Precision CNC Turning Services

Trusted CNC Turning Solutions,Based in China, we offer competitive pricing and fast lead times to meet your manufacturing demands.

- Data Security to Safeguard Your Designs

- Over 100 CNC Machines for High Efficiency

- Lead Times from 5 Days for Quick Turnaround

Expert CNc Turning Services for Your Projects

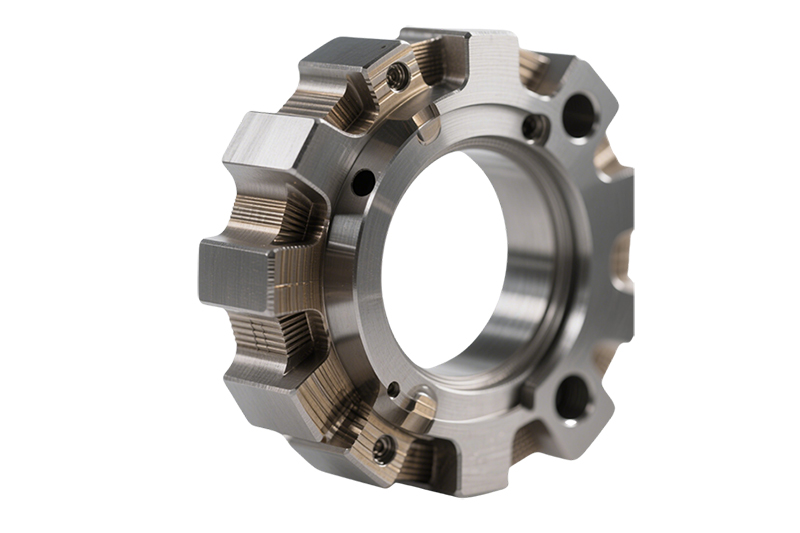

At XTJ Machining, we excel in precision CNc turning to produce high-guality cylindricalcomponents. With over 100 advanced CNC turning machines, we deliver cost-effectivesolutions, fast turnarounds, and exceptional accuracy for prototypes and large-scaleproduction.

we handle projects from simple components to complex designs. Serving industries like aerospace, automotive, and medical, XTJ delivers fast, reliable, and top-quality parts, making precision manufacturing accessible and efficient for your needs.

Why Choose XTJ for CNC Turning?

Competitive Pricing

Our CNC turning services offer exceptional value through cost-effective solutions without compromising quality. By leveraging advanced technology, optimized processes, and strategic sourcing, we deliver precision-engineered components at prices that lead the industry. Whether you’re a small business or a large-scale manufacturer, our commitment to affordability ensures you receive top-tier service tailored to your budget, making us the preferred choice for high-quality, low-cost CNC turning solutions.

High Production Capacity

At XTJ, our cutting-edge facility boasts over 100 advanced CNC machines and more than 40 precision lathes, ensuring unmatched scalability and rapid delivery for projects of any size. This extensive equipment lineup empowers us to efficiently manage high-volume production, intricate designs, and tight deadlines with consistent quality. Whether you need small-batch prototypes or large-scale manufacturing, XTJ’s robust capacity and streamlined operations deliver reliable, high-performance CNC turning solutions tailored to your needs, making us your trusted partner for superior results.

Superior Precision

we deliver exceptional accuracy with tolerances as tight as ±0.005 mm, ensuring components meet the most stringent specifications. Our precision is validated through rigorous inspections using state-of-the-art Zeiss Coordinate Measuring Machines (CMM), guaranteeing unparalleled quality and consistency. Whether for aerospace, medical, or high-tech industries, our advanced CNC turning capabilities and meticulous quality control processes provide reliable, high-precision solutions that exceed expectations, making XTJ the preferred choice for mission-critical applications.

材料の多様性

our expertise spans a wide range of materials, including aluminum, stainless steel, brass, titanium, and various plastics, ensuring tailored solutions for diverse applications. Our skilled team and advanced CNC turning capabilities allow us to handle each material’s unique properties with precision and efficiency, delivering high-quality components for industries like aerospace, automotive, medical, and more. Whether you require lightweight alloys, corrosion-resistant metals, or durable plastics, XTJ’s versatile material proficiency guarantees optimal performance and reliability for your project needs.

CNC Turning Design Reference

This guide, developed by our turning experts, provides ideal specifications for crafting precise turned components. It includes recommended measurements and feasible limits to guide your production process.

| コンポーネント | Ideal Measurement | Acceptable Limit |

|---|---|---|

| Smallest Feature | Ø 2.0 mm | Ø 0.4 mm |

| Internal Radii | R 7 mm | R 0.3 mm |

| Thinnest Section | 0.7 mm (metals) / 1.4 mm (plastics) | 0.4 mm (metals) / 0.9 mm (plastics) |

| Diameter: Ø 0.6 mm / Depth: 12x diameter | Diameter: standard tools / Depth: 5x diameter | Diameter: Ø 0.6 mm / Depth: 12x diameter |

| Thread Standards | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

| コンポーネント | cURL Too many subrequests. |

|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

旋盤での成形は、ワークピースを特定の輪郭やプロファイルに成形する作業です。これは、所望のプロファイルの形状を持つ成形工具を使用して行います。旋盤がワークピースを回転させる間、成形工具を押し当てて、工具の形状を材料に転写します。成形は、カムプロファイルや装飾的な要素など、複雑な形状を作る際に一般的に使用されます。

cURL Too many subrequests.

ねじ切り

Machines internal and external threads for screws and fittings.

面取り

Smooths the end face of a part for a clean finish.

Drilling and Boring

Adds holes or enlarges existing ones with precision.

Grooving and Parting

Cuts grooves or separates finished parts from the stock.

Materials and Surface Finishes Supported by XTJ Machining

Varies by material type, generally high hardness. Tool selection and cutting parameters should be based on specific composition, with attention to wear resistance and thermal stability.

Aluminum (e.g., 6061, 7075)

特徴:軽量、良好な熱伝導性、加工が容易で、チップが壊れやすい。工具の粘着を引き起こすことがあるため、適切な冷却と潤滑が必要です。高速ミリングに適しています。

Steel (e.g., stainless, carbon)

特性:高硬度、耐摩耗性があり、加工中に高い切削力と熱を発生させる。硬い工具(例:カーバイド)を用いた低速ミリングが必要。ステンレス鋼は加工硬化を示すことがある。

チタン

特性:高強度、低熱伝導性、加工中に熱が集中しやすく、工具の摩耗を引き起こす。低速切削、高性能工具、十分な冷却が必要。

真鍮

特性:柔らかく加工しやすく、良好な加工性を持ち、切りくずが容易に折れる。高い表面仕上げに適し、高速ミリングに適しており、熱の発生も少ない。

銅

特性:高い熱伝導性、延性があり、加工中に工具の粘着が起こりやすい。鋭利な工具と適切な潤滑が必要。切りくずが長くなることがあるため、切りくずの除去が重要。

ABS

特性:良好な靭性、加工が容易だが、熱による軟化が起こりやすい。溶融やバリを防ぐために切削速度と冷却の管理が必要。

POM(ポリアセタール)

特性:中程度の硬さ、耐摩耗性、自己潤滑性、加工中の安定性、良好な表面仕上げ。熱変形に注意が必要。

PEEK

特性:高温耐性、耐薬品性、高硬度。硬い工具が必要で、高い切削力が発生し、変形防止のため温度管理が必要。

ポリカーボネート

特性:透明で高靭性だが、応力割れが起こりやすい。過熱を避けるため低速切削が必要で、鋭利な工具が求められる。

ナイロン

特性:高靭性、耐摩耗性だが吸湿性があり、加工中に変形しやすい。切削速度の管理が必要で、低速フライス加工に適している。

カーボンファイバー

Characteristics: High strength, lightweight, but very hard. Prone to delamination or burrs during machining. Requires diamond or carbide tools, and dust protection is necessary.

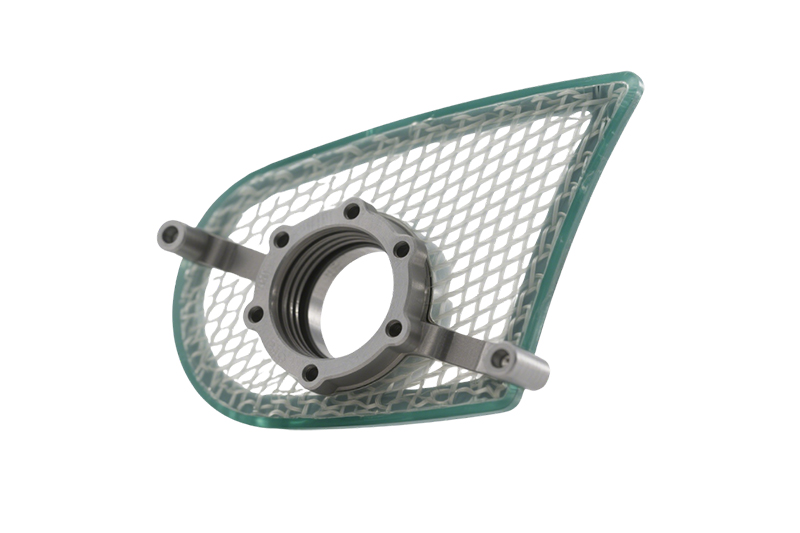

ガラス繊維

Characteristics: High hardness, corrosion-resistant, but abrasive to tools and generates dust during machining. Requires efficient dust extraction and hard tools.

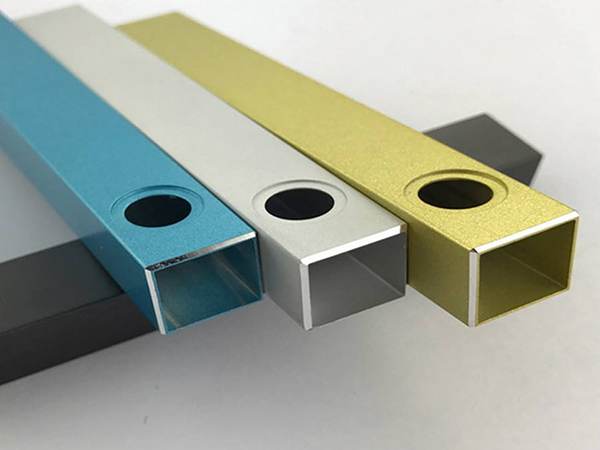

Elevate Your Parts with Advanced Surface Finishing

Enhance the durability, functionality, and aesthetics of your components with XTJ’s range of surface finishing options. Each process is tailored to meet specific performance and design requirements, ensuring your parts not only perform exceptionally but also look their best.

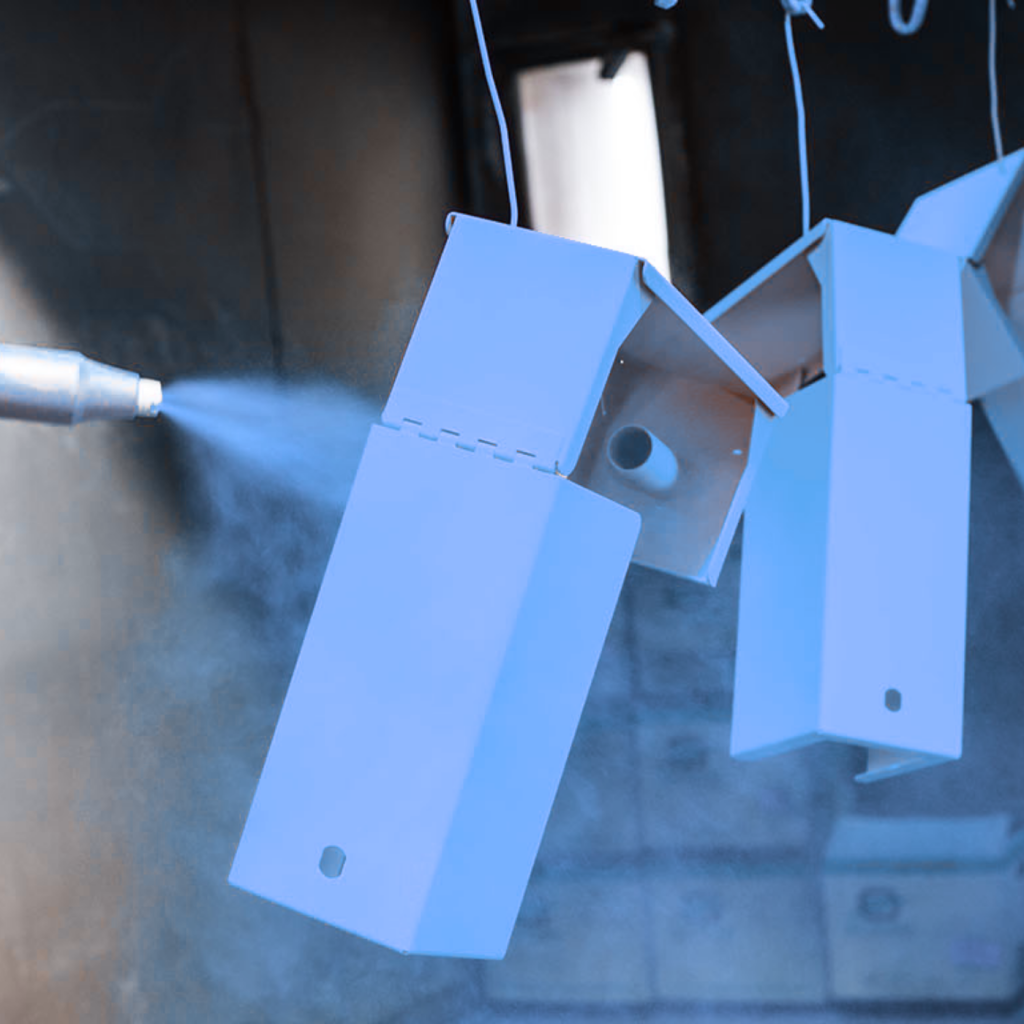

Durable and Versatile Coating for Long-Lasting Protection

Powder coating applies a dry powder—typically a mix of resin and pigment—electrostatically to the part, which is then cured under heat to form a tough, protective layer. This finish is known for its durability and resistance to chipping, scratching, and corrosion.

Durable and Versatile Coating for Long-Lasting Protection

Powder coating applies a dry powder—typically a mix of resin and pigment—electrostatically to the part, which is then cured under heat to form a tough, protective layer. This finish is known for its durability and resistance to chipping, scratching, and corrosion.

Uniform Matte Finish for Enhanced Aesthetics

Bead blasting uses small glass beads propelled at high pressure to create a consistent, non-reflective matte finish on the surface of parts. This process removes surface imperfections and provides a clean, uniform texture.

Mirror-Like Finish for Premium Applications

Polishing involves mechanically smoothing the surface of a part to achieve a high-gloss, mirror-like finish. This process enhances both the visual appeal and the tactile quality of the component.

Enhanced Corrosion Resistance for Stainless Steel

Passivation is a chemical treatment that removes free iron from the surface of stainless steel parts, forming a passive oxide layer that significantly improves corrosion resistance.

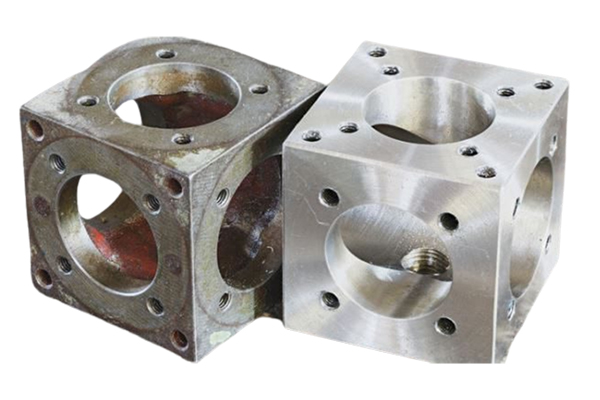

What is CNC Turning?

CNC turning is a subtractive process where a cutting tool moves along a rotating workpiece to create cylindrical parts. At XTJ, we utilize 2-axis, 3-axis, and multi-axis CNC turning to produce components with features like threads, grooves, and tapers, offering flexibility for simple to complex designs.

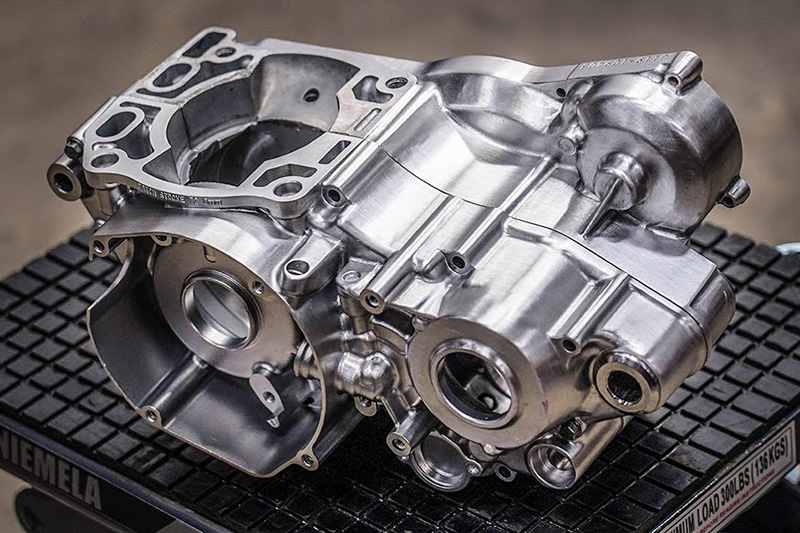

Serving Diverse Industries with CNC Turning Parts

航空宇宙

厳しい航空宇宙基準を満たすタービンブレードや構造部品などの軽量高強度部品を製造します。

自動車

高性能車両向けのエンジン部品、トランスミッション部品、カスタムフィッティングを厳しい公差で生産します。

医療

チタンやPEEKなどの生体適合性材料を用いた精密器具やインプラントを作成します。

電子機器

コンシューマーエレクトロニクスや通信機器向けの小型で複雑な部品、例えばエンクロージャやヒートシンクを製作します。

設計から納品までの5つの簡単なステップ

簡単に協力できます:設計を提出し、専門家のフィードバックを受け取り、見積もりを承認し、生産を開始します。各段階で情報を把握し、信頼性の高い高品質な結果を得ましょう。

Looking for affordable, reliable CNC turning services?

精度、効率、優れた価値を提供するXTJ Precision Mfgと提携してください。