Accelerate Innovation with Rapid Prototyping at XTJ Machining

From concept to reality in days—leverage our expertise in Vacuum Forming, Rapid 3D Printing, and CNC Machining to bring your ideas to life with precision and speed.

Your Partner for High-Quality Prototypes, Delivered Fast

At XTJ, we understand that speed and precision are critical in product development. Our rapid prototyping services, including Vacuum Forming and Rapid 3D Printing, are designed to help you test designs, validate concepts, and iterate quickly. With over a decade of experience in CNC machining and sheet metal fabrication, we provide end-to-end solutions for industries ranging from automotive to medical devices.

Rapid Turnaround

Prototypes delivered in as little as 1-3 days, minimizing downtime in your development cycle.

High Precision

Achieve tolerances as tight as ±0.005mm, ensuring your prototypes meet exact specifications.

Material Flexibility

Choose from 50+ materials, including ABS, PLA, aluminum, and stainless steel, for both functional and aesthetic prototypes.

Scalable Solutions

Seamlessly transition from prototyping to low-volume production with our integrated CNC machining and sheet metal fabrication capabilities.

Tailored Rapid Prototyping Solutions for Every Project

Explore our advanced prototyping capabilities, including Vacuum Forming and Rapid 3D Printing, to meet your design and testing needs.

Vacuum Forming

Vacuum forming is a cost-effective method for creating lightweight, durable plastic prototypes by heating a plastic sheet and forming it over a mold using vacuum pressure.

Applications: Ideal for packaging, enclosures, and large-scale prototypes like automotive dashboards or medical trays.

Materials: ABS, PETG, polycarbonate, and more.

Advantages:

- Low tooling costs compared to injection molding.

- Fast production for large parts (up to 2m x 1m).

- Perfect for low-volume runs or one-off prototypes.

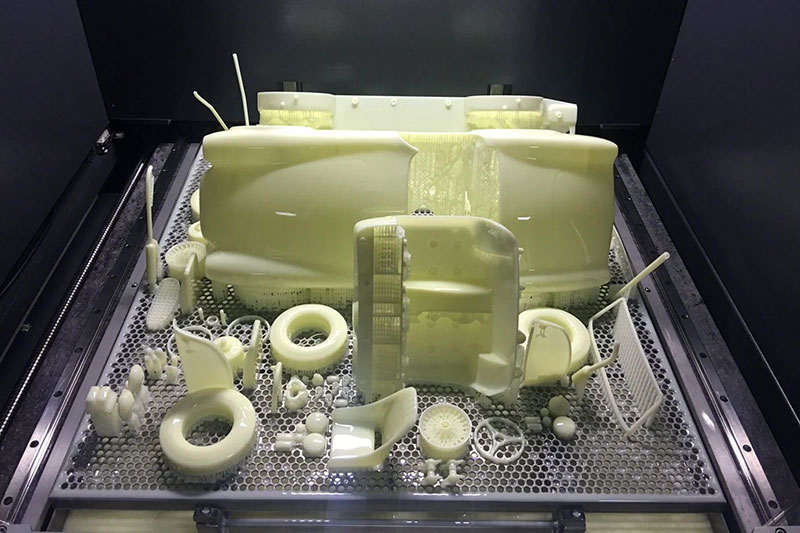

Rapid 3D Printing

Using advanced additive manufacturing, Rapid 3D Printing creates detailed prototypes layer by layer, allowing for complex geometries and quick iterations.

Applications: Functional prototypes, concept models, and small components for industries like aerospace and consumer goods.

Materials: PLA, ABS, TPU, nylon, and resin-based options for high-detail prints.

Advantages:

- No tooling required, reducing upfront costs.

- Supports intricate designs with undercuts and internal features.

- Turnaround as fast as 24 hours for small parts.

CNC Machining for Prototyping

Our 3-Axis and 5-Axis CNC machining services complement rapid prototyping by providing high-precision parts for functional testing.

Applications: Metal and plastic prototypes for automotive, aerospace, and industrial applications.

Materials: Aluminum, steel, titanium, and engineering plastics.

Advantages:

- Superior surface finish and dimensional accuracy.

- Ideal for testing mechanical properties before production.

- Supports low-volume production runs.

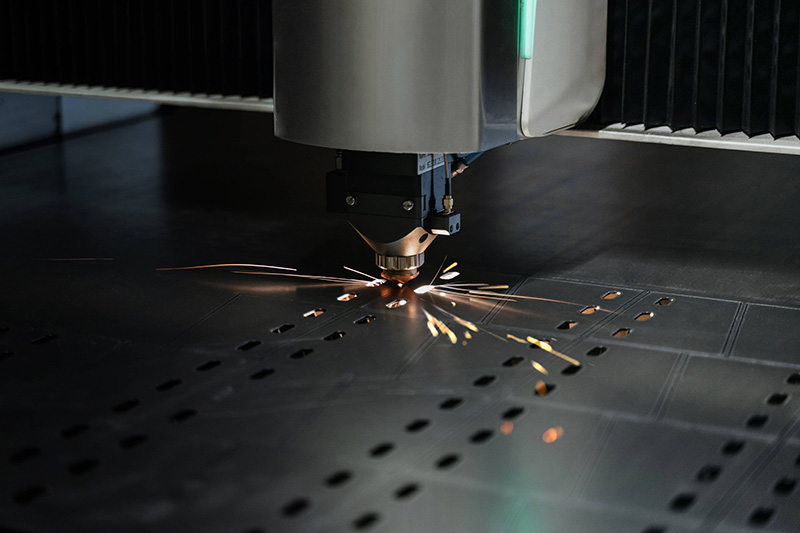

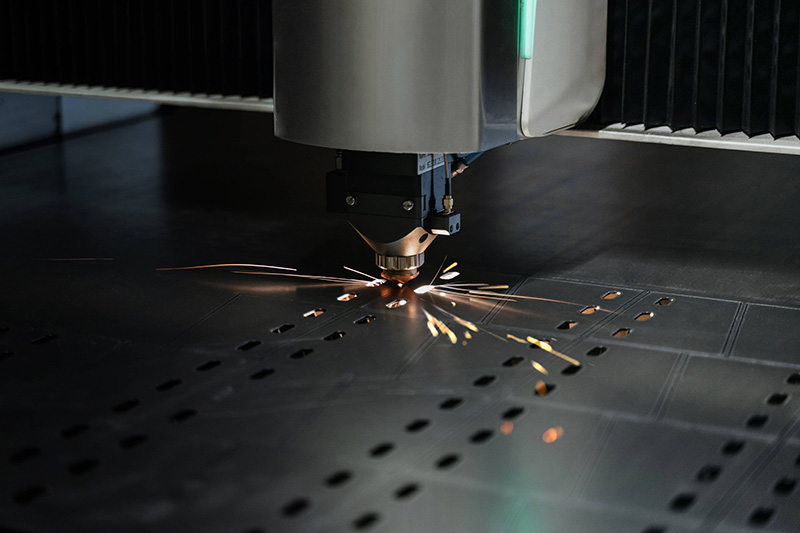

Sheet Metal Fabrication for Prototyping

Our sheet metal fabrication services allow for rapid production of metal prototypes using cutting, bending, and welding techniques.

Applications: Enclosures, brackets, and chassis for electronics, machinery, and more.

Materials: Stainless steel, aluminum, and mild steel.

Advantages:

- High durability for functional testing.

- Custom finishes like powder coating or anodizing.

- Fast lead times for flat or formed metal parts.

From Vision to Victory: Your Prototype in 3 Steps

For Vacuum Forming: We create a mold and form the part in 1-3 days.

For Rapid 3D Printing: We print your part layer by layer, often in under 48 hours.

For CNC Machining/Sheet Metal: We machine or fabricate your part with precision, typically in 3-5 days.

Empowering Innovation Across Industries

Our rapid prototyping services cater to a wide range of industries, delivering prototypes that meet stringent requirements for performance, durability, and aesthetics.

Automotive

Vacuum-formed dashboards, 3D-printed fixtures, and CNC-machined engine components.

Aerospace

Lightweight 3D-printed prototypes and sheet metal brackets for testing.

Medical

Vacuum-formed trays and 3D-printed surgical guides with biocompatible materials.

Consumer Electronics

3D-printed enclosures and CNC-machined connectors for product validation.

Industrial Equipment

Sheet metal prototypes for machinery housings and functional testing.

Your Trusted Partner for Rapid Prototyping Excellence

At XTJ Machining, we combine advanced technology with a customer-first approach to deliver prototypes that exceed expectations. Here’s why clients choose us:

- Certified Quality: ISO 9001:2015 certified, ensuring consistent quality across all projects.

- Advanced Technology: State-of-the-art 3D printers, CNC machines, and vacuum forming equipment for unmatched precision.

- Material Expertise:Over 50 materials and 20+ surface finishes, from anodizing to bead blasting.

- Global Reach: Fast, reliable shipping to over 50 countries with DHL, FedEx, and UPS.

- Dedicated Support: A project manager is assigned to every order, providing updates and technical guidance.

Elevate Your Prototypes with Custom Finishes

Enhance the functionality and appearance of your prototypes with our wide range of surface finishing options, available for Vacuum Forming, Rapid 3D Printing, CNC Machining, and Sheet Metal Fabrication.

- Anodizing: Adds corrosion resistance and color to aluminum parts (Type II and Type III).

- Powder Coating: Durable, protective finish in various colors for sheet metal prototypes.

- Polishing: Achieves a mirror-like finish for aesthetic 3D-printed or CNC-machined parts.

- Bead Blasting: Creates a uniform matte finish for improved surface texture.

- Painting: Custom colors for vacuum-formed or 3D-printed parts, ideal for consumer products.

Turn Your Ideas into Reality Today

Ready to prototype with Vacuum Forming, Rapid 3D Printing, or CNC Machining? Upload your design or reach out to our team for a consultation.