Why Titanium is Ideal for CNC Machining: Properties, Types, and Applications

Introduction

Titanium is a standout material in precision manufacturing, prized for its exceptional strength-to-weight ratio, corrosion resistance, and versatility. In CNC machining, titanium’s unique properties make it a top choice for industries like aerospace, medical, and automotive, where precision and durability are critical. At XTJ Precision Mfg, we specialize in machining titanium and its alloys to deliver high-quality components that meet the stringent demands of these sectors. This article explores titanium’s properties, the types of alloys used in CNC machining, cost-saving design strategies, and how our advanced machining capabilities ensure superior results for your projects.

What is Titanium?

Titanium is a lightweight, high-strength metal known for its remarkable corrosion resistance and biocompatibility. With a low density (about 60% that of steel) and a high tensile strength, titanium is ideal for applications requiring durability without added weight. Its resistance to corrosion in harsh environments, such as seawater or chemical processing plants, makes it a go-to material for critical components. Additionally, titanium’s biocompatibility ensures it’s safe for medical implants, as it integrates well with human tissue.

In CNC machining, titanium’s properties present both opportunities and challenges. Its strength and low thermal conductivity require specialized tools and techniques to prevent tool wear and manage heat buildup. At XTJ Precision Mfg, we leverage state-of-the-art CNC equipment and expertise to machine titanium with precision, delivering components that meet tight tolerances and high-performance standards.

Types of Titanium Alloys for CNC Machining

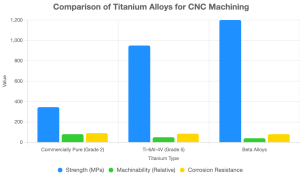

Titanium alloys are classified based on their metallurgical structure—alpha, alpha-beta, or beta phases—which determine their strength, machinability, and weldability. Below, we focus on the most common titanium types used in CNC machining:

-

Commercially Pure Titanium (Grades 1–4): These unalloyed grades offer excellent corrosion resistance and formability but have lower strength. They are easier to machine and ideal for applications like chemical processing equipment.

-

Ti-6Al-4V (Grade 5): The most widely used alpha-beta alloy, Ti-6Al-4V combines high strength, low density, and excellent corrosion resistance. It’s prevalent in aerospace for turbine blades and structural components, as well as in medical implants.

-

Beta Alloys: These alloys, alloyed with elements like molybdenum or vanadium, offer the highest strength and are used in specialized applications like high-stress aerospace parts. However, they are more challenging to machine due to their hardness.

The table below compares key properties of these titanium types to guide material selection for CNC machining:

|

Titanium Type |

Strength (MPa) |

Machinability (Relative) |

Corrosion Resistance |

Weldability |

|---|---|---|---|---|

|

Commercially Pure (Grade 2) |

345 |

High (80%) |

Excellent (90%) |

Very Good |

|

Ti-6Al-4V (Grade 5) |

950 |

Medium (50%) |

Excellent (85%) |

Good |

|

Beta Alloys |

1200 |

Low (40%) |

Good (80%) |

Generally Weldable |

Machining titanium requires precision due to its toughness and low thermal conductivity, which can lead to tool wear and heat buildup. At XTJ Precision Mfg, we use advanced 5-axis CNC machines, high-performance cutting tools, and optimized coolant systems to overcome these challenges, ensuring flawless components every time.

Our team works closely with clients in aerospace, medical, and automotive industries to provide tailored solutions, from prototyping to high-volume production. Whether you need complex geometries or tight tolerances, we have the expertise and technology to deliver. Contact us today for a quote on your next titanium machining project and discover how we can bring your designs to life with cost-effective solutions.

Applications of Titanium in CNC Machining

Titanium’s unique properties make it indispensable in industries requiring high-performance components. Here are key applications where CNC-machined titanium shines:

-

Aerospace: Titanium’s high strength-to-weight ratio and resistance to extreme temperatures make it ideal for aircraft components. For example, the Boeing 787 uses approximately 116 metric tons of titanium for parts like turbine blades, landing gear, and structural frames. At XTJ , we machine complex titanium parts with tight tolerances to meet aerospace standards like AS9100.

-

Medical: Titanium’s biocompatibility and corrosion resistance make it perfect for medical implants, such as hip replacements, dental implants, and surgical instruments. Our CNC machining ensures precision and surface quality critical for medical applications.

-

Automotive: In high-performance vehicles, titanium is used for lightweight, durable components like exhaust systems and suspension parts. Our advanced machining capabilities deliver parts that enhance vehicle performance and durability.

Our CNC machining processes, including milling, turning, and 5-axis machining, enable us to produce intricate titanium components with exceptional accuracy. Whether it’s a turbine blade or a medical implant, we ensure every part meets industry specifications and client expectations.

How Optimized Design Lowers Titanium Machining Costs

Titanium’s premium properties come with higher material and machining costs, but strategic design optimizations can significantly reduce expenses without compromising quality. At Precision CNC Solutions, we collaborate with clients to implement cost-saving techniques, including:

-

Minimizing Material Waste: By optimizing part geometry and nesting designs efficiently, we reduce the amount of titanium used. For example, using near-net-shape designs minimizes excess material removal during machining.

-

Simplifying Geometries: Complex features like deep pockets or intricate contours increase machining time and tool wear. We work with clients to simplify designs where possible, such as using standard radii or reducing unnecessary undercuts, to streamline production.

-

Selecting Cost-Effective Alloys: While Ti-6Al-4V is ideal for high-strength applications, commercially pure titanium (e.g., Grade 2) can be used for less demanding parts, offering lower material costs and easier machinability.

-

Leveraging Advanced Toolpaths: Our 5-axis CNC machines use optimized toolpaths to reduce machining time and tool wear, lowering overall costs. For instance, high-speed machining techniques improve efficiency for titanium parts.

-

Prototyping and Simulation: We use CAD/CAM simulations to test designs before machining, identifying potential issues early to avoid costly reworks.

By integrating these strategies, we help clients achieve high-quality titanium components within budget. Our team provides design-for-manufacturability (DFM) feedback during the quoting process to ensure cost-effective outcomes tailored to your project’s needs.

Why Choose XTJ Precision Mfg for Titanium CNC Machining?

At Precision CNC Solutions, we bring decades of experience in machining titanium and its alloys. Our state-of-the-art facility features advanced 5-axis CNC machines, high-performance tooling, and rigorous quality control processes certified to ISO 9001 and AS9100 standards. We specialize in overcoming titanium’s machining challenges, such as tool wear and heat management, to deliver components with unparalleled precision and reliability.

Conclusion

Titanium’s strength, lightweight nature, and corrosion resistance make it a premier material for CNC machining in high-stakes industries. By optimizing designs and leveraging advanced machining techniques, XTJ Precision Mfg delivers high-quality titanium components that balance performance and cost. From aerospace components to medical implants, we ensure precision and reliability for every project. Ready to start your titanium project? Reach out to XTJ today to discuss your needs and request a quote!