The automotive industry is under constant pressure to improve efficiency and reduce costs. This has led to the adoption of new technologies, such as CNC machining. CNC machining is a process that uses computer-controlled tools to create parts from raw materials. This technology has helped the automotive industry save time and money by reducing the need for manual labor. A host of benefits are associated with the technology, of which we will discuss some examples in this article.

Types of Car Parts that are Machined Using CNC Technologies

CNC technologies are used to machine a variety of car parts. Here are some of the most common parts that are machined using CNC technologies:

Improved durability of parts

These parts, which open and close sections of an assembly line to allow material to be transported, can easily be cut out of metal by CNC tools. They are often found on conveyor belts.

Mirrors

While the mirror assembly was once made using manual methods, this process has been largely replaced by CNC machining. This is possible because CNC machinery, with its ability to precisely cut the glass and assemble the components, can be used to create the best quality parts.

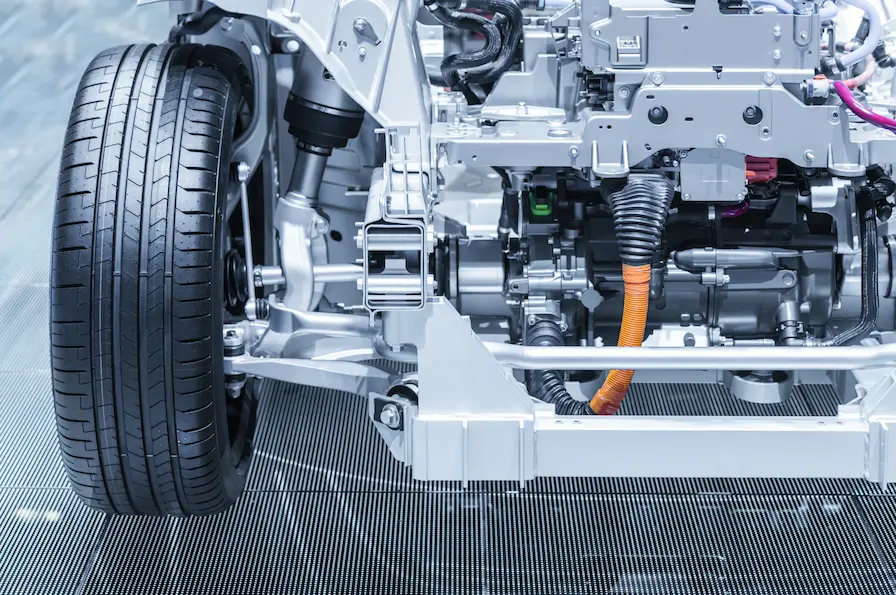

Engine Blocks

Engine blocks are machined to increase the efficiency of an engine. This process, which involves creating perfect surfaces by cutting and forming the material, can be easily be carried out by CNC machines.

Cylinder heads

CNC machining is a technology that is used to create precise and intricate parts from a variety of materials. When it comes to machining cylinder heads, this technology offers several advantages over traditional methods.

Camshafts

Camshafts are used in order to accurately tune the speed of an engine. Camshafts are CNC machined to ensure that they are precisely accurate.

Connecting rods

CNC machines are utilized in order to create precision machined connecting rods. These cylinders are used to ensure that the engine components are held together firmly.

The Different CNC Machines Used in the Automotive Industry

There are a variety of CNC machines used in the automotive industry, including lathes, milling machines, and routers. These machines are used to create parts for cars and trucks.

The different CNC machines used in the automotive industry are:

Lathes

CNC lathes are used extensively in the automotive industry for a variety of machining operations. They are especially well-suited for manufacturing high-precision parts with complex geometries. Depending on the model, a CNC lathe can handle long lengths of up to 10m.

Mills

Many parts for cars and trucks are produced using CNC mills. These machines are capable of creating various metal products, such as parts for a car engine or transmission. These parts include engine blocks, cylinder heads, gears, and suspension components. CNC mills are also used to cut and shape metal parts for air conditioners, cars, cranes, and dump trucks.

Routers

CNC routers are used in the automotive industry for a variety of applications, including trimming and routing car body panels, cutting and shaping engine parts, and milling and drilling wheels. CNC routers can be used in vertical and horizontal positions, and they are versatile enough to cut complex shapes.

Benefits of Using CNC Machining in the Automotive Industry

CNC machining is a cost-effective and time-saving method of manufacturing in the automotive industry. CNC machining can offer many benefits in the car industry including improved accuracy, repeatability, and consistency of parts, as well as increased efficiency and productivity. CNC machining can also help to reduce waste and improve the overall quality of parts.

Increased accuracy and repeatability compared to manual machining.

CNC machining offers repeatability and accuracy that is unmatched by manual machining. When a part is produced using CNC machining, the same process is used each time the part is made. This ensures that each part is identical to the last.

Reduced setup time and lead time.

CNC machining automotive parts is an efficient way to reduce setup time and lead time. The process of CNC machining can be completed in a single setup, which reduces the need for multiple setups and lead times associated with traditional machining methods.

Increased productivity.

CNC machining is a process that can be completely automated. This means that once the machine is set up, it can run without any human intervention. This increases productivity because the machine can run for longer periods without needing to be monitored.

Reduced scrap and rework.

CNC machining can be used to reduce scrap and rework by creating a more precise product. When products are machined using CNC technology, they are produced with a higher degree of accuracy. This means that there is less room for error and that products are less likely to be rejected or require rework.

Increased flexibility and versatility.

The traditional methods of making car parts are generally not very flexible or versatile. This means that they are often unable to produce parts in the exact sizes and shapes that you need. CNC machining allows you to produce many different types of products and parts, which can be designed with a high degree of precision.

Reduced labor costs.

Machining car parts using CNC reduces labor costs. CNC machining can be done by a single operator, thus reducing the labor cost.

Automotive Machining Services at XTJ

Xin Tian Jian Machining is a professional CNC machining service provider with years of experience in the industry. We provide our customers with high-quality products and services while being competitively priced.

Quality that lasts

We use state-of-the-art CNC machining technology to ensure that your parts are fully functional and of the highest quality.

Speed and time-effective

Our machine is designed to minimize cutting time and ensure precision, so you can get your parts back faster. We will always provide you with the best service for your money, with no compromises on quality.

Customizable design

We offer a variety of design options for you to choose from, so you can have your part manufactured exactly according to your needs and specifications. We also offer customization services, so you can have a unique product with your own personal touch.