Online Manufacturing for Metal parts and Plastic Parts, XTJ Precision Mfg Ltd

Mobile: +86 17704021786

Email:[email protected]

Capabilities

CNC Machining Service

✓ Instant Quotes & DFM Feedback

✓ Parts as Fast as 2 days

✓ Tight Tolerances

✓ Hand Metrology, Laser & CMM Inspections

Faster Lead Times

With instant online quotes and rapid production, you can reduce cycle times by as much as 50%.

World-Class Machine Shops

Tap into a highly vetted and managed network of the best machine shops world-wide.

Flexible Pricing

Choose between fast and cost-effective options to find the best price.

Our CNC machining capabilities

At Xin Tian Jian mfg, we consist of two manufacturing facilities and one sales support center, covering a total area of 12,000 square meters. With more than 120 sets state of art CNC machines imported from trusted brands like GROB, DMG, APEC, and Mikron and more than 300 experienced staff, as result, we are the most popular choice across many industries for our multi-axis-milling-capabilities. Our APEC 5 Axis gantry center is capable of processing large dimensional components by up to 4000X 2500 X1000 MM, plus GROB and DMG, two of the most trusted CNC machinery brand from Germany. We can provides high-quality precision CNC machined components for those industries with tight tolerance. Our in house CMM inspection equipment are made by Zeiss and Hexagon enabling us to guarantee quality via CMM, FAI report. The smallest processing dimension and inspection accuracy are plus and minus 0.003mm. We can process an abroad range of materials which includes titanium, steel, aluminum, copper, plastic, and other materials. With all the extensive capabilities we have mentioned above, we can also provide OEM and dust proof assembly service.

3 & 5 axis CNC milling

Our manufacturing facilities has over 30 milling centers, including standard 3-axis mills, 5-axis mills.

CNC Turning

Our manufacturing facilities has over 30 turning centers, including Japan lathes and multi-axis mill turns.

CNC Machining Materials

Finishing Options for CNC Machining

| Name | Applicable Materials | Colors | Can be applied with | |

|---|---|---|---|---|

|

|

Alodine | Aluminum | Clear, gold | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*, Type III Anodizing with PTFE* |

|

|

Anodizing | Aluminum | Clear, black, grey, red, blue, gold | Media Blasting, Tumbling, Alodine* |

|

|

Black Oxide | Steel, Stainless Steel | Black | Media Blasting, Tumbling, Passivation |

|

|

Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

|

|

Electropolishing | Steel, Stainless Steel | — | — |

|

|

Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes except Electropolish and Powdercoat |

|

|

Nickel Plating | Aluminum, Steel, Stainless Steel | — | Media Blasting, Tumbling |

|

|

Passivation | Steel, Stainless Steel | — | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

|

|

Powder Coating | Aluminum, Steel, Stainless Steel | Black (20% or 90% gloss), white (20% or 90% gloss) | — |

|

|

Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | — | All post processes except Electropolish and Powdercoat |

|

|

Zinc Plating | Steel, Stainless Steel | Clear: light blue coating, black: glossy black coating | Media Blasting, Tumbling, Passivation |

From Prototype to Production

Mid Stage Prototypes

Prototype CNC machining is an ideal process for mid-stage functional prototypes. XTJ can help you accelerate development cycles with rapid prototyping by providing instant online quotes, intelligent DFM feedback, and quick lead times.

- Finishing, masking & hardware installation

- CNC Milling, CNC turning, gear hobbing, EDM

- Tolerances as tight as +/- 0.0002″

Production Parts

Custom CNC machining is often leveraged for end-use production grade parts. XTJ’s global manufacturing network is optimized for production machining, with volumes up to 1M units.

- Inspections using CMM or laser scanners

- Material certification available

- ISO 9001 certified, AS 9100 / ISO 13485 compliant

Production Tooling

Online CNC machining services are ideal for manufacturing components needed for production, including fixtures, jigs, gauges, molds, dies, cutting equipment, and patterns.

- Vetted partners in the U.S. and overseas

- Economical pricing options

- 2D drawings accepted

Our In House CNC Machiney Equipments

XTJ Precission simplifies the process of sourcing custom machined parts. We offer you the capacity and capabilities of two of manufacturing facilities, with the ease of dealing with XTJ. You get the experience and specialization of all our manchinery, we handle all the communications, delivery, and quality control .

CNC Machining facility in Dong Guan

Established: 2005

Capabilities: CNC Machining 5, 4, 3 Axis. Mill Turn and turning

Machines: GROB, Mikron

Expertise: Fast, low-cost prototyping. Strong and complex end-use parts

Description: Specializes in highly complex parts with difficult geometries and tight tolerances

CNC Machining facility in Shenzhen

Established: 2012

Capabilities: CNC parts for the medical and consumer products industries

Machines: 40 CNC machines, 6 CNC bending presses

Expertise: Visual prototypes and functional end parts

Description: Produce end-product parts with high cosmetic requirements

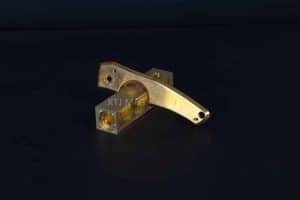

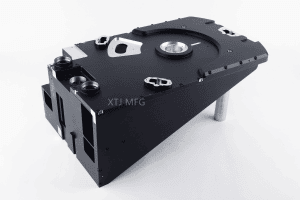

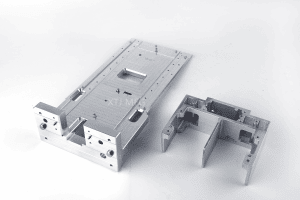

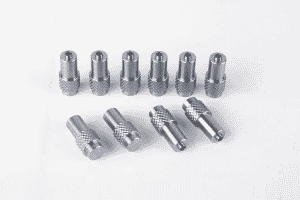

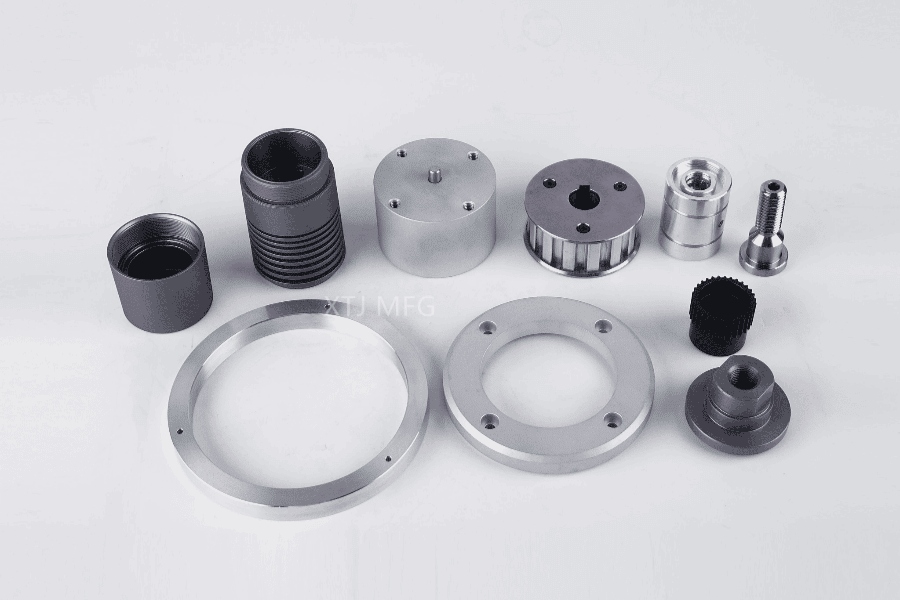

Gallery of CNC machined parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.