Project Overview

A high-cosmetic aluminum chassis front panel featuring a large central cutout, thin surrounding walls, and stringent appearance requirements: full-perimeter mirror-finish high-gloss chamfer, bright silver anodizing, partial horizontal brushing, and conductive anodizing on inner bores. Parts of this type are extremely prone to distortion, tool marks, and inconsistent highlight brightness due to the combination of large size (407 mm) and minimum wall thickness of only 1.8 mm.

(XTJ – 20-year Shenzhen source factory | Prototypes in 5 days | Production ±0.01 mm | Free DFM + quote in 30 mins → [email protected])

Product Structure and Dimensions

Structural Features

- The product serves as an aesthetic and functional exterior part, featuring a central hollow design for weight reduction and assembly ease, along with multiple threaded holes for secure fastening.

- To meet demanding appearance standards, we incorporate post-machining treatments: high-gloss chamfering on edges for a polished look, horizontal brushing on specific faces for texture, conductive treatment on diameter surfaces for electrical performance, and overall high-brightness silver anodizing for durability and shine.

Key Dimensions

- Length: 407 mm

- Width: 259 mm

- Thickness: 15 mm (adjusted from original notations to standard machining units for clarity)

- Wall Thickness: 1.8 mm

These dimensions demand precise control to avoid deformation, which is where our expertise at XTJ shines—ensuring tolerances are met while optimizing for material efficiency.

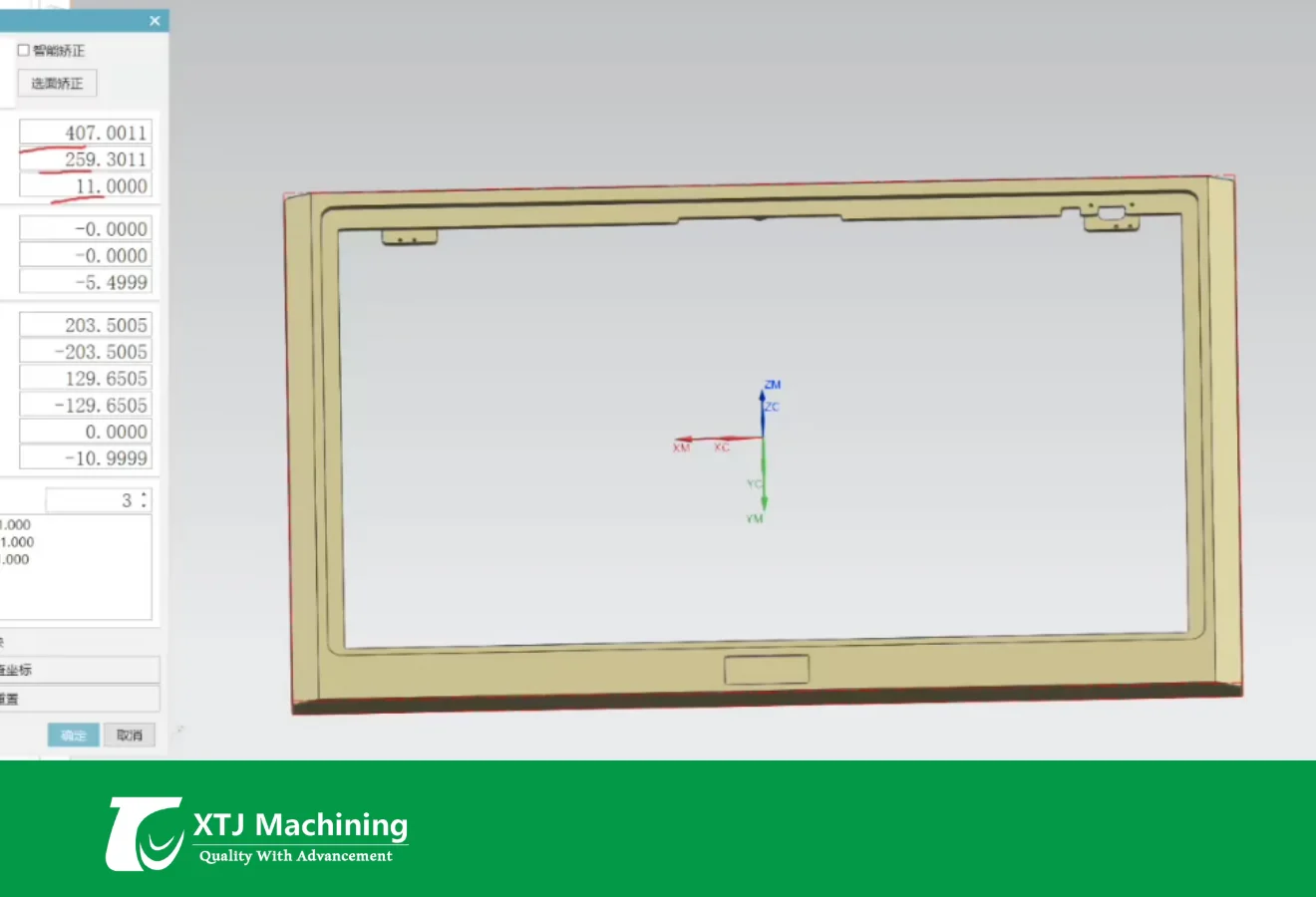

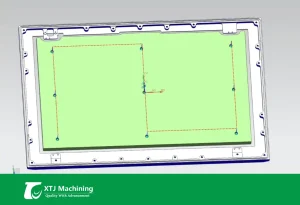

Process Planning and Programming

Drawing on our in-house UG software capabilities, we start with thorough planning to transform client concepts into manufacturable realities.

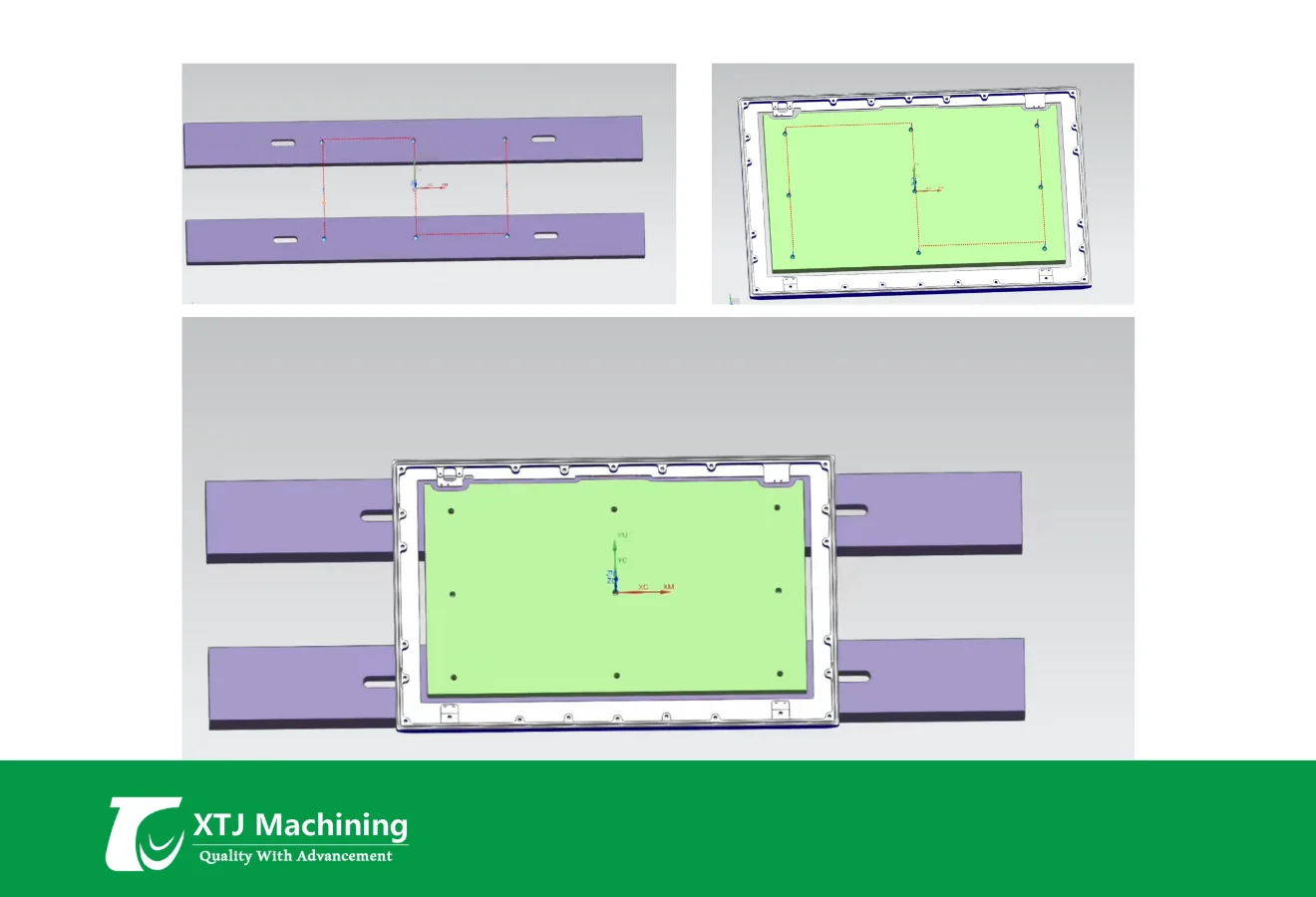

Blanking and Drawing Processing

- Blanking Dimensions: Given the product’s 400 mm length and need for central hollowing with fly cutter roughing, we select a blank size of 415 mm (length) × 270 mm (width) × 15 mm (thickness) to provide ample margins for secure fixturing and waste removal.

- Drawing Conversion: Without a provided 3D model, our engineers use 2D drawings in UG to extrude a precise 3D representation. We meticulously manage bidirectional dimensions, resolving potential conflicts in features like sealing grooves (e.g., reducing size and depth) to maintain integrity and avoid rework.

This step exemplifies our commitment to proactive problem-solving, turning incomplete inputs into seamless production plans.

Surface Treatment Requirements

- Diameter Surfaces: Conductive treatment for enhanced functionality.

- Overall: High-brightness silver anodizing for corrosion resistance and visual appeal.

- Edges: High-gloss chamfering to eliminate sharp edges and add premium finish.

- Specific Faces: Horizontal brushing for a sophisticated, non-slip texture.

At XTJ Precision Mfg, we integrate these treatments into our workflow, partnering with certified vendors to achieve consistent results that elevate product performance.

機械加工プロセス

Our state-of-the-art CNC centers handle the full spectrum of operations, from initial setup to final inspection, minimizing lead times while maximizing accuracy.

Pre-Preparation

- Process Screw Holes Machining: Utilizing the central waste area, we machine M6 screw holes directly into the material for robust plate locking. We also prepare a matching base plate with countersunk holes, ensuring stable fixation throughout processing.

This custom fixturing technique is a staple in our operations, preventing shifts and deformations in thin-walled parts.

Main Machining Operations

First Operation

- Back Side Processing: Once secured with screws, we fly face the back side to expose a clean surface. Inner cavity roughing leaves 0.7 mm on side walls, while outer contour roughing retains 1 mm. With the original 15 mm thickness, we leave 2 mm at the bottom, yielding a 13 mm interim thickness.

- Secondary Roughing: A 4 mm tool performs follow-up roughing for refined material removal.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.