Your Trusted Partner for Rapid Prototyping and Low-Volume Manufacturing

we deliver high-precision components to global industries

Who We Are

Founded in 2005, XTJ (Shenzhen Xin Tian Jian Precision Mfg.) began as a small workshop with a big dream: to deliver precision-engineered parts that drive innovation across industries. Over the past two decades, we’ve grown into a global leader in rapid prototyping and low-volume manufacturing, serving sectors like automotive, aerospace, medical, and consumer electronics. Today, with a 12,000-square-meter facility, 300 skilled employees, and 120 advanced machines, we’re proud to be a trusted partner to industry leaders like Magna, Shimadzu Medical, BEKO, and Electrolux.

Our mission is to provide high-quality, precision parts that meet your exact specifications, on time, every time. Whether you need a single prototype or production runs, we’re here to bring your ideas to life with services like CNC machining, 3D printing, and injection molding.

Our Milestones

Shenzhen TianJian Model Company was founded with a small team of 10, focusing on rapid prototyping.

Renamed to Shenzhen Xin Tian Jian Precision Mfg., expanded to 1,200 square meters with 16 CNC machines and 40 employees.

Achieved ISO 9001:2015 certification, entered the medical equipment industry with 3D printing capabilities, and grew to 80 employees.

Became a system supplier for Magna and Shimadzu Medical, solidifying our presence in automotive and medical sectors.

Imported high-precision 5-axis machines from Germany and Switzerland, enhancing our CNC machining

Founded sub-company Xin Jian Precision Mold Co., Ltd., specializing in rapid tooling, and earned IATF 16949 certification.

Expanded to a 12,000-square-meter facility in Dongguan, adding capabilities for sheet metal fabrication and becoming a supplier for BEKO and Electrolux.

Why Partner with XTJ machining?

We specialize in a variety of manufacturing processes, from CNC machining and 3D printing(SLA, SLS, DMLS) to injection molding and sheet metal fabrication, ensuring we can meet the diverse needs of industries like automotive, aerospace, medical, and consumer electronics. Our expertise also extends to rapid prototyping, vacuum casting, and material extrusion, providing flexible solutions for your projects.

Certified Quality

ISO 9001:2015 and IATF 16949 certifications ensure our processes meet global standards for quality and reliability.

Advanced Technology

Equipped with industry-leading tools like Zeiss CMM and DMG 5-axis machining centers for precision manufacturing.

Our Core Values

Innovation

We continuously invest in cutting-edge technology to stay ahead of industry demands.

Quality

Our rigorous quality management system ensures every part meets your specifications.

Customer Success

Your success is our priority – we’re here to support your projects from rapid prototyping to production.

Integrity

We believe in transparency, reliability, and delivering on our promises.

Our Factory & Facilities

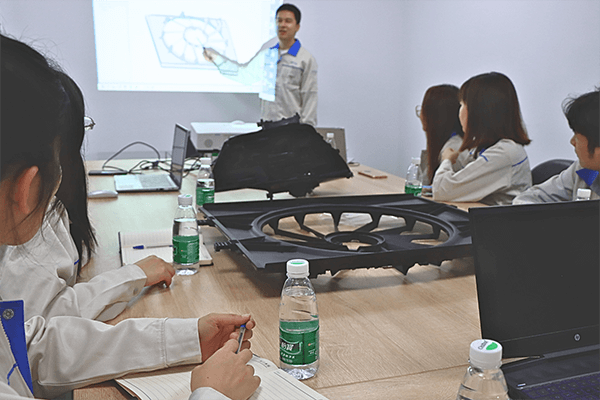

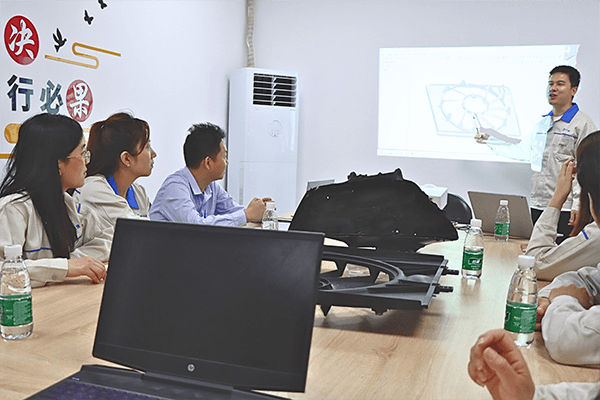

Our 300-strong team includes experienced engineers, technicians, and quality control experts with decades of expertise in precision manufacturing. From design consultation to final inspection, we’re dedicated to ensuring your project is a success, whether it involves CNC machining, 3D printing, or sheet metal fabrication.

Your One-Stop Solution for Rapid Prototyping

Skilled Team, Advanced Technology, Delivering Precision for Global Industries.