Choosing the right sheet metal bending technique shapes your project’s cost, quality, and speed. Imagine you need a precise part—should you focus on material, complexity, or production volume first? Material costs for metals like mild steel or aluminum can range from $0.70 to $5.00 per pound. Simple bends cost less than complex shapes, and high-volume runs can cut your per-part cost by over half. XTJ Precision Mfg helps you match your needs to the best process.

重要なポイント

- 適切な選択 bending technique affects your project’s cost, quality, and speed significantly.

- Air bending offers flexibility and low tooling costs, ideal for prototypes and small batches but less precise.

- Bottom bending provides higher accuracy and repeatability, suitable for medium to high production volumes.

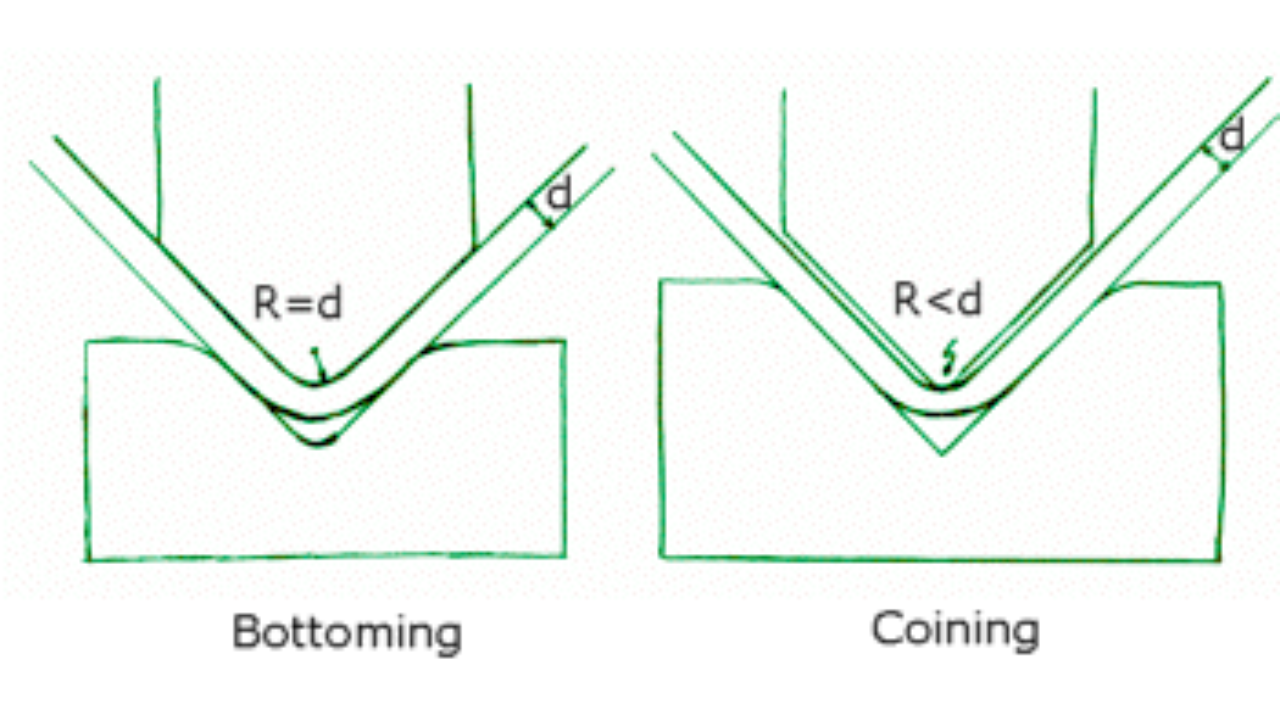

- Coining delivers the highest precision with minimal springback, best for high-volume, exact parts but requires costly tooling.

- Consider material type, thickness, and production volume when selecting a bending method to avoid defects and extra costs.

- Proper part design, including bend radius and grain direction, helps prevent cracks and ensures strong, accurate bends.

- Automation and skilled operators reduce errors, speed up production, and improve consistency in bending processes.

- Consult experts like XTJ精密製造 for complex projects or tight tolerances to choose the best technique and avoid costly mistakes.

Why Choice MattersCost and Quality

You make a big impact on your project’s cost and quality when you choose a bending technique. Each method uses different tools, machines, and labor. Some techniques need expensive tooling or skilled operators, while others work well with automation. If you pick the right method, you can save money and improve quality.

| 側面 | Evidence Summary |

|---|---|

| Cost Impact | Integrated strategies like Lean and Six Sigma have cut costs by 7% to 17% in real-world cases. Some projects saved from $50,000 up to $50 million. |

| Quality Impact | Most projects saw better quality, such as fewer mistakes, shorter wait times, and higher satisfaction. |

| Implementation Themes | Success depends on clear plans, good leadership, and skilled teams. |

| Barriers | Problems often come from poor training, weak data, or not enough support. |

| 結論 | The right strategy, like the right bending technique, leads to better cost and quality results. |

XTJ Precision Mfg helps you weigh these factors. Their team reviews your needs and recommends the best process for your goals.

リードタイム

Lead time means how long it takes to finish your parts. You want to avoid delays and keep your project on track. The bending technique you choose affects how fast you can move from design to finished product.

- Accurate lead time calculations help you estimate costs for materials, labor, and energy.

- Knowing lead times lets you plan for inspections and avoid defects.

- Good planning prevents bottlenecks and keeps your workflow smooth.

- Reliable lead time predictions help you deliver on time and keep customers happy.

XTJ Precision Mfg uses advanced planning tools. They help you pick a method that fits your schedule and keeps your project moving.

一般的な間違い

Mistakes in bending can waste time and money. You can avoid many problems by choosing the right technique and working with experts.

- Automation reduces human error and speeds up repetitive tasks.

- Regular maintenance and clear communication prevent breakdowns.

- Automated panel benders in the auto industry cut production time and labor costs.

- CNC machines improve accuracy and reduce errors in complex bends.

- Poor design, like cURL Too many subrequests., cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests..

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

プロセス

cURL Too many subrequests.

長所と短所

-

- 長所:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- 短所:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests., cURL Too many subrequests.

- 長所:

ヒント: Air bending helps you test how different materials behave. You can spot differences in bendability along the rolling and transverse directions.

Best Uses

- General 板金製作の両方を提供しています

- Projects that need flexible angles or quick setup

- Prototyping and low-volume production

制限事項

- Not ideal for parts that need very high precision

- You must watch for springback and adjust your process

- Material thickness and direction can change results

| Bending Technique | Key Characteristics | 利点 | Typical Tolerances | 用途 |

|---|---|---|---|---|

| cURL Too many subrequests. | Uses a punch and V-die; bend angle controlled by punch depth and die opening | Low tooling cost; flexible angle adjustments; reduced die wear; low tonnage | 該当なし | Versatile, general sheet metal fabrication |

Bottom Bending

プロセス

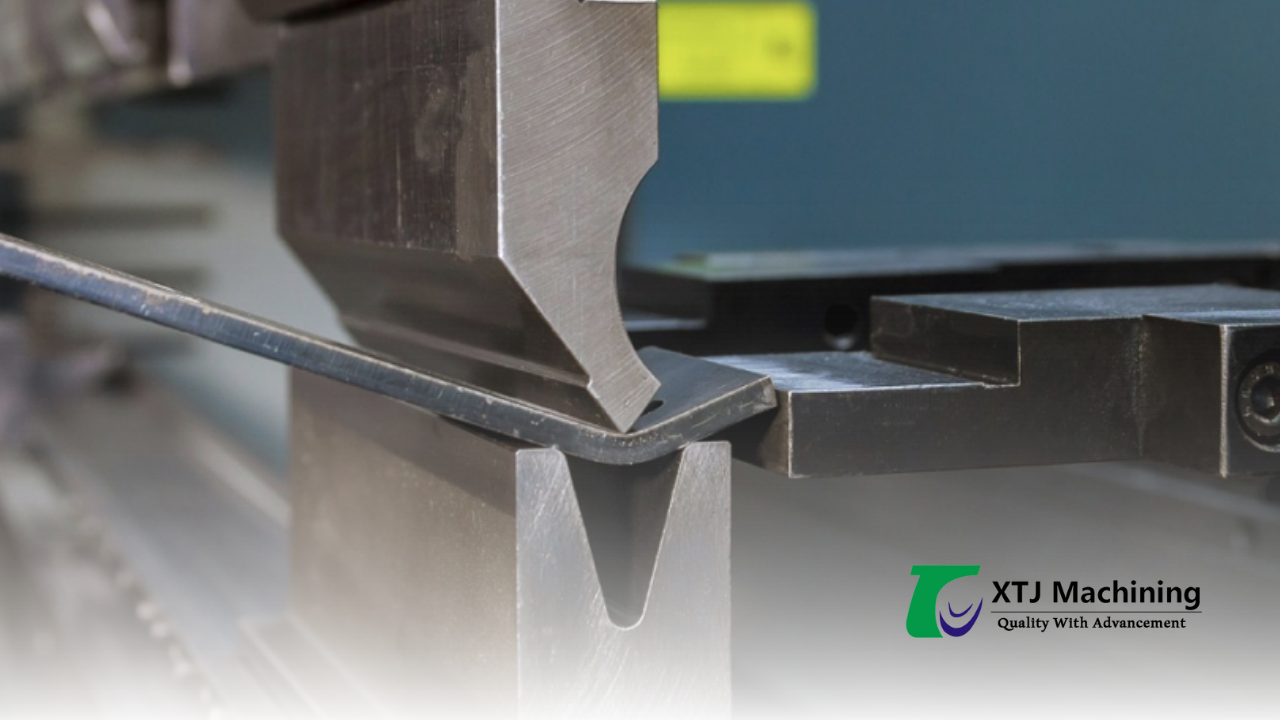

In bottom bending, you press the sheet metal all the way into the bottom of the V-die. The punch forces the metal to match the die angle exactly. You need more force than air bending, but you get a more accurate bend.

長所と短所

- 長所:

- You achieve higher precision and repeatability because the die sets the angle.

- Springback is much less than in air bending, so you get more reliable results.

- This method works well for parts that need tight tolerances.

- 短所:

- You need more force, which can increase machine wear.

- Setup takes longer, and you need a separate die for each angle.

- Tooling costs are higher than air bending.

- Bottom bending achieves precise bends by fully pressing material into the die, reducing springback.

- Key machine parameters like bending force, bending length, and die gap settings affect quality.

- Skilled operators and good procedures help you get the best results.

Best Uses

- High-accuracy parts

- Projects that need consistent, repeatable bends

- Medium to high production volumes

制限事項

- Not as flexible for changing angles

- Higher tooling and setup costs

- Requires careful die selection and setup

| Bending Technique | Setup Time | Force Requirements | Precision and Repeatability | Springback Effect | 用途 |

|---|---|---|---|---|---|

| Bottom Bending | Longer, less flexible | Moderate force to fully press material | Higher precision; consistent angles and tighter tolerances | Significantly minimized; angles more accurate and reliable | Ideal for high accuracy and repeatability needs |

Coining

プロセス

cURL Too many subrequests.

長所と短所

- 長所:

- cURL Too many subrequests. cURL Too many subrequests..

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- 短所:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

Best Uses

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

制限事項

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

| Bending Technique | Key Characteristics | 利点 | Typical Tolerances | 用途 |

|---|---|---|---|---|

| Coining | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | Precision parts, embossed features |

V-Bending

プロセス

You use V-bending when you want to create sharp angles in sheet metal. In this process, you place the metal sheet over a V-shaped die. A punch presses the sheet into the die, forming the desired angle. You can adjust the angle by changing the depth of the punch. V-bending works well for many materials and thicknesses.

長所と短所

- 長所:

- You can achieve a wide range of angles with one set of tools.

- Tooling costs stay low because you do not need a special die for each angle.

- The process is simple and quick to set up.

- You can use V-bending for both small and large production runs.

- 短所:

- Springback can affect the final angle, especially with thinner materials.

- You may see some variation in bend angles if material thickness changes.

- Surface scratches can occur if you do not use clean or well-maintained tools.

Recent studies show that V-bending gives you reliable results when you control key factors like punch depth and material type. Experiments and computer models confirm that you can predict and reduce springback by adjusting these parameters. For example, using optimized settings for materials like aluminum or mild steel improves accuracy and reduces errors to less than 1°. Incremental bending methods also help you achieve tighter tolerances and better efficiency.

Best Uses

- Making brackets, enclosures, and panels

- Projects that need different angles without changing tools

- Both prototypes and mass production

制限事項

- Not ideal for parts that require extremely tight tolerances

- Springback requires careful compensation, especially for thin sheets

- Surface finish may suffer if tools are worn or dirty

ヒント: Always check your material thickness and punch depth before starting V-bending. This helps you get the angle you want and reduces springback.

Folding

プロセス

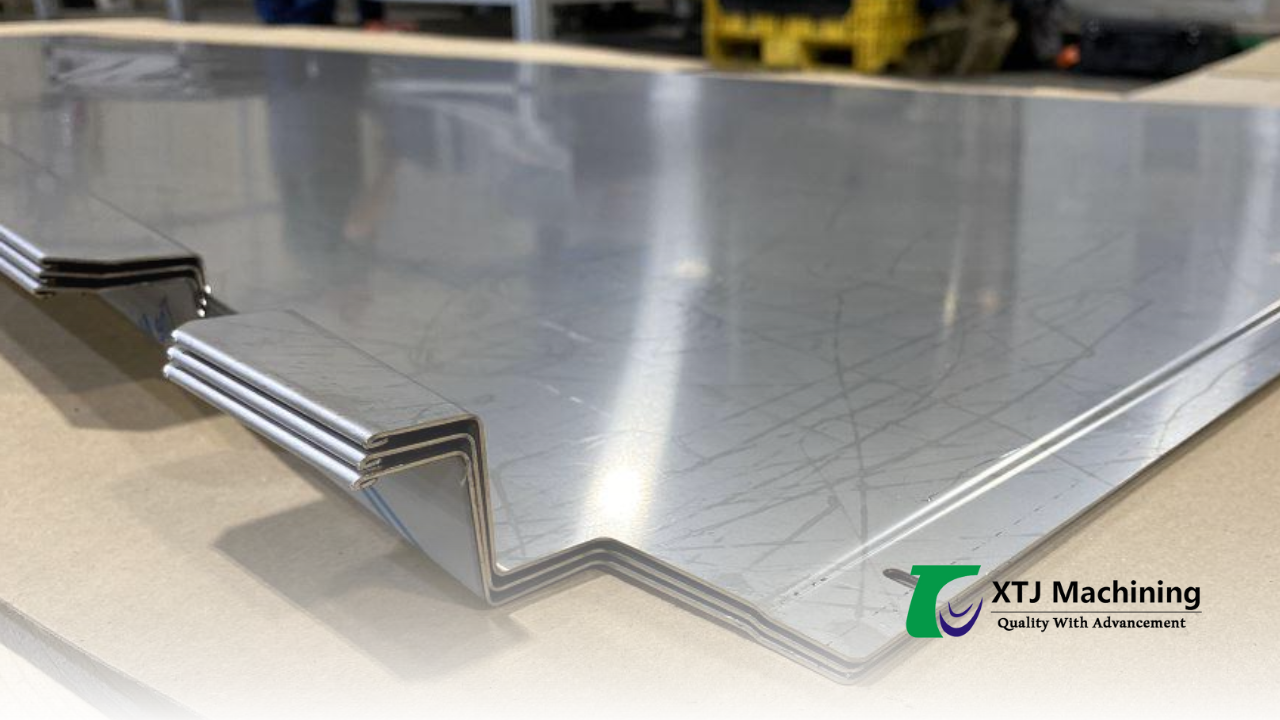

Folding uses a different approach from other bending methods. You place the sheet metal on a flat surface, and a clamping beam holds it in place. A folding beam then lifts or lowers the edge of the sheet to create the bend. You can fold up or down, which makes this method flexible for many shapes.

長所と短所

- 長所:

- You can bend large panels and long parts with ease.

- The process does not scratch or mark the surface as much as other methods.

- You can make complex shapes, including hems and closed profiles.

- Folding works well for thin and delicate materials.

- 短所:

- The machines can be expensive and take up more space.

- Folding is slower than press brake methods for high-volume runs.

- You may need skilled operators for complex folds.

Folding gives you smooth bends and protects the surface finish. You can use it for architectural panels, doors, and cabinets where appearance matters.

Best Uses

- Large sheet metal panels

- Parts that need a clean, scratch-free surface

- Architectural and decorative applications

制限事項

- Not suitable for very thick or hard materials

- Slower for high-volume production

- Machine size limits the maximum part length

注: Use folding when you want to avoid surface scratches and need to bend long or delicate sheets.

cURL Too many subrequests.

プロセス

cURL Too many subrequests.

長所と短所

- 長所:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- 短所:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. |

| Number of Passes | 50% more for ultra-high strength steels |

| Application Examples | Automotive A-pillars, roof rails, complex profiles |

| 制限事項 | Tight tolerances on large radii are difficult; higher loads needed for strong steels |

- Minimum bending radius depends on the method, wall thickness, and steel strength.

- Roll bending works best for round shapes and long curves.

- Always check with your bender to confirm achievable radii for your project.

Best Uses

- Cylinders, pipes, and curved panels

- Automotive parts like roof rails and structural tubes

- Large architectural features

制限事項

- Not ideal for tight angles or small, precise bends

- High springback with strong materials

- Needs skilled setup and regular maintenance

ヒント: Use roll bending for large, smooth curves and when you need to form high-strength materials into complex shapes.

Wipe Bending

プロセス

Wipe bending uses a punch and a wiping die to create a bend along the edge of a sheet. You place the sheet on the die. The punch presses down, forcing the sheet against the edge of the die. The die holds the main part of the sheet flat while the punch bends the free edge upward. This method forms a sharp, consistent angle along the length of the sheet.

ヒント: Wipe bending works best when you need a straight, uniform bend close to the edge of your part.

長所と短所

- 長所:

- You get fast, repeatable bends for high-volume production.

- The process works well for making flanges and hems.

- You can use wipe bending for both thin and medium-thickness metals.

- The setup is simple for standard bends.

- 短所:

- The process can cause surface scratches or marks, especially if you do not use proper die materials or lubrication.

- Springback is common, so you must adjust the punch angle to get the correct final shape.

- You cannot use wipe bending for very thick or hard materials.

- The method limits you to bends near the edge of the sheet.

| 側面 | 利点 | 欠点 |

|---|---|---|

| 速度 | Fast for high-volume runs | Less flexible for custom shapes |

| 表面仕上げ | Good with proper die/lubrication | Risk of scratches without precautions |

| 精度 | Consistent for simple bends | Springback affects accuracy |

| Material Range | Thin to medium sheets | Not for thick/hard metals |

Best Uses

You should choose wipe bending when you need to make:

- Flanges along the edge of panels

- Simple hems for reinforcement

- Enclosures and boxes with straight edges

- Automotive parts like brackets and mounting tabs

Wipe bending is common in industries that need many parts with the same bend, such as appliance manufacturing and automotive assembly.

制限事項

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

注: cURL Too many subrequests.

cURL Too many subrequests.

長所と短所

cURL Too many subrequests.

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Bottom Bending | cURL Too many subrequests. | cURL Too many subrequests. |

| Coining | cURL Too many subrequests. | cURL Too many subrequests. |

| V-Bending | Versatile, simple setup, works for many materials | Springback, surface scratches, angle variation |

| Folding | Great for large panels, protects surface, complex shapes | Slower for high volume, costly machines, size limits |

| cURL Too many subrequests. | Smooth curves, handles long/thick sheets, good for strong metals | Hard to get tight tolerances, high springback, needs skill |

| Wipe Bending | Fast for edges, repeatable, good for flanges | Surface marks, springback, only near edges |

ヒント: Always match your technique to your part’s shape, size, and finish needs. This helps you avoid costly mistakes.

Quick Reference

You can use the next table as a quick reference when you need to compare key features. This table shows you the advantages, precision, tooling, and best uses for each method. It helps you make fast, informed decisions.

| cURL Too many subrequests. | 主な利点 | 精度レベル | Tooling Requirements | 代表的な用途 | Notes |

|---|---|---|---|---|---|

| cURL Too many subrequests. | Flexible, low cost | 中程度 | Simple punch and die | Prototyping, small to medium runs | Some springback expected |

| Bottom Bending | Accurate, repeatable | 高い | Specific die for each angle | High-accuracy, repeatable parts | Less flexible for angle changes |

| Coining | Very precise, strong bends | 非常に高い | Complex, expensive tooling | High-volume, precision parts | Needs high tonnage, not for thick metals |

| V-Bending | Versatile, common method | Moderate-High | Standard V-die | Wide range of parts | Good for many materials |

| Folding | Large, complex panels | 高い | Folding beam and clamp | Architectural, decorative, large sheets | Protects surface, short flanges |

| cURL Too many subrequests. | Smooth curves, long parts | 中程度 | Three rollers | Cylinders, pipes, automotive parts | Needs skill, more passes for hard metals |

| Wipe Bending | Fast, repeatable for edges | 中程度 | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests..

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

| 要素 | cURL Too many subrequests. | cURL Too many subrequests. | Coining |

|---|---|---|---|

| 材料タイプ | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| 生産量 | cURL Too many subrequests. | 中程度 | 高い |

| Tooling Cost | 低い | 中程度 | 高い |

| Precision (Angle) | ±0.5° | ±0.3° | cURL Too many subrequests. |

| Required Tonnage | 低い | 中程度 | 高い |

Material composition and thickness also affect cutting and bending quality. For example, aluminum’s high thermal conductivity changes how it bends. Stainless steel can form heat-affected zones. Thicker sheets need more power and special equipment. If you choose the right method, you get better results and avoid costly mistakes.

Research shows that thickness changes bending performance. In one study, thicker fabrics and higher yarn density increased bending damage. Another test found that thicker resin samples had higher bending resistance. These findings prove that thickness matters for strength and quality.

XTJ精密製造 reviews your material and thickness before recommending a process. Their team checks if your metal and sheet size match the best bending method.

Precision Needs

Precision matters most when your parts have tight tolerances or complex shapes. Some projects need angles accurate to within a fraction of a degree. If you use a low-precision method, your parts may not fit or function as needed.

Statistical tools like Measurement Systems Analysis and error propagation help you measure and control precision. These tools identify where errors come from and help you improve accuracy. Advanced measurement systems can even detect tiny features smaller than a pixel. This technology is important for small, complex parts.

In large projects, like wind towers, you must keep deviations within a few millimeters. Manual measurements often lead to errors. High-precision machines and careful calibration ensure your parts meet strict standards.

XTJ Precision Mfg uses advanced measurement and calibration tools. They help you choose a bending method that matches your accuracy needs.

ヒント: If your design has tight tolerances, always ask for a high-precision bending method.

Volume and Speed

Production volume and speed affect which bending method works best for you. If you need thousands of parts, you want a fast, repeatable process. For small batches or prototypes, flexible methods with low setup costs save you money.

Short run charts track how bending angles change over time. These charts show that some methods have more variation and need more checks. High-volume production benefits from automated machines and stable processes. Low-volume runs can use manual or flexible setups.

- High-volume: Coining and automated bending give you speed and consistency.

- Low-volume: Air bending and folding offer flexibility and lower costs.

- Medium-volume: Bottom bending balances speed and accuracy.

XTJ Precision Mfg asks about your production goals. They help you pick a method that fits your timeline and budget.

If you need fast turnaround, tell your supplier your volume and speed needs up front.

Part Design

You need to think carefully about your part design before you choose a bending technique. The way you design your part affects how well it can be made and how it will perform. If you ignore key design rules, you may face problems like cracks, misalignment, or costly rework.

Accurate setback calculations are essential. Setback is the distance you allow for the bend, and it depends on bend radius, material thickness, and properties like tensile strength and ductility. For example, aluminum needs a larger setback because it springs back more than steel. If you do not account for springback, your parts may not fit together as planned.

You should also consider the cURL Too many subrequests.. cURL Too many subrequests.

公差 cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

XTJ精密製造 cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.. cURL Too many subrequests. cURL Too many subrequests.. cURL Too many subrequests.

| 側面 | cURL Too many subrequests. | cURL Too many subrequests. |

|---|---|---|

| cURL Too many subrequests. | cURL Too many subrequests. | cURL Too many subrequests. |

| Bend Radii Standardization | Use bend radii proportional to material thickness (e.g., 1x for aluminum) | Prevents cracking, improves tooling efficiency |

| Grain Direction | Bend perpendicular to grain when possible | Reduces risk of cracking, improves strength |

| K-Factor Values | Use correct K-factor for thickness (e.g., 0.4 for 0.5 mm, 0.5 for 2 mm) | Ensures accurate flat patterns |

| 公差 | Keep bends within +/- 0.010 inches; radius tolerance +/- 1.0 | Ensures parts fit, reduces rework |

| Software Tools | Use CAD with bend checks, unfolding, and simulation | Improves accuracy, reduces errors |

| Assembly Design | Minimize part count, standardize fasteners, use pilot holes | Reduces assembly time, improves manufacturing ease |

| Documentation | Record standard bend radii, K-factors, grain direction | Provides clear instructions, reduces mistakes |

Tip: Always review your checklist before starting production. This step saves time and prevents costly errors.

Example Scenarios

You can learn from real-world scenarios to choose the best technique for your needs. The table below shows how different approaches lead to better outcomes:

| Scenario Context | Production Focus | Techniques Used | Outcomes / Benefits |

|---|---|---|---|

| New Product Launch | Assess feasibility and risks | Scenario analysis | Helps plan resources, adjust budgets, and reduce risk |

| Manufacturing Project Management | Optimize resource allocation | Scenario analysis, ROI comparison | Supports decisions on project timing, outsourcing, or hiring based on simulated results |

| Strategic Planning | Prioritize under constraints | Scenario simulation | Guides facility expansion or upgrades based on demand and regulations |

- Monte Carlo simulation helps you predict possible outcomes and manage risks.

- Cross impact analysis shows how one change affects other parts of your project.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. XTJ精密製造 cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests..

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

- The decision guide and comparison table help you plan with confidence.

XTJ Precision Mfg supports you with expert advice. The right choice saves time, lowers costs, and ensures quality.

よくある質問

What is the most cost-effective sheet metal bending technique?

You often find air bending the most cost-effective. It uses less force and simple tooling. You can adjust angles easily. This method works well for prototypes and small batches.

How do I reduce springback in my bends?

You can reduce springback by choosing coining or bottom bending. These methods use higher force and set the angle more precisely. Adjusting punch depth and using the right material also helps.

Which technique should I use for high-precision parts?

You should use coining for high-precision parts. This method gives you tight tolerances and almost no springback. It works best for large production runs where accuracy matters most.

Can I bend thick or high-strength metals?

You can bend thick or high-strength metals with roll bending or bottom bending. These methods handle more force. Always check your machine’s capacity before starting.

What is the best way to avoid surface scratches?

You should use folding or well-maintained tools to avoid surface scratches. Clean dies and proper lubrication also help. Protecting the sheet during handling keeps the finish smooth.

How do I choose the right bending technique for my project?

Start by listing your material, thickness, part design, and volume needs. Use the comparison table above. If you feel unsure, consult an expert like XTJ精密製造 for guidance.