Polypropylene CNC Machining Services

Our food-grade white PP is sourced exclusively from FDA-approved suppliers with complete lot traceability.

- Free DFM feedback within 4 hours

- Dedicated food-grade material storage & clean machining zones

- 99.97% on-time delivery rate

- 24/7 engineering support (US & China teams)

CNC Machining Services for Food-Grade White Polypropylene Sheets

we specialize in precision CNC machining of FDA-compliant, food-grade white polypropylene (PP) sheets for the most demanding food processing applications. With over 20 years of experience serving global food & beverage manufacturers, we deliver components that combine exceptional chemical resistance, zero contamination risk, and industry-leading tolerances — all backed by full material traceability and same-day quoting.

Benefits of CNC Machining at XTJ

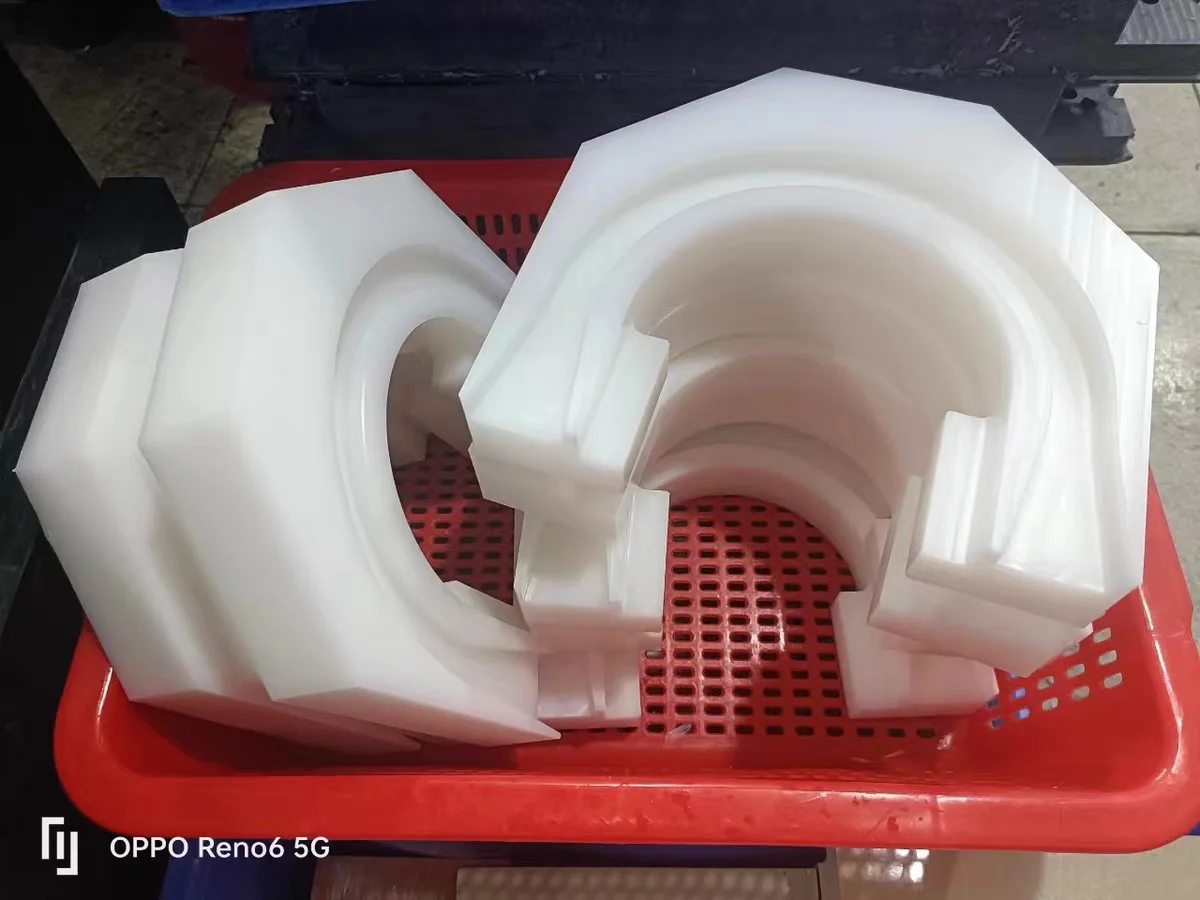

Successful CNC machining of food-grade polypropylene requires specific tooling and machining parameters. High-speed machining with sharp cutting tools and proper cooling strategies prevents material deformation and ensures dimensional stability.

- XTJ Precision Mfg Capability

Precision tolerances:±0.03mm standard, ±0.01mm on request

No MOQ:1 piece to 10,000+ pieces

Lead time:Prototypes in 3-5 days, production 7-12 days

Complex geometries:3-, 4-, 5-axis milling + live tooling

Zero contamination:Dedicated food-grade tooling & compressed-air cooling

Surface finish:Ra 0.4μm polished food-contact surfaces

- Consistent quality across production runs

- Machining Challenges

- Low melting point requires careful speed/feed control

- Material flexibility can cause deflection during machining

- Tendency to gall with improper tooling

- Thermal expansion considerations for tight tolerances

- Specialized cutting parameters needed

- Not cost-effective for very high volumes compared to injection molding

Food-Grade Polypropylene: Properties and Advantages

Food-grade polypropylene (PP) is a thermoplastic polymer specifically formulated to meet stringent food safety requirements. Unlike standard PP, food-grade variants undergo rigorous testing to ensure they contain no harmful substances that could migrate into food products.

Key Physical Properties

| Property | Value |

|---|---|

| Density | 0.91 g/cm³ |

| Density | 33-36 MPa |

| Water Absorption | <0.01% |

| Melting Point | 165°C |

| Operating Temperature | -20°C to +90°C |

Food Industry Advantages

- FDA 21 CFR 177.1520 compliant for food contact

- NSF/ANSI Standard 51 certification available

- Low Thermal Expansion: Stays stable in extreme temperatures, from freezing cold to intense heat.

- Excellent resistance to acids, bases, and cleaning agents

- Low moisture absorption preventing bacterial growth

- Maintains integrity during repeated washing cycles

- Withstands commercial sterilization processes

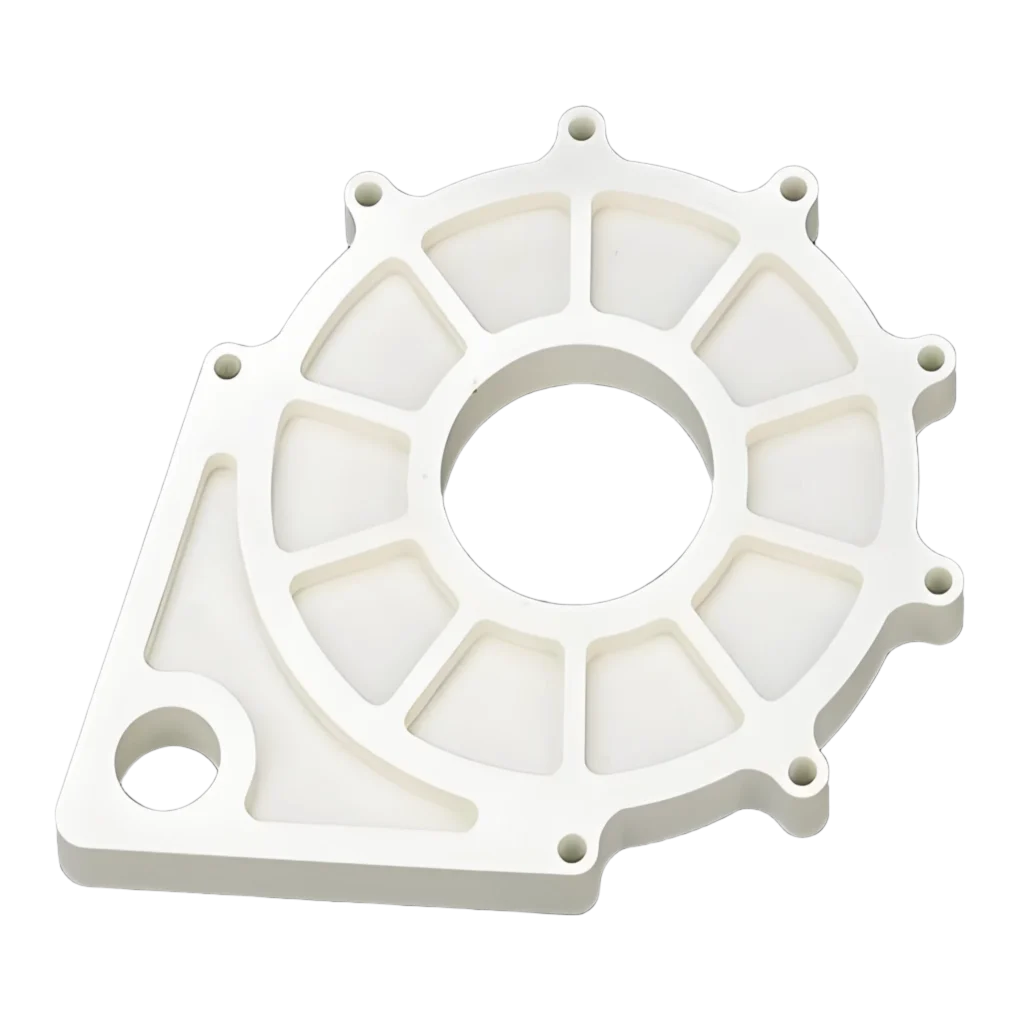

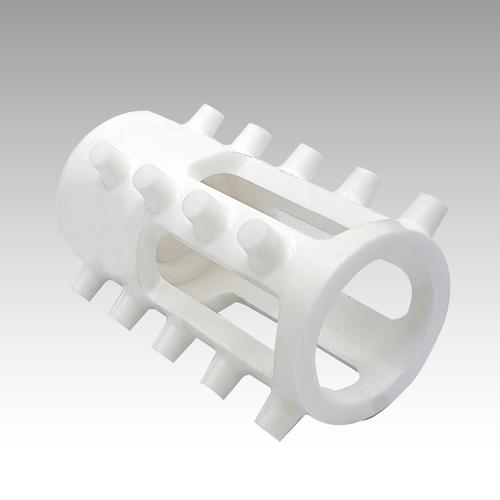

Real Applications We Deliver Daily

Food-grade white polypropylene components are essential in modern food processing operations. CNC machined parts offer superior performance in environments where hygiene, chemical resistance, and durability are paramount.

Conveyor Systems

- Guide rails and wear strips

- Conveyor bed components

- Chain guides and supports

- Transfer plates and diverters

- Mounting brackets and spacers

Conveyor Systems

- Custom storage containers

- Portion control trays

- Sterilization trays

- Specialized food molds

- Ingredient dispensing systems

Conveyor Systems

- Cutting boards and surfaces

- Mixer and agitator components

- Valve bodies and seats

- Filter housings and supports

- Custom machine guards

Our Proven 6-Step Food-Grade Process

The manufacturing process for food-grade polypropylene components involves several critical stages to ensure both precision and regulatory compliance. Each step maintains material integrity and prevents contamination.

Precision Capabilities for Food-Grade Applications

Modern CNC machining centers can achieve exceptional precision when working with food-grade polypropylene. These capabilities ensure components meet the exacting standards required for food processing equipment:

- Standard tolerances of ±0.03mm (±0.0012")

- Surface finishes as smooth as 0.8μm Ra

- Complex 3D contours and geometries

- Threaded features and precision holes

- Tight-tolerance assemblies

Need Custom Food-Grade PP Components?

Our precision CNC machining services deliver FDA-compliant polypropylene parts with industry-leading tolerances and rapid turnaround times.

Surface Finish Options for Food-Grade Applications

Surface finish quality is critical for food-grade applications, affecting both cleanability and bacterial resistance. CNC machining offers several finish options for food-grade polypropylene components.

As-Machined Finish

Ra Value: 1.6-3.2μm

The standard finish directly from CNC machining operations. Suitable for non-contact food applications or where additional finishing will be applied.

Best for: Components with non-critical surfaces, structural parts, or where cost is a primary concern.

Bead Blast Finish

Ra Value: 0.8-1.6μm

A uniform matte finish created by blasting the surface with fine media. Improves cleanability and provides a consistent appearance.

Best for: Food contact surfaces requiring regular cleaning, visual components, and parts with complex geometries.

Polished Finish

Ra Value: 0.2-0.8μm

A smooth, semi-gloss finish achieved through mechanical polishing. Offers superior bacterial resistance and cleanability.

Best for: Direct food contact surfaces, critical hygienic applications, and components requiring maximum cleanability.

Comparing Food-Grade Polypropylene with Alternative Materials

While food-grade polypropylene offers excellent properties for many applications, understanding how it compares to alternative materials helps in making optimal material selections for specific requirements.

| Property | Food-Grade PP | HDPE | PEEK | Stainless Steel |

|---|---|---|---|---|

| Cost | $ | $ | $$$$$ | $$$ |

| Max Operating Temp | 90°C | 80°C | 250°C | 550°C |

| Chemical Resistance | Excellent | Good | Excellent | Good |

| Impact Resistance | Good | Excellent | Good | Excellent |

| Machinability | Good | Good | Excellent | Moderate |

| Weight | Very Light | Very Light | Light | Heavy |

Optimal Application Areas

Food-Grade PP Excels In:

- Chemical processing equipment

- Acid-resistant components

- Lightweight food handling parts

- Cost-sensitive applications

- Components requiring frequent replacement

Consider Alternatives When:

- Operating temperatures exceed 90°C

- Extreme impact resistance is required

- High structural loads are present

- Radiation sterilization is needed

- UV exposure is significant

Hybrid Solutions:

- PP components with stainless fasteners

- PEEK bearings in PP housings

- PP covers over metal structural elements

- Glass-filled PP for higher strength needs

- PP with stainless reinforcements

Why Global Food Giants Choose XTJ Precision Mfg

As a leading OEM manufacturer providing one-stop manufacturing solutions

- 50,000+ food-grade parts shipped in 2025 alone

- Customers include: Nestlé, Kraft Heinz, Danone, Tyson

- Dedicated food-grade material storage & clean machining zones

- Technical Expertise: 20+ years of experience, 300+ specialists handling complex projects across 8 major industries, with NDA support for IP protection.

- Cost Efficiency: Strategic China location reduces costs by 30-40%, maintains global quality standards, offers volume-based discounts, and integrates with 200+ partner suppliers for one-stop solutions.

Ready for FDA-Compliant PP Parts That Actually Last?

Get Your Project Started in 60 Seconds