What is Swiss Machining? A Deep Dive into the Process

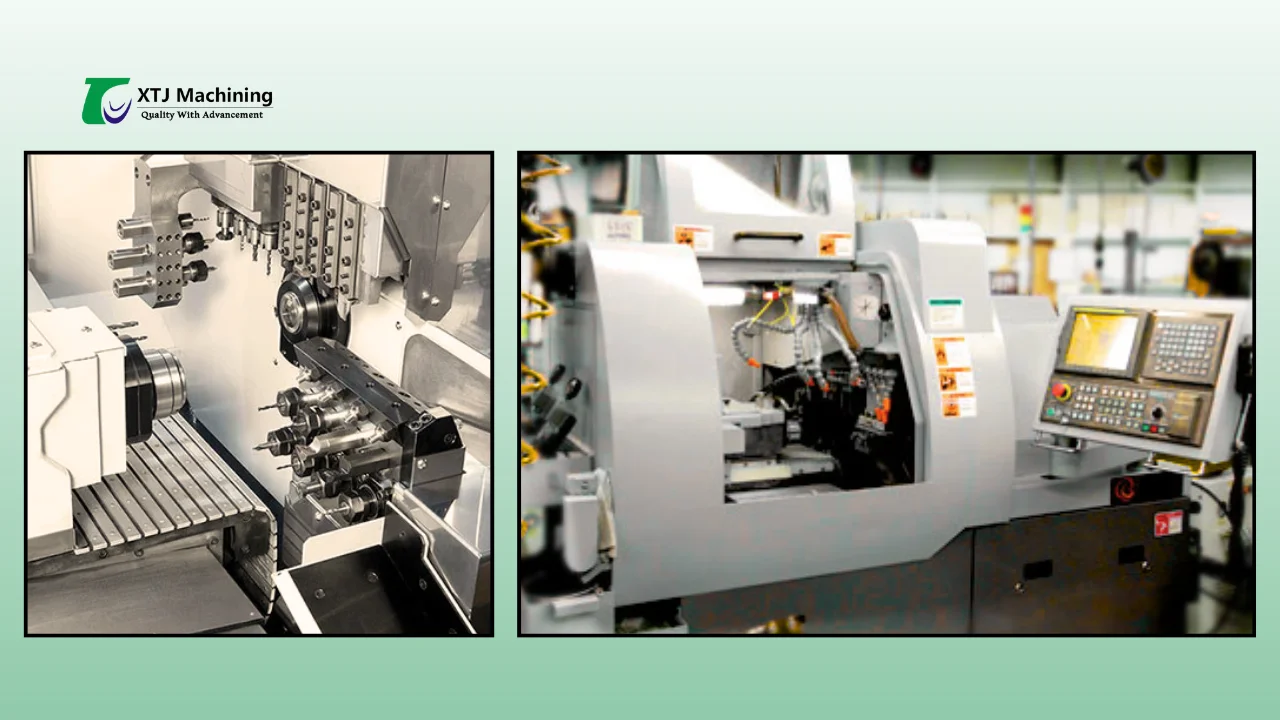

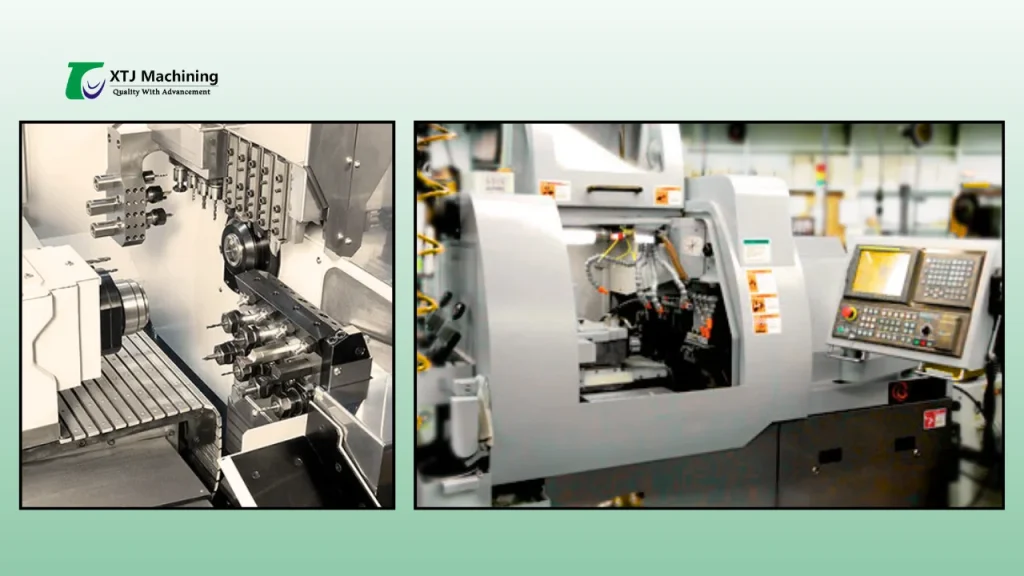

Swiss machining, also known as Swiss turning, is a precision machining process designed for producing small, complex parts with tight tolerances. Unlike conventional turning, Swiss machining uses a sliding headstock that moves the workpiece axially, guided by a fixed guide bushing close to the cutting tools. This setup allows the workpiece to be supported near the cutting area, minimizing deflection and enhancing accuracy.

Core Mechanics and How It Works

- Sliding Headstock: Moves the bar stock longitudinally through a fixed guide bushing.

- Guide Bushing: Holds and supports the part close to the cutting area, reducing vibrations.

- Multiple Tools: Positioned on a turret to perform simultaneous operations like turning, milling, drilling, and tapping.

- High-Speed Spindles: Allow machining of complex shapes from sliding the bar while multiple tools engage simultaneously.

Key Specifications and Capabilities

| Specification | Swiss Machining Detail |

|---|---|

| Maximum part length | Typically up to 12 inches (300 mm) |

| Part diameter range | 0.008″ to 1″ (0.2 mm to 25 mm) |

| Tolerances | ±0.0001″ (2.5 microns) |

| Production volume | Ideal for high-volume production |

| Tooling complexity | Supports multi-tool simultaneous use |

| Materials | Metals like stainless steel, titanium, brass, and plastics |

Pros and Cons of Swiss Machining

Pros:

- Extremely tight tolerances and superior surface finishes

- Excellent for long, slender parts due to guide bushing support

- High-volume production with consistent quality

- Ability to perform complex multi-process operations in one setup

Cons:

- Limited to small diameter parts

- Higher initial machine cost and tooling investment

- Setup can be time-intensive for low volume or prototypes

Swiss machining shines in precision manufacturing, especially for medical devices, aerospace components, and electronics, where accuracy and miniaturization are critical. Its unique mechanics enable unmatched control over small, complex parts that are difficult to machine with traditional CNC turning.

What is Multi-Axis Milling? Mastering Complex Geometries

Multi-axis milling is a CNC machining process that uses multiple rotational axes to cut and shape materials into complex parts. Unlike traditional 3-axis milling, multi-axis CNC machines typically operate with 4, 5, or even more axes, allowing the cutting tool to move around the part from different angles. This capability is essential for creating intricate designs and precise features that simple milling can’t handle.

Core Mechanics and Axis Breakdown

- 3-Axis Milling: Moves the tool along X, Y, and Z axes (left-right, forward-back, up-down).

- 4-Axis Milling: Adds rotation around one axis (usually the X or Y axis), letting the tool reach more facets without repositioning the workpiece.

- 5-Axis Milling: Adds two rotational axes, giving full flexibility to machine complex contours, angled holes, and undercuts in one setup.

More axes mean fewer setups, faster production, and higher precision on complex geometries.

Key Specifications and Capabilities

| Feature | Description |

|---|---|

| Axis Range | Typically 4 or 5 axes (some go beyond) |

| Material Types | Metals, plastics, composites |

| Tolerances | +/- 0.001 inch or better |

| Max Part Size | Varies by machine; often flexible |

| Surface Finish | High-quality smooth finishes |

| Programming Complexity | Requires CAD/CAM software |

Pros and Cons

Pros:

- Can machine highly complex, curved, and irregular shapes

- Reduces multiple setups into one, cutting lead times

- Improves surface finish and accuracy on tight tolerances

- Ideal for aerospace parts, molds, and intricate components

Cons:

- Requires advanced programming and skilled operators

- Higher initial cost compared to simpler mills

- Maintenance can be more demanding due to moving axes

Multi-axis CNC milling is a game-changer when you need detailed parts with complex geometries, making it a popular choice for precision machining in aerospace, medical, and automotive industries.

Head-to-Head Comparison: Swiss Machining vs. Multi-Axis Milling

When deciding between Swiss machining and multi-axis milling, understanding their key differences can help you target the right process for your project. Here’s a quick breakdown and an easy-to-read table to compare their specs and ideal uses.

Ultimate Comparison Table

| Feature | Swiss Machining | Multi-Axis Milling |

|---|---|---|

| Main Process | Sliding headstock, guide bushing for precise turning | CNC milling with 3-5+ axis tool movement |

| Best For | Small, tight-tolerance parts with complex turning features | Complex 3D shapes and contours, multi-surface milling |

| Typical Part Size | Small to very small (micro parts common) | Small to large parts, depending on machine size |

| Precision | Extremely high, tight tolerances (±0.0001″) | High precision, especially in surface finish |

| Production Volume | High-volume, consistent production runs | Low to medium volume, prototyping, complex parts |

| Common Applications | Medical devices, aerospace components, watch parts | Aerospace panels, automotive molds, prototypes |

| Setup & Programming | Moderate complexity, focused on turning operations | Complex programming for multiple axes and tool paths |

| Tool Access | Limited to turning and some milling on small diameters | Full access to multi-directional milling and drilling |

| Materials | Metals like stainless steel, brass, titanium | Wide range including tough metals and composites |

Visual Breakdown

- Swiss machining excels with tiny, cylindrical parts where precision and volume matter. The sliding headstock and guide bushing hold the part firm, making it perfect for turning complex shapes like watch gears or implant components.

- Multi-axis milling is your go-to for cutting complex 3D surfaces, with machines moving around multiple axes to carve out sophisticated shapes, ideal for aerospace parts or detailed molds.

When to Choose Each

- Pick Swiss machining if:

- You need very tight tolerances on small diameters.

- The job involves long production runs with minimal variation.

- Parts are predominantly round or tubular with detailed turning needs.

- Pick Multi-Axis Milling if:

- The part has complex 3D geometry requiring detailed surface work.

- Production volume is lower or you need rapid prototyping.

- You want flexibility for different materials and shapes.

Understanding these key differences helps you select the right precision machining method for your U.S.-based manufacturing needs, balancing cost, complexity, and production scale.

Real-World Applications and Case Studies

Swiss Machining in Action

Swiss machining shines when it comes to producing small, precision parts with tight tolerances. This method is widely used in industries like aerospace, medical devices, and electronics, where components such as tiny screws, pins, and intricate connectors must fit perfectly. The guide bushing and sliding headstock setup allow for continuous support of the workpiece, making it ideal for high-volume production of slender parts that require exact dimensions and minimal play. For example, aerospace components like fuel system fittings often rely on Swiss turning for their consistent precision and smooth finishes.

Multi-Axis Milling in Action

Multi-axis milling is your go-to for creating complex geometries and intricate shapes that would be impossible with simpler 3- or 4-axis machines. It’s extensively used in tooling, automotive, and aerospace industries for parts like turbine blades, engine components, and molds. The ability to rotate the part along multiple axes means fewer setups and faster production times, which is crucial for complex shapes that demand precise contours and tight tolerances. Multi-axis CNC milling also excels in machining parts with undercuts and deep cavities, making it versatile for a range of metal and plastic materials.

Hybrid Approaches

Many industries leverage hybrid machining strategies, blending Swiss machining with multi-axis milling to maximize efficiency and accuracy. For example, a manufacturer might use Swiss turning to produce the base form of a small precision part and then switch to multi-axis milling to add complex features like pockets or contours. This blend is common in aerospace and medical sectors, where parts demand both tight tolerances and complex shapes. Hybrid approaches help reduce lead times, lower costs, and improve overall part quality by using the strengths of both processes.

For more insight on machining benefits and techniques, check out our guide on how to maximize stainless steel CNC machining benefits.

Cost Analysis: Budgeting for Swiss vs. Multi-Axis Projects

When planning machining projects, understanding the cost differences between Swiss machining and multi-axis milling is key to making smart choices for your budget.

Total Cost Breakdown

- Swiss Machining

- Ideal for high-volume production of small, intricate parts with tight tolerances.

- Costs are often higher upfront due to specialized machines like sliding headstocks and guide bushing setups.

- Lower cost per part as volume increases, thanks to efficient running times.

- Setup time is minimal but tooling costs can add up, especially for complex parts.

- Multi-Axis Milling

- More flexible for complex geometries and larger parts.

- Machines handle a variety of jobs but may need longer cycle times, increasing labor costs.

- Setup might take longer, especially for multi-operation parts, but tooling costs tend to be moderate.

- Great for lower to medium volume runs where versatility matters.

Volume Discounts and Cost Estimator Tool

- Swiss machining often benefits from significant volume discounts; the more you produce, the better the rate per piece.

- Multi-axis milling pricing can be steadier regardless of volume but may offer project-based discounts depending on complexity.

- Using an online cost estimator tool can help you quickly compare these variables based on your part size, complexity, and order quantity.

What to Watch for in Your Budget

- Tooling and setup charges

- Machine run times and cycle efficiency

- Post-processing or secondary operations

- Quality assurance and inspection costs

By breaking down these costs early, you’ll get a clearer picture of which process fits your budget and project demands better.

Common Challenges and How XTJ Solves Them

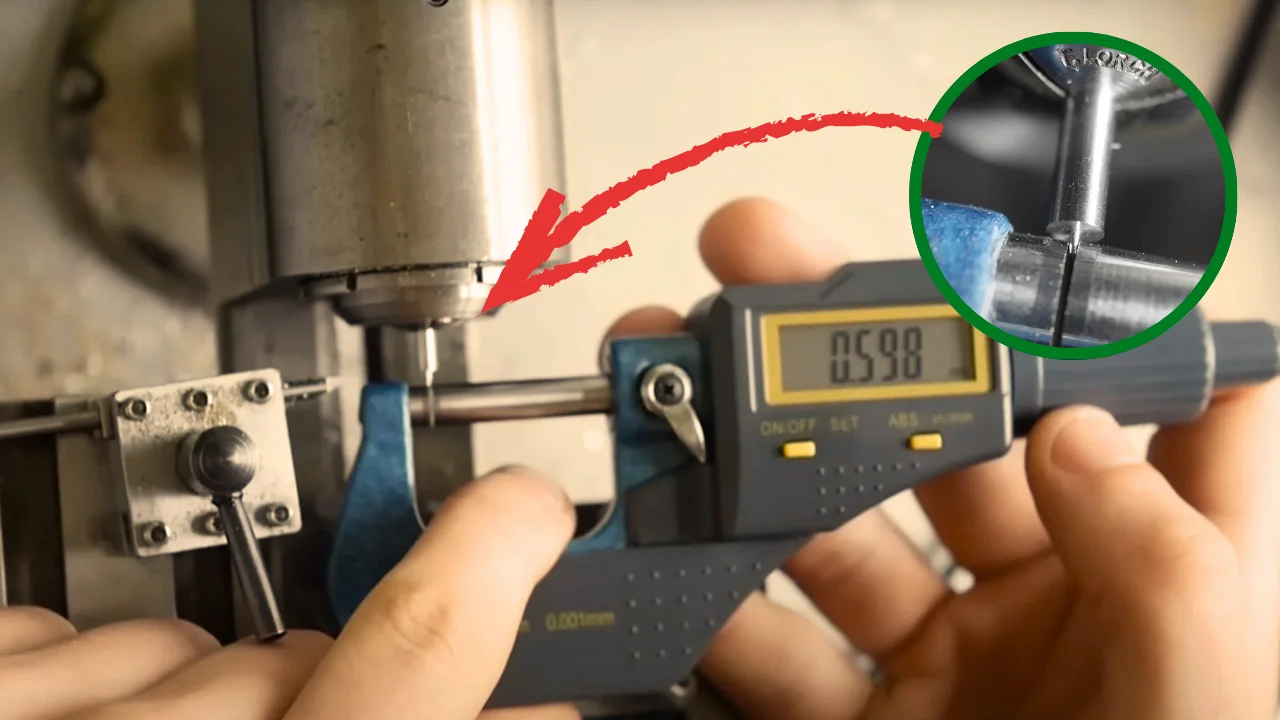

When it comes to Swiss machining and multi-axis milling, a few common challenges pop up: vibration, tooling issues, and maintaining tight quality control. These challenges can affect precision and efficiency—but that’s where XTJ Precision Mfg shines.

Tackling Vibration

Vibration is a big one in high-speed CNC machining. It can lead to surface imperfections and shortened tool life. XTJ uses advanced machine calibration and vibration-dampening technology, ensuring smoother cuts and consistent results. This means your parts hit exact tolerances every time.

Tooling Troubles Made Simple

Tool wear and breakage slow down production and add cost. XTJ’s tooling experts carefully select cutting tools matched to your material and design needs. Plus, they monitor tool performance in real time to swap out or recondition tools before issues occur. This proactive approach keeps your project moving without surprises.

Quality Control That Doesn’t Miss a Beat

Precision machining demands tight quality control. XTJ uses in-line inspection systems and rigorous final checks, identifying any flaws early. Whether it’s Swiss turning or multi-axis CNC milling, they guarantee parts meet your specs with zero compromise.

XTJ Expertise and Assurance

XTJ’s experienced team combines years of machining know-how with state-of-the-art equipment. This ensures your parts are not just made, but made right. The company’s commitment to continuous improvement and customer communication means challenges are solved quickly and effectively.

By managing vibration, optimizing tooling, and enforcing strict quality control, XTJ Precision Mfg delivers precision parts that live up to the toughest demands in aerospace, medical, and high-volume manufacturing industries.

FAQs: Swiss Machining vs. Multi-Axis Milling

Q: What’s the main difference between Swiss machining and multi-axis milling?

Swiss machining uses a sliding headstock and a guide bushing to support long, thin parts during high-volume turning, perfect for tight tolerances. Multi-axis milling, on the other hand, moves the tool across multiple axes to shape complex geometries from a solid block, handling more diverse shapes but often at a slower pace for small parts.

Q: Which method is better for small, precision parts?

Swiss machining typically wins for small, precision cylindrical parts like aerospace components because of its tight tolerance control and efficient high-volume production.

Q: Can multi-axis milling handle complex shapes better than Swiss machining?

Yes. Multi-axis CNC milling excels with complex shapes and multiple angles since it can move on 3, 4, or 5 axes, making it ideal for parts requiring detailed, multi-surface machining.

Q: Is Swiss machining more cost-effective for large runs?

Generally, yes. Swiss machining is highly efficient for large production runs of small, precise parts, reducing labor and cycle time. Multi-axis milling can be more costly for volume but offers flexibility for prototype or varied parts.

Q: What industries use these technologies most?

Swiss turning is popular in medical, aerospace, and electronics for small, precise parts. Multi-axis milling is widely used in automotive, aerospace, and industrial machinery where complex shapes and strong materials are common.

Q: Are there hybrid solutions using both techniques?

Absolutely. Some manufacturers combine Swiss machining for initial turning with multi-axis milling for finishing, optimizing both precision and complexity.

Q: How does tooling differ between the two?

Swiss machining tooling focuses on high-speed, precise cutting of bars with support from the guide bushing. Multi-axis milling uses versatile cutters that move in multiple directions to carve complex profiles.

Q: What about lead times?

Swiss machining often delivers faster turnaround for batch orders of small parts due to its streamlined process. Multi-axis milling can take longer depending on part complexity and setup but shines in one-off or low-volume jobs.