Kovar CNC Machining

XTJ Precision Mfg crafts precision Kovar alloy parts with unmatched expertise, tailored to your toughest project demands.

- コストパフォーマンスの高い価格設定

- 製品認証

- 迅速な納品

Your Trusted Partner for Kovar CNC Machining

Need Kovar alloy parts that perform flawlessly in aerospace or electronics?

XTJ Precision Mfg, an ISO 9001 certified manufacturer, brings over 20 years of expertise to deliver custom Kovar components with tolerances as tight as ±0.002 mm. Our advanced 3-, 4-, and 5-axis CNC machining, combined with Electrical Discharge Machining (EDM), ensures precision for even the most complex designs. From rapid prototypes to high-volume production, we offer tailored solutions with finishes like passivation or electroplating to boost durability and performance. Let’s turn your ideas into reality!

What is Kovar Alloy?

Kovar, or ASTM F15, is a nickel-cobalt-iron alloy prized for its thermal expansion properties that closely match those of borosilicate glass and ceramics. Composed of approximately 29% nickel, 17% cobalt, and 54% iron, with trace elements like manganese and silicon, Kovar ensures reliable hermetic seals across a wide temperature range (-80°F to 450°F). Its stability and machinability make it a top choice for precision components in electronics, aerospace, and medical applications.

| 元素 | Percent by Weight | Function in Alloy |

|---|---|---|

| ニッケル(Ni) | 29% | Controls thermal expansion, improves corrosion resistance |

| Cobalt (Co) | 17% | Enhances thermal stability, adds strength |

| 鉄(Fe) | ~54% | Forms the alloy base, affects magnetic properties |

| シリコン(Si) | ~0.2% | Improves melt quality, reduces oxidation |

| マンガン(Mn) | ~0.5% | Improves melt quality, reduces oxidation |

| 炭素(C) | ~0.02% | Refines grain structure, enhances strength |

Expert Kovar Alloy Machining at XTJ Precision Mfg

Kovar’s properties require specialized machining to achieve precision. XTJ employs the following techniques:

放電加工(EDM)

Non-contact method for complex shapes, minimizing stress and maintaining material integrity with fine finishes.

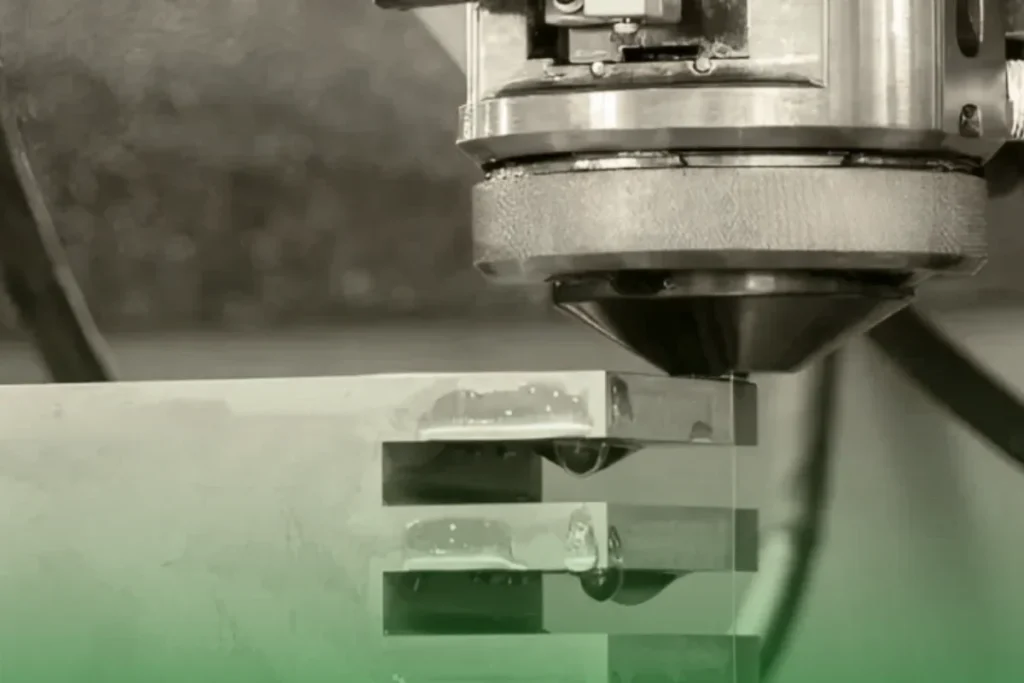

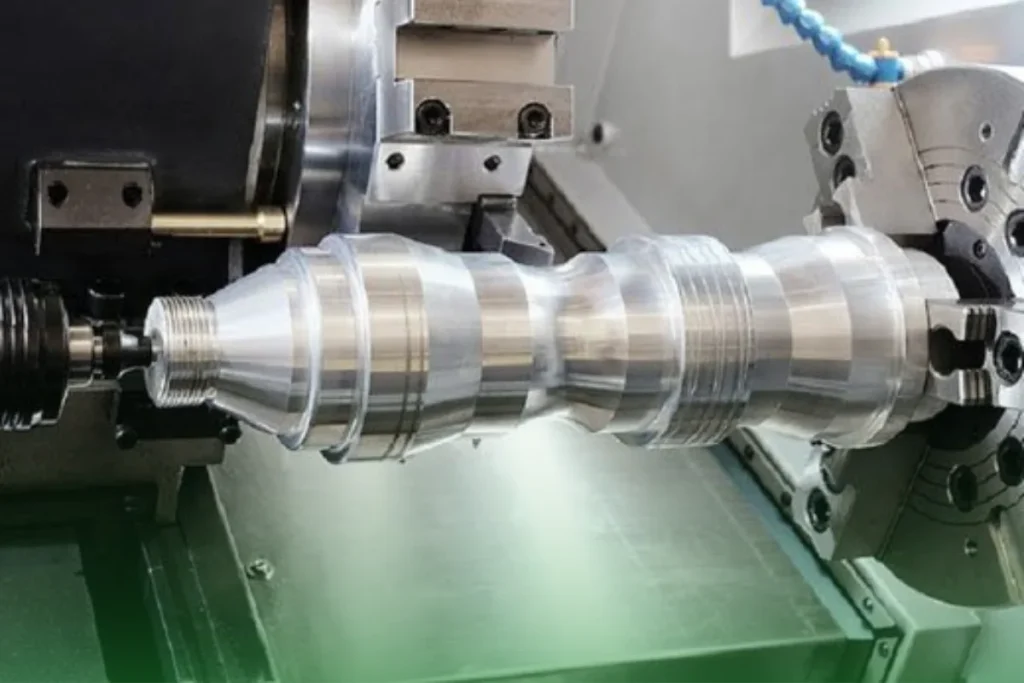

CNC加工

Using 3-, 4-, and 5-axis CNC machines with carbide tools for intricate designs and tight tolerances, optimized for Kovar’s work-hardening nature.

レーザー切断

Precise cuts with minimal heat-affected zones, ideal for intricate patterns and high repeatability.

Tooling Requirements

Sharp carbide or diamond-coated tools with optimized edge angles (>25°) to reduce work-hardening and ensure clean cuts.

Design Tips for Kovar CNC Machining

To maximize Kovar’s performance, consider these design and machining strategies:

Match Thermal Expansion

Align Kovar’s CTE with adjacent materials to prevent stress during temperature changes.

Optimize Speeds and Feeds

Use lower speeds and higher feeds to minimize work-hardening and maintain precision.

Use Carbide Tools

Employ hard-tipped tools to withstand Kovar’s abrasiveness and extend tool life.

Pre- and Post-Annealing

Anneal before machining to relieve stresses and after to ensure dimensional stability.

Surface Finishing

Apply passivation or electroplating to enhance corrosion resistance and solderability.

Industries Served by Kovar CNC Machining

XTJ’s Kovar machining expertise powers industries that demand precision and performance

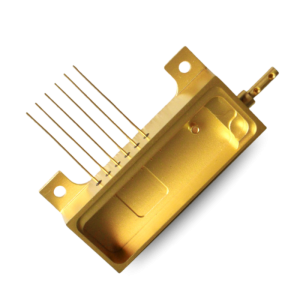

- 電子機器: Hermetic seals for microchips, diodes, and semiconductor packaging.

- Aerospace: Components for satellites and aircraft that endure extreme temperatures.

- cURL Too many subrequests. Nonmagnetic parts for MRI machines and biocompatible implants.

- Telecommunications: Shielded components for reliable high-frequency signal transmission.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- 耐腐食性: cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

特性 | cURL Too many subrequests. | アルミニウム | ステンレス鋼 | 銅 | チタン |

cURL Too many subrequests. | Fe-Ni-Co alloy | Al | Fe-Cr-Ni (varies) | Cu | Ti |

Thermal Expansion (ppm/°C) | 4.6–5.4 (at 30°C) | 23.1 | 17.3 | 16.5 | 8.6 |

加工性 | Moderate (special tools) | 高い | 中程度 | 高い | 低い |

Magnetic Properties | 磁性 | 非磁性 | Usually non-magnetic | 非磁性 | 非磁性 |

耐腐食性 | 良い | 優れている | 優れている | 良い | 優れている |

コスト | より高い | 低い | 中程度 | 中程度 | より高い |

We serve electronics, aerospace, medical, telecommunications, and optics with precision Kovar components.

We serve electronics, aerospace, medical, telecommunications, and optics with precision Kovar components.

We use carbide tools, high-pressure coolants, and precise CNC programming to manage work-hardening and heat buildup.

Yes, our 5-axis CNC and EDM achieve tolerances as tight as ±0.002 mm for demanding applications.

We offer rapid prototyping with lead times as short as 3 days, tailored to your project’s complexity.

よくある質問

Ready to Start Your Kovar CNC Machining Project?

無料見積もりのためにデザインをアップロードするか、チームと連絡してニーズを相談してください。