Understanding Robot Parts Machining Essentials for Buyers

When it comes to robot parts machining, precision is everything. Robots rely on critical components like gears, actuators, and chassis parts that must fit and function perfectly. Even minor deviations can cause performance issues or failures in robotics systems.

Critical Components and Why Precision Matters

- Gears and actuators need tight tolerance machining to ensure smooth motion and durability.

- End effectors and sensor mounts require flawless dimensions to interact correctly with objects.

- Robot chassis parts must be strong and precise for structural integrity and reliability.

Core Machining Processes and Technology

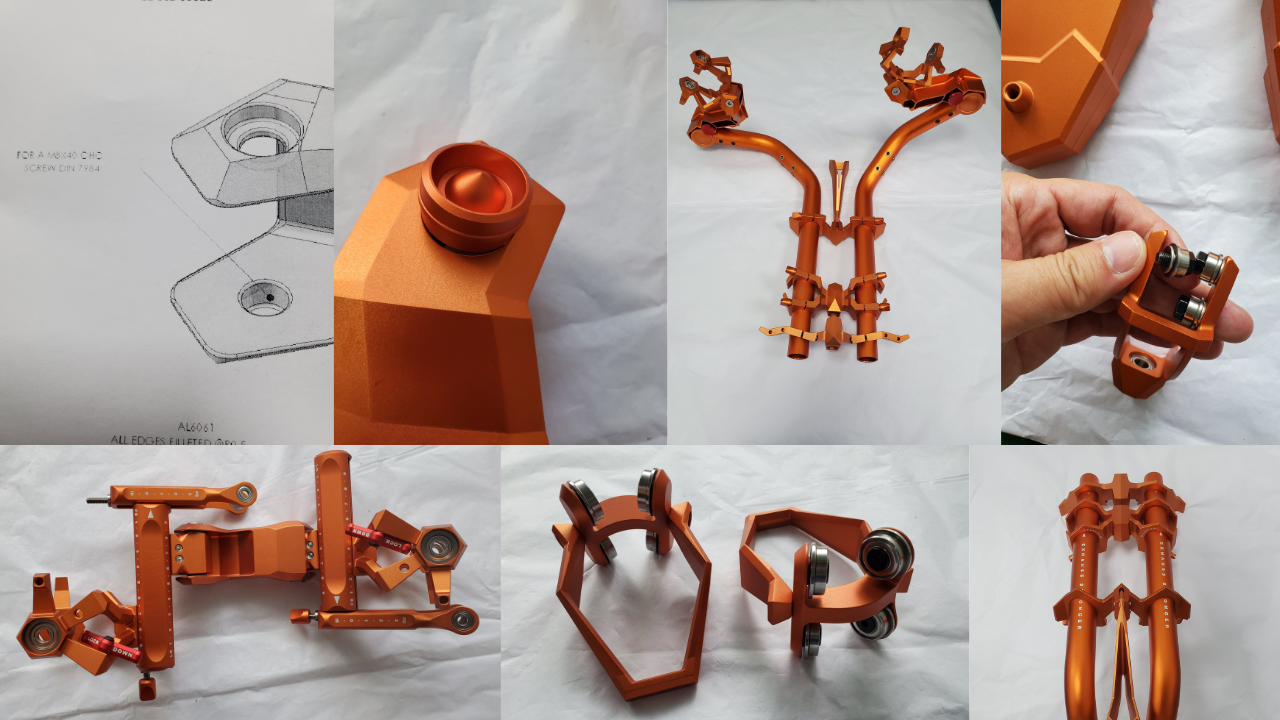

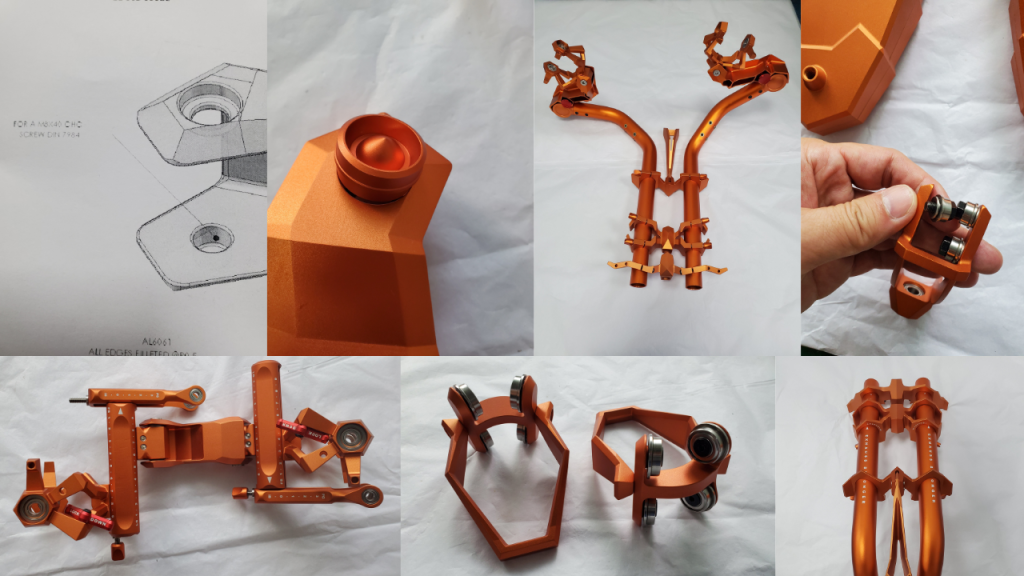

- CNC加工 (especially 5-axis) is the industry standard, offering high precision and complex shapes.

- Additional methods like 板金製作の両方を提供しています help shape lightweight parts like robot arms and end effectors.

- Advanced tech like 迅速なプロトタイピング accelerates development cycles for custom robotic parts fabrication.

Material Selection and Relevance to Robotics

Materials must balance strength, weight, and wear resistance:

- チタン and high-grade aluminum alloys are common for lightweight, durable robot parts.

- Stainless steel suits heavy-duty components requiring corrosion resistance.

- Plastics or composites may be used for insulation or non-load bearing parts.

Local Supplier Advantages and Lead Times

Working with local robot parts machining suppliers offers clear benefits:

- Faster turnaround times reduce development and repair cycles.

- Easier communication means better quality control and customization.

- Shipping costs and delays drop significantly.

Understanding these essentials helps buyers select the right machining partner for reliable, high-quality robotic components.

Key Criteria for Choosing Robot Parts Machining Suppliers

When picking a robot parts machining supplier, you want to be sure they can meet your exact needs without hiccups. Here’s what to focus on:

Precision and Tolerance Standards

Robot parts demand tight tolerances—often in the micron range. Look for suppliers using advanced CNC machining for robotics, like 5-axis CNC machines, that can maintain these strict precision levels. High-tolerance robot gears machining and actuator components need this accuracy to work flawlessly in your robots.

Certifications and Quality Assurance

Choose suppliers with industry-standard certifications such as ISO-certified robotics machining services. These ensure consistent quality and compliance with safety standards. Reliable quality control processes, like in-process inspections and final part testing, show a supplier’s commitment to excellence.

Scalability and Turnaround Speed

Your supplier should handle small prototype runs and scale up to larger production volumes without delays. Rapid prototyping for cobots and quick adjustments in fabrication mean faster time to market. Also, suppliers with local facilities in the US reduce lead times and shipping issues.

Cost-effectiveness and Sustainability

While price matters, it shouldn’t compromise quality. Find suppliers who balance competitive pricing with durable materials and eco-friendly practices—like sustainable machining and waste reduction. This helps keep your costs in check and supports greener manufacturing.

Supplier Vetting Checklist

- Confirm their experience with custom robotic parts fabrication and industrial robot actuator manufacturers

- Verify precision machining capabilities (e.g., titanium robot parts prototyping)

- Check reviews or case studies showing on-time delivery and part accuracy

- Evaluate communication and customer service responsiveness

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests. XTJ cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

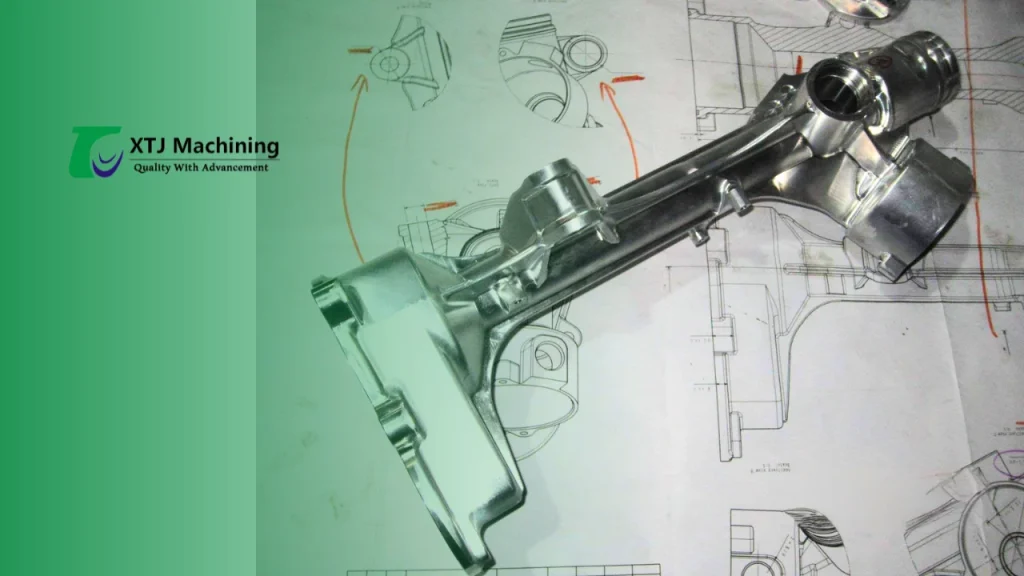

1. XTJ精密製造

強み: cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

長所: Fast turnaround, ISO-certified quality, strong local US support.

短所: Premium pricing on niche services.

2. RoboFab Solutions

強み: Specializes in industrial robot actuator manufacturing with advanced AI-driven machining optimizations.

cURL Too many subrequests. CNC machined robot joints, actuator housings.

長所: Innovative tech, good scalability.

短所: Longer lead times for custom jobs.

3. Precision Robotics Inc

強み: CNC machining for robotics with a focus on sustainability and eco-machining processes.

cURL Too many subrequests. Lightweight aluminum frames, robot chassis components.

長所: Cost-effective, environmentally conscious.

短所: Limited to certain materials.

4. Apex Robot Components

強み: Rapid prototyping for cobots with hybrid manufacturing, combining CNC and 3D printing.

cURL Too many subrequests. Custom cobot grippers, prototype gears.

長所: Great for fast development cycles.

短所: Higher cost for prototypes.

5. Titan Machining Works

強み: Titanium robot parts prototyping and high-strength CNC cutting.

cURL Too many subrequests. Titanium arms, structural brackets.

長所: Durable parts, top materials.

短所: Niche market, not as scalable.

6. Midwest Machining

強み: Local US supplier focused on short lead times, sheet metal fabrication for end effectors, and cost-effective machining.

cURL Too many subrequests. Sheet metal robot covers, end effector housings.

長所: Local presence, budget-friendly.

短所: Limited advanced tech.

7. NextGen Robotics Fabricators

強み: ISO-certified with emphasis on precision and tight tolerances.

cURL Too many subrequests. Precision gears, actuator components.

長所: High-quality parts, full certification.

短所: Slightly higher costs.

8. Dynamic CNC Services

強み: Broad CNC machining range, including Kovar and specialty alloys for robotics.

cURL Too many subrequests. Specialty alloy parts, motor mounts.

長所: Material expertise, versatile machining.

短所: Average turnaround time.

9. Fusion Robotics Machining

強み: AI-driven maintenance optimization for machining processes, reducing costs.

cURL Too many subrequests. Maintenance-ready robotic parts, modular components.

長所: Cost-saving, innovation-driven.

短所: cURL Too many subrequests.

cURL Too many subrequests.

強み: cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.

長所: cURL Too many subrequests.

短所: cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests., cURL Too many subrequests.

- cURL Too many subrequests. 迅速なプロトタイピング cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. like titanium or specialty alloys.

This list aims to help US buyers quickly assess the top suppliers based on your robotics project’s precision, scalability, and innovation needs. For more on machining processes and how to ensure the smoothness of your CNC parts, check this guide on improving CNC machining smoothness.

Emerging Trends and Innovations in Robot Parts Machining

The world of robot parts machining is evolving fast, driven by new tech and changing demands. Here’s what’s shaping the future right now:

Hybrid Manufacturing Combining CNC and 3D Printing

Manufacturers are blending traditional CNC machining with 3D printing to get the best of both worlds. CNC offers unmatched precision for high-tolerance robot components, while 3D printing allows rapid prototyping and complex shapes that were once impossible. This hybrid approach speeds up production, cuts costs, and makes custom robotic parts fabrication more flexible. If you want to understand more about the limits of 3D printing, check out the disadvantages of 3D printing.

AI-Driven Design and Maintenance Optimization

Artificial intelligence is making waves in robot parts machining. AI tools help refine design processes and predict maintenance needs, minimizing downtime and improving reliability for industrial robot actuator manufacturers. This means parts can be optimized for longer life and better performance before production even starts.

Focus on Sustainability and Eco-Machining

Eco-friendly machining practices are becoming a priority. Suppliers are reducing waste, recycling materials, and using energy-efficient machines to deliver sustainable CNC machining for robotics. This aligns well with the green initiatives many US-based companies now expect from their suppliers.

Future Demands from Collaborative Robots

Collaborative robots (cobots) demand new kinds of precision parts that are lightweight but durable—think titanium robot parts prototyping and advanced sheet metal fabrication for end effectors. As these cobots become more common in industries, suppliers need to innovate around speed, scalability, and custom solutions to support evolving robotics needs.

Keeping these trends in mind will help buyers stay ahead and choose suppliers that are ready for what’s next in robot parts machining.

How to Get Started Partnering with a Supplier Like XTJ Precision Mfg

Getting started with XTJ Precision Mfg for your robot parts machining needs is straightforward and designed to save you time. Here’s a simple step-by-step guide:

-

Project Submission

Share your designs or specs through XTJ’s online portal or email. Clear drawings, tolerances, and materials info help speed up quotes and production.

-

Quote and Approval

XTJ provides a detailed, transparent quote quickly. Review costs, timelines, and any suggestions, then approve to move forward.

-

Production and Updates

Once approved, machining starts with real-time progress updates. XTJ keeps you in the loop from raw material sourcing to final inspection.

-

Delivery and Support

Finished parts arrive on time with full quality reports. XTJ offers after-sales support for any issues or future needs.

Common Pitfalls and Supply Chain Tips

- Avoid vague design specs that slow down quoting and raise costs.

- Plan ahead to account for machining lead times and possible supply chain delays.

- Communicate openly about changes or urgency to prevent surprises.

- Confirm certifications and material traceability, especially for aerospace or medical robotics.

XTJ Specific Services and Integrations

- Custom prototyping with rapid turnaround for quick testing.

- Advanced 5-axis CNC machining tailored for high-precision robot components.

- Integration with your supply chain software for smooth project tracking.

- ISO-certified quality control processes ensuring each part meets strict tolerance standards.

Ready for a quote?

If you need reliable, precision robot parts machining, reach out to XTJ精密製造 today. Submit your project and let their experts handle the rest, helping your robotics projects stay on schedule and within budget.