Reaction Injection Molding (RIM) Services

Lightweight, Durable Parts with Unmatched Design Flexibility

- 20+ Years of Advanced Molding Expertise

- Parts Delivered in as Little as 15 Days

- Precision to ±0.1mm

- In-Mold Painting for Stunning Finishes

Overview of Reaction Injection Molding (RIM)

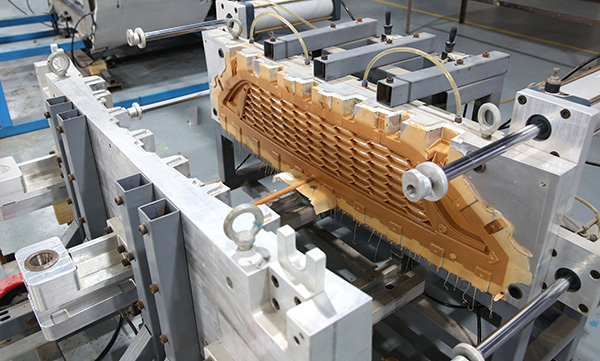

Reaction Injection Molding (RIM) is a specialized process where two liquid components—isocyanate (A side) and polyol (B side)—chemically react inside a mold under low pressure to form a thermosetting polyurethane part. This exothermic reaction, controlled with water lines and advanced mixing systems, enables the creation of large, lightweight, and durable components. RIM excels in producing complex parts with varied wall thicknesses, in-mold coatings, and encapsulated inserts, outperforming traditional materials like steel, aluminum, and SMC.

How RIM Works

Why Choose XTJ for RIM

With over 20 years of expertise, XTJ delivers innovative RIM solutions, Specializing in reaction injection molding, lightweight durable parts, in-mold painting services, and rapid RIM manufacturing. We excel in custom RIM production and design flexibility for your projects.makes us your ideal partner for automotive, medical, and industrial projects.

Unique Advantages of RIM with XTJ

In-Mold Painting

Achieve Class A high- or low-gloss finishes directly in the mold, saving time and costs with durable, chip-resistant coatings.

Design Flexibility

Mold parts with varied wall thicknesses (0.25–1.125 inches) and intricate details, impossible with traditional injection molding.

Enhanced Geometry

Add B-side features (louvers, ribs, bosses) or encapsulate inserts (steel, wood, electronics) for added strength.

Superior Performance

Lightweight parts outperform steel, aluminum, and SMC, boosting fuel efficiency and load capacity while offering thermal/acoustic insulation.

Durability

Polyurethane resists corrosion, chemicals, and impact, maintaining integrity in harsh environments.

Explore RIM Variants

RIM’s versatility stems from its ability to produce diverse part types, enhanced by specialized processes:

Solid Elastomers

Homogeneous, rigid, or flexible materials (e.g., Bayflex series) for automotive fenders and trims, offering high impact strength and in-mold coatings.

Structural Foams

Sandwich-like structures with a dense skin and microcellular core (e.g., Baydur), ideal for load-bearing panels and engine covers with 20–40% weight savings.

Flexible Foams

Soft, resilient materials for ergonomic applications, providing sound damping and a soft feel.

Reinforced Reaction Injection Molding (RRIM)

Adds glass fibers to the polymer for increased stiffness and toughness, used in body panels and fascias.

Structural Reaction Injection Molding (SRIM)

Incorporates a fiber mesh for superior strength, retaining low weight and Class A aesthetics, perfect for door panels and shelves.

These variants allow RIM to outshine traditional injection molding, vacuum forming, and cast molding, offering tailored solutions for your needs.

Materials and Industry Applications

XTJ leverages RIM’s material diversity to meet your project demands.

- Polyurethane: Lightweight, durable, with options for reinforcement (e.g., Baydur, Bayflex).

- Dicyclopentadiene (DCPD): Ideal for large parts up to 120 ft² with excellent impact strength.

- Composites (LFI): Long glass fiber-reinforced for high stiffness and Class A surfaces.

- Automotive: Bumpers, fenders, and spoilers with improved fuel efficiency.

- Medical: Durable housings with thermal insulation.

- Consumer Goods: Furniture and appliance covers with high-gloss finishes.

- Industrial: Structural prototypes with acoustic damping.

Optimize Your RIM Parts

Wall Thickness: Design varied thicknesses (0.25–1.125 inches) for stiffness, avoiding excessive variation to prevent uneven filling.

- Rib Design: Use tall, thin ribs (max 0.66x wall thickness) with 5° draft to enhance stiffness without sink marks.

- Bosses: Limit height to 3x wall thickness, attach to side walls with gussets for venting.

- Inserts: Encapsulate metal or wood inserts (min 1/8–1/4 inch from mold wall) for stiffness and durability.

- In-Mold Coatings: Apply 2.5 mil coatings (±1 mil tolerance) for a flawless finish.

What Our Clients Say About Us

XTJ’s RIM expertise transformed our automotive project. Their in-mold painting and rapid delivery exceeded our expectations!

- Author: John D., Automotive Engineer

We needed durable, lightweight medical device housings, and XTJ delivered beyond what we hoped for. Their precision and quality are top-notch.

- Author: Emily R., Product Manager at MedTech Solutions

The team at XTJ helped us design structural panels that saved us 30% in weight without compromising strength. Their support was invaluable!

- Author: Michael T., Industrial Designer at HeavyDuty Innovations

Get Started Today

Your Partner for RIM Innovation

Need lightweight, durable parts with stunning finishes? XTJ’s reaction injection molding services deliver innovative solutions for large, complex designs. Let’s bring your vision to life!