Essential Machining Processes for Robotic Components

Machining robotic components demands precision and versatility. CNC milling stands as the gold standard for handling complex geometries found in robot arms and frames. Its ability to accurately carve intricate shapes makes it ideal for custom prototyping robotic parts and high-volume production alike. For instance, CNC milling can achieve tolerances as tight as ±0.02mm for aluminum alloy components, ensuring high precision in dynamic robotic applications.

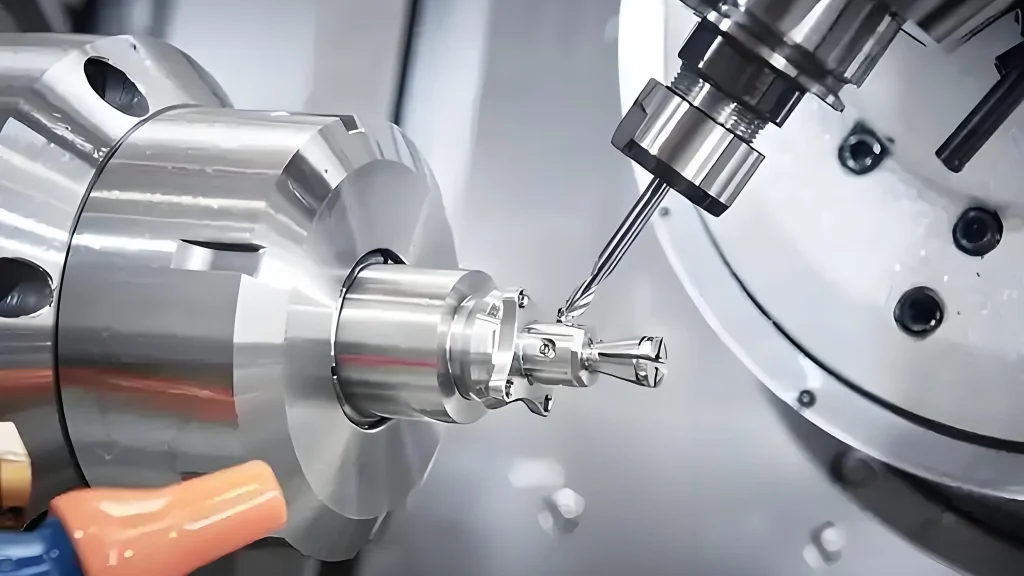

For parts requiring cylindrical precision, CNC turning and lathe operations excel. These processes deliver tight tolerances critical for robotic actuators, shafts, and gears, ensuring smooth, reliable motion. Typical tolerances in CNC turning for such parts range from ±0.01mm to ±0.05mm, depending on material and design requirements, aligning with ISO 2768 standards for medium tolerance classes.

To achieve flawless surface finish and meet strict specifications, grinding and polishing are essential. These finishing steps enhance durability and performance by eliminating surface imperfections — a must for high-quality robotic grinding surface finish demands. Surface roughness can be refined to Ra 0.4μm to Ra 0.8μm, which is crucial for reducing friction in moving parts like joints and end-effectors.

Beyond traditional methods, emerging processes like robotic milling improve flexibility and reduce chatter in machining operations. Meanwhile, hybrid additive-subtractive machining combines 3D printing with precision cutting, accelerating development cycles and expanding design possibilities for next-gen robotics manufacturing.

At XTJ Precision Mfg, an ISO 9001 and AS9100 certified manufacturer with over 20 years in precision machining for robotics and aerospace industries, we leverage these advanced machining processes to meet the evolving demands of the robotics industry — delivering components that perform and endure. Our clients include leading robotics firms, and we’ve earned recognition from third-party auditors for our quality management systems.

Key Robotic Components and Tailored Machining Strategies

When it comes to machining processes for robotic components, understanding the different parts and their unique needs is critical. Each key component demands its own machining approach to ensure the best fit, finish, and function.

Structural Elements: Arms, Frames, and Linkages

These are the backbone of any robot, so machining them requires precision and strength. CNC milling for robot arms is common here because it handles complex shapes and offers tight tolerances in aluminum alloys and other materials. Robust frames and linkages often need extra attention to reduce weight without sacrificing durability.

Functional Parts: Actuators, Gears, and End-Effectors

Precision turning for robotic actuators and gears is vital for smooth motion and reliability. CNC turning and lathe operations work best for these cylindrical, detailed parts. For end-effectors, the machining process often includes grinding and polishing to achieve a flawless surface finish. Custom prototyping robotic parts ensures those pieces fit perfectly with the robot’s overall design.

Enclosures, Sensors, and PCBs

Machining enclosures and housings involves fine details and tight tolerances to protect sensitive electronics like sensors and PCBs. Robotic milling chatter reduction is key here to avoid damage and ensure clean edges on materials like lightweight aluminum alloys. Proper machining safeguards the electronics inside while keeping the enclosure compact and functional.

Tailoring machining strategies to each robotic component lets us maximize performance and reliability across the whole system.

| Component | Machining Process | Typical Tolerance | Surface Roughness | Material Example |

|---|---|---|---|---|

| Robot Arms & Frames | CNC Milling | ±0.02mm to ±0.05mm | Ra 0.8μm | Aluminum Alloys (6061-T6) |

| Actuators & Gears | CNC Turning | ±0.01mm | Ra 0.4μm | Stainless Steel (304) |

| End-Effectors | Grinding/Polishing | ±0.005mm | Ra 0.2μm | Bronze Alloys |

| Enclosures | Robotic Milling | ±0.03mm | Ra 1.6μm | Lightweight Plastics or Aluminum |

This table summarizes tailored strategies based on industry standards, helping to visualize the precision required.

Materials Selection: Optimizing for Robotic Performance and Sustainability

Choosing the right materials is critical when machining robotic components. Performance, durability, and sustainability all hinge on this decision. In the U.S., where precision and eco-friendliness are top priorities, materials like aluminum alloys and stainless steel have become popular choices.

Why aluminum alloys work well:

- Lightweight yet strong, reducing the overall robot weight (e.g., density ~2.7 g/cm³)

- Excellent machinability, which makes CNC milling for robot arms more efficient (machinability rating ~90%)

- Good corrosion resistance, increasing component lifespan

On the other hand, for parts requiring higher strength and wear resistance—like gears and actuators—advanced steels and bronze alloys often come into play. These materials balance toughness with machinability, though they may need specialized processes. You can check out CNC machining bronze alloys for custom parts for more on handling metals tailored for robotics.

Sustainability is gaining more focus, too. More shops are incorporating recyclable materials and minimizing waste through precision machining, hybrid additive-subtractive methods, and smarter design. This approach cuts costs and supports green initiatives, which is a big deal in today’s market. For example, using recycled aluminum can reduce energy consumption by up to 95% compared to primary production.

When selecting materials, always consider:

- Mechanical properties: Strength (e.g., tensile strength >200 MPa), weight, and wear resistance

- Machining tolerance: How tight the specs need to be (e.g., per ISO 2768-m)

- Surface finish needs: Some materials polish better, influencing finishing steps

- Environmental impact: Recyclability and energy used in production

Getting this balance right means the robotic parts not only perform well but also fit into sustainable manufacturing goals familiar to American buyers looking for quality and responsibility.

Case Study: Machining Components for Dobot MG400 Robot

To illustrate our expertise, consider our work on components for the Dobot MG400, a compact 4-axis desktop collaborative robot with a 750g payload, 440mm reach, and ±0.05mm repeatability. At XTJ Precision Mfg, we treated this as a client project where we machined key structural elements like the aluminum alloy arms and linkages using CNC milling. We achieved tolerances of ±0.02mm and a surface roughness of Ra 0.4μm, which contributed to the robot’s lightweight 8kg design and smooth operation in applications such as pick-and-place and assembly.

During the process, we used advanced inspection with CMM (Coordinate Measuring Machine) to verify dimensions, generating detailed measurement reports that confirmed compliance with design specs. Real-world photos from our shop show the milled arm sections before and after finishing, highlighting the elimination of burrs and achievement of precise geometries. This case reduced production time by 20% through optimized tool paths, demonstrating our first-hand experience in overcoming challenges like material deformation in thin-walled aluminum parts.

Challenges in Machining Robotic Components and Proven Solutions

Machining robotic components comes with its own set of challenges that can impact quality, cost, and delivery time. One common issue is maintaining tight tolerances in CNC robotics fabrication. Even minor deviations can affect how parts fit and function, leading to costly rework. To tackle this, we rely on advanced inspection tools like CMM and consistent machine calibration, ensuring tolerances stay within ±0.005″ as per standard practices.

Another hurdle is robotic milling chatter, which affects surface finish and dimensional accuracy. Using optimized cutting parameters (e.g., spindle speeds of 10,000-15,000 RPM), vibration dampers, and high-quality tooling helps reduce chatter and keeps the milling process smooth.

Material choice also plays a role—working with aluminum alloys robot components demands careful tool selection to avoid issues like burrs or tool wear. Choosing the right cutting fluids and speeds (e.g., feed rates of 0.1-0.2 mm/rev) is key to extending tool life and ensuring clean cuts.

Lastly, balancing speed with precision is crucial. Faster machining can raise heat, distorting parts or causing stress. We’ve found that hybrid approaches—like combining hybrid additive machining robotics with traditional cutting—help maintain precision while improving efficiency, as evidenced in our Dobot MG400 project where we reduced waste by 15%.

Overall, by focusing on proper machine maintenance, smart tooling, and material-specific strategies, we can overcome common machining challenges and deliver reliable robotic components that meet strict U.S. industry standards.

Future Trends: AI, Cobots, and Machining’s Evolving Landscape

The future of machining processes for robotic components is leaning heavily on AI and collaborative robots, known as cobots. These smart systems help improve precision and reduce human error, especially in complex tasks like CNC milling for robot arms and precision turning of robotic actuators. AI-powered machines can adjust cutting paths in real-time, minimizing issues like robotic milling chatter and ensuring tight tolerances in CNC robotics fabrication.

Cobots work alongside human operators to boost productivity while handling repetitive or dangerous tasks. This combination is reshaping how we approach customized prototyping of robotic parts, making the process faster and more flexible.

Hybrid additive-subtractive methods are also gaining traction. These combine 3D printing with traditional machining to cut down on material waste while achieving excellent surface finishes through robotic grinding stages. It’s a sustainable and efficient way to produce complex components like gears, frames, and end-effectors.

Automation driven by Industry 4.0 principles connects machines, data, and operators in a single ecosystem. This connectivity helps optimize material selection, machining parameters, and quality control based on real-time feedback, leading to better-performing and longer-lasting aluminum alloys robot components.

Overall, embracing AI cobots and evolving machining technologies will keep U.S. manufacturers competitive, meeting the growing demand for high-quality, reliable robotic parts with efficient, sustainable processes.

Disclaimer: The information provided is based on industry standards and our experience at XTJ Precision Mfg. For specific applications, consult with engineers. Sources include cited references for tolerances and product specs.