If you’re involved in robot parts manufacturing, you already know it’s a high-stakes game. Precision, speed, and durability aren’t just nice-to-haves—they’re non-negotiable. Whether you’re sourcing custom components or refining production with cutting-edge CNC machining, the pressure to deliver flawless parts on tight timelines is intense.

In this post, we’ll cut through the noise and give you actionable insights on the most efficient manufacturing methods, material choices, and scaling strategies. If boosting quality while reducing lead times sounds like your next move, keep reading—because mastering robot parts manufacturing just got easier.

Essential Components in Robot Parts Manufacturing

When you think about building a robot, the parts inside might seem complex, but they all fall into clear categories. In robot parts manufacturing, understanding these essential components helps make sure everything works seamlessly.

Core Structural Elements

At the heart of every robot are the core structural elements. These parts form the frame and skeleton, giving the robot its shape and strength. Think of robotic arms, chassis, joints, and support brackets. They need to be durable, lightweight, and precisely fabricated, often using CNC machining robotics for high accuracy.

Functional Subsystems

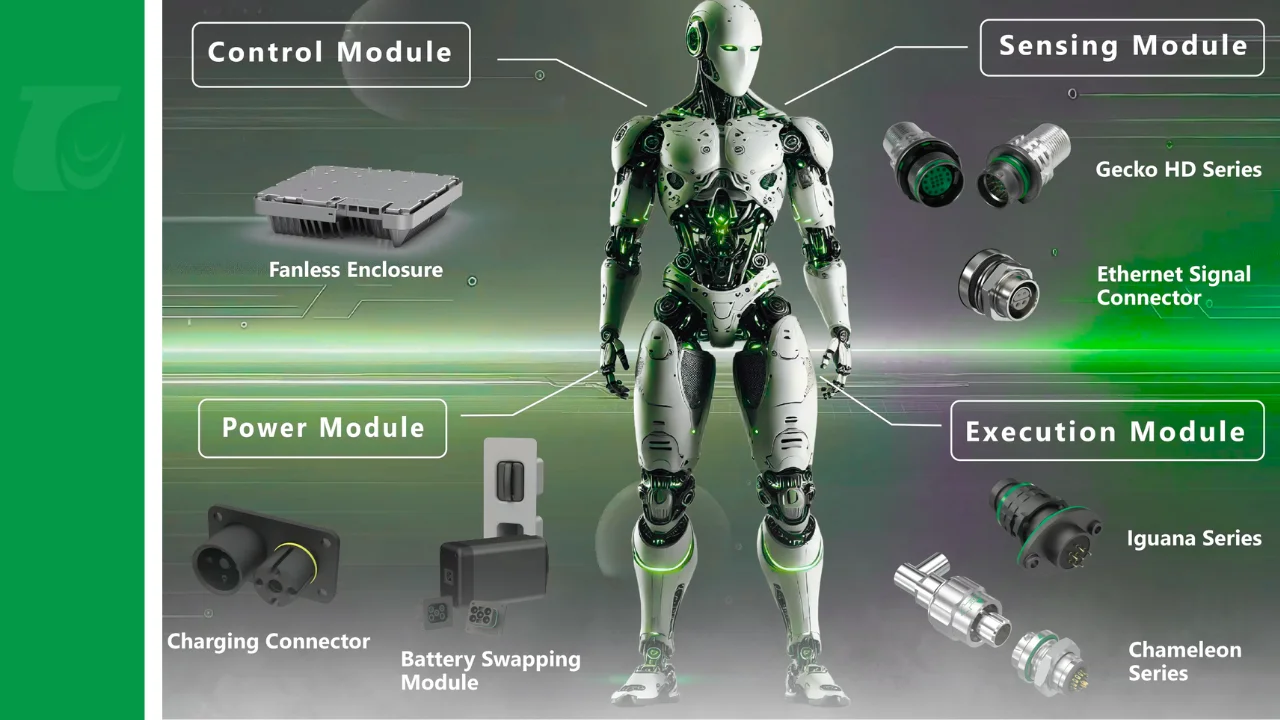

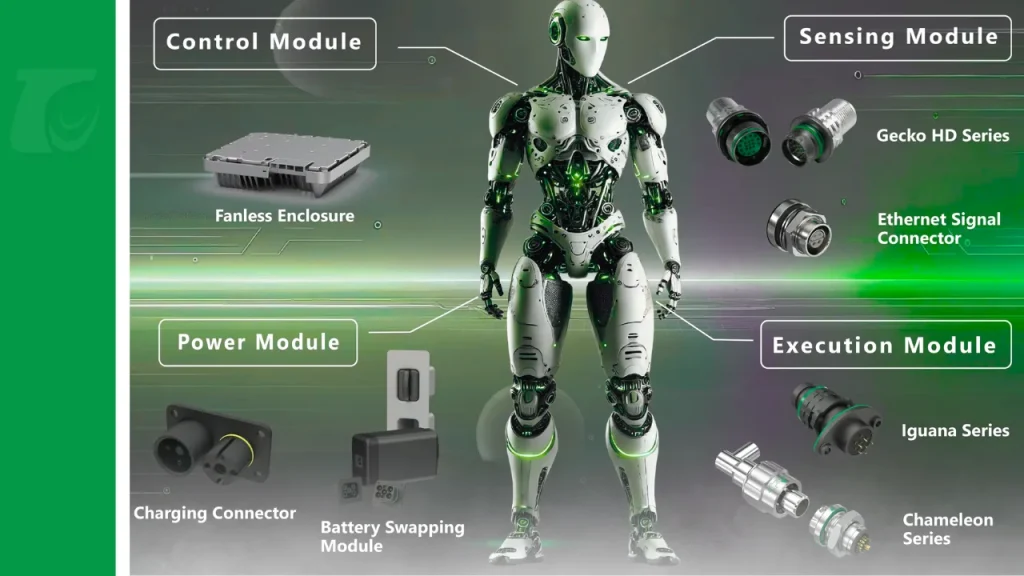

Functional subsystems handle the robot’s movement, sensing, and interaction. This includes:

- Industrial robot actuators that power motion

- Precision grippers production to manipulate objects

- End effectors fabrication that carries out specific tasks

- Sensor integration manufacturing for receiving environmental feedback

Each subsystem works together to bring the robot’s functions to life.

Integration Considerations

Bringing these components together is where it gets really interesting. Integration means more than just assembling parts:

- Ensuring mechanical parts fit and move as intended

- Aligning sensors and actuators for synchronized operations

- Testing the robot’s system as a whole to maintain reliability

Successful integration leads to smooth performance and reduces downtime. Knowing this can help you evaluate and trust suppliers who prioritize not just parts but how they work as a system.

Understanding these essential pieces sets the stage for exploring how advanced manufacturing processes bring robot parts from blueprint to reality. Ready to dive into how precision and innovation drive this industry? Let’s go.

Advanced Manufacturing Processes for Robot Parts

When it comes to making robot parts, the manufacturing process plays a big role in the final product’s quality and performance. Here’s a look at the key methods used in robot parts manufacturing.

CNC Machining for Precision

CNC machining robotics is a go-to process for producing high-precision components like industrial robot actuators, precision grippers, and end effectors. This method uses computer-controlled tools to cut and shape metal or plastic parts with tight tolerances. It’s especially great for custom robotic components that demand consistency and durability. With CNC machining, you get reliable results for both prototypes and high-volume robot assembly runs. For more insights on CNC machining benefits, check out this guide on how to maximize stainless steel CNC machining benefits.

Additive Manufacturing

Additive manufacturing, or 3D printing, is rapidly gaining ground in robot parts fabrication. This method builds parts layer by layer, making it perfect for complex designs or robotics prototyping services where speed and flexibility are key. It’s ideal for producing lightweight cobot parts, sensor housing, or custom enclosures that traditional machining might struggle with. Compared to CNC, additive manufacturing allows quick design tweaks without costly tooling changes, which helps cut lead times.

Other Methods

Besides CNC and additive manufacturing, there are other useful processes like injection molding, wire cutting, and vacuum forming. Injection molding fits well when producing high volumes of plastic parts for the robotics industry. Wire cutting is useful for intricate metal cuts that need fine details, and vacuum forming helps with shaping lightweight covers or panels. These methods often complement CNC machining and additive manufacturing to create a well-rounded production strategy.

Together, these advanced manufacturing processes offer flexibility, accuracy, and efficiency, helping manufacturers meet the varied demands of robot parts production.

Overcoming Key Challenges in Robot Parts Manufacturing

Manufacturing robot parts comes with a set of tough challenges, but addressing them well can make all the difference.

Material Selection and Durability

Choosing the right materials is crucial. Robot parts need to be strong enough to handle repeated motion and stress without wearing out quickly. Industrial robot actuators and precision grippers, for example, often require durable metals or high-grade composites to maintain performance and longevity. Using materials that resist corrosion and fatigue ensures robots stay reliable over time.

Scalability and Cost Efficiency

Producing robot components at scale without breaking the bank is another major hurdle. Whether it’s for custom robotic components or high-volume robot assembly, balancing production speed and cost is key. Advanced CNC machining robotics and additive manufacturing robots help here—they speed up prototyping and final production, cutting expenses while keeping quality high. Finding suppliers who can scale efficiently without sacrificing quality is a must.

Quality Control and Compliance

Consistency matters when parts must fit and work flawlessly every time. Rigorous quality control processes ensure that all robot parts, from end effectors fabrication to sensor integration manufacturing, meet required standards. Compliance with industry regulations also protects companies from costly recalls or downtime. Investing in testing and inspection during manufacturing delivers reliable results that U.S. customers expect.

Rigorous quality control is non-negotiable:

- Inspection: Coordinate Measuring Machines (CMM) verify tolerances to ±0.01 mm, aligning with ISO 9001 standards.

- Non-Destructive Testing (NDT): Ultrasonic testing detects internal defects in metal parts, reducing failure rates by 25%.

- Regulatory Compliance: Adherence to ISO 10218 for robotic safety ensures market acceptance in the U.S.

By focusing on strong material choices, scalable production methods, and strict quality controls, manufacturers in the United States can overcome key challenges and deliver dependable robot parts. For detailed insights into quality standards, check out our guide on quality control in manufacturing.

Industry Applications Automotive and Electronics Logistics and Healthcare Emerging Trends

Robot parts manufacturing plays a key role in several industries across the U.S., especially in automotive and electronics. In automotive, precision grippers production and custom robotic components help automate assembly lines, improving speed and accuracy. Electronics manufacturing relies heavily on sensor integration manufacturing and end effectors fabrication to handle delicate components with care.

Logistics and healthcare sectors are also major users of robot parts. Robots for warehouse automation depend on industrial robot actuators and high-volume robot assembly to move goods efficiently. In healthcare, cobot parts suppliers provide collaborative robots that assist with surgeries, patient care, and lab automation.

Looking ahead, emerging trends like additive manufacturing robots and robotics prototyping services are shaking things up. These innovations make it easier to create complex parts quickly, supporting faster product development and customization to meet evolving U.S. market demands.

Sourcing and Partnering for Robot Parts

Evaluating Suppliers

Finding the right supplier for robot parts manufacturing is crucial. Look for partners with strong experience in producing custom robotic components, especially those skilled in CNC machining robotics and additive manufacturing robots. Check their track record for quality control, on-time delivery, and ability to handle industrial robot actuators and precision grippers production. Reliable communication and flexibility to meet your project’s specific needs are also essential.

Local vs Global Sourcing

Choosing between local and global suppliers depends on several factors:

- Local sourcing offers faster turnaround times, easier communication, and better quality control. It’s ideal for rapid prototyping, small batches, or when you need close collaboration on sensor integration manufacturing or end effectors fabrication.

- Global sourcing can provide cost benefits and access to high-volume robot assembly experts but may involve longer lead times and potential quality variations.

For U.S. businesses, balancing cost with responsiveness often points to local partners, especially when precision and compliance matter.

XTJ Precision Mfg Your Go-To Partner

At XTJ Precision Mfg, we specialize in manufacturing top-quality robot parts using advanced CNC machining robotics and additive manufacturing. We understand the needs of U.S. manufacturers for durable, precise, and scalable robot components—from cobot parts suppliers to full robotics prototyping services. With our commitment to quality and on-time delivery, XTJ Precision Mfg stands out as your trusted partner for all custom robotic components and industrial robot actuators requirements.