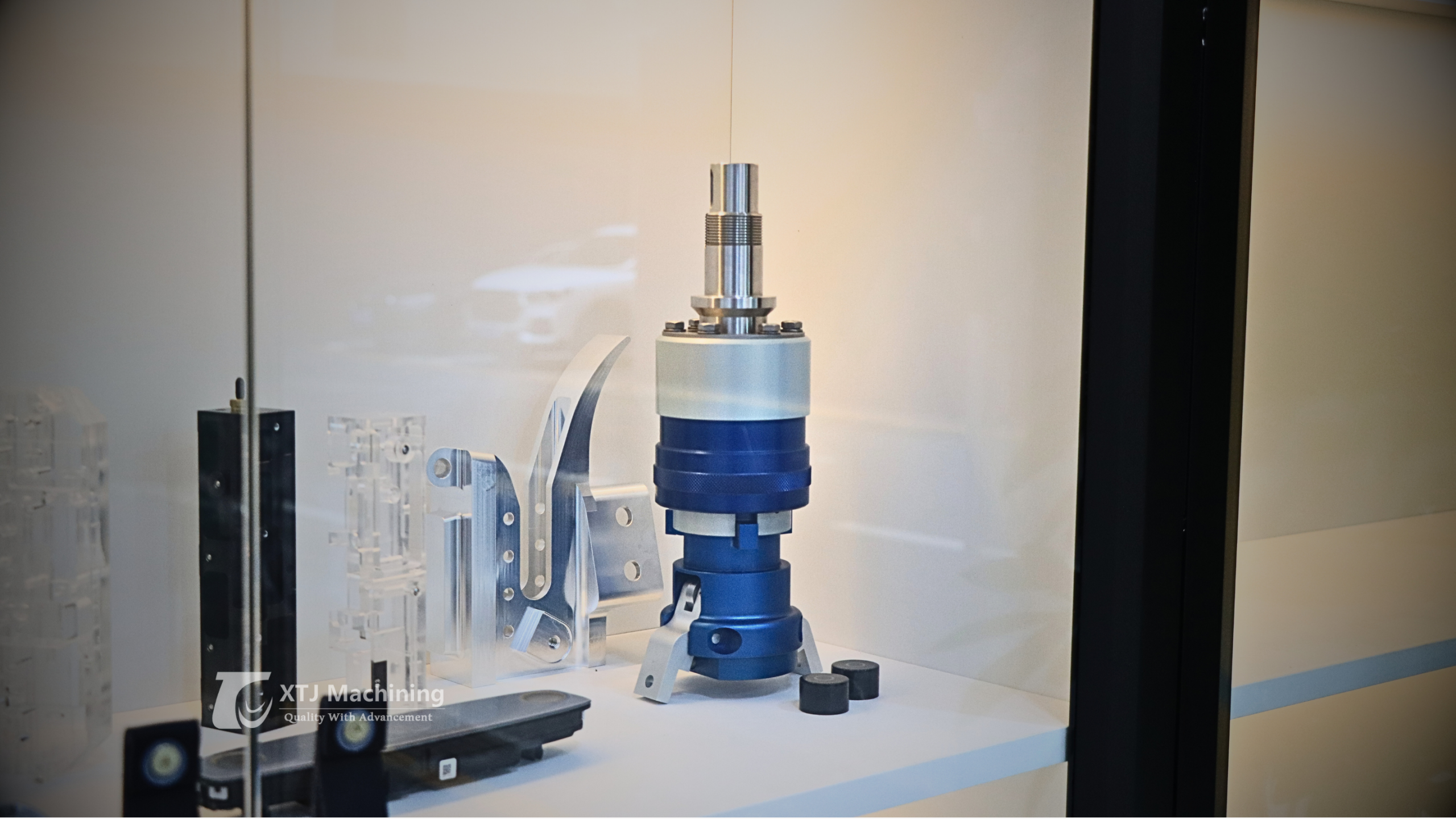

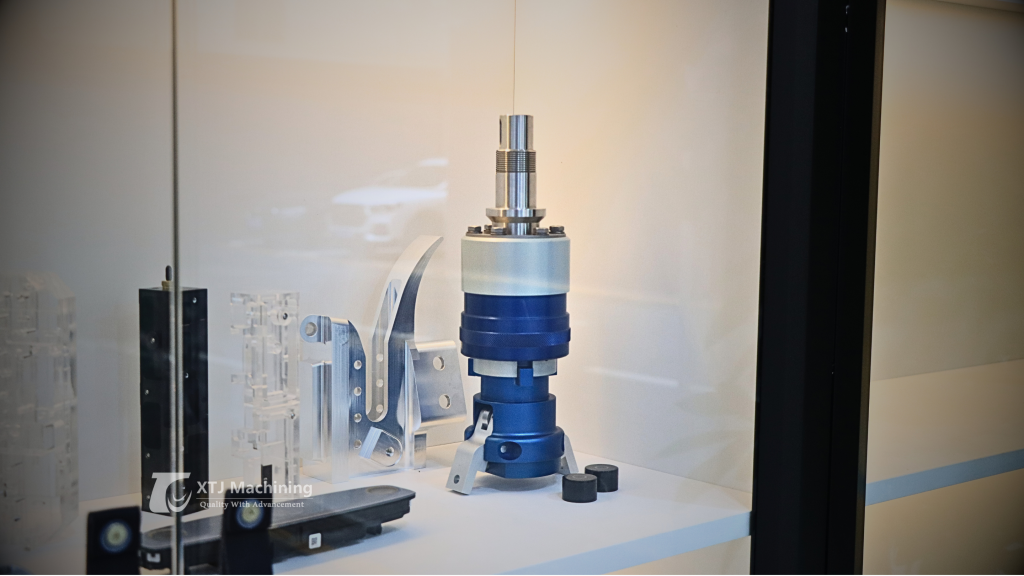

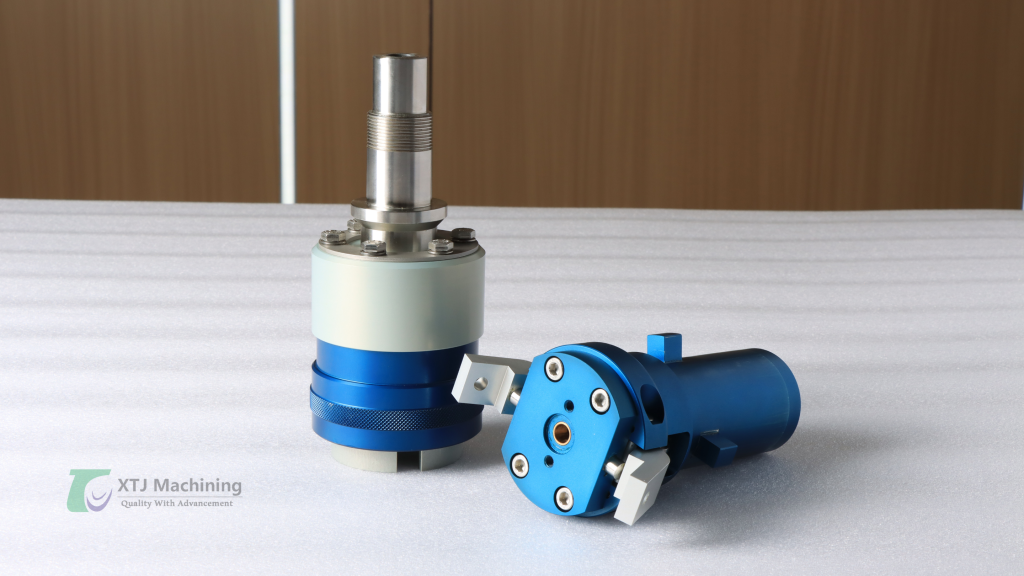

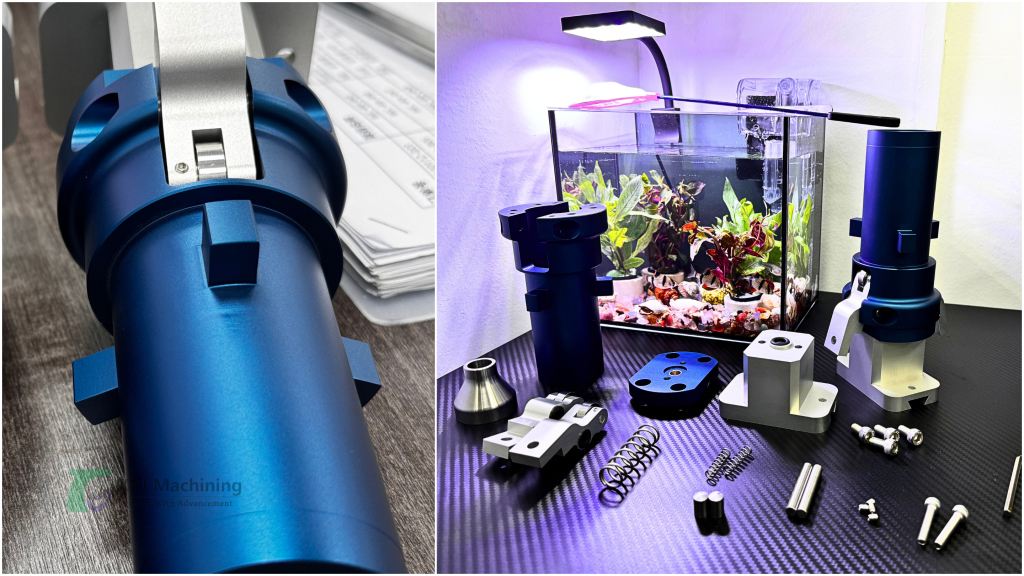

We delivered a custom-designed automation gripper, with key components manufactured by precision CNC machining to ensure repeatability and assembly consistency.The gripper was fully assembled, tested, and delivered as a ready-to-use solution for the customer’s packaging line.

Background

The customer, a globally recognized personal care brand, operates high-speed automated packaging lines handling tens of thousands of bottles per shift.

To support increasing production demand, the cap installation process required higher stability, precision, and long-term reliability.

課題

-

Continuous high-speed operation with hundreds of repetitive gripping and rotation cycles per hour

-

Stable and repeatable gripping force required to ensure consistent cap installation

-

Limited installation space within existing packaging equipment

-

Tight project timeline with minimal allowance for production downtime

解決策

XTJ developed a customized CNC machined gripper assembly integrating gripping and rotational functions into a compact structure, tailored to the customer’s packaging line.

Key components were manufactured using precision CNC machining, ensuring high repeatability and assembly consistency.

The gripper was fully assembled and functionally tested before delivery, supported by XTJ’s strong local supply chain to ensure short lead times.

Results

-

Stable and reliable automated cap installation during continuous operation

-

Improved production efficiency and line consistency

-

Reduced manual intervention and unplanned downtime

Customer feedback:

“The solution has been running continuously without failure since installation.”

We don’t just machine parts — we help customers deliver automation components that work in real production environments.