Unlocking Affordable Custom Metal Enclosures: Insights from the EEVblog Forum and XTJ Precision Mfg’s Practical Approach

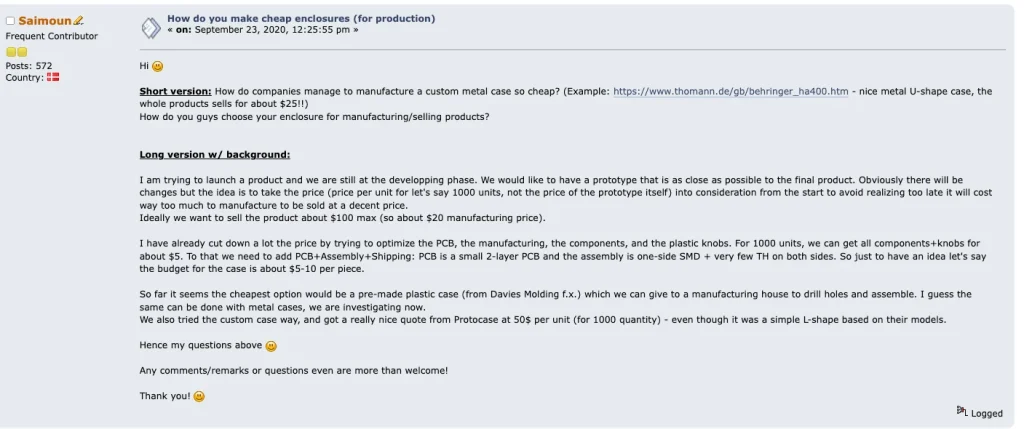

In the world of electronics prototyping and production, sourcing affordable custom metal enclosures is a persistent challenge for makers, engineers, and startups. A deep dive into the EEVblog forum’s “Manufacture” section highlights this struggle vividly. In a thread titled “How do you make cheap enclosures (for production)?,” user Saimoun voiced a common frustration: targeting a $100 retail product with a $20 BOM, they allocated just $5-10 for the enclosure. Quotes from premium prototyping services like Protocase came in at $50 per unit for 1,000 pieces—far exceeding budget. Forum members marveled at budget-friendly products like Behringer’s $25 audio units with sleek U-shaped metal shells, asking, “How do they keep costs so low?”

The forum buzzed with practical advice: laser-cut sheet metal bending is ideal for low-to-medium volumes (around 1,000 units), steel is cost-effective when sourced strategically, and partnering with overseas suppliers can drop costs to $4 for cutting and $4 for bending. Tips included using DXF files to simplify designs and minimize non-recurring engineering (NRE) fees, with suppliers on platforms like Alibaba or in Eastern Europe as go-to options. It’s a story of innovation meeting tight margins—a challenge many engineers face.

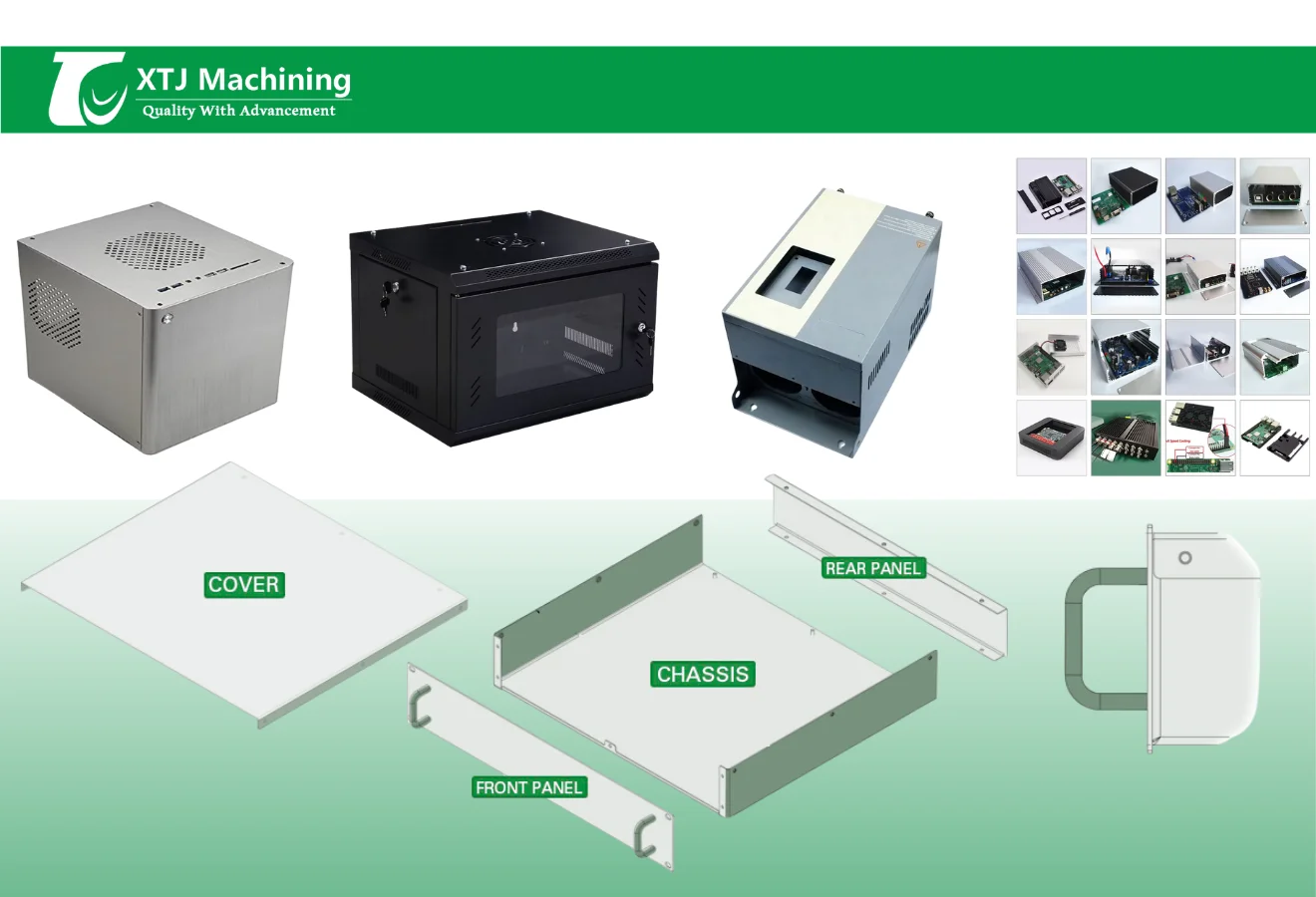

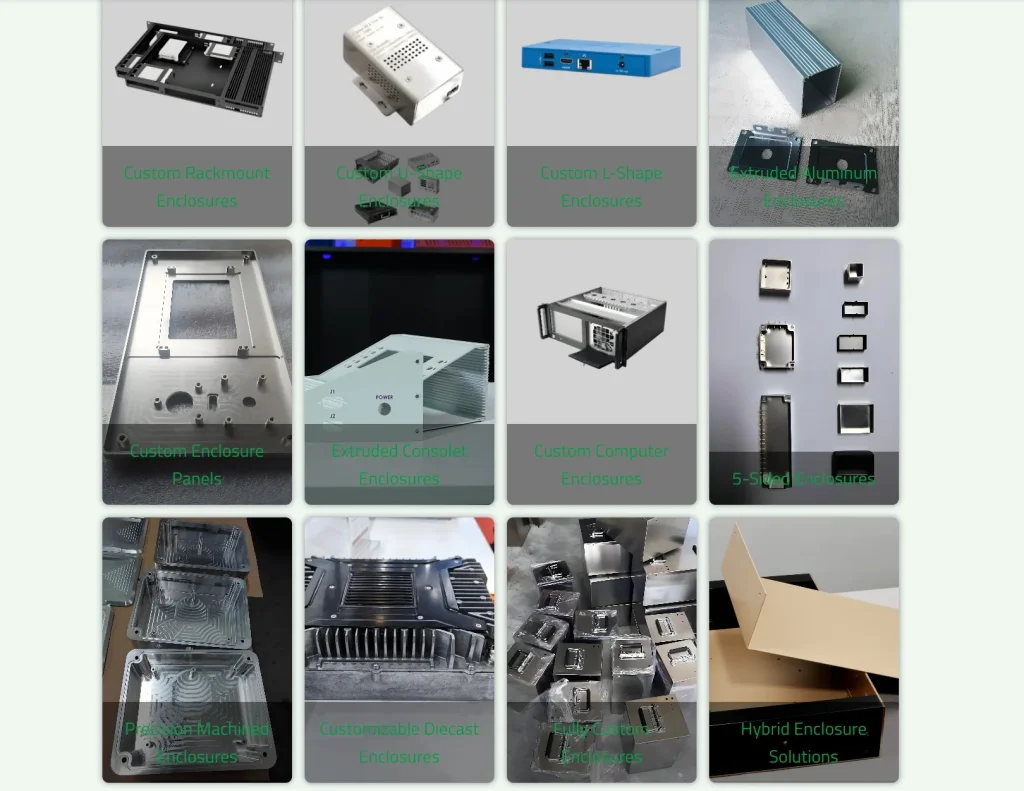

This is where manufacturers like XTJ Precision Mfg, a China-based leader in sheet metal fabrication, step in to turn these frustrations into solutions. XTJ leverages its efficient supply chain and precision expertise to deliver high-quality, cost-effective enclosures tailored for indie developers and scaling businesses. Below, we explore the forum’s challenges, how XTJ addresses them, and why their approach is a game-changer—while also considering the broader landscape of enclosure manufacturing.

The Forum’s Core Challenges: Cost, Complexity, and Scale

The EEVblog thread captures a universal pain point: balancing cost, quality, and scalability. Saimoun’s post resonated widely—pre-fab plastic enclosures from suppliers like Davies Molding work for quick prototypes but lack the premium look of metal. Custom aluminum or steel enclosures, while desirable, often come with steep NRE charges, material markups, and shipping costs from prototype-focused services. Forum contributors like Yansi and Berni emphasized that affordability hinges on volume-efficient processes in regions with abundant raw materials. Simplifying designs (e.g., L- or U-shaped bends for rigidity) and finding a manufacturer that accommodates small-to-medium batches are key. Yet, risks like delayed shipments or inconsistent quality from overseas suppliers often loom large.

XTJ Precision Mfg tackles these challenges head-on, offering a compelling alternative to both Western prototyping services and other overseas manufacturers.

XTJ Precision Mfg: Efficiency Meets Precision

Based in Guangdong, China—a global hub for manufacturing—XTJ Precision Mfg stands out by combining local supply chain advantages with rigorous quality control. Unlike some competitors on platforms like Alibaba, XTJ focuses on custom sheet metal enclosures, delivering solutions that align with the needs of engineers seeking affordability without compromising quality. Here’s how they address the forum’s pain points:

Cost Optimization: From $50 Quotes to Under $10

XTJ delivers laser-cut and CNC-bent enclosures for runs as small as 500-1,000 units at prices that align with tight budgets. While Protocase might quote $50/unit for a 1,000-piece run, XTJ’s quotes often fall between $5-8 per piece for simple U- or L-shaped designs in mild steel or aluminum, including powder coating and basic assembly. Their cost advantage stems from:

- Local Material Sourcing: Steel at $0.50/kg from nearby mills, compared to $1/kg or more elsewhere, eliminates middleman costs.

- Low NRE Fees: DXF uploads enable prototypes in days, with NRE costs under $500 for most projects—significantly below Western standards.

- Optimized Processes: Efficient cutting and bending minimize waste, yielding 20-30% savings passed on to clients.

For example, a recent client needed 1,000 ventilated metal boxes for a MIDI controller. XTJ delivered at $6.50/unit, including EMI shielding and custom silkscreening, keeping the total BOM under $7. With tolerances of ±0.1mm, assembly issues were avoided, proving that affordability doesn’t mean cutting corners.

Reliability and Speed: Overcoming Overseas Concerns

EEVblog threads often highlight risks of overseas manufacturing, such as communication gaps or inconsistent finishes. XTJ counters these with:

- Streamlined Supply Chain: Partnerships with local vendors for anodizing, laser etching, and more keep lead times at 2-4 weeks, even with design tweaks.

- Design Support: Free Design for Manufacturability (DFM) reviews ensure enclosures are production-ready, addressing issues like heat dissipation or IP-rated seals.

- Quality Assurance: As an ISO 9001-certified facility, XTJ maintains consistent standards, with English-speaking project managers simplifying communication via dedicated portals for tracking and revisions.

While concerns like intellectual property risks exist with overseas production, XTJ’s transparent processes and client testimonials—serving everyone from Silicon Valley startups to EU integrators—build trust.

Customization for Real-World Needs

XTJ excels at tailoring enclosures to specific requirements, from RoHS-compliant finishes to complex shapes for heat dissipation. Their ability to handle small-to-medium runs makes them ideal for startups scaling from prototype to production, ensuring designs remain both cost-effective and buildable.

Comparing XTJ to Alternatives

To put XTJ’s value in perspective, consider a typical Western prototyping service versus XTJ and a generic Alibaba supplier:

| Feature | Western Prototype (e.g., Protocase) | XTJ Precision Mfg | Generic Alibaba Supplier |

| Cost per Unit (1,000 units) | $50 | $5-8 | $4-10 |

| NRE Fees | $1,000+ | ~$500 | $300-$800 |

| Lead Time | 4-6 weeks | 2-4 weeks | 3-8 weeks |

| Quality Consistency | High | High (ISO 9001) | Variable |

| Design Support | Paid DFM | Free DFM | Limited |

While generic Alibaba suppliers may offer lower upfront costs, their variable quality and communication challenges can lead to delays or rework. Western services provide reliability but at a premium. XTJ strikes a balance, offering high-quality, cost-effective solutions with robust support.

Why Now? The Perfect Time for Affordable Enclosures

With the electronics industry booming—IoT devices are projected to grow 15% annually, per industry reports—affordable, high-quality enclosures are critical for staying competitive. Whether you’re sketching enclosures for an IoT gadget, audio device, or industrial control unit, XTJ Precision Mfg offers a practical solution. Their efficient supply chain and precision engineering enable cost savings of 40% or more while maintaining a professional metal aesthetic.

Ready to solve your enclosure challenges? Visit XTJ Precision Mfg’s website for a no-obligation quote. Upload your DXF, specify your batch size, and see the results. Have a story about enclosure struggles or successes? Share it in the comments below—we’d love to hear your EEVblog-inspired experiences!