3/5axis CNC Aluminum Machining Services

Affordable Precision Aluminum Machining

From rapid prototypes to high-volume production, XTJ delivers precision aluminum parts with tight tolerances and fast turnaround times.

What is 5-Axis CNC Aluminum Machining Services?

5-Axis CNC (Computer Numerical Control) Aluminum Machining Services refer to an advanced manufacturing process that uses specialized 5-axis CNC machines to precisely shape and cut aluminum parts. Unlike traditional 3-axis CNC machines, which move along only three linear axes (X, Y, and Z), 5-axis machines add two rotational axes (typically A and B or C), allowing the tool and workpiece to tilt and rotate simultaneously. This enables machining of highly complex geometries from multiple angles in a single setup, reducing errors, setup time, and material waste.

Key Features and Benefits

- Precision and Complexity: Ideal for intricate parts with tight tolerances (e.g., ±0.01mm), smooth surfaces, and features like undercuts, curves, or multifaceted designs that are challenging or impossible with fewer axes.

- Efficiency: Minimizes the need for multiple setups or repositioning, speeding up production—e.g., one part might take 16 hours on a 5-axis machine vs. 24 hours on a 3-axis one.

- Material Focus: Aluminum: Aluminum alloys (e.g., Al6061-T6, Al7075) are lightweight, corrosion-resistant, strong, and highly machinable, making them perfect for this process. It’s commonly used for large or detailed parts without distortion.

Our CNC Aluminum Machining Services

We offer these services, ensuring quick turnaround times (e.g., 5-7 days) and support for high-volume production. For quotes or specific details, XTJ Precision Mfg can provide instant online pricing based on your CAD files.

Our simplifies the process of sourcing custom machined parts. We offer you the capacity and capabilities of two of manufacturing facilities, with the ease of dealing with XTJ. You get the experience and specialization of all our manchinery, we handle all the communications, delivery, and quality control.

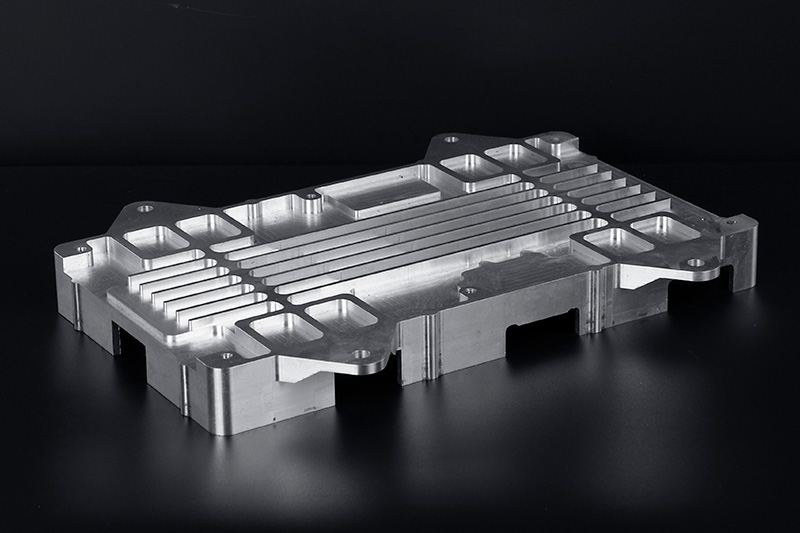

3-Axis CNC Aluminum Machining

Perfect for cost-effective production of simpler parts with high precision.

5-Axis CNC Aluminum Machining

Ideal for complex designs, offering multi-angle machining and reduced setup times for intricate components.

Custom Aluminum Parts

From small runs to high-volume production, XTJ delivers precision aluminum parts with consistent quality. Our ISO 9001-compliant processes, combined with flexible engineering, allow us to tackle complex projects with short lead times.

Why Choose XTJ for CNC Aluminum Machining?

Unbeatable Pricing

Low-cost CNC aluminum machining services without compromising quality—XTJ offers the most competitive prices in the industry.

Mass Production Capability

Over 100 state-of-the-art 3-axis and 5-axis CNC machines, enabling high-volume production with fast lead times.

Superior Efficiency

Our streamlined processes and large-scale setup ensure faster delivery compared to competitors.

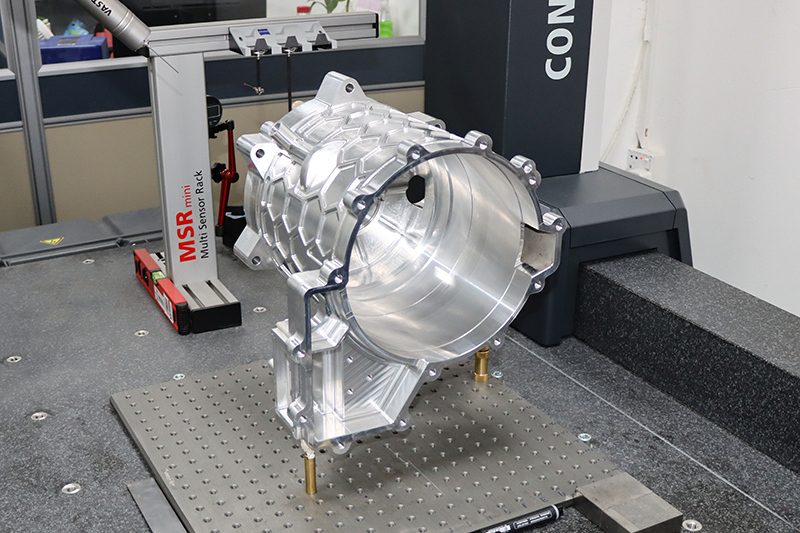

World-Class Quality

Equipped with advanced inspection tools like the Zeiss CMM (Coordinate Measuring Machine), we maintain strict tolerances as tight as ±0.005 mm.

Versatile Solutions

From simple 3-axis cuts to complex 5-axis geometries, we handle all aluminum grades for diverse applications.

Advanced CNC Equipment for XJT

Our cutting-edge fleet includes:

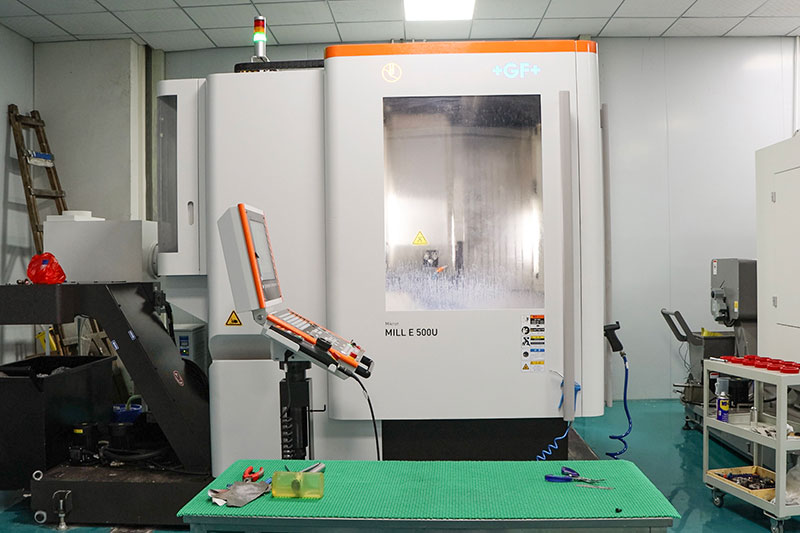

Swiss Mikron 5-Axis Machines

Known for high-speed precision and superior surface finishes, ideal for complex aluminum parts.

DMG 5-Axis Machines

Offer robust stability and dynamic performance for intricate geometries.

GROB 5-Axis Machines

Deliver exceptional accuracy and efficiency, perfect for demanding applications.

AEPC Gantry 5-Axis Machines

Handle large aluminum components with unmatched rigidity and versatility.

This advanced technology ensures XTJ leads in precision and productivity.

Comparing 3-Axis, 4-Axis, and 5-Axis CNC Machining

Understand the differences to choose the best CNC machining solution for your aluminum project:

| Feature | 3-Axis CNC Machining | 4-Axis CNC Machining | 5-Axis CNC Machining |

| Movement | Operates in X, Y, Z axes | Adds rotation around X or Y axis | Full rotation around X and Y axes |

| Shape Complexity | Best for basic geometries | Handles moderately complex shapes | Ideal for highly intricate designs |

| Setup Efficiency | May require multiple setups | Fewer setups than 3-axis | Single setup for most parts, saving time |

| Surface Quality | Good, varies with setups | Improved due to better angles | Superior finish with minimal tool marks |

| Tool Accessibility | Limited by part geometry | Better access than 3-axis | Optimal access, reduces collision risks |

| Cost Efficiency | Most affordable option | Moderately priced due to added axis | Higher cost, but best for complex parts |

At XTJ Precision Mfg, we leverage our 100+ CNC machines to ensure that whether you choose 3-axis or 5-axis, you get the best value, fastest turnaround, and highest quality.

Why Aluminum is Ideal for CNC Machining

Aluminum is a preferred material for CNC machining due to its unique properties, and at XTJ, we maximize these benefits:

- Lightweight Yet Strong: Aluminum offers an excellent strength-to-weight ratio, making it ideal for aerospace and automotive applications.

- Corrosion Resistance: Naturally resistant to rust, aluminum parts are durable in harsh environments.

- High Machinability: Aluminum is easy to machine, allowing for faster production and lower costs—perfect for XTJ’s high-efficiency processes.

- Thermal Conductivity: Ideal for components like heat sinks in electronics, ensuring efficient heat dissipation.

- Recyclability: Aluminum is eco-friendly and can be recycled without losing its properties, supporting sustainable manufacturing.

Commitment to Quality

At XTJ Precision Mfg, quality is non-negotiable. We use international-grade inspection equipment like the Zeiss CMM to ensure every part meets rigorous standards. Our strict tolerance control guarantees precision, making us a trusted partner for 3-axis and 5-axis CNC aluminum projects worldwide.

Frequently Asked Questions (FAQs)

We handle a variety of aluminum alloys, including 6061, 7075, and 5052, to meet your project’s specific needs. Contact us to discuss the best material for your application.

With 5-axis CNC machining, we can machine complex parts in a single setup, reducing production time and ensuring precision—perfect for tight deadlines.

Thanks to our 100+ CNC machines, we offer some of the fastest lead times in the industry. Most projects are completed within 5-10 business days, depending on complexity.

Absolutely! Our large-scale production capacity ensures we can handle high-volume orders efficiently while maintaining quality and competitive pricing.

Get a Free Quote Today

Looking for affordable, high-quality **CNC aluminum machining**? Partner with **XTJ Machining** for the best value in precision aluminum parts. Contact us now to discuss your project and get a free quote.