Your Trusted Partner for Low-Cost CNC Machining and Prototyping

From rapid prototyping to small-batch production, we deliver cost-effective CNC machining, injection molding, and die casting solutions tailored to your needs

- Up to 40% cost savings on prototype molds

- Parts delivered in as fast as 3-5 days

- Precision down to ±0.002mm

- Global delivery, Real factory, welcome to visit

Get A Free Quote Now !

Explore Our Comprehensive Manufacturing Solutions

XTJ Precision Mfg is your trusted partner for transforming concepts into reality with high-quality, cost-effective production solutions. Leveraging extensive expertise and integrated resources, we seamlessly guide you from rapid prototyping to production, meeting the demands of any project while upholding the highest quality standards. Our rapid prototyping services include CNC prototyping, 3D printing, vacuum casting, rapid tooling, sheet metal prototyping, and prototype finishing. For custom manufacturing, we offer CNC machining, plastic injection molding, metal casting, sheet metal fabrication, and parts finishing, ensuring precision and fast turnarounds to bring your designs to market efficiently.

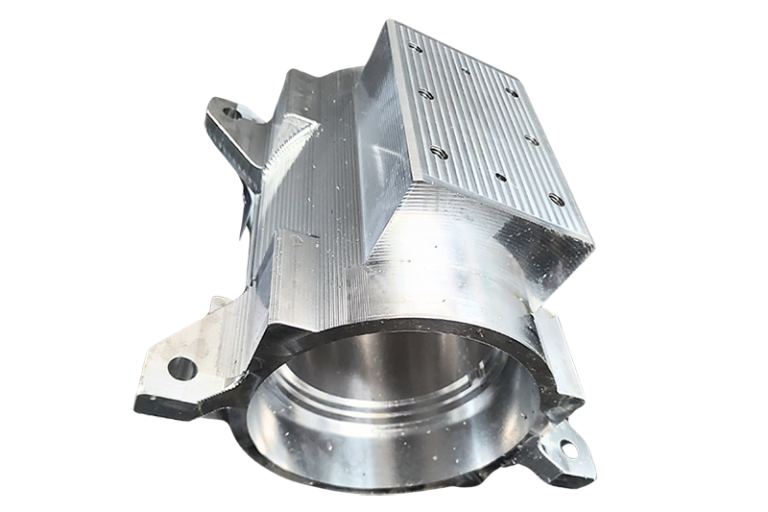

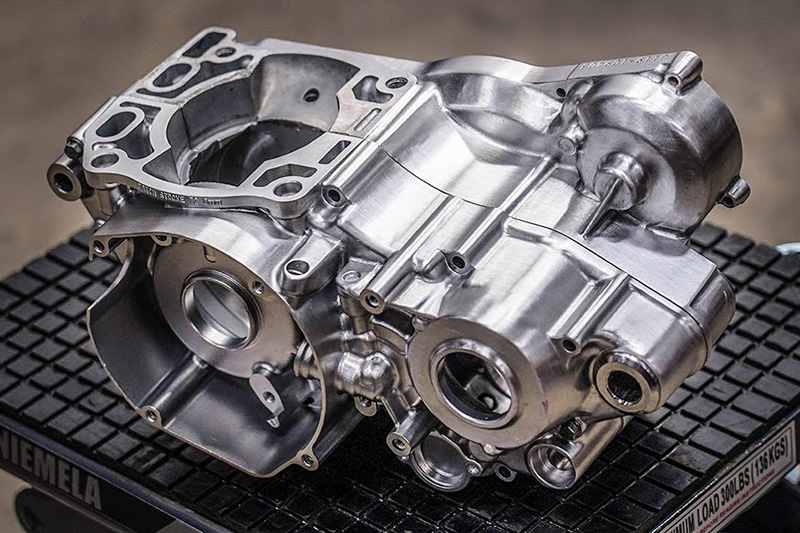

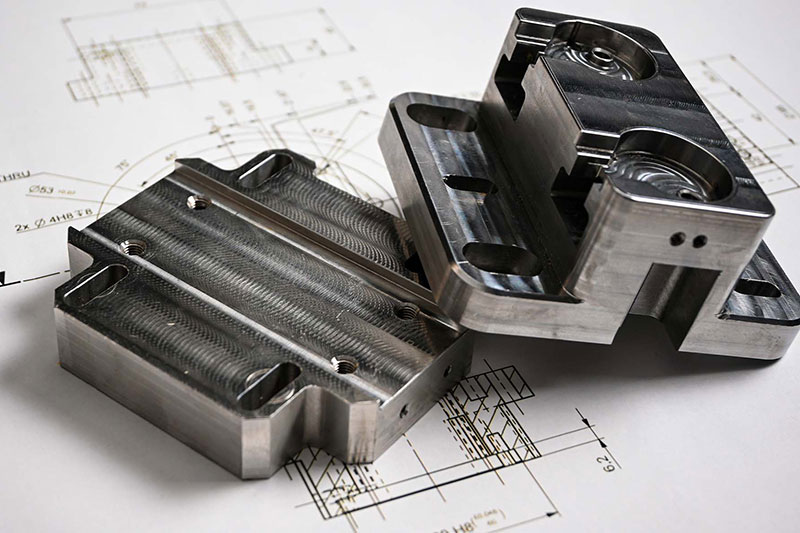

Precision CNC Machining: Innovate Faster with XTJ

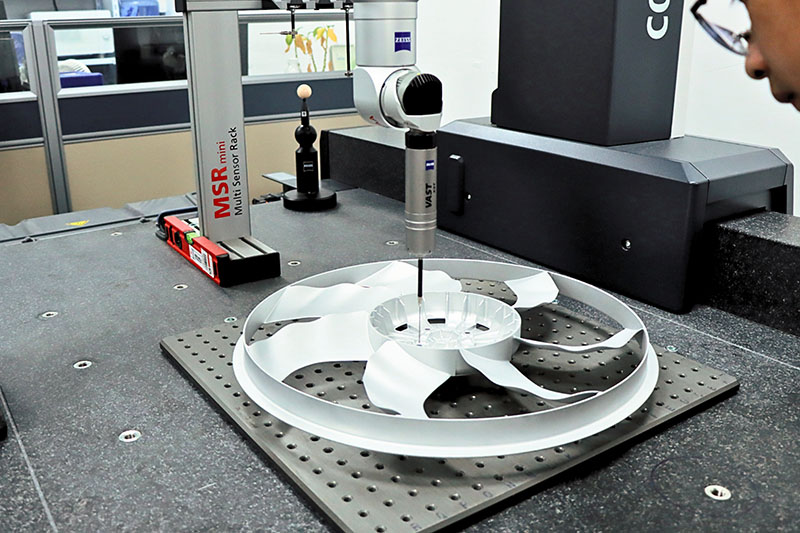

At XTJ Precision Mfg, our ISO 9001-certified expertise spans 20+ years, achieving 99% on-time delivery and customer satisfaction. We craft high-precision parts with tolerances down to ±0.003mm, handling complex geometries in metals and plastics via 120+ advanced machines. From prototypes in just 5 days to low-volume runs without MOQ, our 300+ specialists optimize designs for efficiency, slashing lead times and costs. Rigorous CMM inspections and full traceability ensure every project exceeds expectations, powering industries from aerospace to automotive.

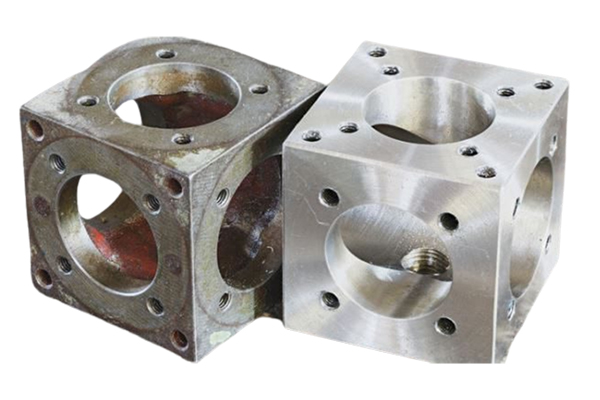

CNC Machining Materials Supported by XTJ Precision Mfg

From metals and plastics to advanced composites, our state-of-the-art CNC machining delivers precision-engineered components that not only meet your exact specifications but also exceed rigorous industry benchmarks—ensuring reliability, durability, and performance in every project.

Metals

Selecting the right metal for CNC machining is critical to achieving optimal performance, cost-efficiency, and durability. XTJ Precision Mfg offers a wide range of metals tailored to your project requirements. Below are some of the key materials we work with:

Aluminum

Characteristics: Lightweight, good thermal conductivity, easy to machine, chips break easily. May cause tool sticking; requires proper cooling and lubrication. Suitable for high-speed milling.

Steel

Characteristics: High hardness, wear-resistant, but generates high cutting forces and heat during machining. Requires low-speed milling with hard tools (e.g., carbide). Stainless steel may exhibit work hardening.

Titanium

Characteristics: High strength, low thermal conductivity, heat concentrates during machining, causing tool wear. Requires low-speed cutting, high-performance tools, and sufficient cooling.

Brass

Characteristics: Soft and easy to machine, good machinability, chips break easily, high surface finish. Suitable for high-speed milling, generates less heat.

Copper

Characteristics: High thermal conductivity, ductile, prone to tool sticking during machining. Requires sharp tools and proper lubrication. Chips may be long, so chip removal is important.

Magnesium

Characteristics: Extremely lightweight and strong, often used in automotive and aerospace applications to reduce weight without compromising strength.

Bronze

Characteristics:Bronze is a copper-tin alloy (typical composition: Cu 88%, Sn 12%), renowned for its distinctive golden hue, corrosion resistance, and mechanical properties. From the ancient Bronze Age to modern applications, it has been widely used in tools and artwork, while contemporary machining techniques make it ideal for high-precision industrial components.

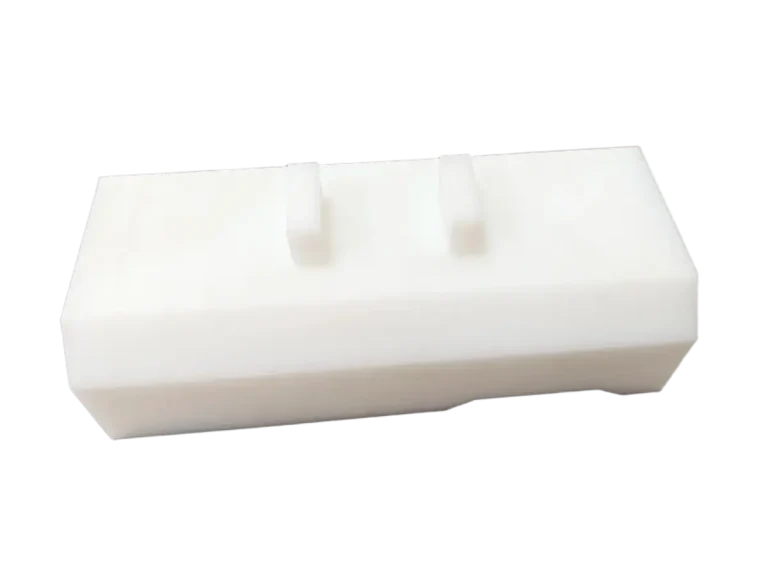

Plastics

XTJ manufactures customized plastic parts on demand.From small quantities to large production runs,XTJ is your reliable source for high-quality CNC plastics machining and precision plastics machining.

Acrylic

Developed in the 1930s as a shatter-resistant alternative to glass, PMMA excels in CNC machining, enabling the production of intricate, high-precision parts with excellent optical properties and ease of fabrication.

ABS

Characteristics: Good toughness, easy to machine, but prone to softening from heat. Requires controlled cutting speed and cooling to avoid melting or burrs.

POM (Polyoxymethylene)

Characteristics: Moderate hardness, wear-resistant, self-lubricating, stable during machining, good surface finish. Be cautious of thermal deformation.

PEEK

Characteristics: High temperature resistance, chemical resistance, high hardness. Requires hard tools, generates high cutting forces, and needs temperature control to prevent deformation.

Polycarbonate

Characteristics: Transparent, high toughness, but prone to stress cracking. Requires low-speed cutting to avoid overheating, and sharp tools are necessary.

Nylon

Characteristics: High toughness, wear-resistant, but hygroscopic and prone to deformation during machining. Requires controlled cutting speed, suitable for low-speed milling.

PTFE

Discovered in the 1930s, PTFE has become a cornerstone material in industries requiring durability under extreme conditions, excelling in CNC machining for producing precise, low-friction components that withstand harsh environments.

PVC

PVC, or Polyvinyl Chloride, is a versatile thermoplastic engineering plastic polymerized from vinyl chloride monomers. It is renowned for its durability, chemical stability, and cost-effectiveness, available in rigid and flexible forms. Rigid PVC is particularly suited for precision machining, while flexible variants incorporate plasticizers for enhanced pliability.

Have a Composite materials Requirement?

Composite materials machining empowers innovative designs with unmatched efficiency and resilience, bridging the gap between performance and practicality. Select fiber-matrix combos (e.g., epoxy-carbon for high-load scenarios) based on project specs. For bespoke solutions, collaborate with experts like XTJ Precision Mfg on prototyping to fine-tune properties, costs, and manufacturability.

Please contact us with your specific material requirements. Our team is committed to finding the right solution for your project needs and will work with you to find and process the best material for your application.

Industry Applications

XTJ delivers exceptional global on-demand manufacturing services. Our greatest asset is our rapidly growing customer base, driven by word-of-mouth from clients worldwide. This diverse group spans independent inventors and designers to large-scale enterprises in industries such as industrial, energy, medical, automotive, and aerospace.

Aerospace

High-precision aluminum components for aircraft and drones, meeting stringent industry standards.

Medical

Custom parts for medical devices and robotic systems, ensuring biocompatibility and precision.

Automotive

Prototypes and production parts for electric vehicles and traditional cars, built for durability.

Consumer Electronics

Durable components for wearables and devices, with fine finishes and tight tolerances.

Energy

From drilling rigs to wind turbines, the energy industry depends on CNC machining to deliver the precision and performance needed to power the world.

Home Appliances

Functional components for household products, balancing aesthetics and performance.

Case Study

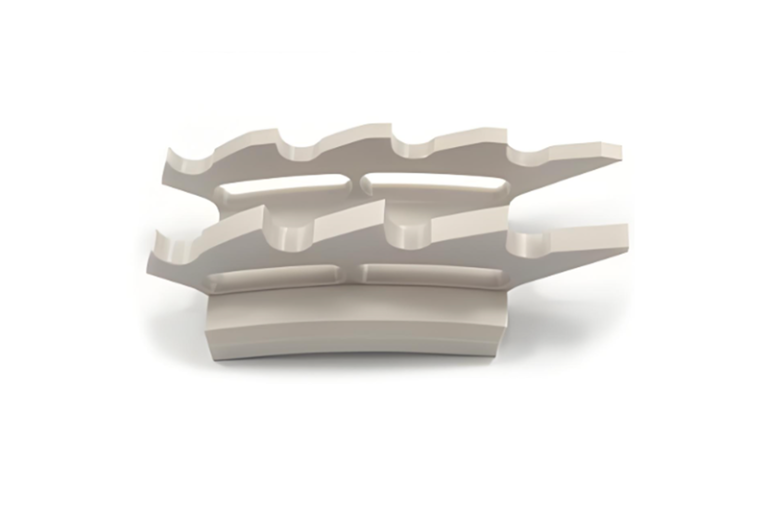

Precision Support System for Outdoor Equipment

Client: A leading manufacturer of outdoor power equipment

Industry: Outdoor Equipment (Agriculture and Landscaping)

Challenge: The client needed a lightweight, durable support system for their new line of backpack-style brush cutters. The system had to withstand harsh outdoor conditions, ensure ergonomic comfort, and meet tight production deadlines for a seasonal product launch.

Solution: Xin Tian Jian Precision Mfg designed and manufactured a high-precision aluminum support system using advanced CNC machining and anodizing processes. We optimized the design for weight reduction while maintaining structural integrity, achieving a 15% lighter system compared to the client’s previous model. The parts were delivered within 10 days, enabling the client to meet their launch timeline.

Results:

- Enhanced Durability: The anodized aluminum system resists corrosion, extending the equipment’s lifespan in rugged environments.

- Improved User Experience: The ergonomic design reduced operator fatigue, earning positive feedback from end-users.

- On-Time Delivery: Production was completed ahead of schedule, supporting the client’s seasonal launch.

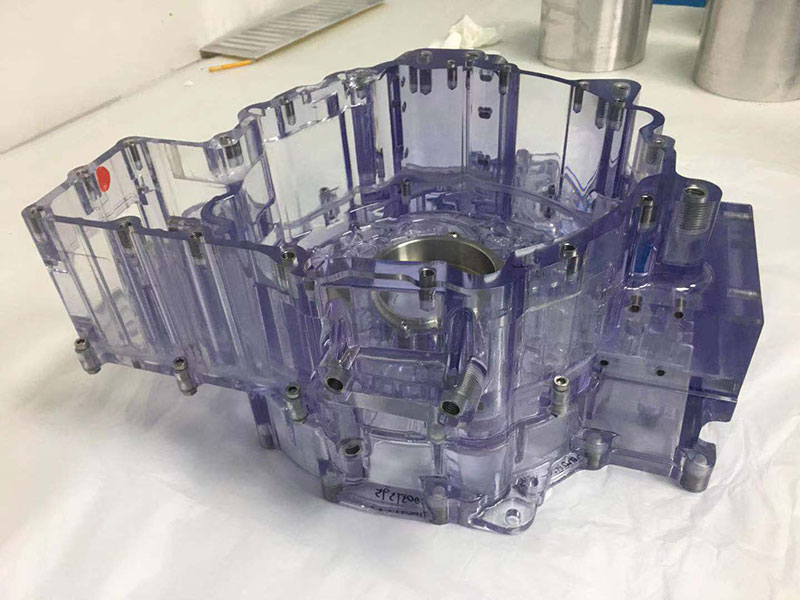

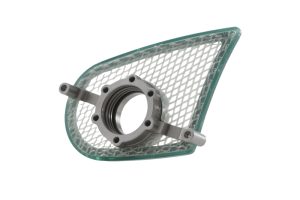

Transparent PC Motor Housing for Huawei Electric Vehicle

Client: Huawei Technologies Co., Ltd.

Industry: Electric Vehicles (Automotive)

Challenge: Huawei required a transparent motor housing for their electric vehicle R&D project. The housing needed to be made from polycarbonate (PC) to allow internal visibility, while meeting strict automotive standards for precision and durability. The project demanded a rapid turnaround to align with their development timeline.

Solution: Xin Tian Jian Precision Mfg leveraged advanced CNC machining to produce the transparent PC motor housing with tight tolerances. We ensured flawless transparency and structural integrity by optimizing the machining process to prevent stress marks and warping. The housing was delivered within 7 days, supporting Huawei’s fast-paced R&D schedule.

Results:

- Superior Transparency: The PC housing provided clear visibility of internal components, aiding Huawei’s testing and validation process.

- High Precision: Achieved tolerances within ±0.1mm, meeting automotive industry standards.

- Accelerated Development: On-time delivery enabled Huawei to stay on track with their R&D milestones.

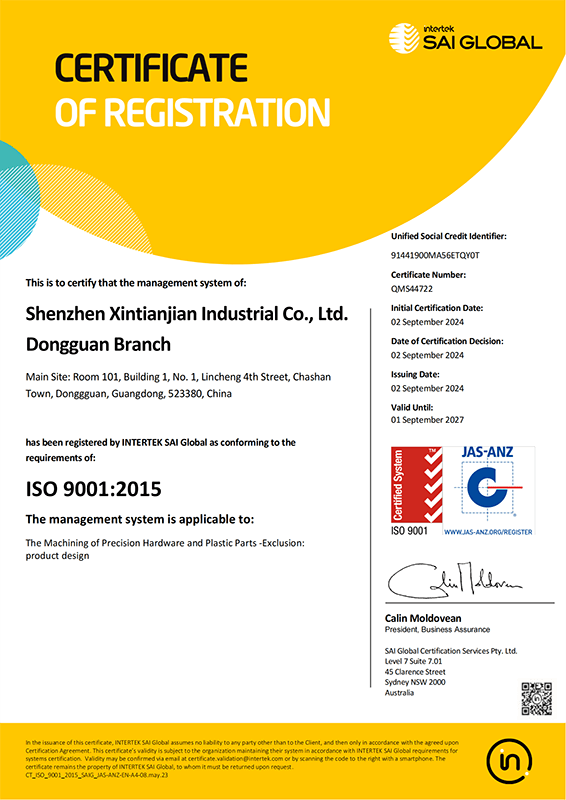

Certified Excellence

We are proud to be certified under international standards, ensuring our processes meet global benchmarks for quality and reliability.

ISO 9001:2015

Quality Management System Certification.

IATF 16949

Automotive Industry Standards.

RoHS & REACH Compliance

Environmentally responsible manufacturing.

Our Clients

We Are Trusted By World Famous Companies

What Our Clients Say About Xin Tian Jian Precision Mfg

“I wish more suppliers were like XTJ in their passion for quality and service. Their customer support has been exceptional throughout our collaboration.”

Napa Auto Ricky

Automotive Industry

“We’re impressed with XTJ’s 100% on-time delivery and quality success. This aligns perfectly with our goal to achieve top performance across the supply chain.”

Zipforce Ken

Industrial Sector

“XTJ’s quick response to our increased volume demands was outstanding. Their support has been invaluable to our operations.”

Hydac Tim

Hydraulic Systems

Quality Assurance

At Xin Tian Jian Precision Mfg, we ensure every part meets the highest standards through rigorous quality control. Trusted by global industries like aerospace, medical, and automotive, our components power millions of devices worldwide. With ISO 9001:2015 and IATF 16949 certifications, we’re a proven partner in automotive excellence—recognized as an Outstanding Supplier by Renault. Our advanced inspection tools guarantee precision and reliability at every stage, from design validation to final delivery.

Design Validation

We verify your design for manufacturability to ensure flawless production.

Material and Process Inspection

Raw materials and manufacturing processes are thoroughly checked for consistency.

Final Quality Assurance

Every part undergoes strict inspections to meet your specifications before shipment.

How to Work with XTJ Machining

Collaborate with us effortlessly: Submit your design, get expert feedback, approve your quote, and launch production. Stay informed at every stage for reliable, high-quality outcomes.

FAQs

We accept a variety of CAD file formats, including STEP, IGES, STL, and SolidWorks files, to ensure compatibility with your design process.

Yes, our engineering team provides free DFM (Design for Manufacturability) feedback to optimize your design for production efficiency and quality.

Absolutely, we offer material certifications and full traceability for all raw materials, ensuring compliance with industry standards.

We have no minimum order quantity, making us ideal for both single prototypes and low-volume production runs up to 100,000 parts.

Yes, we ship globally with flexible shipping options, including air, sea, and express delivery, tailored to your timeline and budget.

Yes, our ISO 9001:2015 and IATF 16949 certifications enable us to meet the strict requirements of regulated industries such as aerospace, medical, and automotive.

We offer a range of surface finishing options, including anodizing, powder coating, polishing, and sandblasting, to enhance durability and aesthetics.

We prioritize confidentiality and can sign NDAs (Non-Disclosure Agreements) to protect your intellectual property throughout the collaboration.

We provide a detailed quote within 24-48 hours after receiving your design files and project requirements.

Yes, we provide post-production support, including assembly, packaging, and quality checks, to ensure your parts are ready for immediate use.

Blog & Latest Updates

Your One-Stop Solution for Rapid Prototyping

Skilled Team, Advanced Technology, Delivering Precision for Global Industries.