Improving Manufacturing Precision and Accuracy in the Aerospace Industry With CNC Machining’s Latest Technologies

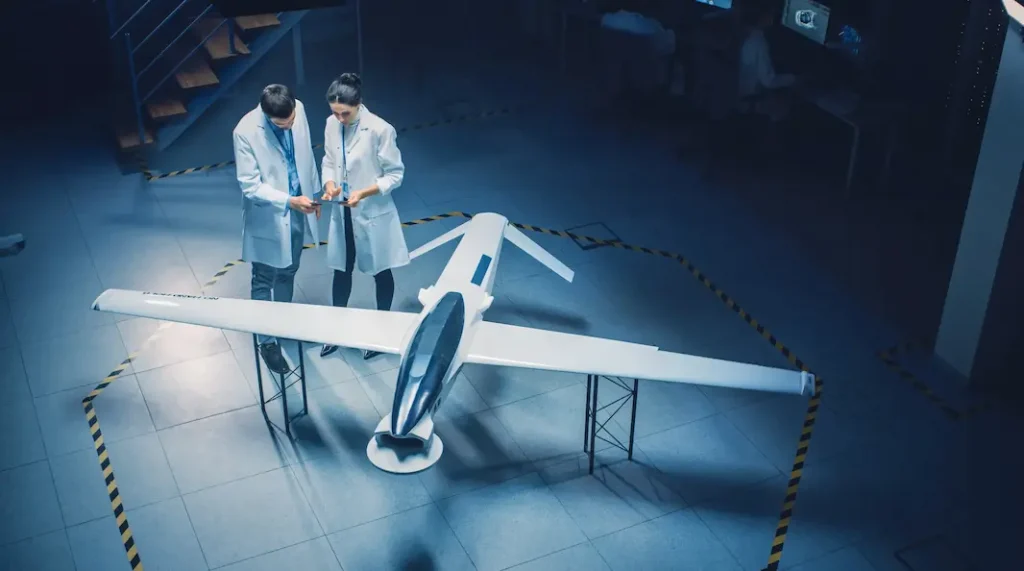

As the aerospace industry continues to become more and more precise, a greater demand has arisen for an organization that can provide CNC machining services that meet aerospace standards. Aerospace CNC machining is a service that will help customers create products and parts with the same level of precision that aerospace manufacturers can provide.

What makes Aerospace Machining a Special Industry

Aerospace Machining is an industry that creates products for aerospace, defense, and commercial purposes. It has been around since before World War II and it continues to be a leading manufacturing sector today with over $600 billion in annual revenue.

Aerospace is an industry where machining errors and inaccuracies are the least tolerated considering the dire consequences a part’s failure can cause. Whether to avoid the safety hazard or the potential financial losses, aerospace production companies are always on the search for high-quality techniques and innovations to improve their production means. Which explains why it was the first industry in the world to use computer numerical control (CNC) machining that allows fo

Aerospace CNC Machining

CNC aircraft components are in high demand due to the advanced machining process used to create them. Aerospace CNC machining involves the utilization of CNC machining techniques to produce parts and components for aircraft. CNC machining is utilized to increase the accuracy and efficiency of manufacturing these parts.

Aircraft manufacturers in the world use a variety of metals in their construction process. Aluminum is the most commonly used metal, but other metals such as titanium and steel are also employed.

Our aircraft parts are made of the highest quality, durable material, and they’re all tested before shipping. In addition to our unmatched services, our professionals are able to help with any machining inquiry, as well as offer consultation on your project size and budget.

The Importance of Precision Machining in the Aerospace Industry

One of the most important steps in the process of creating parts for the aerospace industry is precision machining. As any aircraft builder will tell you, it is vital to produce as many parts with no defects as possible, as well as to keep costs low and production efficient. Defective parts can cause a number of problems, from minor glitches to catastrophic failures. This can lead to costly repairs, missed deadlines, and even loss of life. In the worst-case scenario, defective parts can bring down an entire aircraft.

One of the most important steps in the process of creating parts for the aerospace industry is precision machining. As any aircraft builder will tell you, it is vital to produce as many parts with no defects as possible, as well as to keep costs low and production efficient. Defective parts can cause a number of problems, from minor glitches to catastrophic failures. This can lead to costly repairs, missed deadlines, and even loss of life. In the worst-case scenario, defective parts can bring down an entire aircraft.

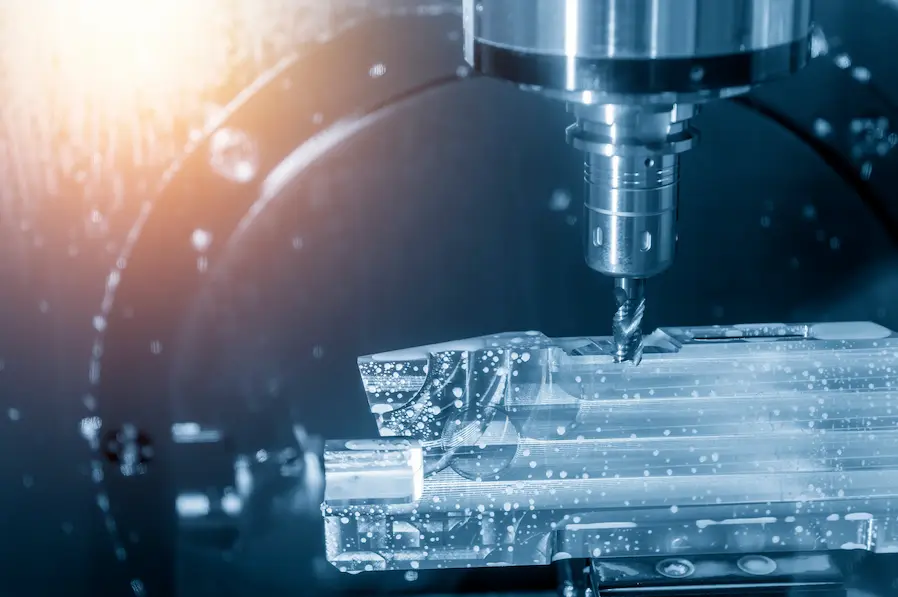

This is when CNC machining steps in as it is the best provider of the quality and accuracy standards the aerospace industry relies on during its production processes. As a matter of fact, CNC machining can save you a considerable amount of money by cutting costs and bringing down production time. CNC machines can create parts with very tight tolerances and extremely precise dimensions.

At Xin Tian Jian Machining, we understand the demands of aerospace CNC machining. Our company is committed to providing excellent service and superior quality. We have cutting-edge equipment and tools to offer our customers a wide variety of services, from simple CNC milling to complex 3D surface milling, turning, and grinding. We also offer laser cutting, micro-drilling, EDM, etc., all of which are available at our manufacturing facilities.

Advanced Aerospace CNC Machining Techniques

There are a few things that can be done in order to achieve greater precision in CNC machining for aerospace applications. First, the latest advancements in CNC technology should be adopted in order to take advantage of the latest tools and machines available. Additionally, a rigorous quality control process should be implemented in order to ensure that all parts produced meet the required specifications.

3-axis CNC machining

3-axis CNC machining is the perfect technology to meet the demands of the aerospace industry. The three-axis CNC machine is a solid workhorse when it comes to producing parts. It is relatively easy to operate, it generates very little dust and noise, and it produces parts with great accuracy and precision. It also has the added benefit of being able to work in a wide variety of materials and features, such as aluminum, stainless steel, and carbon fiber. One of the main advantages of 3-axis machining is that it can machine parts in a very flat plane and it is capable of producing parts at extremely high speeds.

5-axis CNC machining

A five-axis machining process helps to create complex aircraft components. This aerospace machining process allows for parts to be milled, drilled, and manipulated along the X, Y, Z, and rotational axes. These processes can occur simultaneously without having to reconfigure or fixture the part. In the aerospace sector, complexity is seen as an asset because it can reduce weight. This is done by producing parts with a partially hollowed out or complex geometry, without sacrificing quality or performance.

Xin Tian Jian Aerospace CNC Machining Expertise

Our team is comprised of experienced aerospace engineers with a proven track record of providing high-quality CNC machining services to our customers. Xin Tian Jian Machining is confident that we have what it takes to meet your requirements, no matter how complex your project is.

Expertise and Precision

We have the expertise and precision to help you achieve your goals. Our team has extensive experience in designing, machining, and manufacturing complex aerospace components. We understand the importance of meeting precise tolerances, which is what sets us apart from other manufacturing companies.

Intricate Milling

Machining of complex parts requires intricate milling. Our CNC vertical milling technology, along with our custom-designed machining centers, allows us to machine complex parts into precision parts.

Productive partnerships

Xin Tian Jian Machining is committed to ensuring a productive partnership with our clients. Whether it’s aviation, defense, or commercial, we take pride in providing a high-quality product with timely delivery at a competitive price.

Start Your Project With A Free Quote

If you’re looking for a reliable partner to help you get your aerospace machining project off the ground, look no further than us. We have a long history of providing precision machining services to clients in a wide range of industries. Let us put our experience to work for you and start your project off on the right foot.