Electro Discharge Machining (EDM) is a non-traditional machining process used to manufacture complex shapes and designs. It is particularly useful for creating intricate details that are difficult to achieve with conventional machining methods.

The suitability of EDM for small parts manufacturing is a topic of interest among industries that require precision and accuracy. EDM offers a high degree of precision, making it an ideal choice for producing small, intricate parts.

Key Takeaways

- EDM is a non-traditional machining process ideal for complex shapes.

- It offers high precision, suitable for small parts manufacturing.

- EDM is particularly useful for creating intricate details.

- The process is beneficial for industries requiring precision.

- EDM can produce parts with complex geometries.

Understanding Electrical Discharge Machining (EDM) Fundamentals

The fundamentals of EDM are rooted in its ability to erode material through controlled electrical discharges. This non-traditional machining process has become essential in modern manufacturing, particularly for creating complex shapes and designs in hard materials.

The Basic Principles of EDM Technology

EDM operates on the principle of thermoelectric erosion, where material is removed from the workpiece due to a series of electrical discharges between the tool (electrode) and the workpiece. This process occurs in a dielectric fluid, which acts as an insulator until the voltage between the electrode and workpiece is sufficient to break down the fluid, creating a spark.

- Material removal occurs through melting and vaporization.

- The process is controlled by adjusting voltage, current, and pulse duration.

- EDM allows for machining hard materials without the need for post-processing heat treatment.

Types of EDM Processes Relevant to Small Parts

There are several types of EDM processes, with two being particularly relevant to small parts manufacturing:

- Wire EDM: Uses a continuously moving wire electrode to cut through the workpiece.

- Sinker EDM (also known as Ram EDM or Volume EDM): Involves a shaped electrode that is used to create complex cavities.

Historical Development of EDM for Miniature Components

The development of EDM technology has been closely tied to advancements in precision engineering and the need for machining hard, exotic materials. Initially used for machining dies and molds, EDM has evolved to become a critical process for producing miniature components with intricate details. As technology advances, EDM continues to play a vital role in manufacturing small, complex parts for various industries, including aerospace, medical devices, and electronics.

Small Parts Electrical Discharge Machining: An Overview

Small parts EDM is a specialized area of Electrical Discharge Machining that focuses on creating tiny, precise components. This technique is crucial in various industries where miniature parts with complex geometries are required.

Defining “Small Parts” in the Context of EDM

In EDM, “small parts” typically refer to components with dimensions in the range of a few millimeters down to micrometers. These parts often have intricate features and require high precision manufacturing techniques. Characteristics of Small Parts:

- Dimensions: ranging from a few millimeters to micrometers

- Complex geometries and intricate features

- High precision requirements

Key Characteristics of Micro-EDM Processes

Micro-EDM processes are designed to handle the challenges of manufacturing small parts. Key characteristics include:

- Use of very fine electrodes

- High-frequency discharges for precise material removal

- Ability to machine hard and difficult-to-machine materials

Scale Considerations in Miniature Component Manufacturing

When manufacturing miniature components, scale considerations play a crucial role. Factors such as material properties, electrode wear, and machine vibration become more significant at smaller scales.

| Scale Factor | Consideration | Impact on Manufacturing |

|---|---|---|

| Material Properties | Changes in material behavior at micro scale | Affects machining accuracy and surface finish |

| Electrode Wear | Increased wear due to high precision requirements | Influences dimensional accuracy and feature definition |

| Machine Vibration | Greater impact on precision at micro scale | Requires advanced vibration control measures |

Understanding these scale considerations is essential for optimizing micro-EDM processes and achieving the desired precision and quality in miniature component manufacturing.

Advantages of EDM for Small Part Manufacturing

EDM technology provides unparalleled precision in the production of miniature components. This precision is crucial in industries where small parts are used, such as in medical devices, aerospace, and electronics.

Precision and Accuracy Capabilities

One of the primary EDM advantages is its ability to achieve high precision and accuracy. EDM can produce parts with tolerances as low as ±0.0001 inches, making it ideal for applications where exacting standards are required.

Complex Geometry Creation in Miniature Scale

EDM excels at creating complex geometries in small parts, which can be challenging or impossible to achieve with traditional machining methods. This capability is particularly valuable in the production of intricate components for various industries.

Material Versatility for Small Components

EDM offers material versatility, allowing it to work with a wide range of materials, including hardened steels, titanium, and other difficult-to-machine materials. This versatility is essential for manufacturing small parts that meet specific material requirements.

| Material | EDM Capability | Precision Level |

|---|---|---|

| Hardened Steels | High | ±0.0001 inches |

| Titanium | Medium-High | ±0.0002 inches |

| Copper | High | ±0.0001 inches |

In conclusion, EDM offers significant advantages for small part manufacturing, including high precision, the ability to create complex geometries, and material versatility. These benefits make EDM a valuable technology for producing miniature components across various industries.

Limitations and Challenges of EDM for Tiny Workpieces

Manufacturing small parts using EDM involves overcoming various technical and economic hurdles. While EDM offers the precision required for tiny components, its application is not without challenges.

Size-Related Technical Constraints

One of the primary limitations of EDM for small parts is the technical constraint imposed by the size of the workpieces. As components become smaller, maintaining precision and control over the EDM process becomes increasingly difficult. Technical constraints include managing the electrode wear, maintaining stable machining conditions, and ensuring accurate material removal.

Surface Finish Considerations at Micro Scale

The surface finish of EDM-produced small parts is another critical challenge. At the micro scale, achieving a smooth surface finish can be difficult due to the nature of the EDM process, which can leave behind micro-craters and other surface irregularities. Surface finish considerations are crucial for the performance and reliability of small components, particularly in applications where friction, corrosion, or fatigue resistance is important.

Economic Factors in Small Part EDM

Economic factors also play a significant role in the feasibility of using EDM for small part manufacturing. The cost of EDM equipment, the time required for machining small parts, and the need for specialized tooling and electrodes can make EDM more expensive than other manufacturing processes for certain applications. Manufacturers must carefully weigh these economic factors against the benefits of EDM to determine its suitability for their specific needs.

Wire EDM Applications for Small Parts

The precision and versatility of Wire EDM make it an ideal choice for manufacturing small parts. Wire EDM’s ability to cut complex shapes with high accuracy is particularly valuable in industries where miniature components are crucial.

Wire Diameter Considerations for Miniature Cutting

One of the critical factors in Wire EDM for small parts is the wire diameter. Thinner wires allow for more intricate cuts and are essential for producing miniature components with complex geometries. Key considerations for wire diameter include:

- The material being cut and its thickness

- The desired precision and surface finish

- The complexity of the part’s geometry

Precision Capabilities of Wire EDM at Small Scale

Wire EDM offers exceptional precision capabilities, making it suitable for producing small parts with tight tolerances. The technology can achieve micron-level accuracy, which is critical in applications where small parts are used in high-precision devices.

Case Studies: Successful Wire EDM Small Part Applications

Several industries have successfully utilized Wire EDM for producing small parts. For instance, in the medical device industry, Wire EDM is used to manufacture intricate components for surgical instruments and implants. A notable case study involves a medical device manufacturer that used Wire EDM to produce a complex component with micron-level precision. Other successful applications include:

- Aerospace components with complex geometries

- Electronics parts requiring high precision

- Automotive components where small parts are critical

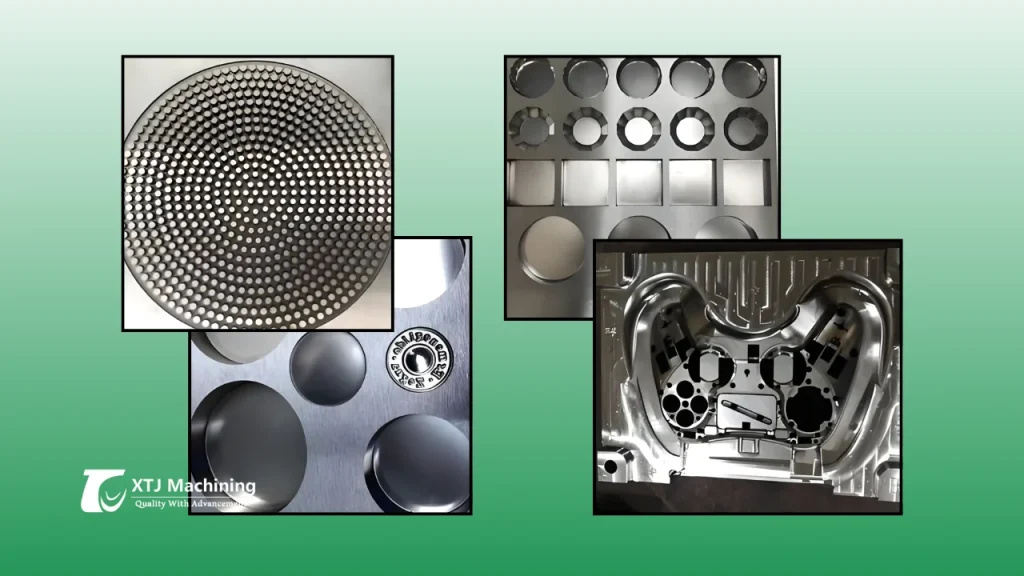

Sinker EDM Techniques for Micro Components

Sinker EDM has emerged as a vital process in the production of micro components with high precision. This technique is particularly valuable for creating intricate features in small parts, which are challenging to manufacture using conventional methods.

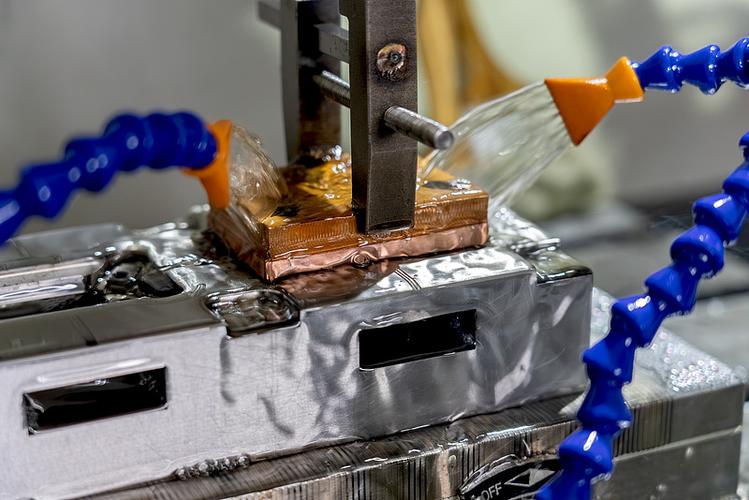

Electrode Design for Tiny Feature Creation

The success of sinker EDM in micro component manufacturing heavily relies on the design of the electrode. Electrode design must be precise to create the desired features on the workpiece. The electrode material, typically copper or graphite, is chosen based on the workpiece material and the required surface finish.

- Copper electrodes are often used for their high electrical conductivity and ability to produce fine details.

- Graphite electrodes offer excellent wear resistance, making them suitable for complex and intricate designs.

Achieving Tight Tolerances in Micro-Cavities

Achieving tight tolerances is crucial in micro component manufacturing. Sinker EDM allows for the creation of micro-cavities with precise dimensions. The process involves careful control of EDM parameters such as discharge energy and pulse duration to minimize deviations from the desired dimensions. Advanced EDM machines equipped with sophisticated control systems enable the achievement of tolerances as low as ±0.1 μm.

Industry Examples of Sinker EDM Micro-Applications

Sinker EDM is widely used in various industries for micro component manufacturing. For instance, in the medical device industry, sinker EDM is used to create intricate features on surgical instruments and implants.  In the aerospace sector, sinker EDM is employed to manufacture small parts with complex geometries, such as fuel injector nozzles.

In the aerospace sector, sinker EDM is employed to manufacture small parts with complex geometries, such as fuel injector nozzles.

- The aerospace industry benefits from sinker EDM’s ability to work with hard materials.

- Medical devices require precise features, making sinker EDM an ideal manufacturing method.

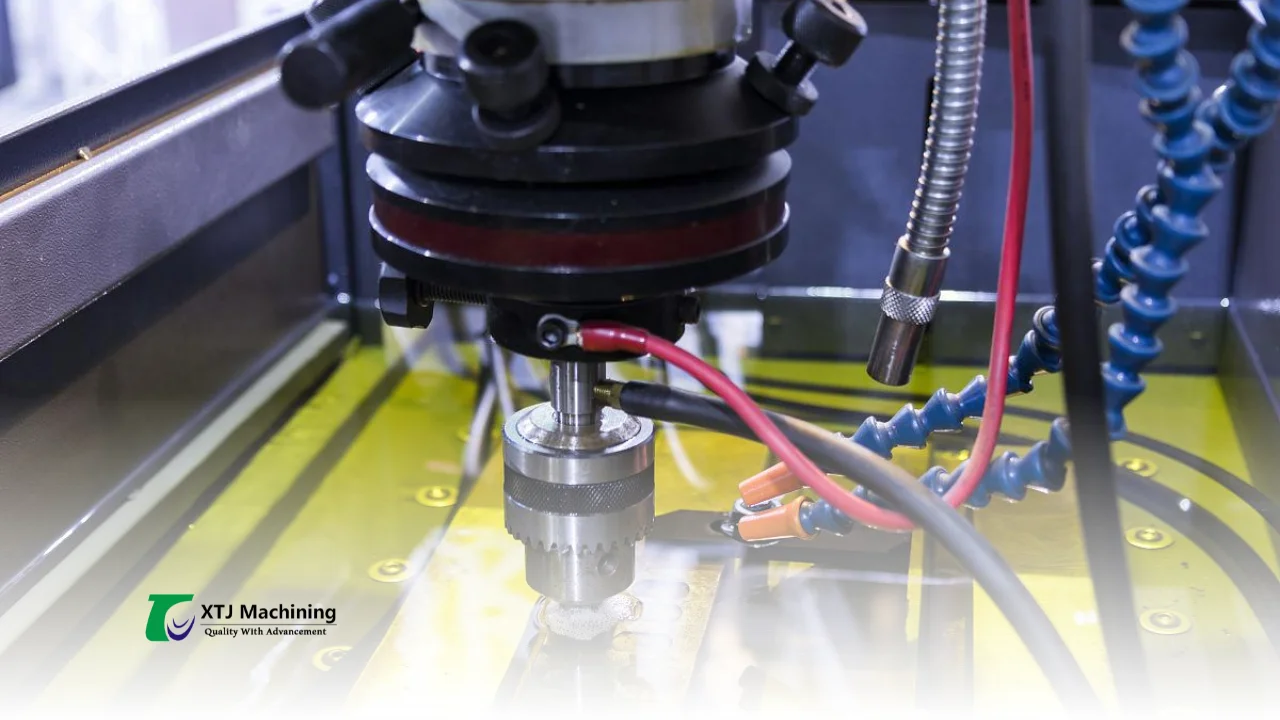

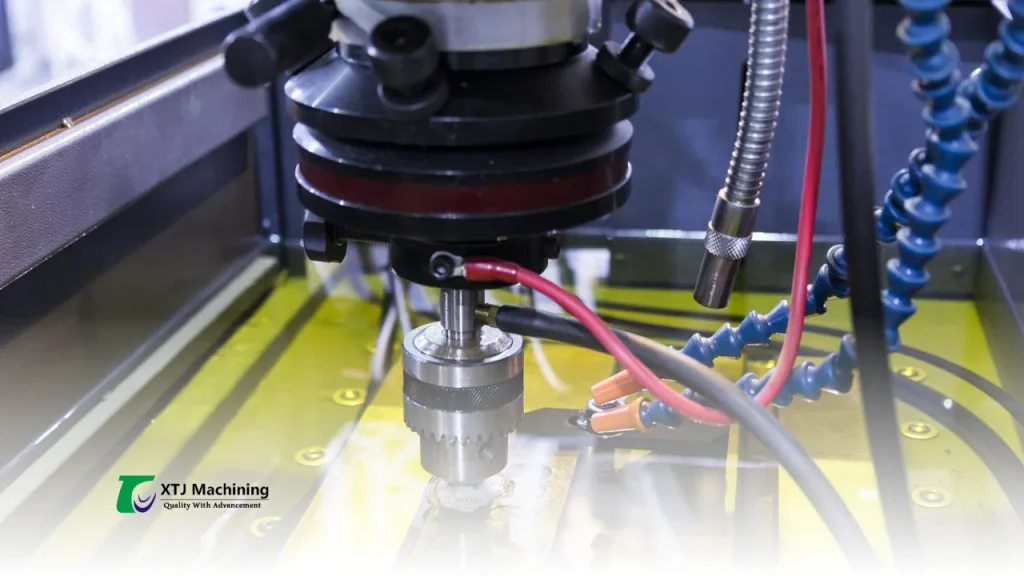

Micro-EDM: Specialized Technology for Ultra-Small Parts

The manufacturing landscape for ultra-small parts has been revolutionized by the advent of micro-EDM technology. Micro-EDM, or micro electrical discharge machining, is a precision process that enables the creation of complex geometries in miniature components. This specialized technology is crucial for industries that require parts with dimensions measured in sub-millimeters.

Equipment Specifications

Micro-EDM equipment is designed to operate at a much smaller scale than conventional EDM machines. High-precision machinery is used to control the electrode and workpiece with nanometer accuracy. This level of precision is necessary for producing features that are just a few micrometers in size. The equipment often includes advanced features such as high-frequency vibration to improve material removal rates and surface finish.

Process Parameters for Sub-Millimeter Components

When working with sub-millimeter components, the process parameters in micro-EDM become critical. Factors such as discharge energy, pulse duration, and electrode material must be carefully controlled to achieve the desired outcome. Optimizing these parameters allows for the efficient machining of tiny features without damaging the workpiece. The process requires a deep understanding of how different materials respond to micro-EDM, as material properties can significantly affect the machining process.

Comparing Micro-EDM with Conventional EDM for Small Parts

While conventional EDM is capable of producing small parts, micro-EDM offers distinct advantages when it comes to ultra-small components. Micro-EDM can achieve much finer features and tighter tolerances than conventional EDM. However, it also requires more sophisticated equipment and a higher level of expertise. The choice between micro-EDM and conventional EDM depends on the specific requirements of the part being manufactured, including its size, complexity, and material. In conclusion, micro-EDM is a powerful technology for the production of ultra-small parts. Its ability to create complex geometries with high precision makes it an invaluable tool in various industries, from medical devices to aerospace. As technology continues to advance, the capabilities of micro-EDM are likely to expand, enabling even more intricate and precise manufacturing.

Material Considerations for Small Part EDM

Material considerations are paramount in EDM for small parts, affecting everything from the machining process to the component’s performance and lifespan. The choice of material influences the precision, durability, and overall quality of the final product.

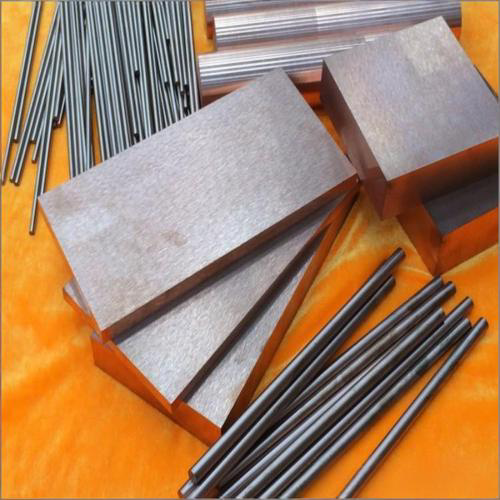

Optimal Materials for Micro-EDM Processing

The selection of optimal materials for micro-EDM is critical. Materials with high hardness and wear resistance are preferred for creating precise features in small components. Tungsten carbide, for instance, is often used due to its excellent properties.

Material Removal Rate Factors at Small Scale

Several factors influence the material removal rate (MRR) in micro-EDM, including discharge energy, pulse duration, and material properties. Optimizing these factors is crucial for achieving efficient machining and maintaining the integrity of the workpiece.

Heat-Affected Zone Implications in Miniature Components

The heat-affected zone (HAZ) is a significant consideration in EDM, particularly for small parts where thermal damage can compromise the component’s structural integrity. Minimizing HAZ through appropriate material selection and process parameters is essential. In conclusion, material considerations play a vital role in the success of EDM for small parts. By understanding the optimal materials and factors influencing the machining process, manufacturers can produce high-quality components that meet precise specifications.

EDM Tooling and Fixtures for Small Workpieces

EDM tooling and fixtures play a crucial role in the precision machining of small workpieces. The complexity of handling tiny parts demands specialized solutions to ensure accurate and efficient processing.

Specialized Workholding Solutions for Tiny Parts

Workholding is a critical aspect of EDM for small parts. Specialized fixtures are designed to securely hold tiny workpieces in place, minimizing the risk of damage or misalignment during the machining process. These fixtures are often custom-made to accommodate the unique geometries of small parts. Precision clamping systems and vacuum fixtures are examples of workholding solutions used in EDM for small workpieces. These systems ensure that the workpiece remains stable and accurately positioned throughout the machining operation.

Electrode Material Selection for Micro-Features

The choice of electrode material is vital in EDM, particularly when creating micro-features. Tungsten and graphite are commonly used electrode materials due to their durability and ability to maintain precision during the EDM process. The selection of electrode material directly impacts the quality of the machined surface and the longevity of the electrode itself. Factors such as material removal rate and electrode wear are considered when choosing the appropriate electrode material for small part EDM.

Tool Wear Considerations in Small Part Manufacturing

Tool wear is an inevitable aspect of EDM, and it becomes particularly significant when machining small parts. Monitoring electrode wear is crucial to maintaining the precision required for miniature components. Strategies to minimize tool wear include optimizing EDM process parameters, such as pulse duration and current, and using advanced electrode materials. By controlling tool wear, manufacturers can improve the consistency and quality of small part production.

Alternative Technologies vs. EDM for Small Part Production

When considering the production of small parts, manufacturers often weigh the benefits of Electrical Discharge Machining (EDM) against other precision technologies. The choice between EDM and alternative methods such as laser micromachining, micro-milling, and micro-turning depends on several factors including material, complexity, and precision requirements.

Laser Micromachining Comparison

Laser micromachining is a non-contact process that uses a laser to remove material, offering high precision and the ability to work with a variety of materials. Unlike EDM, it doesn’t require an electrode, which can be advantageous for certain geometries. However, EDM generally provides a better surface finish and can machine harder materials more effectively.

Micro-Milling and Micro-Turning Alternatives

Micro-milling and micro-turning are traditional machining methods scaled down for small part production. They offer high precision and are suitable for a wide range of materials. While these methods can achieve complex geometries, they may struggle with very hard materials or intricate features that EDM can handle more effectively. Key differences between EDM and traditional micro-machining include:

- EDM can machine harder materials without significant tool wear.

- Micro-milling and turning can be faster for certain geometries.

When to Choose EDM Over Other Micro-Manufacturing Processes

EDM is particularly advantageous when working with very hard materials, creating complex cavities, or achieving very small features. It’s also beneficial for parts that require a high level of precision and a smooth surface finish. Ultimately, the choice between EDM and alternative technologies depends on the specific requirements of the part being manufactured. In conclusion, while alternative technologies like laser micromachining, micro-milling, and micro-turning have their strengths, EDM remains a critical method for small part production due to its unique capabilities and advantages.

Quality Control and Inspection of EDM-Produced Small Parts

Quality control is a critical aspect of EDM manufacturing for miniature components. Ensuring that these small parts meet the required specifications is essential for their functionality and reliability in various applications.

Measurement Challenges for Miniature Features

One of the primary challenges in quality control for EDM-produced small parts is measuring their dimensions accurately. Traditional measurement tools may not be suitable due to the miniature size of the features. Advanced metrology techniques, such as optical microscopy or coordinate measuring machines (CMMs) with high precision probes, are often employed to overcome these challenges. Optical microscopy allows for detailed inspection of surface features, while CMMs provide accurate dimensional measurements. The choice of measurement technique depends on the specific requirements of the part and the level of precision needed.

Surface Integrity Evaluation at Micro Scale

The surface integrity of EDM-produced parts is crucial for their performance, especially in applications where fatigue resistance and surface finish are critical. Evaluating surface integrity at the micro scale involves assessing factors such as surface roughness, recast layer thickness, and the presence of micro-cracks. Advanced techniques like scanning electron microscopy (SEM) and surface profilometry are used to evaluate the surface integrity of EDM-produced small parts. These techniques provide detailed information about the surface topography and help in identifying any potential defects.

Tolerance Management in Small Part EDM

Managing tolerances is a critical aspect of quality control in EDM manufacturing. The process inherently involves certain levels of variability due to factors like electrode wear and discharge energy fluctuations. To maintain tight tolerances, manufacturers must carefully control EDM process parameters and implement robust quality control measures. Statistical process control (SPC) techniques are often used to monitor and control the EDM process, ensuring that the produced parts remain within the specified tolerance limits. By maintaining a high level of process control, manufacturers can minimize variability and ensure consistent quality in EDM-produced small parts.

Cost Analysis of Small Part EDM Operations

Understanding the cost implications of EDM for small parts is essential for manufacturers. The decision to implement EDM technology depends on a thorough analysis of various cost factors.

Equipment Investment Considerations

The initial investment in EDM equipment is a significant factor in the overall cost analysis. Micro-EDM machines, in particular, require precise engineering and advanced technology, which can drive up costs. Manufacturers must consider the cost of the machine, as well as any additional features or accessories required for specific applications. For instance, the cost of a micro-EDM machine can range from $50,000 to over $200,000, depending on the specifications and capabilities. It’s crucial to assess the production needs and choose a machine that meets those requirements without excessive expenditure.

Operating Costs for Micro-EDM Processes

Operating costs for micro-EDM processes include expenses such as electrode wear, dielectric fluid, and energy consumption. Electrode wear is a significant factor, as it directly affects the accuracy and quality of the machined parts. The cost of electrodes, particularly those made from exotic materials, can be substantial. Additionally, the cost of dielectric fluid and its disposal should be considered. Manufacturers can optimize operating costs by implementing efficient fluid management systems and recycling programs.

ROI Calculation for Small Part EDM Implementation

To justify the investment in EDM technology, manufacturers must calculate the return on investment (ROI). This involves comparing the costs of EDM operations with the benefits, such as increased precision, reduced material waste, and improved productivity. A thorough ROI calculation should consider factors like production volume, part complexity, and the cost savings achieved through EDM. By quantifying these benefits, manufacturers can make informed decisions about implementing EDM technology for small part production. Specialized providers, like those at XTJ Precision Mfg with over 20 years in precision wire EDM, can offer insights into balancing these costs for efficient outcomes.

Industry Applications and Success Stories

Electrical Discharge Machining (EDM) has revolutionized the manufacturing of small parts across various industries. Its precision and ability to create complex geometries have made it an essential process in producing miniature components for diverse applications.

Medical Device Manufacturing with EDM

EDM plays a critical role in the production of medical devices, where precision and intricate details are paramount. It is used to manufacture components such as surgical instruments, implantable devices, and diagnostic equipment.

Aerospace Component Production

In the aerospace industry, EDM is utilized for producing small, complex parts that require high precision and reliability. These components are often used in critical systems where failure is not an option.

Electronics and Semiconductor Industry Applications

The electronics and semiconductor industries benefit significantly from EDM’s capabilities. It is used to create intricate parts for electronic devices and semiconductor manufacturing equipment, where miniaturization and precision are key.

Watchmaking and Jewelry Production

In the luxury goods sector, EDM is applied in watchmaking and jewelry production to create intricate designs and complex components. The ability to machine hard materials and achieve high surface finishes makes EDM ideal for crafting detailed watch parts and custom jewelry. The success stories across these industries highlight EDM’s versatility and its role in advancing manufacturing capabilities. For example, companies specializing in precision wire EDM, such as XTJ, have enabled clients to produce high-precision parts from hard alloys with fine geometries and superior surface finishes, supporting innovations in medical and aerospace fields. As technology continues to evolve, EDM is expected to remain a vital process in the production of small, complex parts.

Conclusion: Is EDM the Right Choice for Your Small Part Manufacturing Needs?

Electrical Discharge Machining (EDM) has proven to be a viable option for manufacturing small parts, offering high precision and accuracy. The technology’s ability to create complex geometries and work with a variety of materials makes it an attractive choice for industries requiring miniature components. Throughout this article, we have explored the fundamentals of EDM, its advantages, and limitations. We have also examined various EDM processes, including wire EDM and sinker EDM, and their applications in small part manufacturing. The suitability of EDM for tiny workpieces is evident in its ability to achieve tight tolerances and produce intricate features. When considering EDM for small part manufacturing, factors such as material selection, tooling, and quality control must be taken into account. While EDM offers numerous benefits, it is essential to weigh these against the specific requirements of your project. By doing so, you can determine whether EDM is the right choice for your small part manufacturing needs, ensuring optimal results and efficiency. For tailored solutions in precision wire EDM, resources like those at XTJ can provide expert guidance based on extensive experience.