CNC金属加工

ISO 9001認証のメーカーであり、精密部品向けの高品質なCNC金属加工サービスを提供します。

- コストパフォーマンスの高い価格設定

- 製品認証

- 迅速な納品

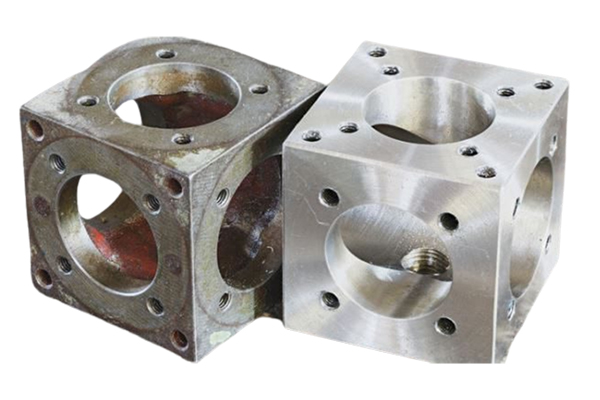

精密CNC金属加工サービス

XTJ Precision MfgはCNC金属加工を専門とし、航空宇宙から医療まで幅広い産業向けに先進的なソリューションを提供します。最新の社内設備には、3軸、4軸、5軸CNC加工、フライス盤、旋盤、放電加工(EDM)、表面研磨が含まれ、±0.002mmの高精度な公差を実現します。迅速な試作や大量生産のニーズに応え、優れた性能と美観を持つカスタム部品をお届けします。

CNC金属加工用材料

CNC加工に適した金属の選択は、最適な性能、コスト効率、耐久性を実現するために重要です。XTJ Precision Mfgは、お客様のプロジェクト要件に合わせたさまざまな金属を提供しています。以下は、私たちが取り扱う主要な材料の一部です:

アルミニウム コスト効率が良く、軽量で加工性に優れた金属であり、高い強度対重量比を持ち、精密CNC加工に理想的です。

- AL6061-T6: 優れた加工性、耐腐食性、コストパフォーマンスの良さから広く使用されています。自動車、航空宇宙、建設部品に最適です。

- AL7075-T6: 高強度のアルミニウムで、疲労耐性に優れ、高ストレスの航空宇宙や自動車部品に最適です。

- AL6082: 6000シリーズで最高の強度を誇り、優れた耐腐食性を持ち、防衛や航空宇宙用途に適しています。

ステンレス鋼は良好な加工性と耐腐食性、強度を兼ね備え、CNC加工において多用途な選択肢です。

- SS304: 成形性と溶接性に優れ、キッチン家電、食品取り扱い設備、配管システムに使用されます。

- SS303: 優れた耐腐食性と耐久性を持ち、ギア、シャフト、航空機用フィッティングに理想的です。

- SS316: モリブデン含有により優れた耐腐食性を特徴とし、医療用インプラントや航空宇宙部品に最適です。

チタンは比強度と生体適合性に優れ、医療機器や航空宇宙用途に理想的ですが、加工コストが高いです。

銅とその合金である黄銅は、熱伝導性と電気伝導性に優れ、電気・配管用途に最適な高加工性の金属です。

- 銅: 高い導電性により電気部品に最適ですが、価格は高めです。

- 黄銅(H59): 銅と亜鉛の合金で、高い引張強度と耐腐食性を持ち、自動車、配管、楽器に使用されます。

マグネシウムは軽量で高い加工性を持ち、自動車や航空宇宙部品に理想的ですが、火災の危険性があるため取り扱いに注意が必要です。

| 材料 | 説明 | 価格シェア |

|---|---|---|

| アルミニウム | 加工が容易 + 優れた比強度バランス | $ |

| ステンレス鋼 | 加工適性良好 + 優れた引張強度 +錆びにくい | $$$ |

| 鉄 | 高い加工性 + 頑丈な引張強度 + 柔軟性と溶接性に優れる | $$ |

| 真鍮 | 滑らかな加工 + 高品質な電気伝導性 + 低摩擦 + 魅力的な金色仕上げ | $ |

| 銅 | 容易に加工可能 + 優れた熱伝導性と電気伝導性 | $$ |

| チタン | 卓越した耐荷重性能 + 高い耐腐食性 | $$$$ |

| マグネシウム | 超軽量 + 印象的な耐荷重比 + 優れた熱伝導性 + 生体適合性 | $$ |

| モリブデン | 優れた耐久性と強度 + 優れた耐熱性と耐腐食性 | $ |

CNC金属加工の考慮すべき要素

適切な金属を選ぶことはコスト、性能、生産時間に影響します。以下は重要な要素です:

加工時間

アルミニウムのような高い加工性を持つ金属は加工時間とコストを削減します。複雑な部品形状は加工時間を増加させ、全体の費用に影響します。

強度と環境要件

部品の用途に基づいて金属を選択します。高ストレス用途にはステンレス鋼やチタンなどの強い金属が必要で、軽量用途にはアルミニウムやマグネシウムが適しています。

仕上げと後処理

XTJは陽極酸化、粉体塗装、研磨などの広範な表面仕上げオプションを提供し、美観を向上させ、加工跡を除去します。金属の種類は仕上げ工程とコストに影響します。

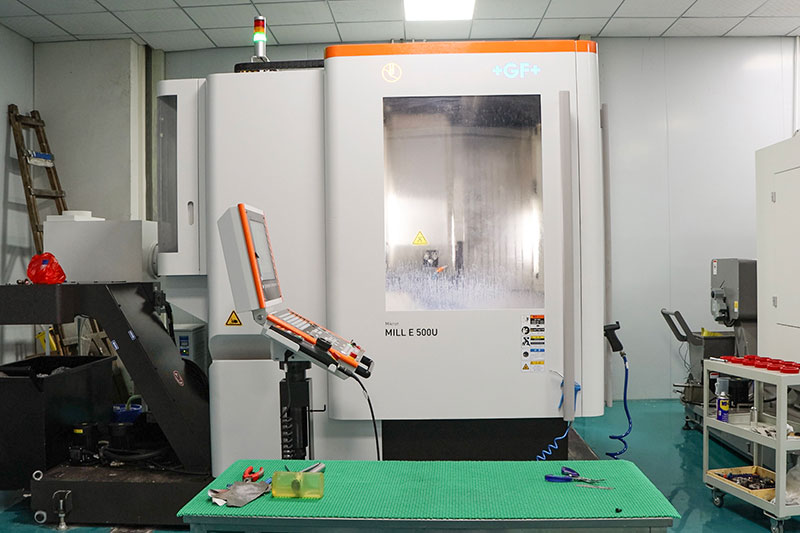

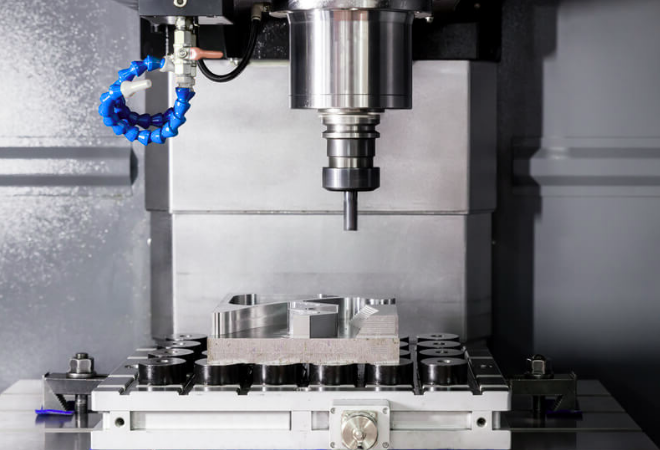

XTJ精密製造のCNCマシン

XTJ精密製造は高度なCNCマシンを使用して高精度の金属部品を提供します。私たちの能力には次のものがあります:

3軸/4軸CNCフライス盤

シンプルな形状に最適で、高い精度を低コストで実現します。

5軸CNCフライス盤

複雑な部品を最小限の加工跡で製造し、航空宇宙や医療用途に理想的です。

CNC旋盤(Lathes)

より複雑な部品の設計柔軟性を向上させる。

ミル-旋盤CNCセンター

フライス加工と旋盤加工を組み合わせ、5軸加工より低コストで複雑な部品を製造。

放電加工(EDM)

シンプルな形状に最適で、高い精度を低コストで実現します。

表面研削

より複雑な部品の設計柔軟性を向上させる。

工程比較

| プロセス | 相対的コスト | 利点 | 制限事項 |

|---|---|---|---|

| CNC旋盤 | 80% | 低コスト、高生産能力 | 円筒形部品に限定 |

| 3軸CNCフライス加工 | 100% | 簡単な形状に高精度、コスト効果的 | 手動位置調整による精度低下 |

| 4軸CNCフライス加工 | 120% | 複雑な部品に対する柔軟性向上 | 3軸より高コスト |

| ミル-旋盤CNCセンター | 130% | フライス加工と旋盤加工を組み合わせ、高い設計自由度 | ツールアクセス制限 |

| 5軸CNCフライス盤 | 180% | 複雑な部品に高精度、最小限の機械加工跡 | 最高コスト |

| 放電加工(EDM) | 150% | 硬い金属や複雑な形状に最適 | 処理速度が遅く、コストが高い |

| 表面研削 | 90% | 滑らかな仕上げ、正確な公差 | 平面に限定 |

CNC金属加工を5つの簡単なステップで

簡単に協力できます:設計を提出し、専門家のフィードバックを受け取り、見積もりを承認し、生産を開始します。各段階で情報を把握し、信頼性の高い高品質な結果を得ましょう。

よくある質問

コストは材料、部品の複雑さ、公差、仕上げ要件によって異なります。お客様のプロジェクトに合わせた見積もりについては、XTJにお問い合わせください。

CNC金属加工は、コンピュータ制御の機械を使用して金属部品を高精度で成形する減算製造プロセスです。

XTJはボルト、ナット、ギア、シャフト、航空宇宙部品、医療用インプラント、さまざまな業界向けのカスタム部品を製造できます。