Electro Discharge Machining (EDM) stands out as a powerful non-traditional process for shaping hard metals and complex geometries.Also known as electrical discharge machining or spark machining, EDM uses rapid electrical discharges to remove material from a workpiece. This method is particularly valuable in industries like aerospace, automotive, and medical devices, where conventional CNC machining might struggle with ultra-hard materials or intricate designs.In this guide, we’ll explore EDM in detail, from its principles to applications, and how it fits into modern manufacturing workflows.

what is electro discharge machining

Electro Discharge Machining (EDM), also known as electrical discharge machining or spark machining, is a non-traditional manufacturing process that removes material from a workpiece using a series of rapid electrical discharges (sparks) between an electrode and the workpiece, both submerged in a dielectric fluid. This thermal energy from the sparks melts and vaporizes tiny portions of the material, which is then flushed away by the fluid, allowing for precise shaping of hard metals or complex geometries that are difficult to achieve with conventional machining.

How Does Electro Discharge Machining Work?

Basic Principle

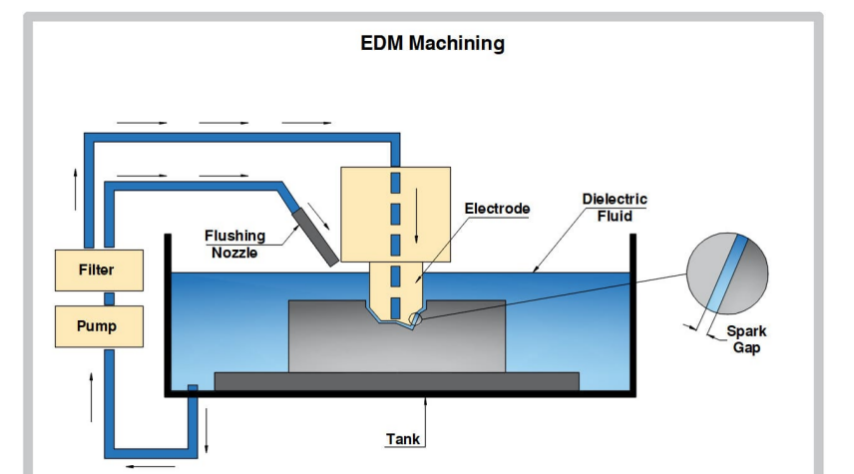

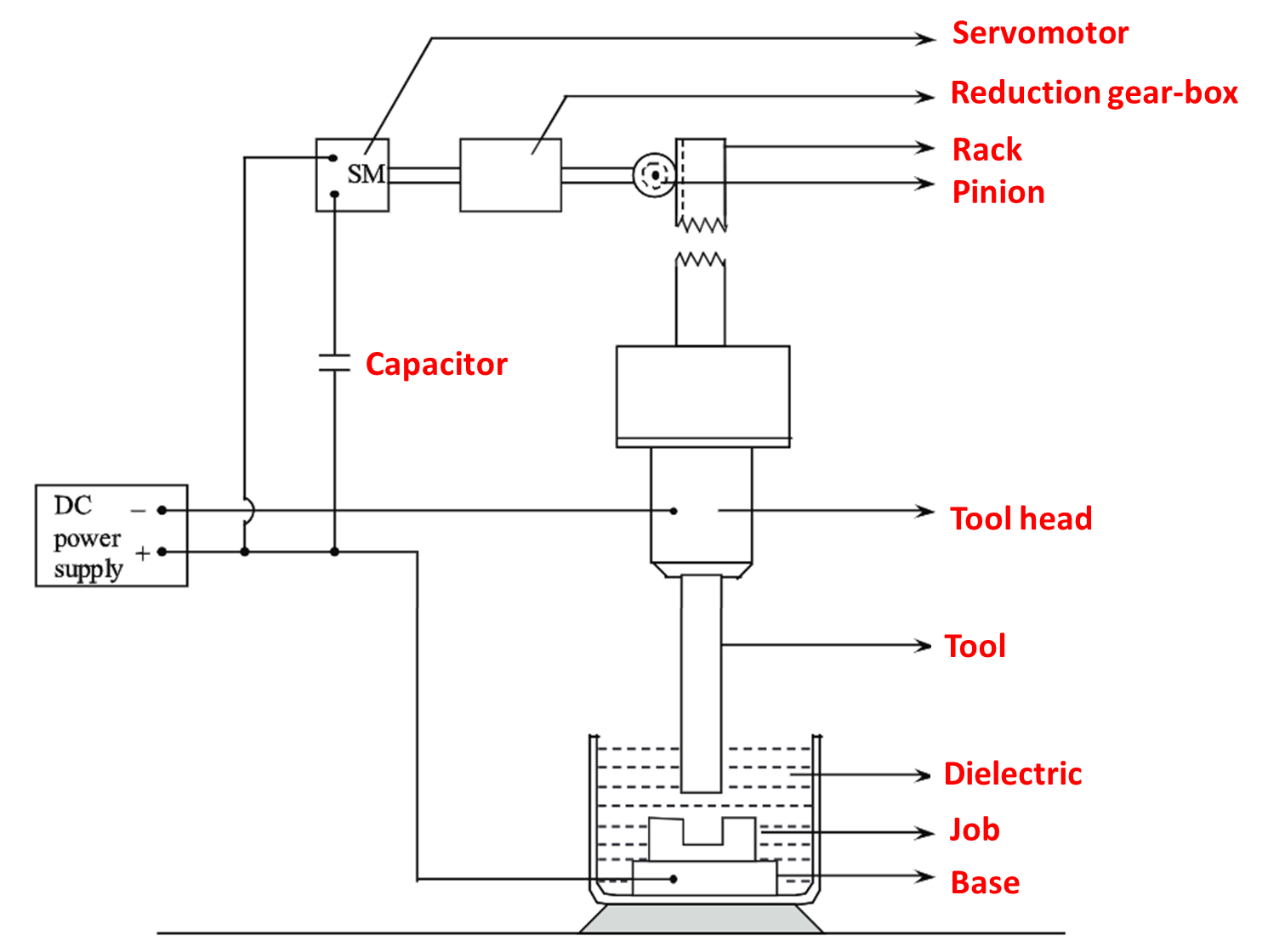

The core of EDM is spark erosion: high-voltage electrical pulses create plasma channels between an electrode (tool) and the workpiece, generating intense heat (typically 8,000–12,000°C) in a tiny gap. This heat melts or vaporizes the material at the point of discharge, and the process repeats rapidly—thousands to millions of times per second—to shape the part. Both the electrode and workpiece must be electrically conductive, and the entire setup is submerged in a dielectric fluid (like oil or deionized water) that insulates, cools, and flushes away debris.

Step-by-Step Process

- Setup: The workpiece is mounted on a table, and the electrode (often made of copper, graphite, or tungsten) is positioned very close to it (gap of about 0.01–0.5 mm) but not touching. The system is immersed in dielectric fluid to prevent premature sparking and aid in debris removal.

- Voltage Application: A DC power supply charges the electrode (cathode) and workpiece (anode). When the voltage reaches a breakdown point, the dielectric fluid ionizes, forming a conductive plasma channel.

- Spark Discharge: The spark jumps the gap, creating a localized explosion of heat that erodes a small crater (about 0.01–0.5 mm in diameter) on both the workpiece and electrode. Material is removed as molten particles or vapor.

- Flushing and Recovery: After each spark (lasting microseconds), the voltage drops, the plasma collapses, and the dielectric fluid rushes in to flush away the eroded particles (called swarf). A servo system adjusts the electrode position to maintain the optimal gap as material is removed.

- Repetition: This cycle repeats at high frequency, gradually shaping the workpiece to mirror the electrode’s form or path.

Key Variants

- Die-Sinking EDM: The electrode is shaped like the desired cavity and “sinks” into the workpiece, used for molds and dies.

- Wire EDM: A thin wire electrode cuts through the material like a bandsaw, ideal for intricate 2D shapes.

- Fast Hole Drilling EDM: Specialized for drilling small, deep holes in tough materials.

EDM excels in precision (tolerances as tight as ±0.0001 inches) without applying mechanical force, avoiding distortion in delicate parts. However, it’s slower than traditional machining and produces a heat-affected zone that may require finishing.

history of electro discharge machining

Early Discoveries (18th Century)

The history of Electro Discharge Machining (EDM) dates back to 1770, when English scientist Joseph Priestley first observed the erosive effects of electrical discharges, or sparks, on metals. This foundational discovery laid the groundwork for understanding how electricity could remove material without mechanical contact, though practical applications wouldn’t emerge for over a century.

Development in the 20th Century (1940s–1950s)

EDM as a controlled manufacturing process truly began during World War II. In 1943, Soviet physicists Boris and Natalya Lazarenko pioneered the modern EDM technique while researching ways to prevent spark erosion on electrical contacts. They developed a method using repeated electrical discharges in a dielectric fluid to machine hard materials, creating the first practical EDM machine known as the “Lazarenko circuit” or resistance-capacitance (RC) generator.

Independently, in the United States, researchers like Harold Stark explored similar concepts around the same time, leading to the patenting of the first metal disintegrator and contributing to EDM’s adoption in America. By the 1950s, EDM gained traction for its ability to work with difficult-to-machine alloys, spurred by demands from aerospace and toolmaking industries.

Advancements and Commercialization (1960s–1970s)

The 1960s marked a significant evolution with the introduction of Wire EDM. The first wire-cut EDM machines emerged, using a thin wire electrode to cut intricate shapes. These became commercially available around 1967, revolutionizing precision cutting.

In 1976, Computer Numerical Control (CNC) was integrated into EDM systems, enhancing automation, accuracy, and repeatability. This period saw EDM transition from experimental to industrial use, with improvements in pulse generators and dielectric fluids for better efficiency.

Modern Era (1980s–Present)

From the 1980s onward, EDM technology advanced rapidly with microprocessor controls, adaptive systems, and finer tolerances (down to microns). Innovations like fast-hole drilling EDM and hybrid processes (combining EDM with other methods) expanded its applications in fields like medical devices, microelectronics, and additive manufacturing.

Today, EDM remains a cornerstone of precision machining, with ongoing developments in eco-friendly dielectrics, AI-optimized parameters, and integration with Industry 4.0 for real-time monitoring. Its non-contact nature continues to make it indispensable for complex, high-hardness components.

applications of electro discharge machining

Electro Discharge Machining (EDM) is employed across numerous industries for its precision in shaping hard, conductive materials like titanium, hardened steel, and superalloys, where traditional machining methods fall short due to material hardness or complex geometries.

Key Industries and Applications

- Aerospace: EDM is crucial for creating intricate components such as turbine blades, engine parts, landing gear, and fuel system elements, enabling tight tolerances and complex shapes in high-strength materials.

- Automotive: Used in manufacturing precision parts like gears, injection nozzles, and dies for body panels, as well as in power tool production and metal cutting operations.

- Biomedical and Medical Devices: Ideal for producing surgical instruments, implants, and prosthetics with fine details and biocompatible materials.

- Mold and Die Making: Commonly applied in creating injection molds, stamping dies, extrusion dies, and coinage dies, where high accuracy and surface finish are essential.

- Tooling and Prototyping: Facilitates the production of micro-tooling, blanking punches, carbide tools, templates, and rapid prototypes for concept builds.

- Jewelry and Small-Scale Manufacturing: Employed for detailed cutting and shaping in jewelry production.

- Specialized Operations: Includes small hole drilling in hard materials, removal of broken tools (e.g., taps or drills), metal disintegration machining, and closed-loop manufacturing processes.

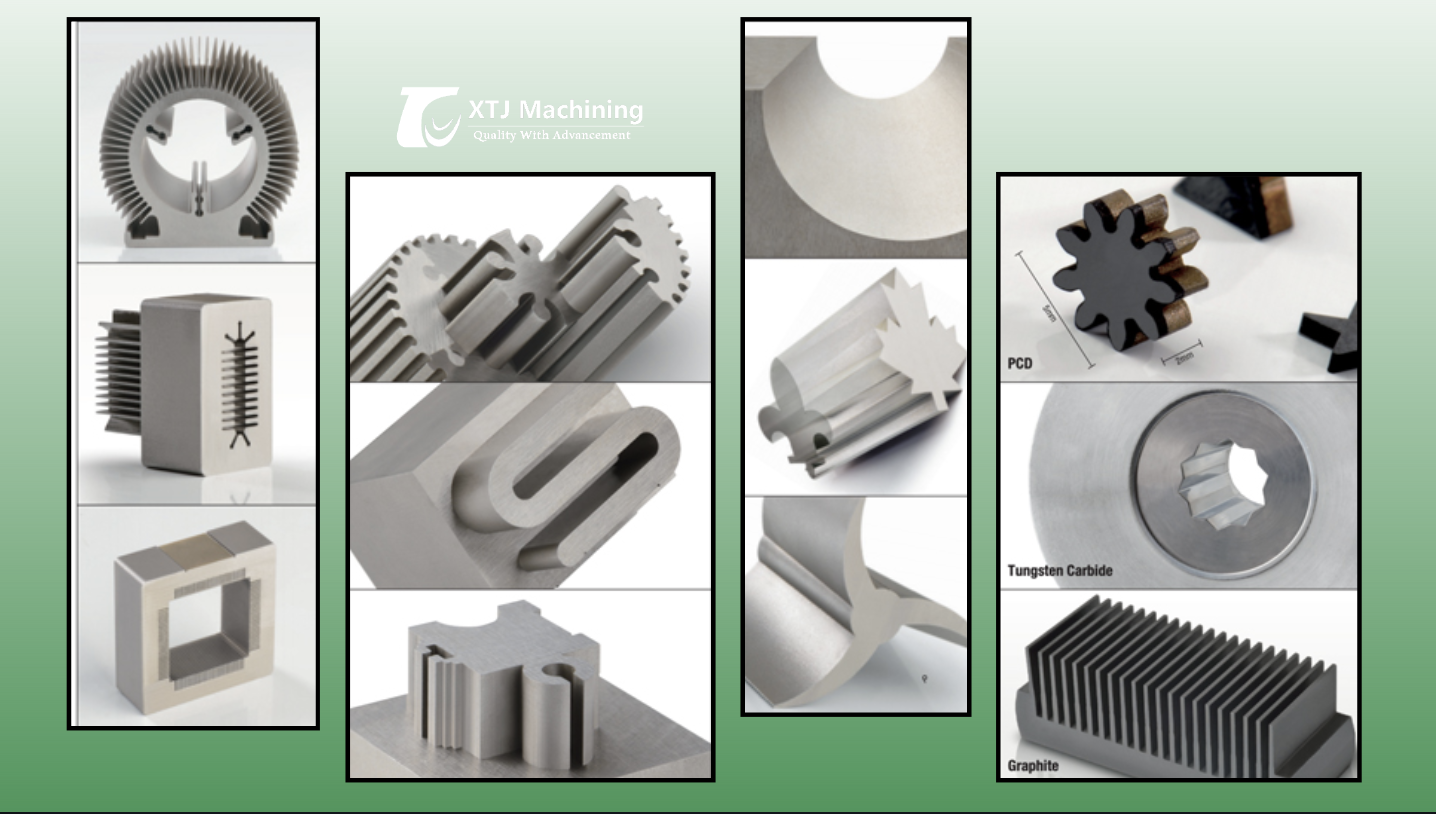

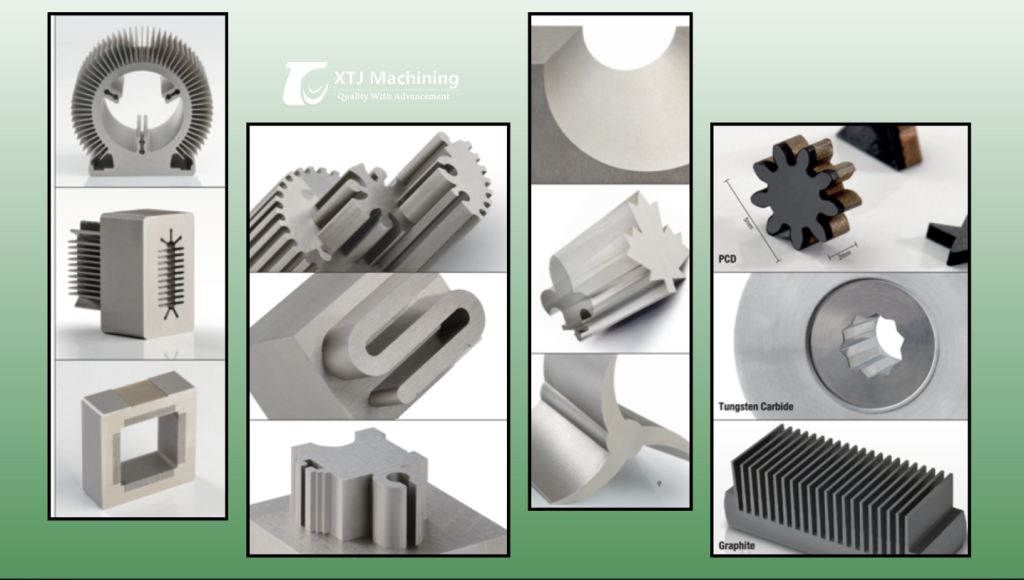

Here are some visual examples of precision components fabricated via EDM:

advantages and disadvantages of EDM

Advantages of Electro Discharge Machining (EDM)

EDM offers several benefits, particularly for precision work on hard materials without mechanical stress.

- High Precision and Tight Tolerances: EDM can achieve accuracies as fine as ±0.0001 inches, making it ideal for intricate shapes and complex geometries that are challenging for traditional machining.

- No Mechanical Force: Since there’s no direct contact between the tool and workpiece, it avoids introducing stresses, burrs, or distortions, which is crucial for delicate or thin-walled parts.

- Machining Hard Materials: It effectively processes super-hard conductive materials like titanium, tungsten carbide, and hardened steel, regardless of their hardness, without tool wear from mechanical cutting.

- Complex Shapes and Features: Enables the creation of deep cavities, sharp internal corners, fine holes, and irregular contours that are difficult or impossible with conventional methods.

- Good Surface Finish: Produces smooth surfaces with minimal need for secondary finishing, though a recast layer may form.

- Versatility in Applications: Suitable for prototyping, mold/die making, aerospace components, and medical devices.

Disadvantages of Electro Discharge Machining (EDM)

Despite its strengths, EDM has limitations that can impact efficiency and applicability.

- Slow Material Removal Rate: The process is time-consuming compared to conventional machining, making it less suitable for high-volume production or large-scale projects.

- Limited to Conductive Materials: Only works on electrically conductive workpieces, excluding non-metals like plastics or ceramics unless modified.

- High Cost: More expensive due to specialized equipment, electrode fabrication (especially for die-sinking EDM), and energy consumption.

- Electrode Wear: The electrode erodes over time, requiring frequent replacement or redressing, which adds time and cost.

- Heat-Affected Zone (HAZ): The thermal process can create a recast layer or microcracks on the surface, potentially requiring post-processing for critical applications.

- Environmental and Safety Concerns: Involves dielectric fluids that may produce fumes or require careful handling, and the process generates debris that needs proper disposal.

EDM in Precision Manufacturing: Complementary to CNC at XTJ

While EDM shines for non-contact erosion of hard materials, it pairs seamlessly with CNC machining for hybrid workflows. At XTJ, our CNC services handle a wide range of metals and plastics with tolerances down to ±0.003mm. If your project involves EDM-like precision, our rapid prototyping (as fast as 5 days) and no-MOQ policy make us your ideal partner.

Explore our CNC machining services or materials guide to see how we can support your needs.

Ready to bring your design to life? Get a free quote today by uploading your CAD files—we’ll provide expert feedback and competitive pricing.