CNC Milling is a high-precision industrial technology used to fabricate parts from a variety of materials, from metal to plastic. The computer numerical control milling machines are equipped with programs for automated cutting and computer-controlled servo systems that guide the machine to cut a workpiece at the exact desired location in a smooth and precise manner. The automotive, aerospace, medical and more industries have all been revolutionized by the high precision and consistent results that this type of machining provides.

In order to perform CNC milling, a variety of tools are required, including a CNC milling machine, computer software, and raw materials. The following article will provide you with an in-depth guide to the CNC milling process.

What is CNC Milling and How Does it Work?

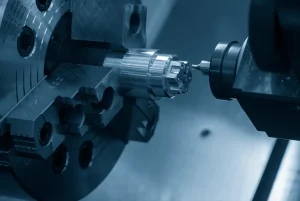

CNC milling is a computer-controlled machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is usually mounted on a spindle and moves in a linear or circular motion while the workpiece is mounted on a table and is fed into the cutting tool.

CNC machines are operated by computer programs that tell the machine what to do. The programs are written in CNC languages, which are similar to regular programming languages but with a few differences. The most common one is G-code. These programs tell the machine how fast to move, what direction to move in, and when to stop. Most machines will have many more options than just these simple ones. Some machines have a touch screen that shows the program on the screen instead of writing it down and is used to edit the program if mistakes are made.

CNC milling machines can perform a variety of milling operations, including end milling, face milling, and slot milling. End milling is a versatile and powerful process, capable of cutting slots, shoulders, flats, and complex 3D shapes. Face milling on the other hand is used to produce a wide variety of flat surfaces on workpieces with large diameters. While slot milling can be used to create grooves and pockets in workpieces for mating components and other purposes. We’ll discuss these types of CNC milling operations in more detail in the following paragraphs.

The Different CNC Milling Operations

There are a variety of different CNC milling processes, each of which can be used for different applications. Here is an overview of the most common CNC milling processes.

Turn Milling

Turn-milling is a versatile machining operation in which a workpiece is held in a chuck and rotated while a milling cutter is fed into it as it proceeds by removing material. The amount of material removed can be controlled by the feed and speed rate of the milling cutter.

This type of CNC turning operation consists of two steps that can be repeated multiple times on the same part while using different tooling in each one of them. The first step is to turn the workpiece on a lathe which creates the cylindrical shape, and the second is the milling of the piece and creating the desired product.

The rotation during the turn-milling process creates a helical path which makes the shape of the cutting edge of the cutting tool best suited to the respective milling operation. It is used to create threads, grooves, and other internal features on a workpiece.

Chamfer Milling

Also referred to as chamfering, it is the process of a small angled cut of material from the edge of a workpiece to achieve a gentle surface called a chamfer. As a result, the two-dimensional chamfer develops a series of angles creating a smooth surface which is generally used to prepare the edges of a workpiece for welding or brazing.

This type of CNC milling process is useful in a wide array of applications and industries. Chamfer milling tools give boards and other materials a smooth, curved edge – perfect for any architectural, engineering, or carpentry project. The medics and electronic engineers are also on hand to create safe and smooth angled edges on the components.

There exist various types of chamfer milling, some of the most common are Square Corner Milling, Outside Corner Milling, Inside Corner Milling, Flat Bottom Milling, and Chamfer Face Milling.

Slot Milling

Slot milling is a type of CNC milling operation where a rotating cutting tool is used to remove material from a workpiece by moving it in and out of a slot. It is specifically used to create keyways, slots, or pockets.

What differentiates it from the other types of CNC milling operations is its ability to cut deeper slots or pockets than what can be achieved with end milling for example. In addition to that, this CNC milling process often results in a cleaner and better surface finish.

Slot milling cutting tools are incredibly versatile. With multiple teeth mounted in a circular pattern on a spindle, they can machine solid-jaw mandrels, guide bars, and flat parts from metal stock. Not only that but they can also cut grooves and recesses, score and cut, drill holes, make round holes, form rectangular, square, and hexagonal slots and pocket openings, and mill the faces of pins and dowels.

Profile Milling process

Profile milling is a CNC machining process used to create intricate three-dimensional surfaces on a workpiece. This tool can be used to create features such as slots, pockets, and contours. The milling operation is generally performed by a multi-axis milling machine that has a milling cutter rotating around the workpiece. The cutter carves through the material, following the tool path as it moves.

Profile milling can be used for three main types of operations:

Roughing

Roughing operations are intended to downsize the thickness of stock in large enough sections to remove excess material from inside or outside of the part. The holes on the face of the workpiece require an end mill that cuts on the periphery or the side of the cutter. The mill that is commonly used in this type of operation is the “peripheral end mill.”

Semi-finishing

Center-cutting tools are used on semi-finishing machines to cut around the holes where they will be located. This allows for more precise placement of the holes before the semi-finishing tools cut the parts.

Afwerking

It is the process of reducing the amount of material removed in roughing, making way for the finishing operations. And it is usually performed using a small finishing end mill. Different machines should be used for roughing and finishing, and an optimized cutting tool should be used for each operation to achieve more precise results.

Face Milling

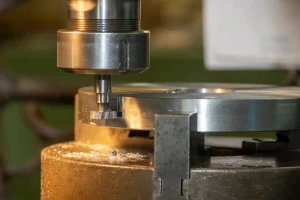

Face milling is the process of machining flat surfaces on a workpiece. A face mill cuts flat surfaces on the workpiece by feeding the workpiece against a rotating cutter with many cutting edges. This is different from drilling, where only one hole is created at a time.

Face milling consists of four steps:

- Before you can start face milling, you need to prepare and set up your material on a vertical milling machine. The workpiece must be secured firmly to the table of the machine to ensure a precise and successful operation.

- Vervolgens moet u de spil van de machine zo positioneren dat deze loodrecht op het oppervlak van het werkstuk staat.

- After properly positioning the cut, you will then adjust the feed. The pace of the headstock is also adjusted to perform a proper cut. The feed can be adjusted by the external spindle handles.

- You can then finally process by machining. In order to produce the desired form and shape of the workpiece, it is necessary to make multiple passes with the cutter. The final product will be cut along the bottom of the pattern that you drew. You will produce multiple cuts before achieving the desired result.

Schouderfrezen

Shoulder milling is a type of CNC milling operation in which the cutter is mounted on a spindle and cuts along the perimeter of the workpiece. The cutter is usually stationary and the cut is completed by tilting the tool spindle along a straight vertical axis. The most common shoulder angle is 90 degrees, but other angles may be used depending on the application.

The purpose of a shoulder CNC milling machine is to produce flat, angular surfaces on the workpiece. What makes a shoulder mill cutter ideal for this job is the need for constant access to the workpiece surface and cutting tools. In contrast to chucking, the milling process cuts in a zigzag pattern rather than in a straight line.

Other CNC Milling Operations

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Angular Milling

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Veelgestelde vragen

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.