Iphone Case,Cellphone Case CNC machining

| Information | |

|---|---|

| Отрасль | Consumer Electronics,Cellphone |

| Product | Iphone Case |

| Challenges | Consistent surface contours and aesthetics, Anodizing with different colors |

| Technology | CNC milling |

| Материал | AL6063 |

| cURL Too many subrequests. | Анодирование |

| Quantity | 100 Sets |

| Срок выполнения | 50 Business days |

About Customer: Jason Lee, Phone Case Trader in Huaqiang Bei,Shenzhen City

Jason Lee is a trader business man in China from shenzhen. He is at shenzhen,he as a small shop at Hua qiang Bei,

He sell the Cellphone Case at Ebay,amazon and shopee and his own e-commerce website.

He can design the Case by CAD Software.

How to Design the case for Cellphne,for example Iphone 15 or Iphone 14?

Whether a CNC user plans on manufacturing a phone case using a 3D Printer or carving it out from a solid material block, it is an uncomplicated project. Furthermore, these cases serve as exceptional holiday presents.

The key is accounting for the dimensions of the phone itself. One can measure the phone, or, in the case of Apple at least, we can obtain the official blueprints they provide for organizations that want to make cases and other accessories. Apple has a page all set up for developers to access. On that page you will find a link to a document called “Case Design Guidelines for Apple Devices.” That’s where you’ll find the dimensioned drawings for all of Apple’s phones and portable devices like iPods and iPads.

Once you get your hands on the document describing your device’s dimensions, you’ll need to put together a CAD drawing that captures the outline of the phone:

iPhone 15 Outline

Using your CAD program, generate the outline of your phone…

I’m using Rhino3D for this project, but most any CAD program capable of 3D modelling can be used to follow along. I simply created a rectangle with the overall height and width of the phone (leaving out the buttons that protrude). I then filleted the corners to the appropriate radius. That yields the yellow outline–very easy!

The next question you’ll have to decide is how thick to make your case. For this project, I wanted a case that would not add bulk to the already svelte iPhone, and that would make it easy to operate the phone’s controls through openings in the case. So, I chose to make the case 1.5mm thick. To do that, I simply offset the inner outline by 1.5mm. All decent CAD software will have the ability to offset a line like that.

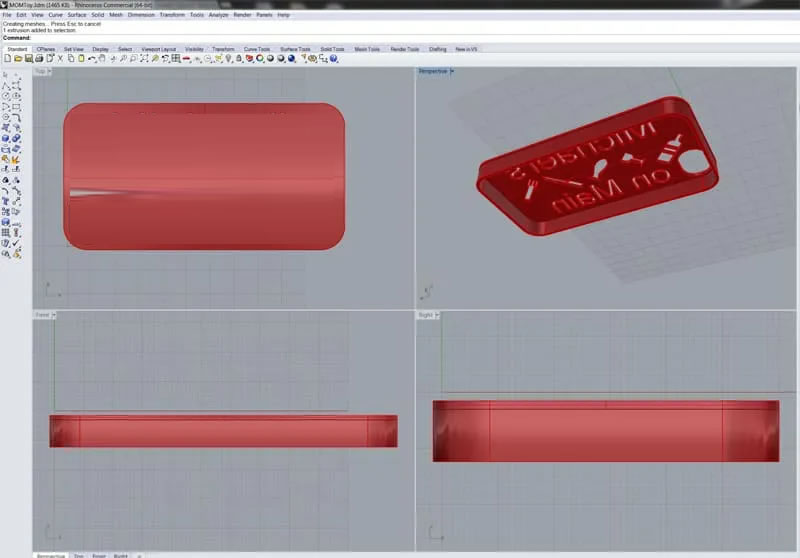

Now I have the basic outline of the case. Time to start converting it into a 3D model. In Rhino, I simply extrude that outline to the some height. This creates the sides of the case:

CaseSides

Phone case sides…

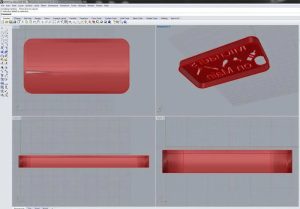

Then I extrude the outer line in the opposite direction for 1.5mm to create the bottom of the case:

CaseBottom

Case with bottom added…

Now I have a solid model of a case. Granted, it’s generic, and I haven’t added the cutouts to access buttons, expose the camera, and so on, but it’s a start that was easily created. Go ahead and add those cutouts and you’ll have a generic case template suitable for your phone. For now, I’ll leave adding all the cutouts to the reader, but let’s have some fun personalizing this case.

You’ll notice I drew the case face down. That’s because the personalization I want to do goes on the back of the case, and I wanted to make that part easy on myself. What I decided on was to create a custom logo’d case for a close friend who owns a local restuarant. I’ve been a Guest Chef there a number of times and I wanted to give him something fun from my world of CNC. There are a variety of things you could do to customize a case like this, but I decided to keep it simple. My task was to create cutouts in the case that create a logo of his restaurant. The finished 3D model looks like this:

MichaelsCase

Finished 3D Model of a custom phone case…

As you can see, this case is an exercise in making a cutout on the back of the case that looks like line art. The first task in doing that is to create the line art:

TextOutline

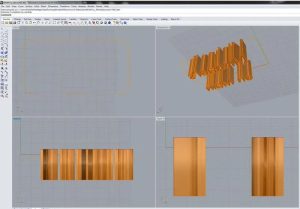

I started with a text outline. I positioned it above the bottom of the case in the Z dimension, and then I extruded it downward:

ExtrudedText

Extruding the text…

Using a similar process, I created the icons of wine bottle, glass, knife, fork, and fish:

CookieCutter

The extruded cookie cutter for the design…

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

ЧПУ-обработка

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

Phone backs are flat metal, plastic, or glass sheets attached to the frame. The simplest method of customizing a phone back is engraving and etching. Manufacturers often use this process to add their logos or phone details on the back of the phone. You can use the same technique to engrave personal messages on phone backs for gifting purposes.

Another means of customization is a complete overhaul of the back design. You can add new design elements and cutouts for limited edition backplates for your smartphone.

XTJ — ведущий производитель OEM, который занимается предоставлением комплексных решений по производству Celllphone Case от прототипа до серийного производства. Мы гордимся тем, что являемся компанией с системой менеджмента качества ISO 9001, и мы стремимся создавать ценность в каждом клиентском взаимодействии. Мы достигаем этого через сотрудничество, инновации, улучшение процессов и исключительное мастерство.