How to Get the Most from Stainless Steel CNC Machining Services

You can boost your project success by choosing the right CNC machining provider and making communication a top priority. Selecting a certified partner, such as XTJ precision Mfg, can cut product defects by 40% and reduce delivery time by 25%.

| Benchmark Description | Numerical Value | Implication for CNC Machining Services |

|---|---|---|

| Reduction in product defects after ISO 9001 | 40% | Shows the value of strict quality controls in provider selection. |

| Delivery time reduction by choosing closer provider | 25% | Faster logistics with a closer provider. |

| Shipping cost reduction from logistics shift | 15% | Save costs with strategic provider selection. |

| Stay informed through regular updates and assign a clear point of contact. These steps help you avoid costly mistakes and keep your CNC machining project on track. |

Key Takeaways

- Choose an experienced and certified CNC machining provider to reduce defects and speed up delivery.

- Understand the CNC machining steps: design, programming, machining, and inspection for better results.

- Select the right stainless steel grade (304, 316, or 17-4 PH) based on your part’s strength and corrosion needs.

- Use advanced tools and cooling methods to manage tool wear and maintain part quality.

- Communicate clearly with your provider using detailed specs and regular updates to avoid costly mistakes.

- Plan post-processing steps like deburring, polishing, and passivation early to improve part finish and durability.

- Leverage CNC machining benefits such as high precision, durability, versatility, and cost savings.

- Collaborate closely with your provider throughout the project to ensure smooth production and timely delivery.

CNC Machining Process

Overview

You use CNC machining to shape stainless steel into precise parts. The process relies on computer-controlled machines that cut, mill, drill, and shape metal with high accuracy. Advanced software creates tool paths, while high-speed spindles and multi-axis movement allow you to produce complex geometries. You benefit from real-time monitoring and predictive maintenance, which reduce downtime and improve efficiency.

Tip: Industry 4.0 technologies, such as IoT and AI, now play a big role in CNC machining. These tools help you achieve better precision and faster production.

The global CNC machining market continues to grow, especially in sectors like automotive, aerospace, and medical devices. Automation and robotics make your operations smarter and more reliable. Hybrid manufacturing, which combines CNC machining with 3D printing, expands your options and reduces waste.

Steps

Design

You start with a digital model of your part. CAD (Computer-Aided Design) software lets you create detailed drawings and specifications. You define dimensions, tolerances, and surface finishes. Good design helps you avoid errors and ensures the part meets your needs.

Programming

Next, you use CAM (Computer-Aided Manufacturing) software to convert your design into machine instructions. The software generates G-code, which tells the CNC machine how to move. You can optimize tool paths and cutting strategies to improve speed and surface quality. Adaptive dynamic roughing and side cutting edge finishing help you balance tool load and achieve a smooth finish.

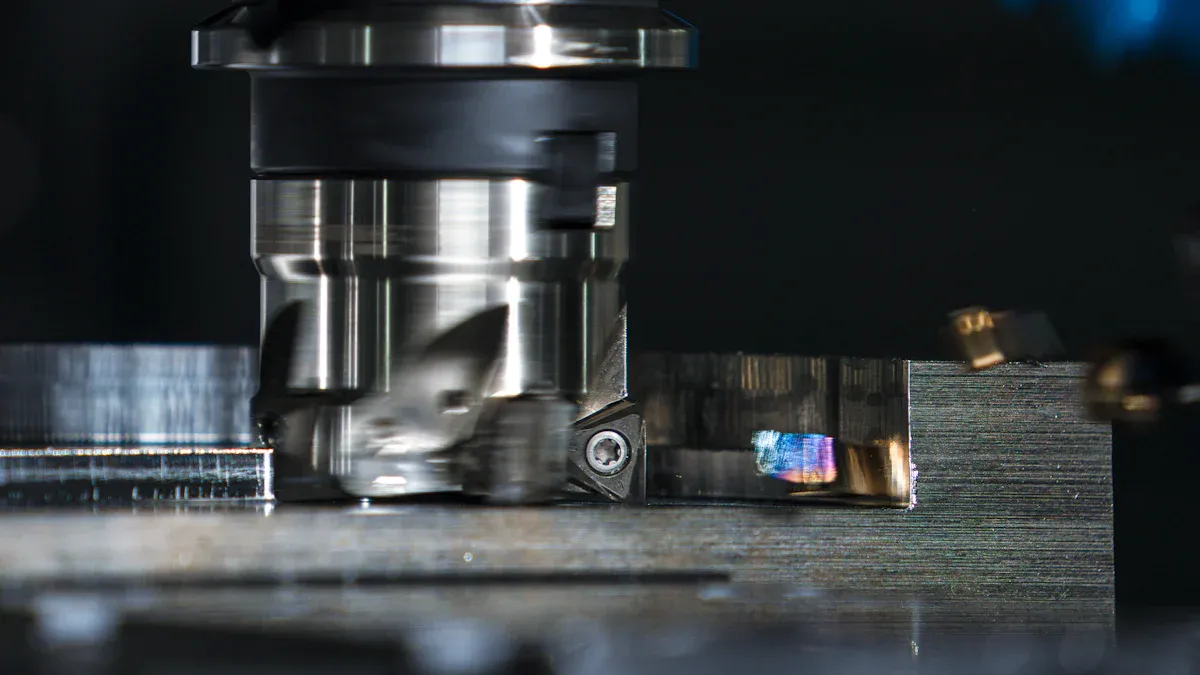

Machining

You set up the CNC machine by installing the right cutting tools and securing the stainless steel workpiece. You input the material type and adjust parameters like spindle speed, feed rate, and depth of cut. You run a dry test to check the tool path. During machining, you monitor coolant flow to control heat and prevent workpiece damage.

- Power on the CNC machine and perform system checks.

- Install the correct cutting tool for your stainless steel grade.

- Secure the workpiece to prevent movement.

- Input material data and set machining parameters.

- Load the G-code and measure tool offsets.

- Run a test cycle to verify everything.

- Start machining and monitor the process.

Note: Using coated carbide cutters and internal cooling tools helps you manage heat and tool wear, especially with tough grades like 17-4 PH.

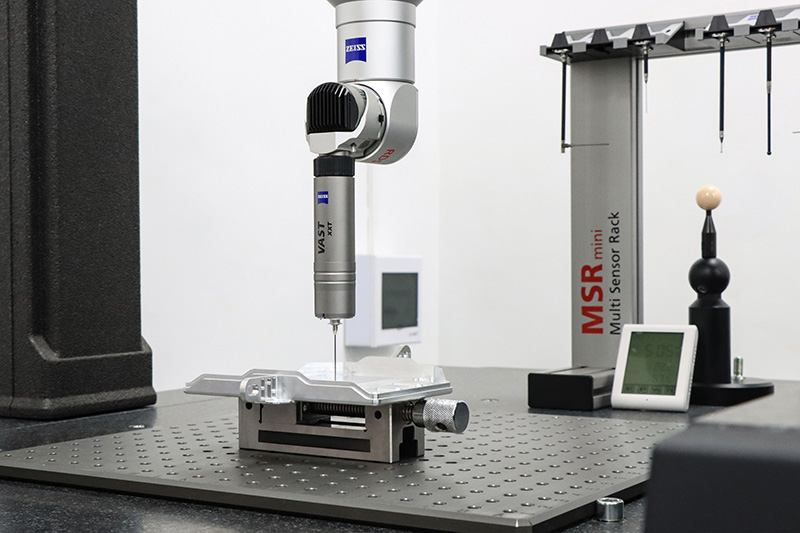

Inspection

After machining, you inspect the part for accuracy. You measure dimensions and check surface finish. Precise fixture design during setup ensures repeatability and reduces distortion. You may use surface finishing processes like electropolishing or passivation to improve corrosion resistance and appearance.

Stainless Steel Types

304

304 stainless steel is the most common grade you will use. It offers good corrosion resistance and ductility. You can machine it with moderate cutting speeds and standard carbide tools. Its typical yield strength is around 215 MPa, which influences your choice of feed rates and tool materials.

316

316 stainless steel contains molybdenum, which gives you better corrosion resistance, especially in harsh environments. It is slightly softer than 304, so you can use similar machining parameters. You often choose 316 for medical or marine applications.

17-4 PH

17-4 PH is a martensitic stainless steel with high tensile strength (about 1034 MPa) and hardness (33 HRC). You face challenges like surface hardening and poor thermal conductivity when machining this grade. You need to use coated carbide or ceramic tools, lower cutting speeds, and efficient cooling to maintain quality and tool life.

| Stainless Steel Grade | Tensile Strength (MPa) | Elongation (%) | Hardness |

|---|---|---|---|

| 17-4 PH | 1034 | 8 | 33 HRC |

| 304 | 683 | 52 | 85 HRB |

| 316 | 586 | 56 | 81 HRB |

You see that 17-4 PH provides the highest strength but is less ductile, while 304 and 316 offer a balance of strength and workability.

- Selecting the right cutting speed and tool material for each stainless steel type helps you balance tool life and part quality.

- Managing tool wear and using coolants are essential for high-strength grades.

- Optimizing cutting depth and ensuring proper setup prevent errors and maintain accuracy.

By following these steps and choosing the right stainless steel grade, you improve your CNC machining results. You achieve better part quality, longer tool life, and more efficient production.

Benefits

Precision

You gain unmatched accuracy when you use stainless steel CNC machining. Modern CNC machines achieve tight tolerance standards up to 0.001 inch. This level of precision means your parts fit perfectly and function as intended. Surface finishes can be as smooth as 15Ra, which reduces friction and improves performance.

- ISO 9001:2015 certified inspections ensure every part meets strict quality standards.

- Advanced holding techniques, such as vacuum, chuck, and vise systems, keep your workpiece stable during machining.

- The latest CAD/CAM software helps you design and manufacture parts with high efficiency and minimal error.

You also benefit from advanced quality control. Coordinate Measuring Machines (CMMs) and laser scanning systems check your parts for accuracy. These tools reduce human error and catch problems early. In-process monitoring with IoT sensors tracks temperature, vibration, and feed rates in real time. This allows you to make quick adjustments and prevent defects.

Tip: Use carbide or DLC-coated tools for better wear resistance and precision. TiAlN coatings help reduce friction and heat, which keeps your parts accurate.

Durability

Stainless steel CNC machining gives you parts that last. You get excellent corrosion resistance and strength, even in harsh environments. Heat treatment processes, such as solution annealing and age hardening, improve the metal’s durability and stability. Stress-relief treatments help your parts keep their shape and resist cracking.

- Quality control starts with certified materials and careful temperature management during forging.

- Post-forging inspections, including ultrasonic and dye penetrant testing, catch internal and surface flaws.

- Mechanical tests check tensile strength, impact resistance, and hardness, so you know your parts will perform under stress.

Corrosion testing is common for critical parts. This ensures your components resist rust and chemical damage over time. These steps mean your stainless steel parts can handle tough jobs and keep working longer.

Versatility

CNC machining offers you unmatched design flexibility. You can create complex shapes and intricate details using multi-axis machines. This technology supports 3-, 4-, and 5-axis operations, so you can produce parts with fewer setups and less waste. Integration with CAD/CAM systems lets you test and optimize designs virtually before production.

The global CNC machining market, valued at about $83 billion in 2022, shows strong demand for precision and complex parts in industries like aerospace, medical, and automotive. You can machine a wide range of metals and plastics, including exotic materials. Rapid prototyping services let you test ideas quickly and make changes without delaying your project.

| Material Type | Common Applications | Key Properties |

|---|---|---|

| Metals (Aluminum, Steel, Titanium, Brass, Copper, Alloys) | Aerospace components, automotive parts, industrial equipment | Strength, durability, lightweight, corrosion resistance |

| Engineering Plastics (ABS, Nylon, PEEK, Acrylic, Polycarbonate) | Medical devices, consumer products | Chemical resistance, electrical insulation |

| Composites | Aerospace, specialized tooling | Customizable properties, lightweight |

You can scale production from a single prototype to mass manufacturing without changing tools. This versatility helps you adapt to new requirements and deliver consistent quality at any volume.

Cost Savings

You can achieve significant cost savings when you use stainless steel CNC machining services. This process helps you control expenses at every stage of production. You see savings in both direct and indirect costs, which improves your return on investment (ROI) over time.

CNC machining lets you produce parts with high accuracy. You reduce the number of defective parts, which means you waste less material. You also save money on rework and scrap. When you use advanced machines, you can run faster production cycles. This speed helps you meet tight deadlines without extra labor costs.

Modern CNC machines use real-time monitoring and predictive maintenance. IoT sensors and AI algorithms track machine health. You avoid unexpected breakdowns and reduce downtime. This lowers your maintenance costs and keeps your production line running smoothly.

You also benefit from energy-efficient machines. Newer models use less power for each part they produce. You save on electricity bills and reduce your carbon footprint. Some machines combine both additive and subtractive manufacturing. This hybrid approach saves space and reduces the need for extra equipment.

Choosing the right machine size for your project also impacts your costs. Small CNC machines work well for short runs and quick setups. Large machines handle continuous production and bigger parts. You match your machine to your needs, which helps you avoid overspending.

| Feature / Parameter | Description / Technical Aspect | Economic Benefit / ROI Justification |

|---|---|---|

| Customization & Speed | Advanced tooling options, adjustable spindle speeds, faster feed rates | Higher initial cost but leads to faster production, better meeting specific manufacturing needs, improving ROI over time |

| Real-Time Monitoring & Predictive Maintenance | IoT sensors combined with AI algorithms for continuous monitoring | Reduces downtime and maintenance costs, lowering operational expenses despite higher upfront investment |

| Material Versatility | Capability to machine superalloys, composites, advanced ceramics | Requires stronger, more accurate machines, increasing cost but enabling processing of diverse materials, expanding applications |

| Power Efficiency | Work done per kWh ratio | Higher initial cost models save money on energy consumption and reduce carbon emissions, lowering long-term operational costs |

| Hybrid Machines | Support for both additive (3D printing) and subtractive manufacturing | Saves space and capital expenditure by combining two functions in one machine, reducing future investment needs |

| Small vs Large CNC Machines | Small machines for quick setups and short runs; large machines for continuous operation | Selection based on production needs optimizes efficiency and cost-effectiveness, aligning with budget and facility constraints |

Tip: You can maximize your savings by working with a provider who uses the latest CNC technology and energy-efficient machines.

You also save money by reducing the need for manual labor. CNC machines automate many tasks, so you need fewer operators. This automation lowers your labor costs and reduces the risk of human error.

When you choose stainless steel CNC machining, you invest in a process that pays off in the long run. You get high-quality parts, faster production, and lower operating costs. These benefits help you stay competitive and grow your business.

Choosing a Provider

Experience

You should always check a provider’s experience before starting your project. Providers with years of hands-on work in CNC machining understand the challenges of stainless steel. They know how to handle complex parts and tight tolerances. Experienced teams can spot design issues early and suggest improvements. This helps you avoid costly mistakes and delays.

Look for companies that have completed projects similar to yours. Ask for case studies or references. Providers with a strong track record in your industry can deliver better results. They know the standards and requirements for aerospace, medical, or automotive parts. You gain confidence when you see proof of successful projects.

Tip: Choose a provider that invests in ongoing training. Skilled machinists and engineers keep up with the latest techniques and tools.

Technology

Advanced technology sets top providers apart. Modern CNC machining shops use high-performance machines with features like multi-axis movement, high-speed spindles, and real-time monitoring. These machines produce parts faster and with greater accuracy.

You should also pay attention to the type of motors used in the equipment. The table below shows how different motor types affect performance:

| Motor Type | Function and Impact on CNC Performance |

|---|---|

| Servo Motors | Provide closed-loop control for higher precision; key parameters include torque (Nm) and speed (RPM). |

| Stepper Motors | Convert motor movement into precise tool paths; accuracy influenced by lead screw pitch or belt drive characteristics. |

Providers who use servo motors can achieve tighter tolerances and smoother finishes. Shops that use predictive analytics and AI can reduce downtime and improve efficiency. Multi-axis machining and laser cutting allow for more complex designs and faster production cycles. These features help you get better parts and meet tight deadlines.

Quality

Quality should be your top priority when choosing a CNC machining partner. Reliable providers use strict quality control methods to ensure every part meets your standards. They often use sampling techniques such as simple random sampling, stratified sampling, and acceptance sampling based on AQL. These methods help catch defects early and keep production consistent.

You can also compare providers using key quality metrics:

| Quality Metric | Description | How It Supports Provider Selection Evaluation |

|---|---|---|

| First-Pass Yield (FPY) | Percentage of products manufactured correctly the first time without rework | Identifies production efficiency and process reliability, highlighting supplier quality consistency |

| Defect Rates (DPPM, DPMO) | Defective parts or defects per million opportunities, measuring frequency of defects | Helps pinpoint stages with frequent defects and compare supplier performance |

| Scrap Rate | Percentage of materials wasted or discarded during production | Indicates material waste and supplier input quality, aiding in supplier selection |

| Supplier Defect Rate | Percentage of supplied materials failing to meet quality specifications | Directly measures supplier quality and reliability |

| Incoming Supplier Quality | Percentage of materials received that meet quality requirements | Assesses supplier compliance and consistency in delivering quality inputs |

Providers with high first-pass yield and low defect rates show strong process control. Certifications like ISO 9001:2015 prove a commitment to quality. Always ask about inspection equipment, such as CMMs and laser scanners. These tools help ensure your parts meet every specification.

Support

You need strong support from your machining provider to keep your projects on track. Good support means you get answers quickly, solve problems fast, and feel confident about your orders. When you choose a provider, look for a team that values your time and understands your needs.

A reliable provider gives you a dedicated point of contact. This person helps you with questions, updates, and any changes to your order. You should never feel lost or ignored. Fast and clear communication builds trust and helps you avoid mistakes.

You can measure support quality using several key metrics. These numbers show how well a provider handles customer needs:

- Customer Satisfaction Score (CSAT): Shows how happy customers feel after getting help.

- Support Performance Score: Combines different factors to rate overall support.

- Customer Effort Score (CES): Tells you how easy it is to get help.

- First Response Time (FRT): Measures how quickly you get a reply.

- Average Resolution Time: Tracks how long it takes to fix your issue.

- Escalation Rate: Counts how often problems need higher-level help.

- Net Promoter Score (NPS): Shows if customers would recommend the provider.

- Customer Churn Rate: Tells you how many customers stop using the service.

- Ticket Volume: Counts the number of support requests.

- Auto-Resolution Rate: Shows how many issues get solved automatically.

- First Contact Resolution (FCR): Measures how often problems get fixed in the first try.

- Average Handle Time (AHT): Tracks the time spent on each support case.

- Interactions per Ticket: Counts how many times you need to contact support for one issue.

- Average Sentiment Score: Uses AI to measure how customers feel about their support.

- Top Conversation Intents: Lists the most common reasons customers reach out.

Tip: Ask your provider about these metrics. High scores in CSAT, FCR, and NPS mean you can expect great support.

You should also check if the provider uses modern tools like AI chatbots or automated ticketing. These tools help solve simple problems fast and free up staff for complex issues. Providers who invest in these systems care about your experience.

Support goes beyond just answering questions. You want a provider who helps you plan, gives you updates, and solves problems before they grow. Look for companies that offer training, clear documentation, and regular project reviews. These steps help you avoid delays and keep your project moving forward.

XTJ precision Mfg stands out for its strong customer support. You get fast responses, clear updates, and expert advice at every stage. This level of support helps you finish projects on time and with fewer headaches.

Maximizing Results

Design Tips

You can improve your CNC machining outcomes by focusing on smart design strategies. Start by using simulation-driven design tools. These tools let you test your ideas early and catch problems before production. You can use CAD and CAE software together to create designs that are easy to manufacture. This approach helps you avoid costly changes later.

- Try topology optimization to remove unnecessary material. This method keeps your parts strong but uses less metal, which saves money.

- Use parametric modeling to quickly test different shapes and sizes. You can find the best design without making many physical prototypes.

- Share your digital models with your team. This step helps everyone stay on the same page and reduces mistakes.

Machine learning and data-driven modeling also help you predict how your part will behave. These methods let you control process variables and improve quality. You can use these tools to spot defects early and make better decisions about your design.

Tip: Simulate the entire manufacturing process. This step helps you plan for material flow and avoid production delays.

Material Selection

Choosing the right material is key to a successful project. You need to balance machinability, cost, and performance. The table below shows common materials, their properties, and machining tips:

| Material | Key Properties | Machining Tips | Cost Range (per kg) | Common Uses |

|---|---|---|---|---|

| Aluminum | Soft, easy to machine | Use high-speed tools, light coolant | $2–$5 | Brackets, auto parts |

| Titanium | Strong, hard to cut | Low speeds, cryogenic cooling, coated tools | $30–$50 | Turbine blades, implants |

| Stainless Steel | Corrosion resistant, tough | Moderate speeds, heavy coolant, sharp tools | $5–$10 | Medical, marine fittings |

| Brass | Very machinable, corrosion resistant | Standard speeds, moderate coolant | $5–$10 | Electrical, decorative |

| PEEK | Stable, chemical resistant | Standard tools, careful handling | ~$100 | Aerospace, medical |

You should match your tool coatings to the material’s hardness. For tough metals like titanium, use cryogenic cooling to extend tool life. For stainless steel, keep your cuts shallow and use plenty of coolant to avoid work hardening. Always consider the final use of your part when picking a material.

Note: Decision matrices can help you weigh cost, durability, and machinability for your application.

Communication

Clear communication with your CNC machining provider leads to better results. You should always specify your tolerance requirements in detail. Use GD&T (Geometric Dimensioning and Tolerancing) to show exactly what you need. This practice reduces errors and keeps costs down.

- Set realistic tolerance ranges. Tight tolerances increase cost and production time, so only use them where needed.

- Define strict upper and lower limits for part dimensions. This step makes quality control easier and ensures your parts fit together.

- Share your design intent with your provider. When everyone understands the goal, you avoid misunderstandings.

Case studies show that clear tolerancing improves efficiency and reduces defects. In aerospace projects, using GD&T helped teams achieve perfect fits and maintain safety standards. In satellite navigation, precise tolerances ensured mission success.

Tip: Regularly review your specifications with your provider. This habit helps you catch issues early and keeps your project on track.

Post-Processing

You can improve the quality and performance of your stainless steel parts by focusing on post-processing. This step comes after the main machining work. It helps you achieve the right finish, remove sharp edges, and boost corrosion resistance. You should always plan your post-processing steps before starting production. This way, you avoid surprises and get the results you want.

Common Post-Processing Methods:

-

Deburring:

You remove small metal burrs left from cutting or drilling. Burrs can cause parts to fit poorly or create safety risks. You can use hand tools, tumbling, or abrasive brushes for this task. -

Polishing:

You smooth the surface to improve appearance and reduce friction. Polished parts look better and work better in moving assemblies. You can choose between mechanical polishing, buffing, or even electropolishing for a mirror-like finish. -

Passivation:

You treat the stainless steel with a mild acid. This process removes free iron from the surface and forms a protective oxide layer. Passivation makes your parts more resistant to rust and chemicals. -

Heat Treatment:

You may need to heat treat some stainless steel grades. This step can increase hardness or relieve stress from machining. Always check if your part needs this extra step. -

Cleaning:

You must remove oils, dust, and metal shavings. Clean parts are safer and ready for assembly or shipping.

Tip: Always match your post-processing method to your part’s final use. Medical and food parts often need extra cleaning and polishing.

Post-Processing Comparison Table

| Method | Main Benefit | Typical Use Case | Special Notes |

|---|---|---|---|

| Deburring | Safety, fit | All machined parts | Essential for sharp edges |

| Polishing | Appearance, function | Visible or moving parts | Improves surface finish |

| Passivation | Corrosion resistance | Medical, marine, food | Required for harsh environments |

| Heat Treatment | Strength, stability | High-stress components | Not needed for all grades |

| Cleaning | Safety, readiness | All parts | Final step before delivery |

You should always inspect your parts after post-processing. Use gauges, calipers, or visual checks to confirm quality. If you need a special finish, tell your provider early. This helps them choose the right tools and methods.

Note: Good post-processing can extend the life of your parts and reduce maintenance costs.

You can work with your provider to select the best finishing options. Clear instructions and early planning help you avoid delays and extra costs. When you focus on post-processing, you get parts that look better, last longer, and perform as expected.

Common Mistakes

Vague Specs

You risk project failure when you provide vague or incomplete specifications. CNC machining relies on exact details. If you leave out important information, your parts may not fit or function as you expect. You should always give clear measurements, tolerances, and surface finish requirements. Use drawings or CAD files to show your design. If you only describe your part with words, you create confusion.

- Specify all critical dimensions.

- List the required tolerances.

- Include material grade and finish.

Tip: Use GD&T (Geometric Dimensioning and Tolerancing) symbols on your drawings. These symbols help your provider understand exactly what you need.

When you skip details, you increase the risk of errors. Your provider may guess or make assumptions. This leads to delays, extra costs, or even scrap parts. You can avoid these problems by double-checking your specs before you send them.

Wrong Material

Choosing the wrong material can ruin your project. Stainless steel comes in many grades. Each grade has different properties. If you pick the wrong one, your part may not last or perform as needed. For example, 304 stainless steel works well for general use. 316 stainless steel resists corrosion better, so you use it in marine or medical settings. 17-4 PH offers high strength but is harder to machine.

| Stainless Steel Grade | Best Use Case | Key Property |

|---|---|---|

| 304 | General parts | Good ductility |

| 316 | Marine, medical | High corrosion resistance |

| 17-4 PH | Aerospace, tooling | High strength |

You should always match the material to your application. Ask your provider for advice if you are unsure. They can help you choose the right grade for your needs.

Note: Using the wrong material can lead to early failure, safety risks, or extra costs.

Ignoring Finishing

You should never ignore finishing steps in CNC machining. Finishing affects how your part looks and works. If you skip deburring, sharp edges can cause injuries or assembly problems. Without polishing or passivation, your part may rust or wear out faster.

Common finishing options include:

- Deburring for safety and fit

- Polishing for smooth surfaces

- Passivation for corrosion resistance

You need to plan finishing from the start. Tell your provider what finish you need. If you wait until the end, you may face delays or extra charges. Some industries, like medical or food processing, require special finishes for safety and hygiene.

Tip: Always review finishing options with your provider before production begins. This step ensures your parts meet all requirements.

By avoiding these common mistakes, you improve your CNC machining results. You get parts that fit, last, and look the way you want.

Poor Collaboration

Poor collaboration can ruin even the best CNC machining projects. When you and your provider do not work as a team, you face delays, errors, and extra costs. You need to build a strong partnership to get the best results from stainless steel CNC machining services.

You might think that sending your design files is enough. In reality, you must stay involved at every stage. If you do not share updates or respond to questions, your provider may make wrong choices. Misunderstandings can lead to parts that do not fit or work as you expect.

Common signs of poor collaboration include:

- You receive late updates or no updates at all.

- Your provider does not ask for feedback or clarification.

- You do not review prototypes or samples before full production.

- You ignore your provider’s suggestions or warnings.

- You do not set clear roles or responsibilities.

Tip: Set up regular check-ins with your provider. Weekly calls or emails help you catch problems early.

You can use a simple table to track your collaboration:

| Collaboration Task | Who Is Responsible | How Often | Status |

|---|---|---|---|

| Share design updates | You | Weekly | In Progress |

| Review prototypes | Provider & You | As needed | Not Started |

| Approve material choices | You | Once | Complete |

| Confirm delivery schedule | Provider | Weekly | In Progress |

When you work closely with your provider, you solve problems faster. You can ask questions and get answers right away. You also learn about new options or better ways to make your parts.

Here are some steps you can take to improve collaboration:

- Assign a main contact person on both sides.

- Use shared documents or project management tools.

- Give feedback on samples and prototypes.

- Respond quickly to questions or requests.

- Listen to your provider’s advice—they have experience with stainless steel machining.

Note: Good collaboration saves you time and money. It also helps you build trust with your provider.

You should treat your CNC provider as a partner, not just a vendor. When you work together, you get better parts, fewer mistakes, and a smoother project from start to finish.

Applications

Aerospace

You play a key role in the aerospace industry when you use stainless steel CNC machining. This field demands high precision and reliability. You often need to create parts like turbine blades, aircraft frames, and missile components. CNC machining helps you achieve the tight tolerances and smooth finishes required for flight safety and performance.

Here is a table that highlights the importance of CNC machining in aerospace:

| Aspect | Details |

|---|---|

| Major End-User Industry | Aerospace & Defense sector |

| Key Components | Turbine blades, aircraft frames, missile parts |

| Market Size (2023) | USD 68.2 billion (global CNC Machining Services market) |

| Projected Market Size (2032) | USD 105.7 billion |

| CAGR (2024-2032) | 5.0% |

| Growth Drivers | Demand for aircraft, advanced defense, lightweight materials |

| CNC Services Highlighted | Milling, grinding (critical for tight tolerances and surface finish) |

| Regional Presence | Strong in North America and Europe |

| Importance of Grinding | Essential for high precision and surface finish |

| Compliance | FAA and EASA standards drive quality requirements |

You rely on multi-axis CNC machines to produce intricate parts with complex shapes. These machines use high-speed spindles and adaptive control software. Real-time tool path optimization ensures every part meets strict aerospace standards. You also benefit from stainless steel’s strength and resistance to extreme temperatures. This makes your components safer and longer-lasting.

Tip: Always check that your provider follows FAA and EASA regulations. This ensures your aerospace parts meet global safety standards.

Medical

You depend on stainless steel CNC machining for many medical devices. This process gives you the precision and consistency needed for patient safety. You use CNC machining to make surgical instruments, orthopedic implants, and dental components. Stainless steel offers corrosion resistance, biocompatibility, and mechanical strength.

- You need tight tolerances and complex shapes for medical devices.

- Quality assurance systems like ISO 13485 and ISO 9001 are essential for compliance.

- Advanced CNC technologies and optimized CAD/CAM software improve accuracy and productivity.

- You should choose experienced manufacturers who use strict inspections for reliable results.

- CNC machining provides unmatched repeatability, which reduces defects and ensures every part is identical.

- Automation in CNC machining helps minimize human error and supports regulatory standards.

- Stainless steel grades 316L and 17-4 PH are popular for their corrosion resistance and ability to withstand repeated sterilization.

- You use CNC machining for surgical tools, orthopedic screws, and prosthetic parts.

- Biocompatibility is critical to avoid tissue reactions, especially for implants.

- Materials must survive sterilization methods like autoclaving and gamma radiation without degrading.

Note: Even small deviations in medical parts can cause serious complications. Always specify exact requirements for every device.

Automotive

You rely on CNC machined stainless steel parts to boost safety and efficiency in automotive manufacturing. Stainless steel components, such as exhaust systems and engine parts, resist rust, corrosion, and wear. CNC machining ensures precise cuts and smooth finishes, which eliminate weak points and extend the life of your vehicle.

CNC machining also supports automotive safety standards. The process delivers parts that meet strict specifications every time. You benefit from faster production and less variability, which means higher quality and quicker turnaround.

- You use CNC machining for engine components, transmission cases, and suspension systems that require high durability.

- The technology offers accuracy down to fractions of a millimeter, ensuring parts fit and function perfectly.

- CNC machining speeds up production by running continuously without manual adjustments.

- You save material and reduce costs through optimized cutting paths.

- The process supports complex designs and allows you to use various materials, including stainless steel, for better safety and longevity.

- Compared to traditional methods, CNC machining gives you better precision, speed, flexibility, and efficiency.

Tip: Choose CNC machining for automotive parts when you need reliability, repeatability, and high production speed.

Food Processing

You rely on stainless steel CNC machining to meet strict standards in the food processing industry. Food safety and hygiene matter most. Stainless steel parts help you avoid contamination and keep your equipment clean. CNC machining gives you the precision you need for parts that fit perfectly and work reliably.

You use CNC-machined stainless steel for many food processing components:

- Mixing blades

- Conveyor parts

- Valves and fittings

- Pumps and housings

- Nozzles and sprayers

These parts must resist corrosion from water, cleaning chemicals, and food acids. Stainless steel, especially grades like 304 and 316, gives you excellent corrosion resistance. You can clean these parts easily and sterilize them often. This helps you meet food safety regulations.

Tip: Always choose stainless steel grades approved for food contact. 316 stainless steel works well for salty or acidic foods.

CNC machining lets you create smooth surfaces and tight tolerances. Smooth surfaces prevent bacteria from hiding in cracks or crevices. You reduce the risk of contamination and make cleaning faster. You also get parts that last longer because CNC machining removes sharp edges and burrs.

Here is a table that shows why stainless steel CNC machining fits food processing:

| Requirement | How CNC Machining Helps | Stainless Steel Benefit |

|---|---|---|

| Hygiene | Smooth, easy-to-clean surfaces | Resists bacteria and mold |

| Corrosion Resistance | Precise machining for tight seals | Withstands cleaning chemicals |

| Durability | Strong, wear-resistant parts | Handles repeated use |

| Regulatory Compliance | Consistent, repeatable quality | Meets FDA and EU standards |

You must also think about post-processing. Polishing and passivation improve corrosion resistance and surface finish. These steps help you meet industry standards and keep your equipment safe for food contact.

You should work closely with your CNC provider. Share your cleaning and sanitation requirements. Ask for documentation on material traceability and certifications. This ensures your parts meet all food safety rules.

Note: Regular inspection and maintenance keep your stainless steel parts in top condition. Replace worn or damaged parts quickly to avoid downtime and contamination.

You can trust CNC machining to deliver the quality and reliability you need in food processing. Stainless steel parts help you protect your products, your customers, and your reputation.

Challenges

Tool Wear

You face tool wear as a major challenge in stainless steel CNC machining. Every time you cut or shape metal, your tools lose sharpness. This wear affects the cutting edges and can lead to poor part quality or even tool failure. If you ignore tool wear, you risk higher costs and more downtime.

Several factors influence how quickly your tools wear out:

- Tool material and design

- Machining parameters like cutting speed, feed rate, and depth of cut

- The type of stainless steel you use

- Cooling and lubrication methods

- Operator skill and experience

You see different types of tool wear during machining. These include flank wear, crater wear, built-up edge, abrasive wear, notch wear, and adhesive wear. Each type affects your tool and part in a unique way.

Tip: Early detection of tool wear signs—such as chipping, changes in surface quality, or unusual noise—helps you prevent bigger problems.

You can use both manual inspection and automated monitoring systems to track tool wear. Sensors and software now let you monitor wear in real time. This technology helps you make quick adjustments and schedule tool changes before failure happens.

Here are some key strategies to minimize tool wear:

- Optimize your cutting conditions. Cutting speed has the biggest impact, so adjust it carefully.

- Use wear-resistant tool materials or coatings. Carbide and ceramic tools last longer with tough stainless steels.

- Apply proper cooling and lubrication. This reduces heat and friction, which slow down wear.

- Monitor tool life regularly. Real-time data helps you plan tool changes and avoid unexpected stoppages.

Tool wear can have a big impact on your costs and efficiency. Maintenance for tool failure can account for 15–40% of your total manufacturing costs. Stoppage time from tool failure can make up about 20% of your overall downtime. You can reduce these numbers by using predictive analytics and digital monitoring. For example, adjusting machining parameters based on sensor data can extend tool life and save hours on large production runs.

Note: New technologies like digital twins and sensor-based predictive models are making it easier to track tool wear and make smarter decisions.

By understanding and managing tool wear, you keep your CNC machining process efficient and your parts high quality. Regular monitoring and smart adjustments help you save time, reduce waste, and get the most from your tools.

Complex Geometries

You often need to create parts with complex shapes when using stainless steel CNC machining. These shapes may include deep cavities, thin walls, undercuts, or intricate curves. Complex geometries push the limits of both your design and the machine’s capabilities. You must plan carefully to achieve the right results.

Stainless steel makes the challenge even greater. The material resists cutting and can cause tools to deflect or vibrate. You may see problems like uneven surfaces, dimensional errors, or even tool breakage. Multi-axis CNC machines help you reach difficult angles, but you still need to think about every step.

Common Challenges with Complex Geometries:

- Tool access becomes limited in deep pockets or narrow channels.

- Thin walls may bend or vibrate during machining.

- Undercuts require special tools or multiple setups.

- Heat buildup can distort small or delicate features.

- Maintaining tight tolerances across complex surfaces is difficult.

Tip: Use simulation software before machining. You can spot potential issues and adjust your design or tool paths.

You can follow several best practices to improve your results:

- Break down your design into simpler features. Machine each feature in stages.

- Use shorter, rigid tools to reduce vibration and improve accuracy.

- Select the right cutting strategy. High-speed machining or trochoidal milling can help with tough shapes.

- Plan for multiple setups if needed. Sometimes you must reposition the part to reach all areas.

- Communicate with your CNC provider about your design’s most critical features.

Here is a table to help you match common geometry challenges with solutions:

| Geometry Challenge | Solution | Benefit |

|---|---|---|

| Deep cavities | Use long-reach tools, step-down passes | Reduces tool deflection |

| Thin walls | Lower feed rates, support structures | Prevents bending or vibration |

| Undercuts | Special tooling, multi-axis machining | Accesses hard-to-reach areas |

| Intricate curves | Fine stepovers, slow speeds | Improves surface finish |

You should also consider the order of operations. Machine the most stable features first. Leave thin or delicate areas for last. This approach keeps your part strong during the process.

Note: Always review your design with your CNC provider. Their experience can help you avoid costly mistakes and get the best results for complex parts.

By understanding these challenges and planning ahead, you can achieve high-quality stainless steel parts with even the most complex geometries.

You get the best results when you choose an experienced provider, focus on smart design, and keep communication clear. Review your specs, select the right stainless steel, and plan finishing steps early. XTJ precision Mfg helps you reach high quality and efficiency with expert support. Apply these strategies to every project. You will see better parts, fewer mistakes, and faster delivery.

FAQ

What is the best stainless steel grade for CNC machining?

You often choose 304 or 316 stainless steel for most projects. 304 offers good machinability and corrosion resistance. 316 works better for harsh environments. For high strength, you can use 17-4 PH.

How do you reduce tool wear when machining stainless steel?

You can use coated carbide tools and plenty of coolant. Lower cutting speeds and regular tool checks help extend tool life. Always match your tool material to the stainless steel grade.

Why do you need post-processing for CNC machined parts?

Post-processing removes burrs, improves surface finish, and boosts corrosion resistance. You get safer, longer-lasting parts. Common methods include deburring, polishing, and passivation.

How do you ensure part accuracy in CNC machining?

You should provide clear tolerances and use detailed CAD drawings. Reliable providers use advanced inspection tools like CMMs and laser scanners. Regular quality checks catch errors early.

Can you use CNC machining for small batch production?

Yes, you can. CNC machining works well for prototypes and small batches. You get fast turnaround and high precision without needing expensive molds or tooling.

What information should you give your CNC provider?

You need to share CAD files, material grade, tolerances, and surface finish requirements. Include any special post-processing or inspection needs. Clear details help avoid mistakes.

How long does it take to machine stainless steel parts?

Lead times depend on part complexity and order size. Simple parts may take a few days. Complex or high-volume orders can take several weeks. Ask your provider for a timeline.

What industries use stainless steel CNC machining the most?

You see stainless steel CNC parts in aerospace, medical, automotive, and food processing. These industries need strong, precise, and corrosion-resistant components.