Affordable Prototype Mold Manufacturing for Rapid Product Development

At XTJ, we deliver cost-effective mold manufacturing solutions, including Low Volume Injection Molding, Plastic Injection Molding, RIM, and Die Casting, to bring your designs to life quickly and efficiently.

High-Quality Molds at a Fraction of the Cost

Developing a prototype mold doesn’t have to break the bank. At CNC Parts XTJ, we specialize in low-cost prototype mold manufacturing, offering a range of services like Low Volume Injection Molding, Plastic Injection Molding, Reaction Injection Molding (RIM), and Die Casting. Our goal is to help you test your designs, validate functionality, and move to production without the high costs of traditional mold manufacturing. With our expertise and advanced technology, you get precision molds delivered fast—often in as little as 5-7 days.

Cost-Effective

Save up to 50% on prototype mold costs compared to traditional methods.

Fast Turnaround

Molds ready in 5-7 days, accelerating your product development timeline.

Precision Engineering

Achieve tolerances as tight as ±0.02mm for reliable, functional prototypes.

Scalable Solutions

Seamlessly transition from prototyping to low-volume production with our integrated services.

Comprehensive Mold Manufacturing Solutions for Every Need

From Low Volume Injection Molding to Die Casting, we provide affordable, high-quality prototype molds tailored to your project requirements.

Low Volume Injection Molding

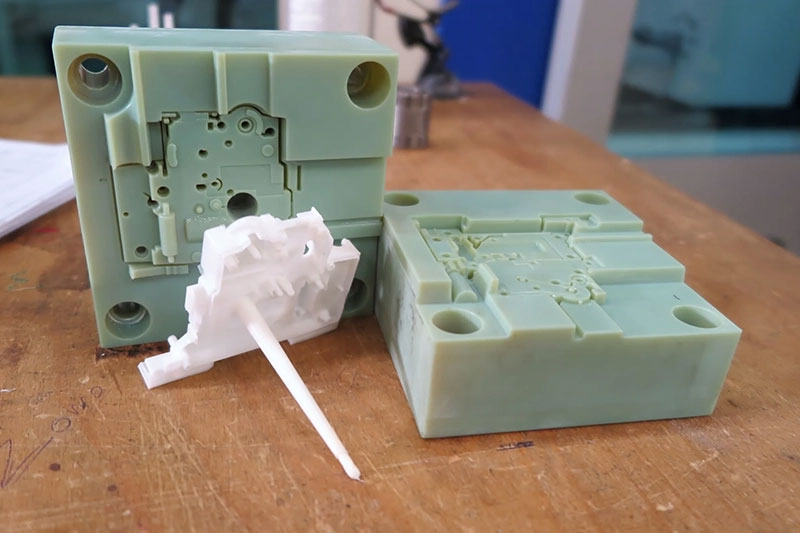

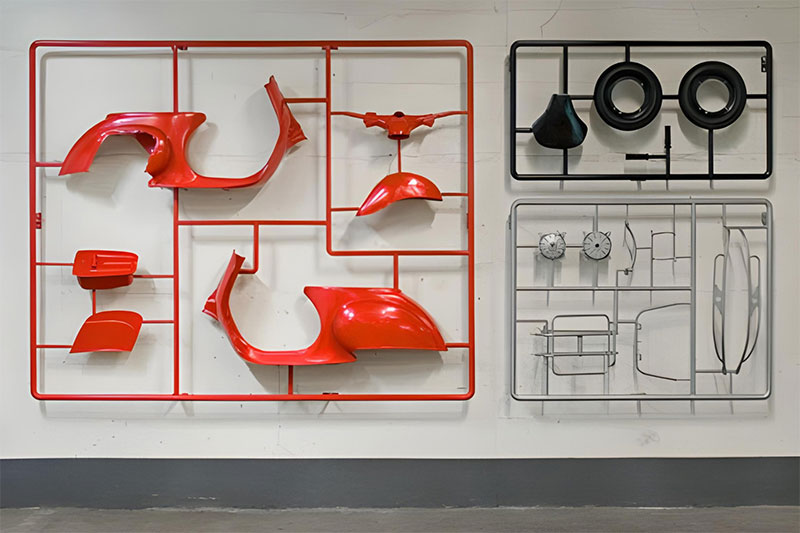

Low Volume Injection Molding uses simplified molds to produce small batches of plastic parts, ideal for prototyping and early-stage testing.

Applications: Functional prototypes, consumer product testing, and bridge production for electronics, medical devices, and automotive parts.

Materials: ABS, PC, PP, POM, and more.

Advantages:

- Reduced mold costs (up to 70% less than production molds).

- Fast lead times (5-10 days for mold and parts).

- Supports batches as small as 100-1,000 units.

Plastic Injection Molding

Plastic Injection Molding for prototyping involves creating high-quality molds to produce plastic parts with excellent surface finish and dimensional accuracy.

Applications: Enclosures, housings, and components for consumer goods, medical devices, and industrial equipment.

Materials: Nylon, PEEK, TPE, and custom blends.

Advantages:

- High repeatability for consistent prototype quality.

- Wide range of material options for functional testing.

- Cost-effective for complex geometries with minimal waste.

Reaction Injection Molding (RIM)

RIM uses a two-part polyurethane mixture injected into a mold to create lightweight, durable prototypes with excellent impact resistance.

Applications: Large parts like automotive bumpers, medical equipment housings, and industrial panels.

Materials:Polyurethane (rigid or flexible).

Advantages:

- Low-cost molds for large, complex parts.

- Excellent for producing parts with varying wall thicknesses.

- Fast cycle times (molds ready in 7-10 days).

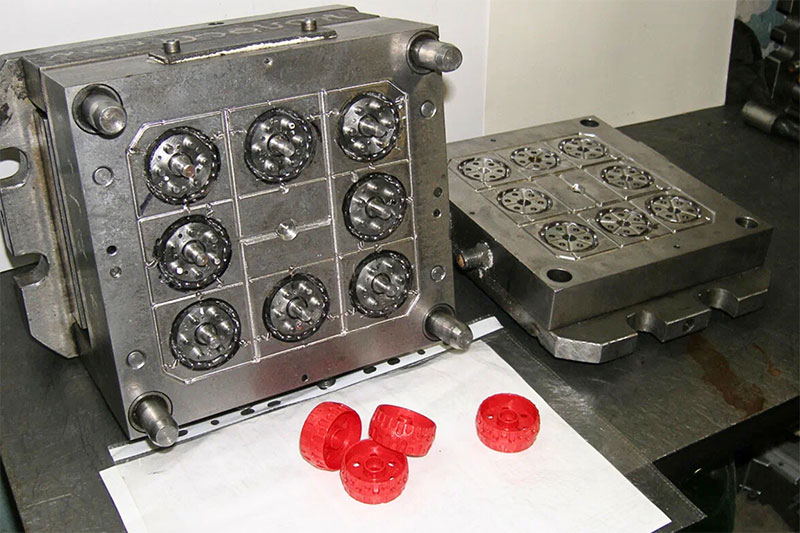

Die Casting

Die Casting for prototyping involves creating metal molds to produce high-precision metal parts using molten aluminum, zinc, or magnesium.

Applications: Automotive components, machinery parts, and consumer electronics housings.

Materials: Aluminum, zinc, magnesium alloys.

Advantages:

- High strength and durability for functional testing.

- Tight tolerances (±0.02mm) for precision parts.

- Cost-effective for small runs (100-500 units).

From Design to Mold in 3 Simple Steps

Prototype Molds for Every Industry

Our low-cost prototype mold manufacturing services support a wide range of industries, delivering molds and parts that meet strict performance and quality standards.

- Automotive: Injection-molded dashboards, die-cast engine components, and RIM bumpers.

- Medical: Plastic injection-molded device housings and RIM equipment panels.

- Consumer Electronics: Low-volume molded enclosures and connectors for product testing.

- Industrial Equipment: Die-cast machinery parts and injection-molded fittings.

Your Trusted Partner for Affordable, High-Quality Molds

At XTJ, we combine cost efficiency with precision engineering to deliver prototype molds that meet your exact needs. Here’s why clients choose us:

Cost Savings

Up to 50% lower costs than traditional mold manufacturing, with no compromise on quality.

Advanced Technology

State-of-the-art CNC machines and 3D printing for rapid mold production.

Material Expertise

Over 30+ materials for injection molding, RIM, and die casting, including custom blends.

Global Delivery

Fast shipping to over 50 countries with reliable carriers like DHL and FedEx.

Dedicated Support

A project manager oversees every order, ensuring clear communication and timely delivery.

FAQ

Got Questions About Low Cost Prototype Mold Manufacturing? We’ve Got Answers!

Explore our FAQs to learn more about our affordable mold manufacturing services and how we can help bring your designs to life.

Low cost prototype mold manufacturing involves creating simplified molds for prototyping and small-batch production, using cost-effective materials like aluminum or 3D-printed resins instead of hardened steel. Unlike traditional mold manufacturing, which is designed for high-volume production and can cost tens of thousands of dollars, our approach reduces costs by up to 50% while maintaining quality for prototype testing. At CNC Parts XTJ, we use techniques like Low Volume Injection Molding, RIM, and Die Casting to deliver molds in 5-14 days, perfect for early-stage product development.

The cost of a prototype mold depends on factors like complexity, material, and production method. For example, a simple aluminum mold for Low Volume Injection Molding can start as low as $500, while a more complex die-cast mold might range from $1,000 to $3,000. Our focus on low-cost solutions ensures you save up to 50% compared to traditional molds, with no compromise on quality. Upload your design for an instant quote tailored to your project!

At CNC Parts XTJ, we pride ourselves on fast turnarounds. For Low Volume Injection Molding and Plastic Injection Molding, molds are typically ready in 5-10 days. RIM molds take about 7-10 days, while Die Casting molds may take 7-14 days, depending on complexity. Once the mold is ready, we can produce your prototype parts in as little as 1-3 days. Our streamlined process ensures you get your parts quickly without sacrificing precision.

We offer a wide range of materials to suit your project needs. For injection molding (Low Volume and Plastic Injection Molding), options include ABS, PC, PP, POM, nylon, PEEK, and TPE. For RIM, we use rigid or flexible polyurethane. For Die Casting, we work with aluminum, zinc, and magnesium alloys. We also provide over 30 material options and can source custom blends if needed. Contact our team to discuss the best material for your prototype!

Our prototype molds are engineered for precision. For Plastic Injection Molding and Low Volume Injection Molding, we achieve tolerances as tight as ±0.03mm. For Die Casting, tolerances can be as precise as ±0.02mm. RIM parts typically have slightly looser tolerances (±0.5mm) due to the nature of the process, but they’re ideal for large, complex parts. We use advanced CMM (Coordinate Measuring Machine) inspection to ensure every part meets your specifications.

Yes, in many cases! Our prototype molds, especially those made for Low Volume Injection Molding, are designed to produce small batches (100-1,000 units) with high quality. While these molds aren’t built for high-volume production (e.g., millions of cycles), they can often be used for bridge production or market testing before investing in a production mold. For Die Casting and RIM, we can also adapt molds for low-volume runs. Let us know your production goals, and we’ll recommend the best solution.

Each method has its strengths:

- Low Volume Injection Molding: Ideal for small plastic parts like enclosures, fittings, or consumer product components (e.g., 100-1,000 units).

- Plastic Injection Molding: Best for high-quality plastic prototypes with complex geometries, such as medical device housings or electronic connectors.

- RIM (Reaction Injection Molding): Perfect for large, lightweight parts with varying wall thicknesses, like automotive bumpers or medical equipment panels.

- Die Casting: Suited for metal prototypes requiring high strength, such as automotive components or industrial gear housings.

- Not sure which method is right for your project? Upload your design, and our team will provide expert recommendations.

Yes, we provide a variety of surface finishing options to enhance the functionality and appearance of your molded parts. Options include texturing (matte, glossy), painting, polishing, and plating (e.g., chrome or nickel for die-cast parts). These finishes can be applied to parts made through injection molding, RIM, or die casting. Check out our Surface Finishing Services page for more details, or include your finishing requirements when requesting a quote.

We accept all major CAD file formats, including STEP, IGES, STL, and SLDPRT. If you have a 2D drawing, we can work with PDF or DWG files as well. If you’re unsure about your file format or need assistance with your design, our engineering team is here to help. Simply upload your file, and we’ll provide Design for Manufacturability (DFM) feedback within 24 hours to ensure your mold is production-ready.

Getting started is easy! Simply upload your design using our online quote form, and we’ll provide an instant quote along with DFM feedback. If you have questions or need guidance, you can also contact our team directly—we’ll assign a dedicated project manager to assist you every step of the way. From mold design to prototype production, XTJ makes the process seamless and affordable. Start your project today!

Ready to Create Your Prototype Mold?

Upload your design or contact our team to discuss your low-cost mold manufacturing needs.