CNC Metal Machining

ISO 9001 certified manufacturer, delivers top-tier CNC metal machining services for precision parts.

- Cost-Effective Pricing

- Product Certification

- Rapid Delivery

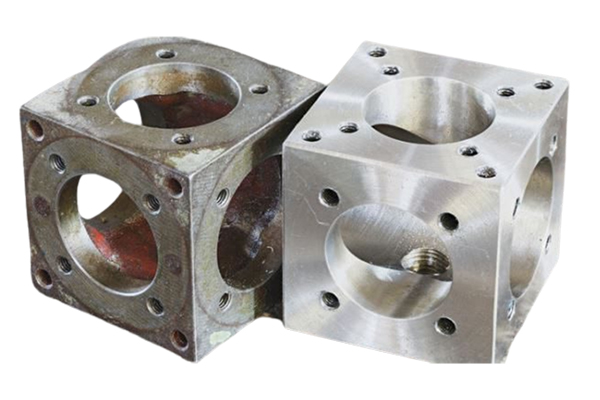

Precision CNC Metal Machining Services

XTJ Precision Mfg specializes in CNC metal machining, offering advanced solutions for industries ranging from aerospace to medical. Our state-of-the-art in-house capabilities include 3-, 4-, and 5-axis CNC machining, milling, turning, Electrical Discharge Machining (EDM), and surface grinding, achieving precision tolerances as tight as ±0.002 mm. Whether you need rapid prototyping or large-scale production, we deliver custom parts with superior performance and aesthetics.

CNC Metal Machining Materials

Selecting the right metal for CNC machining is critical to achieving optimal performance, cost-efficiency, and durability. XTJ Precision Mfg offers a wide range of metals tailored to your project requirements. Below are some of the key materials we work with:

Aluminum is a cost-effective, lightweight metal with excellent machinability and a high strength-to-weight ratio, ideal for precision CNC machining.

- AL6061-T6: Widely used for its excellent machinability, corrosion resistance, and affordability. Ideal for automotive, aerospace, and construction components.

- AL7075-T6: High-strength aluminum with superior fatigue resistance, perfect for high-stress aerospace and automotive parts.

- AL6082: Offers the highest strength in the 6000 series, with excellent corrosion resistance, suitable for defense and aerospace applications.

Stainless steel combines good machinability with corrosion resistance and strength, making it a versatile choice for CNC machining.

- SS304: Known for its formability and weldability, used in kitchen appliances, food handling equipment, and piping systems.

- SS303: Offers excellent corrosion resistance and durability, ideal for gears, shafts, and aircraft fittings.

- SS316: Features superior corrosion resistance due to molybdenum content, perfect for medical implants and aerospace components.

Titanium offers an exceptional strength-to-weight ratio and biocompatibility, making it ideal for medical devices and aerospace applications, though it is costly to machine.

Copper and its alloy, brass, are highly machinable metals with excellent thermal and electrical conductivity, ideal for electrical and plumbing applications.

- Copper: High conductivity makes it perfect for electrical components, though it is more expensive.

- Brass (H59): A copper-zinc alloy with high tensile strength and corrosion resistance, used in automotive, plumbing, and musical instruments.

Magnesium is lightweight and highly machinable, ideal for automotive and aerospace parts, but requires careful handling due to fire hazards.

| Materials | Description | Price share |

|---|---|---|

| Aluminum | Easy to machine + Excellent strength-to-weight balance | $ |

| Stainless Steel | Well-suited for machining + Superior tensile strength + Rust-proof | $$$ |

| Steel | Highly workable + Robust tensile strength + Great flexibility and weldability | $$ |

| Brass | Smooth machining + Top-notch electrical conductivity + Low friction + Attractive golden finish | $ |

| Copper | Easily machined + Outstanding thermal and electrical conductivity | $$ |

| Titanium | Exceptional strength-to-weight performance + Highly corrosion-resistant | $$$$ |

| Magnesium | Ultra-lightweight + Impressive strength-to-weight ratio + Good heat conductivity + Biocompatible | $$ |

| Molybdenum | Exceptional durability and strength + Superior resistance to heat and corrosion | $ |

Factors to Consider for CNC Metal Machining

Choosing the right metal for CNC machining impacts cost, performance, and production time. Here are key factors to consider:

Machining Time

Metals with high machinability, like aluminum, reduce machining time and costs. Complex part geometries increase machining time, impacting overall expenses.

Strength and Environmental Requirements

Select metals based on the part’s intended use. High-stress applications require strong metals like stainless steel or titanium, while lightweight applications may favor aluminum or magnesium.

Finishing and Post-Processing

XTJ offers extensive surface finishing options, including anodizing, powder coating, and polishing, to enhance aesthetics and remove machining marks. The choice of metal affects the finishing process and cost.

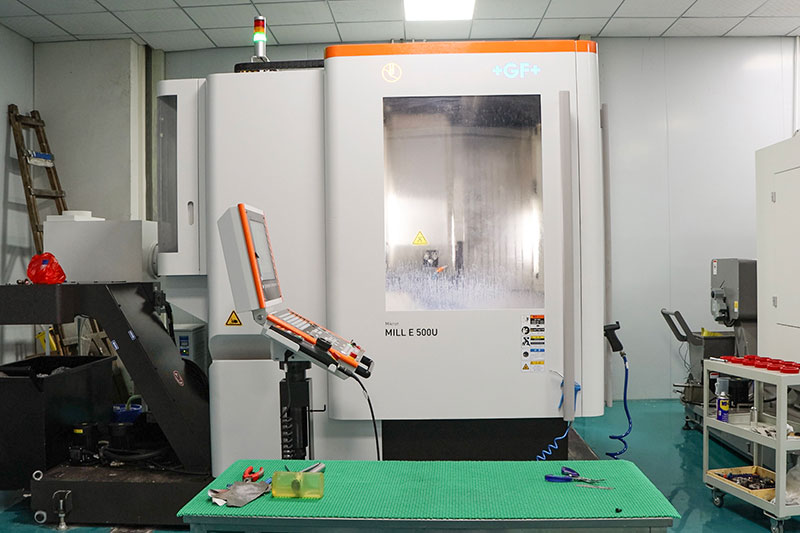

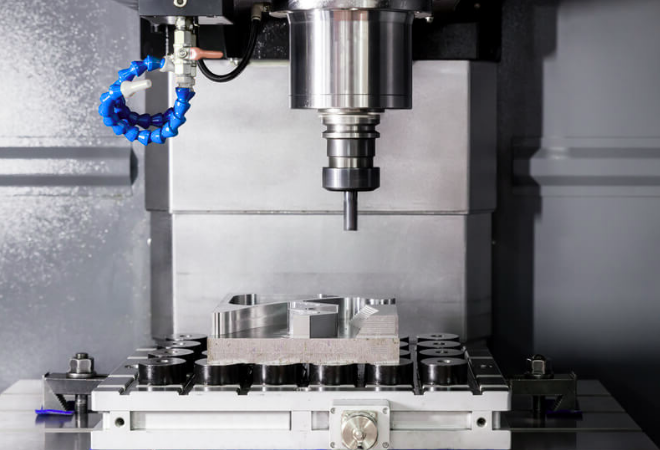

CNC Machines at XTJ Precision Mfg

XTJ Precision Mfg utilizes advanced CNC machines to deliver high-precision metal parts. Our capabilities include:

3/4-Axis CNC Milling

Ideal for simple geometries, offering high accuracy at a low cost.

5-Axis CNC Milling

Produces intricate parts with minimal machining marks, ideal for aerospace and medical applications.

CNC Turning (Lathes)

Enhances design flexibility for more complex parts.

Mill-Turning CNC Centers

Combines milling and turning for complex parts at a lower cost than 5-axis machining.

Electrical Discharge Machining (EDM)

Ideal for simple geometries, offering high accuracy at a low cost.

Surface Grinding

Enhances design flexibility for more complex parts.

Process Comparison

| Process | Relative Cost | Benefits | Limitations |

|---|---|---|---|

| CNC Turning | 80% | Low cost, high production capabilities | Limited to cylindrical parts |

| 3-Axis CNC Milling | 100% | High accuracy for simple geometries, cost-effective | Manual repositioning reduces accuracy |

| 4-Axis CNC Milling | 120% | Enhanced flexibility for complex parts | Higher cost than 3-axis |

| Mill-Turning CNC Centers | 130% | Combines milling and turning, high design freedom | Tool access restrictions |

| 5-Axis CNC Milling | 180% | High precision for complex parts, minimal machining marks | Highest cost |

| EDM | 150% | Ideal for hard metals and intricate shapes | Slower process, higher cost |

| Surface Grinding | 90% | Smooth finishes, precise tolerances | Limited to flat surfaces |

CNC Metal Machining in 5 Simple Steps

Collaborate with us effortlessly: Submit your design, get expert feedback, approve your quote, and launch production. Stay informed at every stage for reliable, high-quality outcomes.

Frequently Asked Questions

Costs vary based on material, part complexity, tolerances, and finishing requirements. Contact XTJ for a custom quote tailored to your project.

CNC metal machining is a subtractive manufacturing process that uses computer-controlled machines to shape metal parts with high precision.

XTJ can produce bolts, nuts, gears, shafts, aerospace components, medical implants, and custom parts for various industries.

Looking for affordable, reliable CNC Metal Machining services?

Partner with XTJ Precision Mfg for precision, efficiency, and great value.