Need custom rackmount enclosures? XTJ Precision Mfg offers a seamless one-stop shop experience.

→ Fully customizable by material, finish, graphics and permanent marking

- Rapid Enclosure Prototyping

- No Minimum Order Enclosures

- Global delivery, Real factory, welcome to visit

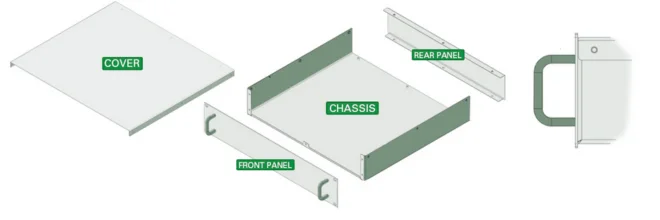

Our Custom Enclosure Manufacturing Capabilities

At XTJ Precision Mfg, we deliver 100% custom rackmount enclosures in just 3-5 days, with no minimum order requirements. Whether you need a standard 19” configuration or a bespoke design crafted to your precise width specifications, our streamlined manufacturing process ensures a perfect fit for your project.

Say goodbye to time-consuming drilling and filing. Our enclosures come with precision custom cutouts, tailored to your needs. We include all necessary hardware and fasteners, such as handles and drawer slides, for a complete, ready-to-use solution. Need internal components like brackets, backplanes, or partitions? We’ve got you covered with fully integrated designs.

Select from a broad range of finishes, graphics, and permanent marking options to achieve both the functionality and aesthetic your project demands. From servers and rack-mounted PCs to specialized components housed in racked cabinets, XTJ Precision Mfg builds fully finished, application-specific rackmount enclosures in 3-5 days, with no minimum order.

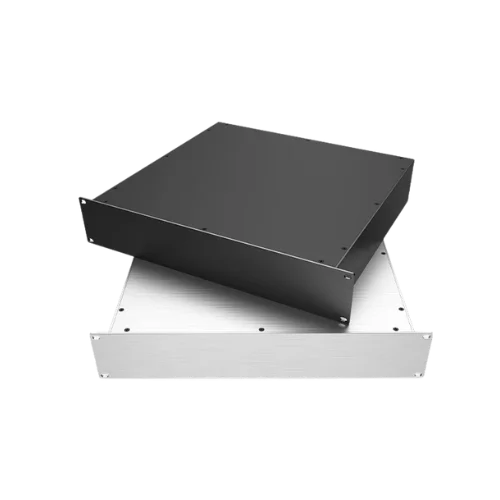

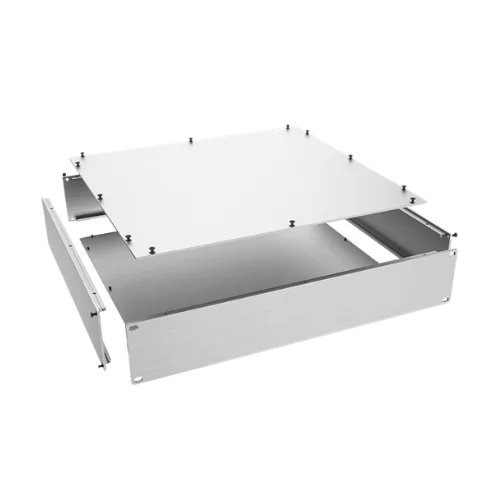

Rackmount Enclosures Examples

- RoHS Compliant

- Fully custom width and heights accomodated at no extra cost

- Fully customizable with materials, finishes, graphics, and markings.

Materials and Hardware for Custom Rackmount Enclosures

At XTJ Precision Mfg, we offer a diverse selection of high-quality sheet metal materials to craft custom rackmount enclosures tailored to your specific needs. Our material options ensure durability, aesthetic appeal, and functionality for any application. Available materials include:

Custom Materials

Need a specialized material not listed? Contact us online to discuss your unique requirements, and we’ll source or customize materials to meet your project’s specifications.

With XTJ Precision Mfg, you can create fully customized rackmount enclosures using these premium materials, delivered in 3-5 days with no minimum order.

Stainless Steel Sheet

Strong, corrosion-resistant, and ideal for demanding environments requiring a professional finish.

Brushed Stainless Steel

Features a linear, textured finish for a sleek, modern look with enhanced scratch resistance.

Brushed Stainless Steel

Features a linear, textured finish for a sleek, modern look with enhanced scratch resistance.

Matte Stainless Steel

Offers a non-reflective, subdued finish for a sophisticated, understated appearance.

Industrial Stainless Steel

Heavy-duty and rugged, perfect for industrial applications where durability is paramount.

Galvanized Steel

Zinc-coated for superior corrosion resistance, ideal for enclosures needing a paintable or powder-coated finish.

Mild Steel (Iron)

A cost-effective, versatile option for robust enclosures with excellent structural strength.

Aluminum

Lightweight, corrosion-resistant, and durable, perfect for applications prioritizing reduced weight.

Enhance your enclosure with a variety of hardware options tailored to your needs:

Fasteners

Precision-engineered screws, bolts, and rivets to securely assemble your enclosure.

Handles

Ergonomic, durable handles in various styles for easy installation and transport.

Rubber Feet

Non-slip, vibration-dampening feet to stabilize and protect your rackmount in any setup.

Additional Hardware

Customize with drawer slides, mounting brackets, hinges, or cable management solutions to meet your specific requirements.

Finishes for Custom Enclosures

we offer a range of premium finishes to enhance the durability, performance, and visual appeal of your custom rackmount enclosures. Select from the following options to align with your project’s needs:

Powder Coating

A tough, protective coating available in various colors, providing excellent resistance to corrosion, abrasion, and UV exposure.

Chem-Film Coating

A chromate conversion layer for aluminum, boosting corrosion resistance and electrical conductivity.

Passivation

A chemical process for stainless steel that removes surface contaminants, enhancing corrosion resistance and maintaining a pristine finish.

Anodizing

Strengthens aluminum surfaces with a corrosion-resistant, customizable colored finish.

Grained Finish

A linear, brushed texture that delivers a sleek, modern aesthetic with improved resistance to scratches.

Vibratory Finish

A uniform, non-directional polish that creates a smooth, professional look suitable for diverse applications.

Custom Graphics & Labeling

Transform your custom rackmount enclosure with high-quality graphics and permanent markings for branding, serialization, labeling, or decorative purposes. XTJ Precision Mfg provides in-house solutions customized to your requirements:

Digital Printing: Vibrant, high-resolution graphics for logos, labels, or intricate designs, offering flexibility for full-color applications.

Silkscreening: Durable, precise printing in single or multiple colors, ideal for clear, long-lasting text and branding.

Laser Marking: High-precision etching for permanent serial numbers, barcodes, or detailed designs, ensuring durability and clarity.

Ready to Start Your Custom Project?

Upload your design for a free quote or connect with our team to discuss your needs.