Precision Surface Finishing for Superior Parts Performance

We specialize in transforming metal and plastic parts into high-performance solutions that meet stringent industry standards.

- Lead times as short as 7 days.

- Surface roughness down to Ra 0.05 μm.

- ISO 9001:2015 and AS9100D certified quality.

Why Surface Finishing Matters

Surface finishing isn’t just about appearance—it’s a critical step in part optimization:

Enhanced Durability

Finishes like anodizing and electroplating increase resistance to wear, corrosion, and fatigue by up to 50% (depending on material and environment).

Functional Precision

Reduces friction (e.g., polished surfaces lower coefficient of friction by 20–30%) and ensures tighter tolerances.

Aesthetic Excellence

Achieve mirror-like finishes or custom colors to align with branding and market expectations.

Regulatory Compliance

Meet standards like MIL-A-8625 (anodizing) or ASTM B117 (salt spray testing) for aerospace, medical, and automotive applications.

Our Surface Finishing Capabilities

We offer a comprehensive suite of finishing techniques, each backed by advanced equipment and rigorous process controls. Below are detailed descriptions of our services, including technical insights and measurable benefits:

Bead Blasting

Process: High-pressure propulsion of glass beads (50–150 μm diameter) to abrade surfaces, removing tool marks and oxide layers.

Technical Specs: Achieves surface roughness of Ra 1.6–3.2 μm; adjustable blast angles for complex geometries.

Benefits:

- Uniform matte texture reduces light reflection by 80%.

- Prepares surfaces for coatings, improving adhesion by 25%.

Applications: Aluminum housings, stainless steel fixtures, and ABS prototypes.

Lead Time: 1–2 days for standard parts.

Anodizing (Type II & Type III)

Process: Electrochemical oxidation forms a 5–25 μm (Type II) or 25–50 μm (Type III) aluminum oxide layer, with optional sealing for enhanced protection.

Technical Specs: Hardness up to 65 HRC (Type III); withstands 1,000+ hours of salt spray testing (ASTM B117).

Benefits:

- Corrosion resistance improved by 10x compared to raw aluminum.

- Custom dyeing available (MIL-A-8625 compliant colors).

Applications: Aerospace brackets, medical implants, and automotive trim.

Lead Time: 3–5 days, depending on thickness and color.

Powder Coating

Process: Electrostatic application of dry powder (polyester, epoxy, or hybrid) cured at 180–200°C for a 50–100 μm thick layer.

Technical Specs: Adhesion strength exceeds 10 MPa; withstands 500+ hours of UV exposure without fading.

Benefits:

- Impact resistance 30% higher than liquid paint.

- Over 200 RAL color options for customization.

Applications: Outdoor machinery, automotive chassis, and consumer goods.

Lead Time: 2–4 days.

Polishing

Process: Multi-stage mechanical polishing with diamond abrasives, achieving Ra 0.05–0.2 μm (mirror finish).

Technical Specs: Reflectivity up to 95%; flatness within 0.01 mm for optical-grade parts.

Benefits:

- Reduces surface friction by 25–35%, ideal for moving parts.

- Enhances cleanability for medical-grade components.

Applications: Acrylic lenses, stainless steel molds, and decorative hardware.

Lead Time: 2–3 days.

Painting

Process: Wet spray application of polyurethane or acrylic paints in a controlled cleanroom, with optional primer and topcoat layers (total thickness 20–80 μm).

Technical Specs: Gloss levels from 10–90 GU; adhesion per ASTM D3359 (5B rating).

Benefits:

- UV resistance extends part life by 3–5 years in outdoor conditions.

- Precise color matching to Pantone or RAL standards.

Applications: Consumer electronics enclosures, automotive dashboards.

Lead Time: 2–4 days.

Electroplating

Process: Deposits 5–50 μm layers of metals (nickel, chrome, zinc) via electrolytic bath; multi-layer options available.

Technical Specs: Hardness up to 800 HV (chrome); conductivity improved by 40% (nickel).

Benefits:

- Wear resistance increased by 50% over base material.

- Aesthetic chrome finishes with 90% reflectivity.

Applications: Electrical connectors, decorative trim, and wear parts.

Lead Time: 4–6 days.

Sanding

Process: Manual or automated sanding with grits from 80–1000, reducing roughness step-by-step to Ra 0.8–1.6 μm.

Technical Specs: Removes burrs up to 0.5 mm; ensures flatness within 0.02 mm.

Benefits:

- Cost-effective base finish for subsequent coatings.

- Improves dimensional accuracy post-machining.

Applications: Pre-paint preparation, plastic housings, and metal brackets.

Lead Time: 1–2 days.

Laser Etching

Process: Fiber laser (20–50W) engraves patterns or text with depths of 0.01–0.5 mm, adjustable for contrast.

Technical Specs: Resolution up to 1200 DPI; permanent marks withstand 1,000+ hours of abrasion testing.

Benefits:

- High-precision branding with tolerances of ±02 mm.

- No material weakening or surface damage.

Applications: Serial numbers, logos on titanium tools, and plastic casings.

Lead Time: 1–2 days.

Custom Finishing Needs? Our engineers can develop hybrid processes (e.g., bead blasting + anodizing) tailored to your project. Contact us to explore options!

Our Surface Finishing Process

We combine cutting-edge technology with meticulous oversight:

Compatible Materials

We finish a broad spectrum of CNC-machined materials:

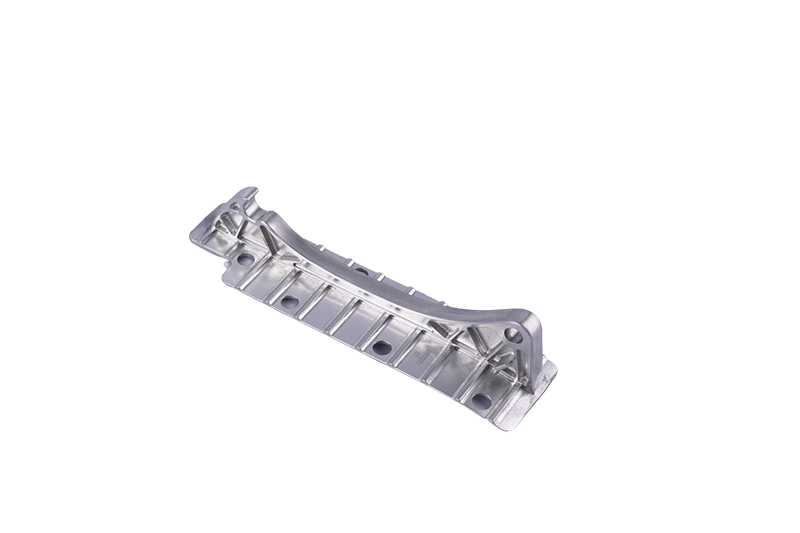

Aluminum (6061, 7075)

Anodizing, powder coating.

Stainless Steel (304, 316)

Polishing, bead blasting.

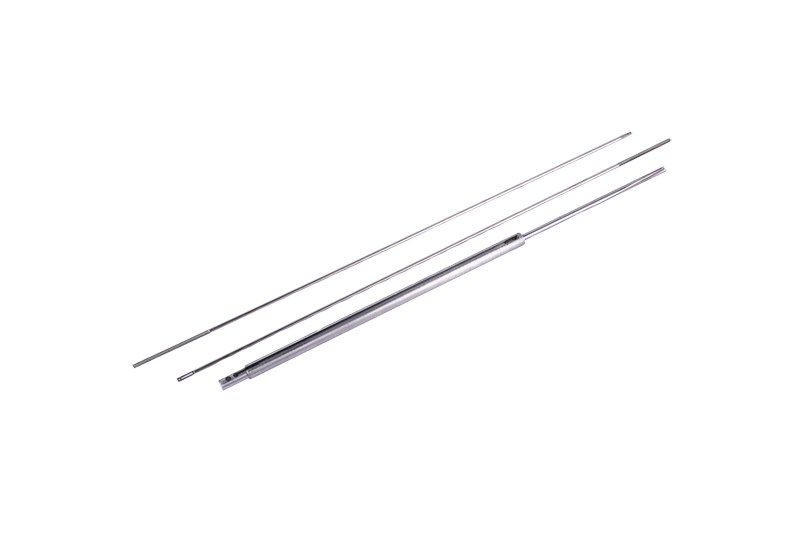

Titanium (Grade 5)

Electroplating, laser etching.

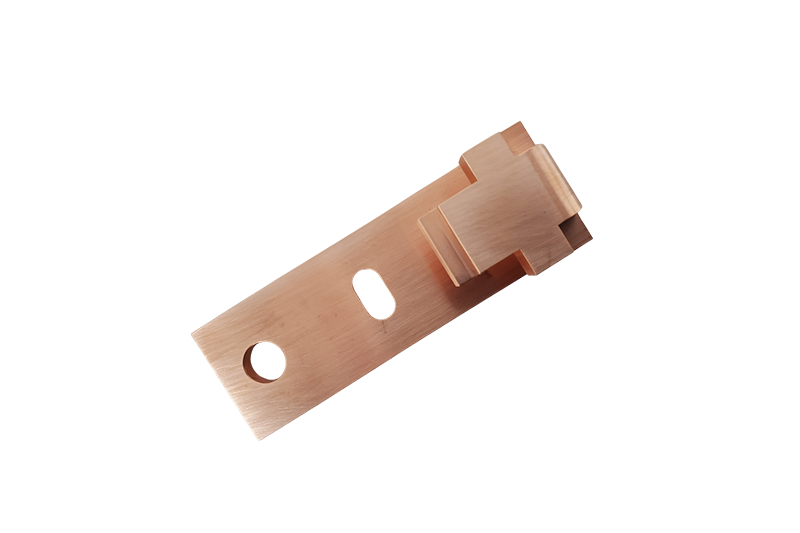

Brass, Copper, Zinc

Custom plating and polishing.

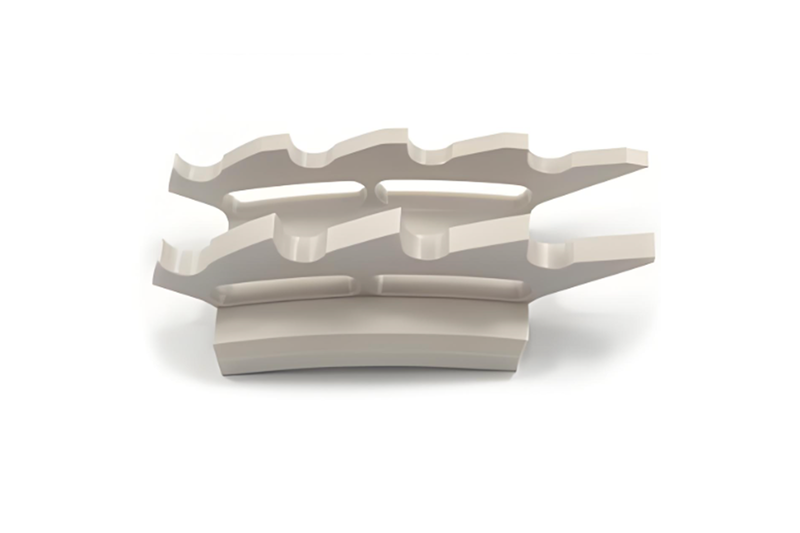

ABS, Nylon

Painting, sanding.

PEEK, Polycarbonate

Polishing, laser etching.

POM, PTFE

Smooth sanding for low-friction surfaces.

Industry Applications

Our finishes power innovation across sectors:

- Aerospace: Anodized aluminum frames (MIL-spec) with 30% weight reduction.

- Automotive: Powder-coated EV battery housings with 500+ hours of corrosion resistance.

- Medical: Polished PEEK implants with Ra 0.2 μm for biocompatibility.

- Electronics: Laser-etched PCB enclosures with ±0.01 mm precision.

- Industrial: Bead-blasted steel jigs with 20% longer lifespan.

Surface Roughness & Standards

We deliver precise finishes to your specs:

- As-Machined: Ra 3.2–1.6 μm (cost-effective baseline).

- Smooth Machined: Ra 1.6–0.8 μm (balanced performance).

- Super-Finished: Ra 0.8–0.2 μm (high-functionality).

- Mirror-Polished: Ra 0.1–0.05 μm (optical-grade).

- Standards: ASME B46.1, ISO 1302, and custom tolerances available.

Need Specific Ra Values? Share your requirements for a tailored solution.

Get Started with XTJ Precision

Unlock the full potential of your parts with our surface finishing expertise.