Why CNC Machining is Essential for Robotic Components

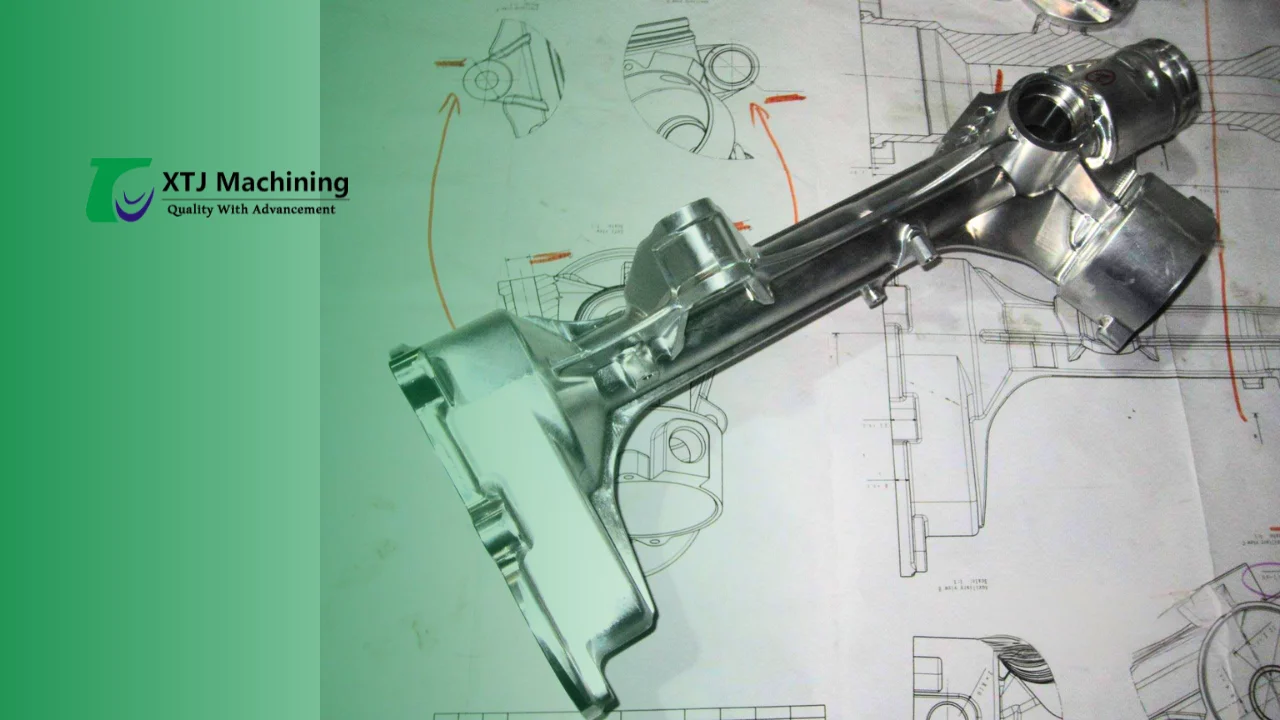

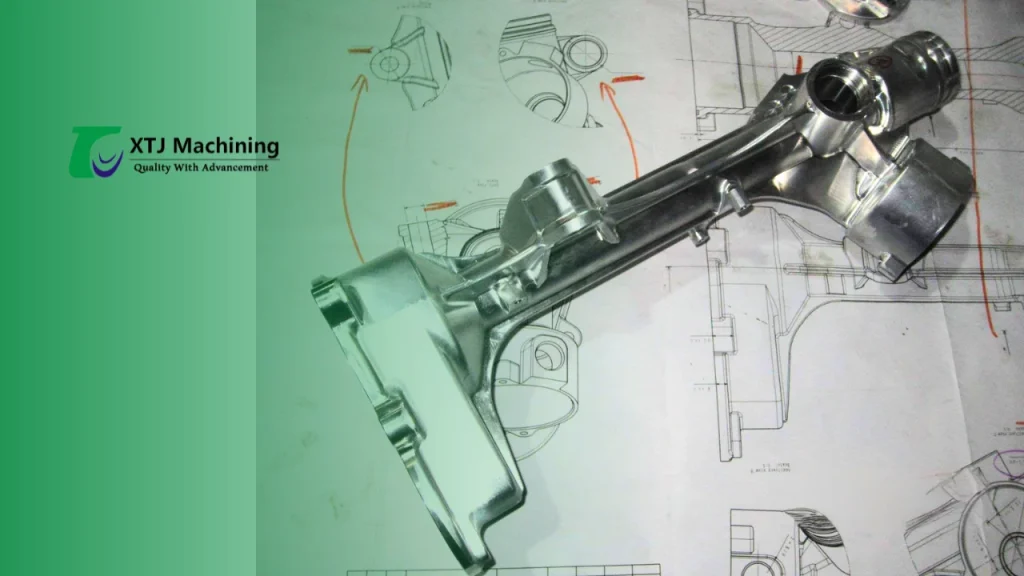

When it comes to building robotic components, CNC machining plays a crucial role. It offers high precision, repeatability, and versatility that are essential to meet the demanding standards of robotics. With CNC machining, manufacturers can create parts that fit perfectly, perform reliably, and endure continuous operation.

Robotics requires specialized components like servo mounts, reducers, and frames that not only demand exact dimensions but also need superior material strength. CNC machining allows the use of advanced alloys and plastics that provide durability and corrosion resistance, making sure parts hold up in tough environments.

One of the biggest challenges in producing robotic parts is overcoming traditional machining limits, especially when iterating designs rapidly for collaborative robots (cobots). CNC machining addresses this by enabling fast prototyping and adjustments without compromising accuracy.

At XTJ Precision Manufacturing, we operate over 100 CNC machines capable of achieving an impressive 0.002mm accuracy. This level of precision ensures your robotic components meet tight tolerances for optimal performance—whether you’re working on low-volume custom parts or scalable production runs.

Key Criteria for Choosing a CNC Machining Supplier for Robotics

When picking a supplier for custom CNC machined robotic components, precision is non-negotiable. Look for vendors that meet aerospace-grade standards and hold certifications like ITAR and AS9100. These ensure tight tolerances critical for robotics parts where every micron counts.

Materials expertise is another must. Your supplier should handle corrosion-resistant alloys and plastics that work well in demanding robot environments. Compatibility with specialty materials means your components won’t fail under stress or wear.

Lead times matter, especially when moving from rapid prototypes to full production. The best suppliers offer scalable options, including hybrid solutions that combine CNC machining with 3D printing. This flexibility speeds up development without sacrificing quality.

Quality certifications like ISO 13485 signal strong process control and traceability, which is vital for medical or sensitive robotics. Also, prioritize suppliers committed to sustainability, such as reducing waste and using eco-friendly manufacturing practices.

Cost is always a factor. Find a balance between custom run fees and return on investment. On-demand CNC machining services help reduce stock and lower upfront expenses, but make sure the pricing aligns with your project size and goals.

Finally, consider local habits. Domestic suppliers in the US or EU typically offer faster turnaround and easier communication. For projects targeting Asian markets, choosing regional partners can cut down supply chain delays and improve responsiveness.

Top Suppliers of Custom CNC Machined Robotic Components A Curated Comparison

When looking for custom CNC machined robotic components, it helps to know who stands out in the market. Here’s a quick rundown of top suppliers serving the U.S. and global markets, highlighting their strengths and areas to watch.

XTJ Precision Mfg

- Overview: A precision-focused manufacturer with over 100 CNC machines, including state-of-the-art Swiss lathes.

- Highlight:

Xometry

- What they offer: Instant quotes with a massive global network of CNC machine shops.

- Pros: Fast turnaround, wide material options, great for rapid prototyping and low-volume runs.

- Cons: Pricing can vary, and quality depends on the specific partner shop used. Best for generalized CNC machining needs rather than tight tolerance parts.

Fictiv

- Specialty: Gear hobbing and complex CNC machining, perfect for industrial robot gears and parts needing precise mechanical function.

- Lead times: Competitive but sometimes longer for larger or custom batches.

- Costs: Moderate to premium pricing depending on complexity and volume.

Aztalan Engineering

- Focus: Regional supplier with a strong reputation for tight tolerances and aerospace-grade CNC machining.

- Best for: Clients needing high precision custom robot parts, especially where strict certification requirements apply.

- Location: Midwest USA, supporting quick domestic shipping and communication.

Premium Parts

- Capabilities: Hybrid CNC and 3D printing service, flexible for producing complex end-of-arm tooling and specialized robotic components.

- Volume: Ideal for small to mid-scale production runs but may have volume caps for certain processes.

- Strengths: Material versatility, including advanced plastics and alloys for corrosion resistance.

Supplier Comparison Table

| Supplier Name | Key Advantages | Applicable Scenarios | Website/Contact | Source Citation |

|---|---|---|---|---|

| Xometry | AI-driven instant quotes, global network of 500+ factories, supports titanium/aluminum robot parts. | Small-batch prototypes and complex geometry robot arms. | xometry.com | https://cncpartsxtj.com/best-cnc-fabrication-companies-2025-features-pricing/ |

| Fictiv | End-to-end supply chain, specializes in CNC robot parts, DHL fast logistics. | High-precision collaborative robot components. | fictiv.com | |

| XTJ Precision Mfg | CNC + additive manufacturing hybrid, focuses on durable robot parts, ISO certified. | Custom sensor housings and joints. | cncpartsxtj.com | |

| Protolabs | 24-hour quotes, 5-axis CNC, ideal for rapid iteration. | Robot prototype development. | protolabs.com | https://hy-proto.com/top-machining-parts-manufacturers-compare |

| UPTIVE | Advanced manufacturing platform, multi-process integration (CNC + 3D printing). | US-based robot innovation projects. | uptivemfg.com | |

| WayKen | Precision surface finishing, efficient Asian production. | Large-batch robot chassis. | waykenrm.com | |

| eMachineShop | No minimum order, design validation tools. | Entry-level custom robot parts. | emachineshop.com | |

| DMG Mori | High-end 5-axis machines, global service. | Industrial robot precision components. | dmgmori.com |

Finding the right supplier comes down to your specific robotic project needs—whether that’s speed, precision, materials expertise, or scalability. For demanding U.S. customers, XTJ Precision Mfg offers a solid balance of quality, speed, and local support.

Case Studies Real World Success with XTJ Precision Mfg

At XTJ Precision Mfg, we’ve helped clients across multiple industries achieve real results with custom CNC machined robotic components.

Automotive Robotics

We designed and machined custom grippers that significantly cut down errors on assembly lines. By improving fit and precision, our parts boosted robot accuracy and reduced downtime.

Medical Cobots

For surgical applications, XTJ delivered lightweight titanium components with fine tolerances. These parts ensure reliability and precision in delicate medical cobots, meeting strict healthcare standards.

Industrial Automation

We produced scalable, high-volume reducers and frames that stand up to tough industrial conditions. XTJ’s expertise supports manufacturers needing consistent quality at scale.

Lessons Learned

- Metrology Fitment: Accurate measurement and inspection processes ensure parts fit perfectly in complex assemblies.

- Material Selection: Choosing corrosion-resistant alloys and plastics improves longevity and performance.

If you’re interested in custom robot parts crafted with precision, check out our robot parts alloy options that highlight material expertise for robotics.

How to Get Started Partnering with XTJ Precision Mfg for Your Robotics Project

Getting your custom CNC machined robotic components started with XTJ Precision Mfg is straightforward. Here’s the simple process to follow:

- Upload Your CAD Files: Submit your design files directly through their online platform to get the process rolling.

- Request a Quote: XTJ offers instant, accurate quotes so you know costs upfront without any surprises.

- Select Your Specifications: Choose material types, tolerances, and finishes tailored to your project needs.

- Prototype and Test: Rapid prototyping helps you validate designs quickly before committing to larger production runs.

- Scale Production: Easily shift from prototype to full scale thanks to XTJ’s flexible manufacturing capacity and 100+ CNC machines.

To help you design smarter and faster, XTJ also provides design audits and material selectors to optimize your parts for performance and cost.

If you’re ready, don’t miss their special offer: request a quote today and get 20% off your first robotics order.

For best results, consider local supply chains and optimize your sourcing by leveraging XTJ’s network of US-based suppliers as well as partners in China — balancing speed and cost depending on your project’s needs.

Explore how XTJ can make your robotic components precise, scalable, and reliable—start your project now.

For more info on custom robotic part materials, check out XTJ’s guide on customize aluminum alloy robots arm bone CNC machining.

Future Trends in CNC Machining for Robotics

CNC machining is evolving fast, especially for robotic components. One big move is the rise of AI-optimized toolpaths. This means cutting and milling are becoming smarter—not just faster, but also more precise by predicting the best routes for tools to reduce wear and cycle times. Hybrid robotic CNC cells are also gaining ground, combining robots and CNC machines for flexible, automated workflows that boost productivity without sacrificing quality.

Sustainability is becoming a major focus too. More suppliers, including XTJ Precision Mfg, are using recyclable materials and pushing zero-waste prototyping processes. This shift helps reduce environmental impact while meeting the high standards of the robotics industry.

Looking ahead, XTJ is investing in six-axis machining tech, opening doors for complex shapes and tighter tolerances vital for next-gen autonomous robots. This advanced capability supports everything from lightweight aerospace components to intricate medical robots.

With these trends, suppliers like XTJ Precision Mfg are positioned to support U.S. manufacturers needing innovative, eco-friendly, and highly precise CNC machined robotic parts.