A CNC axis machine is a computer-controlled device that moves along linear or rotary axes to perform various tasks, such as cutting or drilling. How many axes are there exactly? The standard answer says that a CNC machine has typically three axes: the X-axis, the Y-axis, and the Z-axis. These axes correspond to the movement of the machine’s tool in the corresponding direction. However, some CNC machines may have more or fewer axes, depending on their design.

In fact, there are a variety of different types of CNC axis machines. Each machine has its own specific purpose and benefits. Some machines are designed for large-scale projects, while others are smaller and more versatile.

In this article, we will explore in detail the different types of CNC axis machines and their uses.

The 2-Axis CNC Machine

A 2 axis CNC machine is a computer numerical control machine that has two axes of movement which are typically the x-axis and the y-axis. It can be used to create a variety of parts and objects with precise accuracy. The 2-axis machine can cut and drill machine parts. It can also be used to engrave various materials, including wood, plastic, and metal. This type of CNC lathe enables you to create a lot of different parts and products, anything from simple ornaments to complex designs that make interesting and complex art.

The Applications of 2-Axis CNC Machining

2-axis CNC machining is widely used in many industries, such as the automotive industry (producing parts for engines, transmissions, and other components), the aerospace industry ( aircraft engines, landing gear,…etc.), the medical field (producing parts for medical devices, such as pacemakers, hearing aids, and artificial joints), and consumer electronics production (parts for televisions, stereos, DVD players, and digital cameras).

The Advantages of a 2 Axis CNC Machine

A 2-axis CNC is a very useful machine to have in one’s workshop. It provides numerous benefits including:

1. Improved accuracy and precision in manufacturing.

A two-axis CNC machine can be used to produce more complex shapes and mechanical components than a traditional manual lathe or mill, making it a more versatile tool for manufacturing.

2. Reduced time to make complex parts.

This type of CNC machining can quickly produce complex parts that would be difficult or impossible to create with traditional methods.

3. Increased repeatability of finished parts.

The CNC machined parts we get using this type of machine are more consistent in terms of size and shape, which can be important for applications that require precise measurements.

4. Increased range of materials that can be cut.

The 2-axis machines can cut more complex shapes and are better suited for tasks such as engraving.

5. Faster removal of waste parts.

A CNC two-axis machine tool can quickly remove waste parts from a workpiece, which can speed up the manufacturing process.

The Cost of a 2-Axis CNC Machine

The cost of owning and managing a two-axis CNC machine varies depending on the type, size, features, and location in which it will be operated and stored. These machines generally cost more than manual milling machines, but they make an excellent investment.

Learn more about 2 Axis CNC Machining in this Ultimate Guide

3-axis CNC Milling Machines

3-axis CNC mills operate on the same basis as their fellow 2-axis mills, but an additional linear movement is included for use with other tools such as laser engravers, polishers, and more. A 3-axis mill consists of two independent rotational axes and one linear axis. A mechanical or electrical linkage connects the three axes and allows the cutting tool to rotate along each axis.

A 3-axis CNC machine moves along three axes:

- Z-axis: perpendicular to the cutting tool, it adjusts the Z-feed so the latter can cut along the face of a workpiece.

- X-axis: parallel to the cutting tool, it allows the milling head to move along the length of the workpiece as well as across the workpiece.

- Y-axis: perpendicular to the cutting tool, enabling the milling head to move on a workpiece from end to end.

The Uses of 3-Axis CNC Machining

Just like the 2-axis machine, the 3-axis is used in a variety of industries, including aerospace, automotive, medical, and manufacturing. By using this type of CNC technology, different industries’ manufacturers are able to create complex shapes and components that are precise and durable.

The Benefits of Using a 3-Axis CNC Machine

The main advantage of a 3-axis CNC machine is the greater control over motion and more accurate positioning. Many can cut and drill up to 4 inches of metal in a single pass, or machining operations can be carried out at previously unheard-of speeds. Other pros of 3-axis CNC machining include:

- A 3-axis CNC machine can produce more complex shapes than a 2-axis machine. It is also easier to set up and maintain.

- It is less expensive than a 2-axis machine because the drive motors are not needed. With the majority of manufacturers concentrating on larger machines, many users have found small 3-axis CNC routers are often more affordable options. Even high-end units tend to be cheaper than equivalent 2-axis machines.

- It is more compact and powerful than a 2-axis CNC machine. A 3-axis CNC router is able to take on the larger jobs that a 2-axis machine simply cannot handle.

- cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

4-Axis CNC-bewerking

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Er zijn enkele factoren om te overwegen bij het kiezen tussen 4-as en 3-as CNC-bewerking:

- cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

- Duurzaamheid: 3-as machines zijn beter geschikt voor lichte, hogere snelheidsbewerkingswerkzaamheden. Dit komt doordat het mogelijk is om een kleinere snijkop te gebruiken en minder vibraties te veroorzaken tijdens het bewerken.

- cURL Too many subrequests.

cURL Too many subrequests.

Wat u moet weten over de 4-assige CNC-machine

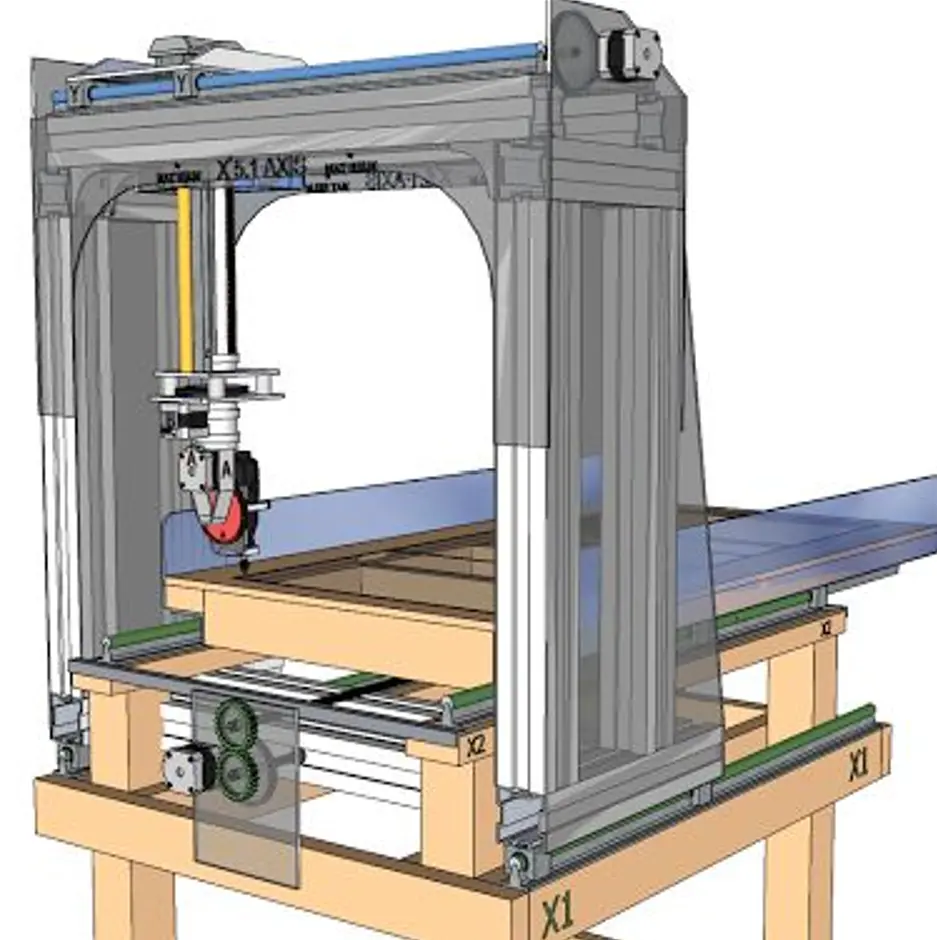

5-Axis CNC-bewerking

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

3+2 Asmachines

cURL Too many subrequests. multiaxis machine can achieve most of the results that regular 5-axis machines can, making it a great option for projects that require precision and accuracy. This type of configuration can be obtained by attaching a tilting rotary table to a vertical machine. The main characteristic of 3+2 axis machines is that the workpiece remains stationary and fixed throughout the process, with the cutting tool instead enabled to move along two additional axes.

4+1 Asmachines

This is a configuration of 5-axis machining that uses stationary axes. In this method, only a single rotary axis holding the substrate is held in a fixed orientation. This configuration is a simplified version of regular 5-axis CNC machining, which takes advantage of the dynamic movements of three translational axes and one rotary axis. This method can also be described as surface-independent machining, as the cutting angle is not necessarily determined by the surface angle. 4+1 axis machine can maintain a constant angle, increasing the stability of the workpiece, and minimizing the changes in speed that often characterize surface-dependent machining. Yet, this method is restricted to only a limited set of cylindrical shapes.

Gelijktijdige 5-assige machines

This is the regular form of the 5-axis CNC machine. It is a surface-dependent machining process which means that the cutting tool is continuously perpendicular to the substrate, and allows movement of the cutting tool along the three primary axes, as well as rotation of the workpiece along with the three rotational axes. This configuration would enable the cutting or milling tool to remove material in areas that are hard to reach using the other 5-axis configurations. This method is the most effective for complex parts.

Applications of 5-Axis CNC Machining

5-axis milling and machining is perfect for industries like energy and aerospace. The latter in particular requires several components with complex shapes and precise measurements. The spindles and highly customizable orientation of a 5-axis CNC machine can target specific areas and handle extreme cutting conditions and fine-tuned designs.

With the recent growth of robotics and automated industrial machinery, the 5-axis CNC method will make projects that were previously challenging and complex now accessible.

The Pros and Cons of The 5-Axis Method

The potential of 5 axis machines is expanding with the use of multiple cutting tools and advances in technology. Nonetheless, there are still challenges facing its industrial applications.

The benefits of 5-axis machines:

- An increased accuracy that facilitated the creation of complex geometries

- The centralized setup that multiaxis machines offer

- A significantly better surface texture due to the short cutting tool that 5-axis machines come with.

- A significantly decreased time required to machine complex components

Despite the observable advantages, a lot of challenges accompany the use of 5-axis CNC machines. A few of these include:

- The cost of a 5-axis machine is quite high: As most of its applications have implemented computer-aided processes, the required software can also add to the costs.

- The maintenance of 5-axis machines is not only costly but also demanding in terms of worker skill.

- An increased labor costs, as well as the risk of error since operating a 5-axis machine, requires intricate programming to manipulate the several axes and the cutting tool.

Get More Information About 5 Axis CNC Machining

6-Axis Machining Routers

The additional axis on a 6-axis CNC machine can create complex shapes and improve machining capabilities. Other configurations may have the main advantage of 6-axis machines, but the speed and ability to significantly decrease production times make the latter a clear winner. Several industrial use cases have reported a 75 % cut in production time when using a 6 axis machine. They are designed to achieve maximum precision and maintain the same alignment, grip, and seamless use. This is especially true in high volume operations, where it is the most optimal choice, and almost a standard, as they can produce larger parts in less time.

Applications and Uses of 6-Axis CNC Machines

6 axis machines offer many advantages over other types of machines, including precision, speed, and reduced production times. This makes them an optimal choice for many applications.

The aerospace industry relies on 6 axis CNC machines due to its high demand for highly complex and expensive parts, usually made from very solid material. Aircraft wings can sometimes reach up to 24 meters (80 ft) in size, requiring the use of some specialized 6-axis machines. Military aircraft also contain components that require the precision of 6-axis CNC machines.

6-axis CNC machines are also relied on by the automotive industry for their ability to quickly produce high-quality components.

Last but not least, due to the need for fast and precise motions that can only be achieved with the help of 6 axis CNC machines, there is a high demand for custom CNC machined pieces with intricate specifications in the medical industry.

Advantages And Limitations of the 6-Axis CNC Machining

It is clear enough that 6-axis machines provide a larger range of benefits compared to the other CNC models. Six-axis CNC machines can quickly and precisely create complex shapes and highly customized pieces that look great. There are many ways in which a 6-axis CNC machine can improve quality and productivity. In some cases, a 6-axis machine is the only way to get the job done. Other projects, however, are only possible or cost-effective in an industrial setting.

However, 6-axis CNC machines do have some limitations. They are often used mainly for high scale or volume operations, due to their high cost. The current advances in industry and technology are further enabling the capabilities of 6 axis CNC machines, making this technology more available and easier to use. However, for now, this is still a costly piece of equipment, with very high capabilities.

6-axis CNC machines are still quite a marvel of modern engineering. This piece of equipment can take multiaxis machining to new levels and has the potential to revolutionize manufacturing. Despite its high cost and demand for skilled workers, the manufacturing of complex parts is becoming increasingly popular, making it possible to produce innovative pieces of technology.

Learn More About 6 Axis CNC Machining

7-Axis CNC Machines

The 7-axis CNC machine is one that operates over 7 axes (3 translational axes for the movement of the cutting tool, 3 rotary axes holding the workpiece, and an additional axis enabling the rotation of the arm holding the tool head). This configuration relates to a wider paradigm of multiaxis that was built upon. 7-axis CNC machines can quickly and precisely perform all the tasks of their predecessor configurations and have additional improved capabilities.

What Makes the 7-Axis Machine Special Than Its Other Multiaxis Predecessors

The accuracy and precision of 7-axis CNC machines are one of the main advantages. Although 3-axis or 5-axis CNC machines are perfectly capable of producing many complex shapes, 7-axis CNC centers can produce them at a higher rate, making them more optimal for operations with high demand.

7 axis CNC machining is one of the great capabilities of modern industry. Though it is a costly investment, the results can be great. The size of workpieces that a 7 axis CNC center can handle can vary, but many centers are capable of handling mostly average-sized pieces. However, there are also specialized centers with more capabilities.

Applications Of 7 Axis CNC Machining

7 axis CNC machining is now widely used in a variety of industries with a high demand for complex and solid pieces with tight tolerances. For example, in the automotive industry, many of the required parts and components can be produced with the help of a 5 axis or 6-axis CNC machine, which results in increased capabilities and accuracy. Industrial robot arms with 7-axis capabilities can help speed up the process of creating prototypes of automobiles.

The aerospace industry wouldn’t be where it is today without the help of 7-axis CNC machining. Parts for aircraft often require a lot of precision and complexity, which is why 7-axis CNC centers are so important. They can produce large or complex parts quickly and efficiently, making them essential for aircraft manufacturing. Even the largest components, like airplane wings and jet engines, can be made with a 7-axis machine.

Benefits And Limitations of 7-Axis Machining

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

De kernpunten

cURL Too many subrequests.