Choosing the best CNC fabrication partner in 2025 is important. It affects how well your project does and how good your product is. The worldwide CNC machining service market was about USD 4.5 billion in 2023. It may grow to USD 10.3 billion by 2032. This growth shows that more people want precision manufacturing and fast prototyping. Technical skills, engineering help, and quality systems matter more now. They help companies finish work on time and meet industry rules. Companies with vertical integration can work faster and save money. They are important for businesses that want good and steady results.

Key Takeaways

- Top CNC companies use new machines and smart tools. They make parts that are exact, fast, and dependable.

- Picking the best CNC partner depends on your project. You should think about your budget, quality, and speed.

- Prices are different for basic and fancy machines. Choose what matches your order size and how hard your job is.

- Automation and AI help CNC shops work faster. They also lower mistakes and save money when making things.

- Being green is important. Many companies use machines that save energy and follow eco-friendly rules.

- Good customer support and clear talking make people happy. This also helps build trust with customers.

- Certifications like ISO 9001 and AS9100 show a company is safe and high quality.

- Planning early and asking for references helps you pick a CNC partner. This makes sure you get great results.

Top CNC Fabrication Companies 2025

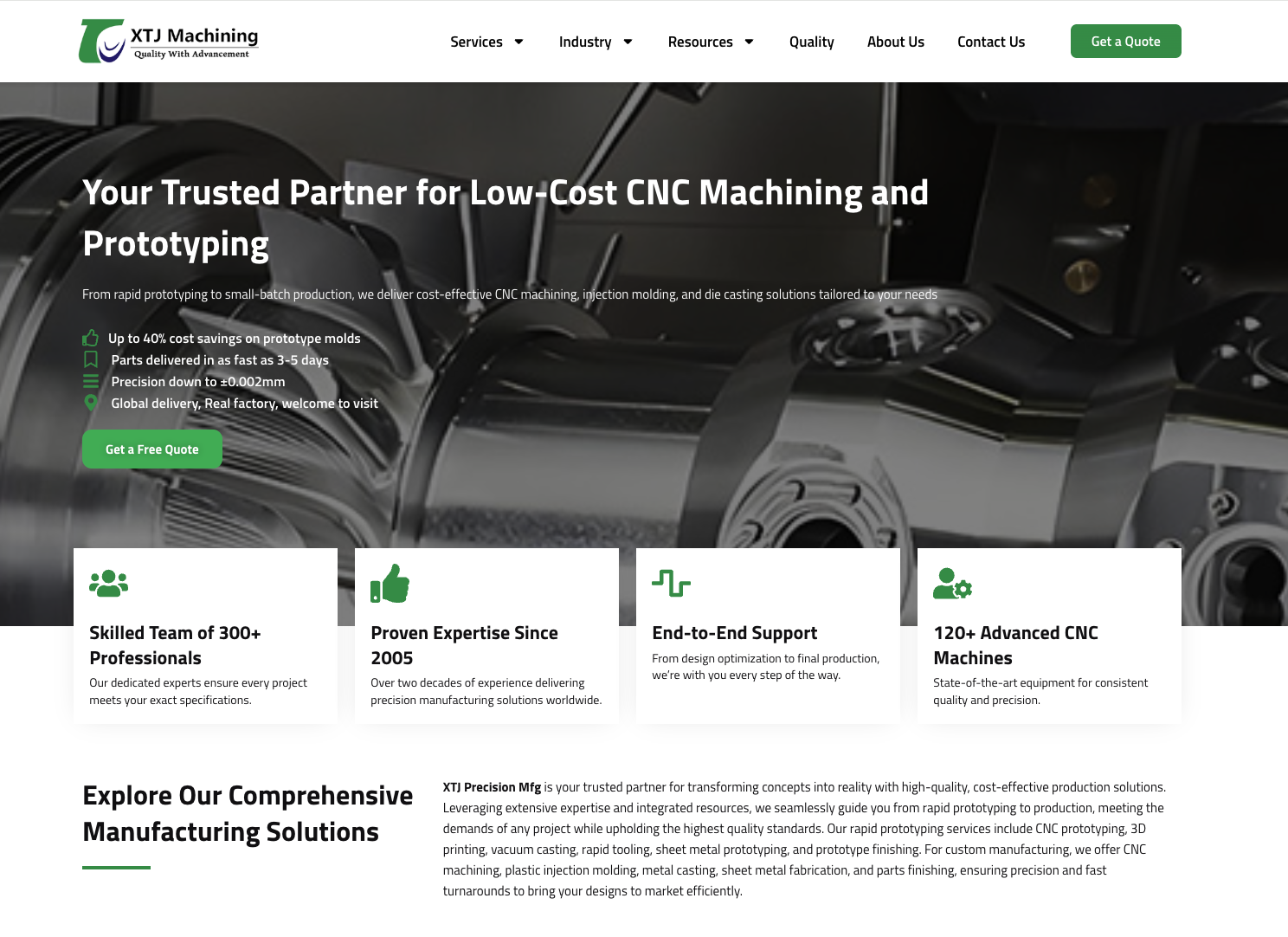

XTJ Precision Mfg

Overview

XTJ Precision Mfg is a top CNC fabrication company.Many of the online manufacturing parts foundry companies on the market today help their customers with their machining needs by combining resources, they don’t have the ability to self-produce, so there is definitely an extra portion of service fees in the price, even though they don’t reflect it on the bill.

And XTJ is a cnc machining company that actually owns its own super factory, has the unparalleled price advantage in the industry. From the factory to the customer’s first-hand price to the customer, there is no middleman to earn the difference. Product quality is guaranteed, the factory single-handedly control, perfect quality inspection mechanism, several sets worth millions of various types of testing instruments.

They use 5-axis machining, so machines move in five ways at once. This helps XTJ make hard parts with fewer steps and better accuracy. XTJ also uses very fast CNC controllers. These controllers help make parts that are high quality. The company uses Industry 4.0 tools like smart factories, IoT, big data, and AI analytics. These tools help XTJ work faster and better. XTJ has ISO 9001 certification, which means they care about quality.

2025 Highlights

-

Achieves tolerances as tight as ±0.002mm.

-

Uses predictive maintenance to minimize downtime.

-

Offers rapid delivery for both small and large orders.

-

Employs smart factory tools for process control and data tracking.

-

Known for reliability and high customer satisfaction.

XTJ Precision Mfg is a leader in quality, speed, and new ideas for CNC fabrication.Get a Quick Quote!

Protolabs

Rapid Prototyping and Production

Protolabs is a global leader in on-demand CNC fabrication, offering rapid prototyping and low-to-high-volume production. Their automated quoting system and digital manufacturing platform streamline the process from design to delivery. Protolabs serves industries like aerospace, automotive, and medical with precision machining.

Highlights

-

Tolerances as tight as ±0.005mm for critical applications.

-

Offers same-day or next-day turnaround for urgent projects.

-

Supports a wide range of materials, including metals and plastics.

-

Integrates AI-driven design analysis to optimize manufacturability.

-

ISO 9001 and ISO 13485 certified for quality and medical applications.

Protolabs’ speed and digital tools make it ideal for fast-paced projects requiring precision.

Xometry

Scalable Manufacturing Solutions

Xometry provides CNC fabrication services through a vast network of vetted manufacturing partners. Their platform offers instant quotes and connects clients with shops for custom parts. Xometry serves industries like defense, aerospace, and electronics with flexible production capabilities.

Fictiv

Global Manufacturing Network

Fictiv provides CNC fabrication via vetted global shops, emphasizing speed and transparency. Their platform offers real-time tracking, serving robotics and medical industries. Third-party coordination may increase costs.

3ERP

Precision Prototyping

3ERP specializes in CNC fabrication for prototyping and low-volume production, serving automotive and aerospace. They rely on partner facilities, which may add service costs. Their engineering support ensures quality for complex designs.

3ERP excels in prototyping, though costs may reflect third-party involvement.

RapidDirect

Custom Manufacturing

RapidDirect offers CNC fabrication for custom parts through a network of shops. Their platform provides instant quotes and design feedback, serving electronics and medical industries. Service fees may be embedded in pricing.

-

Supports metals, plastics, and composites.

-

AI-driven process optimization.

-

ISO 9001 and ISO 14001 certified.

RapidDirect balances speed and quality, with potential added costs from outsourcing.

Hubs

On-Demand Fabrication

Hubs connects clients with global CNC shops, simplifying orders and ensuring quality through vetting. Serving automotive and aerospace, their model may include service fees for coordination.

Hubs’ global reach is reliable, but pricing may reflect platform fees.

Key Features of CNC Fabrication Leaders

Precision and Quality

Tolerances

Top CNC fabrication companies try to make parts very exact. They can reach tiny tolerances, even as small as a micrometer. This is important for things like airplanes and medical tools. Their machines can keep accuracy within ±0.002mm. This helps parts fit together and work right. Many things affect how close they can cut:

- The material, like aluminum or stainless steel, changes how exact the machine can be.

- The part’s shape and size matter too. Small or tricky parts need tighter tolerances.

- The tools and how fast they cut also change how close the machine can get.

- Machines need regular checks and care to stay accurate.

- Industry rules, like ISO 2768 or ASME Y14.5, help companies pick the right tolerance.

Planning early and getting expert help lets companies choose the best tolerance for each job.

Material Capabilities

CNC leaders can work with many materials. They machine metals like steel, titanium, and aluminum. They also use plastics, composites, and some ceramics. Each material is different, like being hard or handling heat. Companies pick the right tools and settings for each one. This helps them do jobs for many industries, like cars and electronics.

- Companies follow strict rules to make sure every part is good.

- Skilled workers and advanced machines help keep quality high for all materials.

- They test and check parts often to make sure they meet the needed specs.

Automation and AI

Robotics

Many top companies use robots to help with CNC work. Robots can load and unload parts. They can change tools and check finished pieces. This makes work faster and lets machines run all day and night. Robots also help stop mistakes and keep workers safe.

- Robots let machines work all the time, which makes more parts and saves money.

- Automated systems can do hard jobs with less help from people.

Software Integration

Modern CNC shops use smart software to run machines. Digital twin tech lets them make virtual models and test before making real parts. Real-time monitoring checks how machines are working and when they need fixing. AI software can change cutting paths and speeds for better results.

- Software helps stop delays and makes parts more accurate.

- AI can find problems early and suggest fixes, so work keeps going.

- These tools help companies make custom parts and answer customer needs fast.

Sustainability and Innovation

Eco-Friendly Solutions

CNC leaders care about the planet. They use machines that save energy and recycle when they can. Industry 4.0 tools, like IoT and big data, help use resources better. Predictive maintenance keeps machines running longer and uses less energy.

- Companies use real-time data to make supply chains better and waste less.

- Eco-friendly coolants and cleaners use fewer chemicals and help nature.

- Many companies join groups to share ideas and get better at being green.

Customization

New ideas help companies make custom parts for each customer. Advanced machines and AI software make it easy to change designs and make special parts. Companies can switch jobs fast and handle both small and big orders.

- Custom work helps companies serve many fields, like health and clean energy.

- Flexible systems let them fill special orders without slowing down.

- Customers get parts that fit just right, which makes them happy and helps products work better.

Customer Support

Customer support is very important for CNC companies. The best companies have strong support that makes customers trust them. Good support helps people want to buy again. They work hard to talk clearly and help after the sale.

Communication

Good communication makes customers feel important. Top companies use many ways to talk with people. They answer questions by phone, email, and chat. Some also use social media to help and listen. If someone has a problem, the company can reply fast. This quick help can stop small problems from getting bigger. It also shows the company cares about its customers.

Some companies use special tools to watch for online comments. These tools find complaints or questions right away. When someone shares a problem, the company adds it to their records. The sales or service team then gives answers or fixes. This helps companies make better connections and improve their help.

Tip: Companies that reply fast and clearly make customers happier and more loyal.

After-Sales Service

After-sales service means helping even after a sale. The best CNC companies give training, repairs, and support. They have easy guides and videos to help. Many offer 24/7 hotlines or online help. This support helps customers fix problems quickly and keep machines working.

High customer happiness scores show these ideas work well. When people feel helped, they want to buy again. Studies say companies with 95% happy customers get 20% more loyal buyers. This loyalty brings repeat sales and a good name.

After-sales teams also ask for feedback to get better. They use this to fix problems and make better machines. By listening and helping, companies keep customers happy and stay ahead.

- Quick replies

- Good training and guides

- 24/7 help choices

- Regular check-ins and feedback

These things help the best CNC companies stand out from others.

CNC Fabrication Pricing Comparison

Pricing Models

CNC fabrication companies have different ways to set prices. Each way works for different customers and projects.

Per-Part

The per-part model means you pay for each part made. This is good for small orders or when you need a prototype. You pay for how many parts you want. The price covers the material, machine time, and worker pay. Companies use this for simple jobs or when you want to try a design.

Project-Based

The project-based model gives one price for the whole job. This is best for big or hard projects. The price covers everything from design to delivery. Companies look at how many parts, what material, and how long it takes. This helps customers know the full cost before work starts.

Subscription

Some companies let you pay a set fee every month or year. This is called a subscription. You get to use machines, get help, and sometimes get materials. This is good for businesses that need CNC work often. Subscriptions can save money for regular users and help plan spending.

Tip: Pick the pricing model that fits your order size, how hard the job is, and how often you need CNC work.

Studies show that prices change by country and company type. For example, companies in China often charge less per part because labor and materials are cheaper. Companies in the USA may cost more but give better quality and faster help. The table below shows key points from recent studies:

| Comparative Study Title | Focus | Key Cost Factors | Advantages | Disadvantages |

|---|---|---|---|---|

| How Much Does it Cost of CNC Machining: China vs. USA | Cost comparison between China and USA CNC machining services | Labor, material costs, quality, logistics | Lower labor/material costs in China; High-quality standards in USA | Higher costs in USA; Logistical/shipping complexities from China |

| Comparative Analysis of CNC Machining Costs: China vs. USA | Cost, labor, material costs, cost reduction tips | Labor/material costs, operational expenses | Competitive pricing and skilled labor in China; High precision in USA | Higher labor and operational costs in USA |

| Glocal CNC Machining Comparison: China vs Japan vs USA vs Germany | OEM CNC lathing, custom parts, rapid services | Delivery speed, quality, technology | Reliable quality and delivery speed; Wide industry applications | Potentially higher costs; Technology accessibility limits |

Price Ranges 2025

XTJ’s direct manufacturing cuts costs by eliminating intermediary fees common in platforms like Xometry or Fictiv.

-

Prototyping: $50–$500 per part (small runs).

-

Low-Volume Production: $10–$100 per part (100–1,000 units).

-

High-Volume Production: $2–$50 per part (1,000+ units).

-

Complex Parts: $500–$5,000+ (tight tolerances, exotic materials).

Cost Factors

Many things change the final price of CNC work. Companies look at materials, how hard the part is, and how fast you need it.

Materials

Material cost is a big part of the price. Some materials, like aluminum, are cheaper and easy to cut. Others, like titanium, cost more and are harder to machine. The grade of the material also changes the price. For example, aerospace-grade aluminum costs 30-40% more than regular grades. Prices can go up or down based on the market and supply. Waste from cutting also adds to the cost.

| Material | Relative Cost | Machinability | Typical Applications |

|---|---|---|---|

| Aluminum | Low | Excellent | Prototypes, electronics enclosures |

| Brass | Moderate | Very Good | Electrical components, decorative |

| Carbon Steel | Moderate | Good | Structural components, tooling |

| Stainless Steel | High | Moderate | Medical devices, food-grade equipment |

| Titanium | Very High | Poor | Aerospace components, medical implants |

Complexity

Harder parts cost more to make. Parts with tricky shapes need more machine time and special setups. Advanced machines, like 5-axis models, may be needed. Hard jobs also need skilled workers and careful planning. More steps and checks mean a higher price.

- Tricky parts take longer to make.

- Advanced machines may be needed.

- Special steps, like turning or forming, add cost.

- Hard programming and setup take more time.

- More assembly steps help stop mistakes but cost more.

- Skilled workers are needed for tough jobs.

Lead Time

Lead time means how fast the company can finish your job. If you need it fast, it often costs more. Companies may need to work extra hours or use more machines. Short lead times can raise the price by 20% or more. Planning ahead helps keep costs down.

Note:Rush orders (3–5 days) increase costs by 20–50%. XTJ’s in-house production minimizes rush fees.

Value for Money

People want to get the most for their money when picking CNC fabrication. In 2025, new tech and business ideas help people save and get better parts.

- The CNC services market is growing quickly. Experts think it will grow by 6.1% each year until 2030. This means more companies trust CNC machines for their jobs.

- IoT tools let companies watch machines and fix problems early. This means machines break less, so repair costs go down.

- Digital twinning lets engineers test ideas on computers first. They can find mistakes sooner and set up machines faster. This saves time and cuts down on waste.

- Manufacturing as a Service (MaaS) lets people share expensive machines. This makes it cheaper for each user and helps more people use high-end machines.

- More shops use 5-axis and 6-axis machines now. These machines finish jobs faster and make fewer mistakes. Companies can make more parts in less time.

- Special software helps plan and check every job. This means less scrap and damage, so companies waste fewer materials. Customers get better quality parts.

Market data comes from many places. Distributors, suppliers, and government groups share info. Experts use math and talk to managers to check the numbers. This careful work helps customers trust prices and services.

Tip: Customers should pick shops with new tech and good reviews. These shops usually give the best value for money.

Comparing companies side by side helps buyers see who gives the best mix of price, quality, and service. When companies use the newest machines and software, they can give better deals and faster delivery. This makes CNC fabrication a smart choice for many businesses in 2025.

Choosing a CNC Fabrication Partner

Assessing Needs

Industry Requirements

Each industry needs something special from CNC fabrication. Aerospace companies want very exact parts and strong materials. Medical device makers need safe materials and careful checks. Car and energy companies want parts they can trust and track. XTJ’s direct model ensures reliability.

The table below shows what matters most and how it helps:

| Criteria / Technology | Description / Benefit | Quantitative Evidence / Impact |

|---|---|---|

| Near-net-shape starting materials | Uses less raw material | 30-40% less waste |

| Optimized toolpaths | Makes better use of material | 15-25% more material used well |

| Precision tolerances | Needed for aerospace | ±0.0005 inches or tighter |

| Inspection technology accuracy | Checks part size and shape | CMMs accurate to ±0.0001 inches |

| Statistical Process Control (SPC) | Watches the process in real time | Less variation, shows what the process can do |

| First Article Inspection (FAI) | Checks first parts for quality | Makes sure parts are good before big runs |

| Workforce training | Makes workers better | More training and teamwork |

Companies should also check if workers are trained and work well together. Good partners keep track of materials and fix problems fast. They get checked often and listen to feedback to get better.

Volume and Scale

How many parts you need changes which partner is best. Small jobs work well with flexible machines like 3- or 5-axis. Big jobs need machines that can do more at once for speed and cost. What material you pick changes price and time. Titanium takes longer and costs more than aluminum. Hard designs and tight rules mean more time and checks. Good partners can make just a few or lots of parts and still keep quality high.

- Aerospace needs strong parts and tough checks.

- Medical needs safe materials and careful testing.

- Defense and energy want to track every part.

- Extra steps like coating or plating add cost and value.

A good CNC partner can handle all these needs and keep quality high.

Evaluating Companies

Reputation

Reputation is important when picking a partner. Companies with good quality, on-time delivery, and fair prices stand out. Studies say 77% of manufacturers pick suppliers for quality. Almost 60% have delays from bad partners. Price matters, but not if it means lower quality. The table below shows what makes a good reputation:

| Reputation Metric | Description | Supporting Data / Source |

|---|---|---|

| Quality Assurance | How the company checks quality | 77% care most about quality (ISTMA) |

| Delivery Performance | How often they deliver on time | 60% have delays (AMT study) |

| Cost-Effectiveness | Total cost, including fixing mistakes | 45% feel pressure to cut costs (BCG) |

Certifications

Certifications show a company follows the rules. ISO 9001 means good quality checks. AS9100 is needed for aerospace jobs. ISO 13485 is for medical devices. ISO 45001 is for safe workplaces. These need checks, training, and strict rules. Certifications help buyers trust the company. XTJ’s certifications and in-house inspection tools build trust.

| Certification | Industry Focus | Key Benefits and Reliability Factors |

|---|---|---|

| ISO 9001 | General Quality Management | World standards, risk checks, gets better over time |

| AS9100 | Aerospace Manufacturing | Adds aerospace rules and risk checks |

| ISO 13485 | Medical Devices | Focuses on medical device quality and rules |

| ISO 45001 | Health & Safety | Shows the company cares about safety |

Why XTJ Precision Mfg

Unique Advantages

XTJ Precision Mfg is special because we are a real own factory with an unrivaled price advantage in the industry. From the factory to the customer’s first-hand price to the customer, there is no middleman to earn the difference. Product quality is guaranteed, the factory single-handedly control, perfect quality control mechanism, several units worth millions of various types of testing instruments.

Currently on the market online manufacturing and cnc machining company many are through the factory resource integration to help customers to complete the processing needs, they do not have the ability to self-production, so in terms of price is certainly to be more a part of the service fee, although they do not reflect it on the bill.

XTJ Precision Mfg has a strong history. Customers say they are happy and trust XTJ for big and small jobs. The support team fixes problems fast, so there are fewer delays. XTJ has worked since 2005 and trains workers well, making them a good choice for many fields. Many customers come back for more because of XTJ’s quality and service.

Tip: Always ask for references and check what jobs a company has done before you choose.

CNC fabrication is growing fast in 2025. They use smart tech like IoT and AI to watch machines and make parts more exact. Eco-friendly designs and flexible machines help with new industry needs. Picking a company that matches your project helps you get the best results. XTJ Precision Mfg is known for great quality and service. You can look at the chart and checklist to help you choose. Asking for quotes or talking to companies is a good way to start working together.

FAQ

What does CNC stand for?

CNC means Computer Numerical Control. A computer tells machines how to move. This lets companies make parts that are very exact and the same every time.

How do companies decide CNC fabrication prices?

Companies check what material is used and how hard the part is. They look at how long the machine runs and how many parts you want. If you need it fast or want special things, it can cost more. You can ask for a price to see what it will cost.

Why do tolerances matter in CNC machining?

Tolerances tell how close a part is to its plan. Small tolerances mean parts fit better and work well. Some jobs, like in planes or hospitals, need very small tolerances to be safe.

What materials can CNC machines handle?

CNC machines can cut metals like aluminum, steel, and titanium. They also work with plastics, composites, and some ceramics. Each kind of material needs its own tools and settings.

How does automation help CNC companies?

Automation uses robots and smart programs. Robots put in parts, check if they are good, and keep machines working longer. This helps stop mistakes and saves time. Companies can finish more work with fewer errors.

What certifications should a CNC company have?

ISO 9001 means the company checks quality well. AS9100 is needed for airplane parts. ISO 13485 is for medical tools. These show the company does good work and can be trusted.

How can a customer choose the right CNC partner?

Customers should look at the company’s name, certificates, and what others say. They should ask if the company has done jobs like theirs before. Comparing what each company offers, their prices, and help makes it easier to pick the best one.