Xin Tian Jian Manufacturing is a precision ISO-9001:2015 Certified custom contract manufacturer specializing in laser cutting, precision sheet metal fabrication, and metal stamping across a wide range of applications.

We offer state-of-the-art equipment and processes to handle the full range of sheet metal fabricating. This includes hi-speed laser cutting, turret presses, and forming equipment which allows us to cut, punch, bend and shape to your exact requirements. Our “lights-out” laser cutting gives us capabilities to process the largest of orders with exacting precision and quality.

With the flexibility of an in-house tooling department, Xin Tian Jian Manufacturing can offer fast turnarounds and maximum cost-effectiveness with the quality you demand.

Xin Tian Jian Manufacturing also offers a broad range of value-added operations that can deliver a product ready for packaging, and/or assembly without additional processing, thus saving you time and money in your operations.

Advantages of Sheet Metal Fabrication

What is Sheet Metal Fabrication?

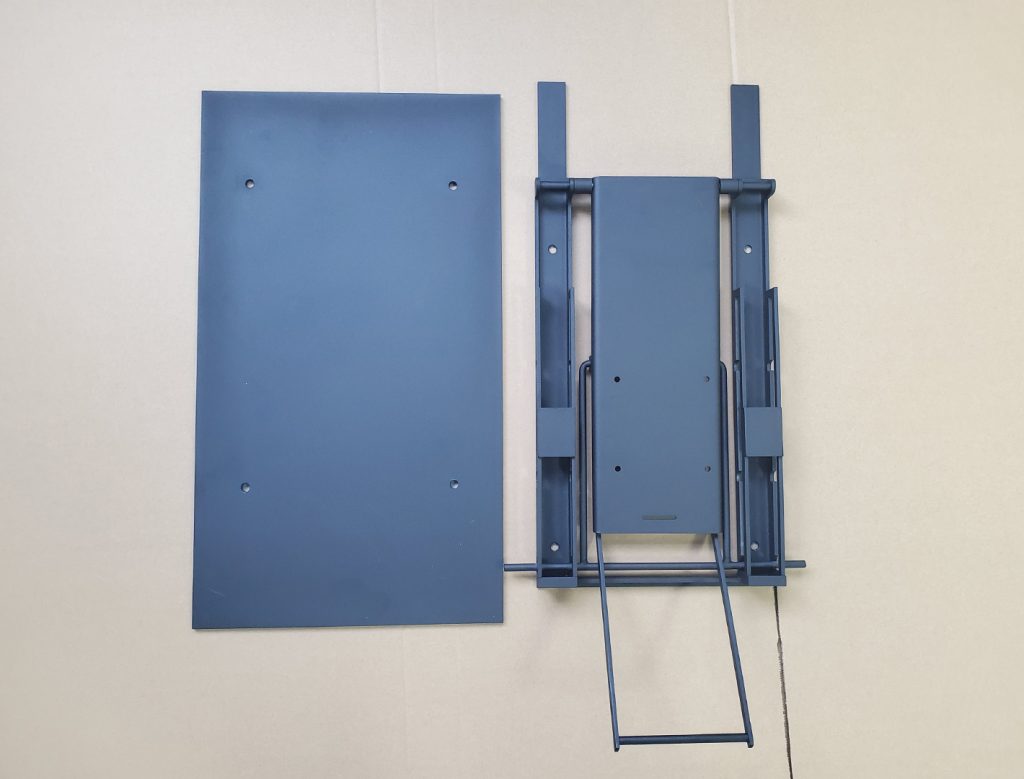

Sheet metal fabrication is a set of manufacturing processes used to turn sheet metal stock into functional parts. The sheet metal is usually between 0.006 and 0.25 inches (0.015 and 0.635 centimeters) thick.

There are several processes that fall under the umbrella of ‘sheet metal fabrication’. These include cutting, bending and punching, and can be used either in tandem or individually.

Sheet metal fabrication can be used to create either functional prototypes or end-use parts, but end-use sheet metal parts generally require a finishing process before they are ready for market.

Sheet Metal FAQ

The type of cutting machine used depends on the chosen material and the gauge of the sheet, as well as factors like desired lead time and tolerances.

We know which projects need which equipment, so you don’t need to specify a particular cutting machine.

In general, a part that is cut, bent and punched will cost more than a part that is, for example, just cut using a laser cutter.

However, most sheet metal parts demand a combination of forming processes, and this will not increase the price by a drastic amount.

No. You can order a one-off prototype or 1,000+ units.