is accompanied by Zeiss inspection reports, CoC, and full traceability back to machine, operator, program revision, and calibrated instrument certificates.

Because XTJ Precision Mfg invests heavily in Zeiss metrology and rigorous quality systems (ISO 9001 & IATF 16949 certified), our customers receive automation parts that are not just “within tolerance”—they are consistently perfect, ensuring zero defects and uninterrupted performance on their production floors.

Industries That Use CNC Automation Parts

CNC parts power innovation across sectors.

Robotique

From joint shafts to end effectors, they enable precise movements in collaborative robots (cobots).

Factory Automation (FA)

Conveyors and pick-and-place systems rely on brackets and guides for efficient workflows.

Fabrication de dispositifs médicaux

Sterile, precise fixtures ensure accuracy in assembling implants or diagnostic tools.

Semiconductor Production

High-precision housings protect sensitive chips in cleanroom environments.

Automotive Assembly Lines

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

Why Many Companies Prefer Custom CNC Parts

- cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

Final Words

CNC automation parts are essential components that drive the efficiency and precision of modern automated systems, from shafts and brackets to custom fixtures. Choosing a professional manufacturer ensures high-quality, durable parts tailored to your needs.

Custom CNC machining supports modern automation by enabling innovation, reducing costs, and improving reliability. For your next project, contact us at XTJ for expert custom CNC automation parts—let’s optimize your system today!