Brass, Bronze, Copper: Comprehensive Guide for CNC Machining Excellence

At XTJ Precision Mfg, we live and breathe precision machining, and materials like brass, bronze, and copper are our bread and butter. These red metals—named for their copper base and reddish tones—are CNC powerhouses, each with unique strengths. Choosing the wrong one can derail your project, so we’ve crafted a detailed guide, inspired by industry leaders, to dive deep into their compositions, histories, properties, differences, and CNC applications. With a no-nonsense style and rich insights, this will help you pick the perfect metal for your next build.

Brass vs Bronze vs Copper: Material Comparison for CNC Machining

These metals all start with copper but diverge with alloying elements. Here’s the breakdown, including key grades for CNC machining.

-

Copper: A pure, naturally occurring metal—99%+ Cu, sporting a reddish-brown hue. Minimal alloying keeps it close to its elemental form, with grades tailored for specific uses.

-

Key Grades: C101 (oxygen-free, high electrical conductivity for electronics), C110 (electrolytic tough pitch, excellent thermal/electrical performance), C122 (phosphorus-deoxidized, great for welding/formability), C145 (tellurium-enhanced for superior machinability in rods and bars).

-

-

Brass: An alloy of copper (60-70%) and zinc (30-40%), often spiked with lead, tin, or manganese for enhanced properties. Its golden shine varies with zinc content—more zinc means yellower and stronger but potentially brittle.

-

Key Grades: C260 (cartridge brass for ammunition and fasteners), C272 (yellow brass for industrial/architectural parts), C330 (low-lead for plumbing), C353 (clock brass for precision components), C360 (free-cutting brass, a CNC favorite for hardware/valves), C385 (architectural brass for extrusions), C464 (naval brass for corrosion resistance and hot forming), C48200-C48500 (leaded naval brass for machining rods).

-

-

Bronze: Copper (88-95%) blended with tin (5-12%), often with aluminum, phosphorus, or nickel for specialized traits. Its duller gold-brown tone reflects higher copper content than brass.

-

Key Grades: C91300 (tin bronze for bearings), C932 (high-leaded bearing bronze for bushings/washers), C954 (aluminum bronze for high-strength industrial/marine parts), MTEK 375 (aluminum bronze for gears/dies), C83600 (manganese bronze for high-pressure valves).

-

Pro Tip: For CNC, check alloy specs upfront. Leaded brass (C360) machines effortlessly, while lead-free bronze suits food/medical compliance.

History of Red Metals in Precision Machining

The histories of copper, brass, and bronze are as rich as their applications, shaping human progress and influencing their modern CNC roles.

-

Copper: One of humanity’s oldest metals, used since 8700 BC in Mesopotamia for tools, ornaments, and early plumbing. Its natural antibacterial properties made it a go-to for water systems in ancient Egypt and Rome. By the Industrial Revolution, copper’s conductivity powered telegraphs and electrical grids, cementing its role in modern electronics. Today, CNC machining leverages its purity for precision electrical components.

-

Brass: Emerging around 500 BC, brass was a game-changer for the Romans, who used it for coins, armor, and decorative engravings. Its zinc-copper blend was refined in the Middle Ages, with Europe mastering production by the 16th century. The Industrial Era saw brass in ammunition (hence “cartridge brass”) and fittings due to its workability. In CNC, brass’s machinability traces back to these early uses, making it a staple for intricate, high-volume parts.

-

Bronze: Kicking off the Bronze Age around 3500 BC, this copper-tin alloy revolutionized tools, weapons, and sculptures across Mesopotamia, Egypt, and China. Its strength and corrosion resistance made it ideal for ship fittings and bells by the Middle Ages. Modern bronze alloys, like aluminum bronze, evolved for industrial and marine durability. CNC shops prize bronze for its historical toughness, perfect for wear-resistant components.

Pro Tip: Bronze’s legacy in marine applications informs its CNC use in saltwater-exposed parts. Copper’s ancient plumbing role echoes in today’s HVAC machining.

Brass, Bronze, and Copper: Comparing Strength and Performance

Properties drive CNC performance—from tool wear to part longevity. This mega-table compares mechanical, physical, corrosion, and machining traits, tailored for CNC applications.

|

Property |

Copper |

Brass |

Bronze |

|---|---|---|---|

|

Density (g/cm³) |

8.96 (heaviest, impacts weight-sensitive designs) |

8.4-8.7 (midweight, good for fittings) |

7.7-8.9 (lightest, ideal for aerospace) |

|

Tensile Strength (MPa) |

210-220 (soft, easily formed) |

350-635 (moderate, zinc-dependent) |

338-800 (strongest, aluminum bronze excels) |

|

Yield Strength (MPa) |

33-70 (low, great for bending) |

95-124 (decent for structural parts) |

125-800 (high, load-bearing champ) |

|

Hardness (Brinell) |

35-95 (softest, prone to wear) |

55-290 (versatile, lead boosts) |

65-420 (hardest, wear-resistant) |

|

Elongation (%) |

40-50 (highly ductile) |

20-50 (good formability) |

5-35 (less ductile, brittle in some alloys) |

|

Melting Point (°C) |

1,085 (high, stable for casting) |

900-940 (lower, easier to melt) |

913-1,085 (varies, tin raises it) |

|

Thermal Conductivity (W/m·K) |

223-400 (best for heat sinks) |

64-120 (moderate, suitable for fittings) |

109-229 (better than brass, marine use) |

|

Electrical Conductivity (% IACS) |

100 (gold standard for wiring) |

28-30 (usable for connectors) |

15-20 (lowest, still functional) |

|

Corrosion Resistance |

Excellent (patina protects, antibacterial) |

Good (manganese helps, but dezincifies in acids/salt) |

Superior (patina thrives in saltwater) |

|

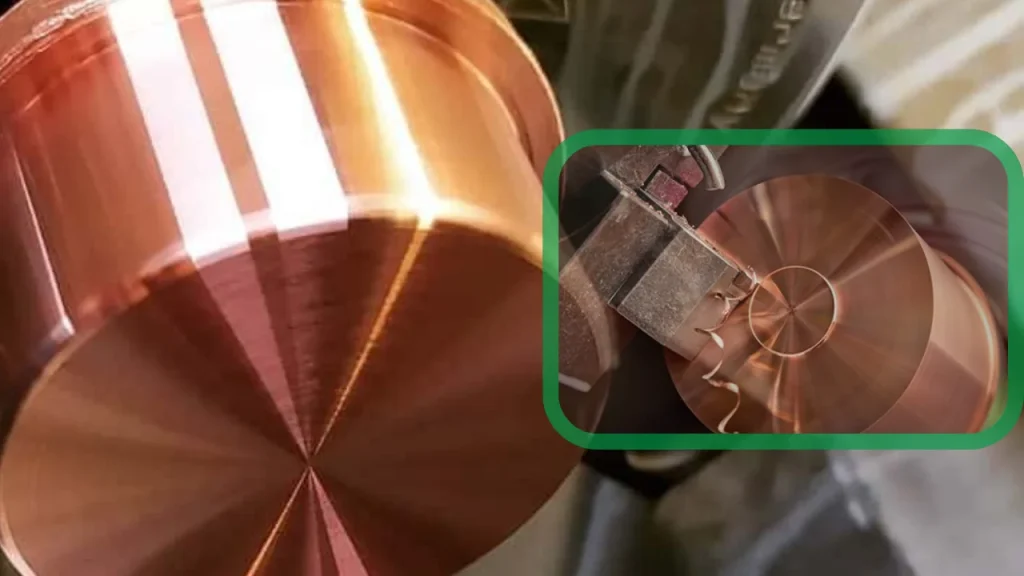

Machinability |

Fair-good (soft/gummy, needs sharp tools, coolant, 100-200 SFM) |

Excellent (leaded C360 chips clean, 600+ SFM) |

Moderate (harder, tool wear up, 200-400 SFM) |

|

Weldability |

Excellent (MIG/TIG, low distortion) |

Good (low-zinc best, leaded cracks) |

Fair-good (unleaded risks cracking, SMAW best) |

|

Fatigue/Wear Resistance |

Moderate (wears in high-friction) |

Moderate (cracks under cyclic stress) |

Excellent (low-friction bearings/gears) |

Machinist’s Take: Copper’s softness clogs tools—use carbide, low feeds, and coolant. Brass (C360) is a high-speed dream, minimizing cycle times. Bronze (C954) demands robust setups to avoid cracking but holds tight tolerances.

Pro Tip: For electrical CNC parts, copper’s 100% IACS is unmatched. For lightweight aerospace components, bronze’s lower density saves grams.

Key Differences in Brass, Bronze, and Coppe

While all rooted in copper, their alloying creates distinct profiles for CNC applications.

-

Strength & Durability: Bronze (up to 800 MPa) is the heavyweight for gears and bushings; brass (up to 635 MPa) handles moderate loads; copper (220 MPa) is flexible but deforms under stress.

-

Conductivity: Copper’s 100% IACS rules electronics; brass (28-30%) works for connectors; bronze (15-20%) lags but suffices for non-critical electrical.

-

Corrosion & Environment: Bronze’s patina dominates marine/acid settings; copper’s antibacterial and oxide layer suits medical/plumbing; brass struggles with dezincification in harsh acids or salt.

-

Aesthetics & Acoustics: Copper’s reddish hue turns green with age; brass shines gold for decor; bronze’s dull gold-brown fits rugged parts. Sound test: Copper’s low hum, brass’s bright ring, bronze’s sharp clang.

-

Cost & Availability: Brass (C360) is cheapest and widely available; copper’s purity drives up cost; bronze varies (aluminum bronze pricier).

-

CNC Behavior: Brass chips cleanly, reducing tool wear; copper’s gumminess slows production; bronze’s hardness increases tool costs but ensures stability.

Pro Tip: For prototypes, brass’s low cost and machinability speed iterations. For marine durability, bronze’s corrosion resistance is non-negotiable.

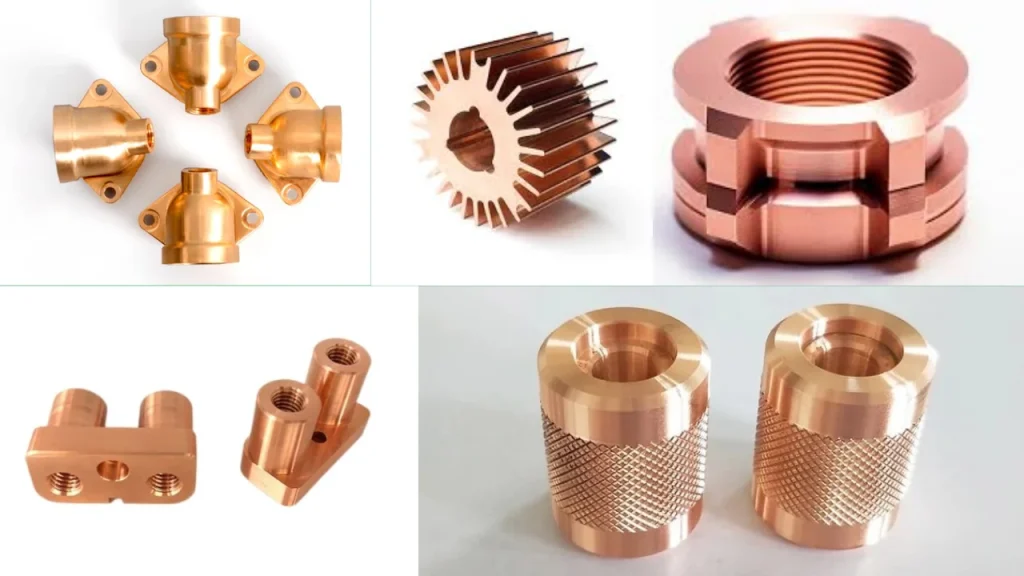

Brass, Bronze, and Copper: CNC Machining Applications Deep Dive

At CNC Parts XTJ, we’ve machined these metals across industries. Here’s where they excel, with CNC-specific insights.

-

Copper: Conductivity champion for electrical connectors, busbars, heat exchangers, HVAC coils, and antimicrobial medical components. CNC excels in milling fine features for circuit boards or turning plumbing fittings.

-

Example: C110 for telecom busbars—high-speed milling for precision slots.

-

CNC Notes: Use sharp carbide tools, low cutting speeds (100-200 SFM), and coolant to avoid material buildup.

-

-

Brass: Machinability star for fittings, valves, fasteners, locks, hinges, ammo casings, musical instruments, and decorative hardware. Its low friction suits small gears and knobs.

-

Example: C360 for plumbing valves—high-speed CNC milling (600+ SFM) for tight tolerances and smooth finishes.

-

CNC Notes: Leaded brass minimizes chip welding; use high feed rates for volume production.

-

-

Bronze: Durability leader for bearings, bushings, marine propellers, pump/valve components, gears, springs, oil/gas wear rings, and non-sparking tools. Its corrosion resistance thrives in harsh environments.

-

Example: C954 aluminum bronze for naval shaft sleeves—CNC turning for dimensional stability in saltwater.

-

CNC Notes: Slower speeds (200-400 SFM), robust carbide tools, and rigid setups prevent cracking.

-

Pro Tip: For high-wear parts, bronze’s low friction extends life. For aesthetic CNC parts, brass’s polishability adds value.

Pros and Cons: CNC Shop Perspective

Each metal has trade-offs for machining and end-use.

-

Copper:

-

Pros: Unrivaled electrical/thermal conductivity, highly ductile for complex shapes, antibacterial, recyclable, excellent weldability (MIG/TIG).

-

Cons: Softness causes deformation, gummy chips clog tools, higher cost, visible oxidation over time.

-

-

Brass:

-

Pros: Top-tier machinability (saves tools/time), cost-effective, attractive gold finish, low friction for moving parts, good mild corrosion resistance.

-

Cons: Moderate strength, prone to cracking under stress, dezincifies in acids/salt, lower conductivity than copper.

-

-

Bronze:

-

Pros: Superior strength/wear resistance, excellent corrosion resistance (marine/acid), dimensional stability, low friction for bearings.

-

Cons: Harder to machine (increases tool wear), pricier than brass, some alloys brittle, lower conductivity.

-

Pro Tip: For tight budgets, brass prototypes cut costs. For long-term durability in harsh settings, invest in bronze.

XTJ Precision Mfg: Crafting Custom Metal Parts and Prototypes for You

At XTJ Precision Mfg, we specialize in delivering high-quality custom metal parts and prototypes tailored to your needs. Whether you’re unsure about choosing the right material—such as brass, bronze, or copper—or need guidance on your project, our expert team is here to help. With decades of experience in precision machining, we provide professional advice to ensure your components outperform the competition.

We offer comprehensive manufacturing and prototyping services, including CNC machining, sheet metal fabrication, die casting, and forging. Simply upload your design file, and within 48 hours, you’ll receive a detailed quote and Design for Manufacturability (DfM) analysis. Our transparent processes, backed by ISO 9001:2015 certification, guarantee precision with tolerances as tight as ±0.003mm and cost savings of up to 40%. Contact us today to start your project with confidence!